I/O SystemsState of technology RepoRt - Home - Putman … · · 2015-03-19I/O SystemsState of...

Transcript of I/O SystemsState of technology RepoRt - Home - Putman … · · 2015-03-19I/O SystemsState of...

State of technology RepoRt

I/O SystemsFrom Connectors & Cordsets to Intrinsic Safety and Power Supplies: the Latest Technology Trends,Back-to-Basics Tutorials, and Application StoriesAll Together in One Convenient eBook

March 2015

3

Table of ContentsTrends in TechnologyIncremental Thinking Won’t Solve Automation Challenge 5

Brain Power for Power Supplies 7

Why Aren’t Industrial Couplers Commodities? 8

Smarter I/O Addresses Host of Issues 10

A New Fashion in Industrial Enclosures? 12

Back to Basics Intrinsically Safe Fieldbus Applications 14

Power Supplies Get In On The Reliability Act 17

Wire, Cable, and Connectors Are Crucial 18

Power Supplies & Circuit Protection 22

Maintaining Connections 23

Technology in ActionCordsets Survive a Great Flood 26

The Water Works 29

A Charming New Facility 33

Advertiser IndexWago, http://www wago us/XTR 2

Opto 22, http://op22 co/ethernetio 4

Advantech, http://www advantech com 9

Weidmuller, http://www weidmuller com 11

5

trends in technology

As the project execution arm of the global energy giant, ExxonMobil Development Company typically is in-volved with more than 100 active projects around the

world at any given time. And while automation engineer-ing is a critical aspect of them all, it’s an “infrastructure” activity that is wholly dependent on other engineering dis-ciplines for its design inputs. Consequently, it often rests on the critical path for project completion. Sandy Vasser wants that to change.

On behalf of ExxonMobil and the rest of the user com-munity, Vasser several years ago began challenging the company’s automation suppliers to throw away traditional thinking in order to address its most pressing project needs. “Because automation hardware and software design is to-tally dependent on plant design data from other disciplines, input data frequently changes throughout the project de-sign cycle,” Vasser explained in his closing keynote address to the 2014 Honeywell Users Group (HUG) Americas Sym-posium in San Antonio, Texas. “Late input changes put us in continuous recycle mode on our engineering designs and drawings.”

Vasser leads a group of some 120 design engineers respon-sible for the electrical, instrumentation and automation as-pects of ExxonMobil’s increasingly large “mega” projects. “Despite increasing scale and complexity, little time has been added to project schedules,” Vasser said. “Whereas things used to be done more sequentially, now all disciplines are working full steam ahead from the start.”

He described the complexity and inflexibility of time-hon-ored I/O design and commissioning practice, such as en-gineered junction boxes and marshalling and controller

cabinets that result in 15 to 25 wire terminations for each instrument. Weight, floor space, cooling load and tedious factory acceptance tests (FATs) are also the target of Exxon-Mobil’s campaign to simplify, streamline and, where possi-ble, eliminate system components and steps along the way. “We realized we couldn’t continue to do automation this way and be successful,” Vasser added.

A wish listTo begin to address these issues, the company brought its

Incremental Thinking Won’t Solve Automation ChallengeAutomation’s off the critical project path, but more work remains

By Keith Larson, VP Content

"We realized we couldn't continue to do automation this way and be

successful." ExxonMobil's Sandy Vasser on the need to take automa-

tion off the critical path for its many global projects.

6

trends in technology

suppliers together and challenged them with a 13-item wish list of priorities:

1. Eliminate, simplify and/or automate steps in the auto-mation execution process;

2. Minimize custom engineering;3. Shift custom engineering to software and rely on stan-

dardized hardware components;4. Use virtualization to separate hardware from software;

validate software independent of hardware. Eliminate hardware FAT;

5. Prevent design recycle and hardware/software rework;6. Eliminate components not necessary in the system ar-

chitecture and standardize those that remain;7. Eliminate or minimize physical, data and schedule de-

pendencies with other disciplines;8. Simplify the configuration of interfaces with third-party

packages;9. More easily accommodate even very late changes;10. Mitigate the effects of software and hardware version

changes;11. Eliminate, simplify and/or automate generation of re-

quired documentation;12. Manage alarms and ensure cybersecurity by design;13 . Challenge traditional approaches and solutions.Vasser further noted the persistent barriers to achieving

these goals, including the impulse to focus on “perfecting” current processes. “Improvement only results in incremen-tal change,” he said. “We have to think differently if we’re to transform the way we do things.”

Progress to dateAlthough work remains to be done, progress toward Exxon-Mobil’s goals has been made. New I/O technology, such as Honeywell Process Solutions’ Universal I/O, together with its cloud engineering environment and lean engineering for automation projects (LEAP) methodology showcased at the HUG Americas event, are making a difference.

“So far we’ve eliminated 66% of the components in the

system and 60 to 70% of the wire terminations. We’ve elim-inated marshalling cabinets altogether and have fewer con-troller-only standard cabinets,” Vasser said.

Other forward progress includes:• Reduced heat load, space and weight;• Reduced quantity of spares;• All system design customization now in the software;• Standard junction boxes, with easily configurable I/O,

ordered by part number; and,• No hardware FAT.

Key items that have now bubbled to the top of Vasser’s wish-list include:

• “DICED” I/O that allows systems and instruments to auto-detect, auto-interrogate, auto-configure, auto-en-able and auto-document;

• A standardized and simplified interface for electrical sys-tems;

• Multivariable transmitters that, for example, convey flow, pressure and temperature data over a single cable via a single process penetration;

• The direct programming of safety system logic by trans-lation from cause-and-effects tools; and,

• DC power to eliminate inverters.“It’s the packaging of many technologies that will achieve

the necessary outcomes,” Vasser said. Meanwhile, the com-pany is benefiting from many strides forward in technology and project methodology. “We’ve taken automation off the critical path.”

“We’ve eliminated 66% of system components

and 60-70% of the terminations."

7

trends in technology

Brain Power for Power SuppliesIf controllers and field devices already have diagnostics power,

why can’t tower supply devices have it too?

by Jim Montague, Executive Editor

Everything is getting “smart,” and this trend appears to be holding true for power supplies as well. Devices that used to only deliver power, convert it and maybe offer

surge protection are now monitoring and measuring current and voltage profiles, implementing alerts and alarms for pre-defined operating ranges, and sending data on power supply performance up to higher-level systems and users for analy-sis and optimization efforts.

For instance, Richard Anderson, senior automation spe-cialist at Solid State Automation and Controls (http://sol-idstateautomation.com) in Houston, Texas, reports in a whitepaper, “How to Develop Cost-Effective, Ruggedized, Skid-Based Applications for Remote Deployments,” that SSAC recently designed and built a viscosity-reducing, skid-based, oil-mixing system for an unmanned production plat-form in the Gulf of Mexico, and employed Siemens Indus-try’s Siplus S7-1200 PLCs, ET200M I/O modules, MP377 HMIs and two power supplies in an explosion-proof, NEMA 7 enclosure and intrinsically safe track pad.

The two power supplies consist of two Sitop units, both capable of 24 Vdc and 120 Vac with a redundancy module between them. They support and maintain high availability on the skid’s equally redundant PLCs, which pull data from a flow sensor, and use 4-40 mA analog wiring, HART, Pro-fibus and Profinet communications protocols and Siemens’ Scalance wireless modules to transmit it to the user’s onshore DCS. Likewise, S7-1200 PLCs can also use Modbus RTU and Modbus TCP for communicating between legacy RS-232 and RS-485 systems and industrial Ethernet, while Si-top 1600 DC uninterruptible power supplies have two Ether-net ports for integrating with Profinet and reporting to users’ higher-level networks.

I’d add not to take my word that power supplies are getting smarter, but I can’t because when I researched this topic, I ran across two articles I wrote on it last year and the year before. In the earlier article, “Power Supplies Take Sophisti-cated Paths”, Roolf Wessels, business unit manager for mon-itoring and protection at Pepperl+Fuchs, said, “Power sup-plies have always been a bit of a stepchild compared to other process control devices, but users are recognizing that power is the most critical element in their applications. You can lose a few I/O points and networking nodes and still run an application, but losing power means losing your whole application, so it’s worthwhile investing in high-reliability, high-efficiency power. As a result, users want more diagnos-tics in their power supplies. They already have diagnostics for predictive maintenance and asset management in their controllers and field devices, and now they want it them their power supplies, too.”

In the more recent article, “Power Supplies Get in on the Reliability Act”, Mike Garrick, power supply manager at Phoenix Contact, added, “Applications become more robust when a power supply can report when its connected field devices are drawing too much current, while the integrity of the DC bus is intact. For example, if the system is designed for 10 amps, it’s become a reasonable expectation for the power supply to provide a signal to the process controller when the load starts to draw more than 10 amps. This sig-nal is an early warning that the load is drawing too much current, and maintenance should be scheduled. When this early warning is received, the controller knows the process is running at the proper voltage at a current beyond the nomi-nal rating of the supply. The reason for this could be a field device that’s getting old and requires service.”

8

trends in technology

Why Aren’t Industrial Couplers Commodities?Maybe we should ask if couplers can be procured on the basis of cost only

by John Rezabeck, Columnist

When fieldbus pioneers expressed concerns about sin-gle points of failure in simple two-wire buses, Relcom engineered and patented the “SpurGuard,” a com-

pact assembly that could be substituted for pluggable termi-nals on their wiring blocks. Any “spur” (what fieldbus calls a single-pair drop to a device) fitted with a “SpurGuard” could sustain a water-logged or otherwise short-circuited condition without cratering the whole network.

SpurGuards were expensive, so Relcom and its compet-itors began to design and manufacture “couplers,” wiring blocks pre-fitted with short-circuit protection for each spur. Since about 2009, end users have been able to choose from a wide selection of couplers that are registered and tested by the Fieldbus Foundation. So can couplers be procured on the basis of cost only?

There are distinctions. If you’re creating a wiring block or “brick,” you have to make choices regarding how many spurs you can wire to each brick.

Pepperl+Fuchs has one of the wider selections of bricks, which can be purchased with 4, 6, 8, 10 or 12 spurs per brick. P+F and Phoenix Contact go a step further to optimize scalabil-ity in their lines of snap-together modular coupler hardware. Both P+F’s RM-SP* line and Phoenix Contact’s FB-ET lines allow you to build up couplers with between two and 26 spurs. A pluggable bus rail extends the bus for up to a half-dozen more modules, each extending the base unit in increments of four spurs. These solutions may provide the optimal solution for those who want to minimize junction box size.

I used to think the original Relcom “Megablock” had a comforting ruggedness due to its physical mass, but Rel-com’s Cyrus Kelly explains the “heft” came from “potting”—

encasing the entire electronics assembly in a substance that sealed the circuitry from its environment. Cyrus’s research revealed that potting was no better than the significantly more cost-effective technique of “conformal coating” —sealing the circuit with what amounts to a coating of a sim-ilar non-conductive substance, such as acrylic lacquer. So perhaps “heft” isn’t an infallible indicator of reliability or ruggedness.

MooreHawke’s couplers are extremely rugged. The case of the TG200 series is metal, and an eight- or 12-block spur block might break a toe if you dropped it on your foot. MooreHawke also has unique “auto terminator” circuitry that adds the required impedance-matching terminator at the furthest end of the trunk automatically. While other couplers may add a short-circuit load of 50 mA to 60 mA when a spur is shorted, MooreHawke couplers add only a few, once a short-circuit is detected.

R. Stahl offers another line of couplers that have low-qui-escent short-circuit current. This can be a factor when one is computing the maximum power budget for a segment: The 30 mA you save could facilitate adding an additional device or allow test equipment to be connected without causing communication errors. Stahl couplers also have special ac-commodations to limit inrush current when powering up an entire segment.

Arguably, any of the certified couplers will be one of the most reliable components of one’s fieldbus networks. But there are ample features and distinctions that have their ap-peal for individual users and cultures.

John Rezabek is a process control special is t for ISP Corp. , L ima, Ohio. Email him a t [email protected]

10

trends in technology

Smarter I/O Addresses a Host of IssuesMicroprocessor-based I/O reports the ongoing health of its own electronics

by Dan Hebert, Senior Technical Editor

You’ve just completed the control system design for your latest project, but now a level switch needs to be changed to a level transmitter.

That would mean adding another analog input card, sub-stantially changing the design and also generating a change order from the electrical contractor for additional wiring. Or maybe your control system is up and running, but overall processing speeds aren’t up to snuff.

How about a case where all the control system I/O is com-patible with your selected digital fieldbus network, except for one specialized instrument that doesn’t feature the con-nectivity that you need?

In all of these cases, the solution is “smart I/O.” This tech-nology provides a microprocessor at the I/O level—adding flexibility, protocol conversion and/or high-speed local I/O processing and control.

One of the newest “smart” innovations is software-con-figurable I/O. “With our universal safety I/O, each module can be configured via software to accept any signal type—analog or digital, input or output,” says Erik de Groot, the marketing manager for safety systems at Honeywell Process Solutions (http://hpsweb.honeywell.com).

Only one type of module is needed for each project, and the only question is how many total modules are needed. I/O spares are reduced to one part number instead of a min-imum of four. Each module is connected to the host proces-sor via an Ethernet network, eliminating the need for home-run discrete and analog wiring.

“The engineering tools used to configure each universal I/O module generate an electronic record of the entire au-tomation system’s wiring configuration. This makes mainte-nance much easier because there’s automatically generated documentation,” adds de Groot.

Smart I/O can add intelligence to each module and also to a group of modules via a local processor at the I/O rack. “Intelligence at the I/O module and rack level gives the abil-ity to perform complex functions such as scaling, thermo-couple linearization, digital counting and latching, analog clamping, alarming, event reactions, waveform generation, ramping, pulse generation, totalization and PID loop con-trol,” observes Tom Edwards, a senior technical advisor at Opto 22 (www.opto22.com).

“The complicated algorithms and calculations required for PID loops can adversely affect a typical control system’s performance very quickly, but a distributed control archi-tecture gives you the modules you need to acquire your in-puts, the processing power required to perform the complex math, and the modules needed to set the outputs and con-trol the process—all local and completely self-contained on the I/O rack,” explains Edwards.

Smart I/O modules can also perform protocol conversion, taking a 4-20mA or other analog signal as an input and send-ing a digital network signal out to a centralized processor. “Our dual-channel I/O cards allow users to establish digi-tal fieldbus communication via HART based on pre-existing 4-20 mA connections,” notes Matt Boudjouk, product man-ager with Turck’s network division (www.turck.com).

Local diagnostics are yet another feature of smart I/O. “Microprocessor-based I/O reports the ongoing health of its own electronics,” says Jim McConahay, the senior field ap-plications engineer at Moore Industries-International www.miinet.com). “Any detected errors of the input/output signal or of the internal analog converters that exceed the defined range of the I/O device are reported to the host processor, which can indicate if a particular channel’s data is no longer within expected ranges.”

Condition Orange! Rely on PROmax Power Supplies.

Let’s connect.www.weidmuller.com

Weidmuller’s new PROmax Power Supplies offer unparalleled performance for your toughest applications.• Powerful output surge capability up to 300%• Integrated relay contact output• Both parallel and series connections• Agency approved for harsh environments• Starts up at -40°C

12

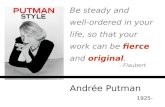

trends in technology

Unlike clothing fashions, enclosure styles don’t change a lot from year to year. A 40-year-old enclosure doesn’t stand out like your dad’s leisure suit. After all, a big

metal box is pretty much a big metal box, even with the added glitz of ventilation, temperature control or an ex-plosion-proof or safety rating. However, like a classic, tai-lor-made suit, enclosure styles are slowly evolving. Driven by the advent of electronic marshalling, as surely as hemlines get shorter, enclosure boxes are getting smaller and becom-ing more standardized.

Dan McGrath, solutions manager at physical infrastruc-ture products and solutions provider Panduit, explains: “Electronic marshalling provides the ability to more read-ily distribute enclosures around facilities, rather than need-ing as many home runs to central consolidation marshalling points. Ultimately, we are talking about standardizing with best practice designs rather than ‘one-offs,’ or every designer needing to sweat the details and develop custom specifica-tions each time.”

So how did this happen? The short answer is a shift in the way marshalling is done. Emerson Process Management led the way in 2010 with its “characterization modules” or CHARMs. When the system is installed remotely, each loop’s field wiring is landed on one of the special terminal blocks, and the loop signal is characterized by plugging the appropriate CHARM into the terminal, and the marshalling is configured electronically, eliminating the spaghetti nest of cross wiring.

While Emerson was first out of the gate, other automa-tion vendors have not been far behind. Honeywell Process Solutions is offering its Universal Process I/O for its Series C I/O. The module reduces or eliminates marshalling and allows immediate configuration without the need for addi-

tional hardware. Released in May of 2012, the SIL-3-certi-fied solution uses a single, universal, optionally redundant, 32-channel I/O module that can accept DIN, DOU, AIN, AOU or smoke/heat/gas detector signals.

Joe Bastone, Honeywell’s solution manager for Experion control I/O, describes it this way: “It’s a funny looking mod-ule with a termination assembly. What plugs into that is the I/O module. These communicate with the controller. It’s to-tally software-configurable, and it’s all done from the engi-neering console.”

Invensys Foxboro’s I/A Series Intelligent Marshalling from Invensys, released in late 2011, also takes a crack at eliminat-ing much of the marshalling work. Its FBM247 Universal Fieldbus Module for the Foxboro I/A Series DCS fits into the standard I/A series base plate. Base plate-mounted termi-nation assemblies provide the link between field wiring and the FBM247 modules.

“This module is a hybrid type,” says Thad Frost, who over-sees Foxboro’s intelligent marshalling solution. “It bypasses the marshalling process. It can handle multiple types of I/O signals. [With this system] you are able to bypass the mar-shalling cabinet and go directly to the control cabinet..”

Although each of these approaches is technically different in some respects, the result is similar: fewer wires, more flex-ibility, a much more compact footprint, lower costs, reduced inventory and an installation that is much more forgiving of late changes in engineering plans.

Heading for size 0?Anyone who follows women’s fashions will tell you that over the past couple of decades, the “ideal size” has shrunk from 6 to 4 to 2 to 0. Is the same thing going to happen to enclo-sures? Up to a point, yes.

A New Fashion in Industrial Enclosures?Will electronic marshalling mean the end of the “bespoke” enclosure?

by Nancy Bartels, Managing Editor

13

trends in technology

Charlie Norz, product manager for I/O systems at com-ponent supplier Wago, says, “We’re seeing users continu-ing to downsize. This need has triggered a push for com-prehensive, all-in-one systems for ever-condensing control footprints and enclosures. Ultimately, enclosure issues drill down to I/O size and keeping the control system’s footprint compact for future expansion. Thus, the primary focus will continue to be space-efficient I/O.”

Scott Pries, marketing manager for Emerson’s smart wire-less systems, points out, “One of the things that will be go-ing away is one of the two cabinets you need for home-run cable. You don’t need one whole cabinet. Intrinsically safe operation is being incorporated into electronics. Now a sin-gle card incorporates that and reduces another 20% of the cabinet. If you reuse the old cabinets, you can use the extra space for more I/O.”

Standard issueMore standardization is also in the offing. Erik de Groot, marketing manager at Honeywell Process Solutions says, “There are always going to be places where you have a cus-tom-built cabinet, but one of the things we’re working at is putting together a cabinet that will have 64 I/O, and can be all bundled together with all the known parts. Customers don’t want to specify all the individual parts that go into the cabinet. That’s time-consuming. If you can stamp out the [required] cabinets and make them all identical, you don’t have to do a FAT [factory acceptance test] on every one. We’re exploring this with leading-edge customers.”

Frost says this standardization is appealing to some of his largest customers. He tells the story of a large oil producer to whom he was pointing out the virtues of his system—the shortened wiring times, the ability to do remote configura-tion, the ease of late changes to the plans, the reduction of inventory, the lower costs.

The customer told him, “I don’t care about all that. In a mega-project, those things amount to petty cash. What I do care about is the fact that we could take the cabinets full of

intelligent marshalling modules, ship them to the site and finish them up there. What you have done is break the de-pendency between control system design and I/O system in-stallation. This gives me schedule compression and makes scheduling easier.”

Emerson Process Management offers its own enclosure options for DeltaV, version 11, systems. The “canned” solu-tion is a factory-tested enclosure which will hold electronic marshalling equipment. The company also offers both con-figure-to-order and design-to-order enclosures.

A new classic?Software-based marshalling is beginning to look a lot like a new classic—say a pair of jeans for the I/O world. It won’t happen overnight, of course. The process industries are full of “fast followers,” waiting for the other guy to try it first. But ARC Advisory Group points out that the installed base of systems 20 years or older is $53 billion. Existing enclosures will have a much longer useful life, but upgrades are defi-nitely on the horizon.

As for how this will affect the enclosures business, it will change too, if only incrementally.

Panduit’s McGrath says, “Enclosure suppliers need to consider product mix as part of their business strategy. Large marshalling panels will diminish and be replaced with smaller panels in many cases. Panduit sees demand for a similar approach with network zone enclosures, so [we’ll see] a building-block approach with smaller enclosures stra-tegically deployed to provide plant coverage in harsh areas.”

But there are also plenty of opportunities for new and dif-ferent enclosures, he adds. “Custom enclosures will most certainly be required, as innovation never stops, and there are new devices, sensors and controllers that will require custom housing. The exciting part about standardization, though, is that as the industry advances, the building blocks will need to evolve and become smarter, providing advan-tages for customers that can adopt new technology with re-duced risks and deployment times.”

14

Back to Basics

Intrinsically Safe Fieldbus ApplicationsThis article takes a look at ways companies get around limited power and other hazardous

environment barriers to connect more fieldbus devices using a technology that goes

beyond FISCO.

by Mike O’Neill, C Eng

As one of the more successful communication protocols for process control and industrial automation, fieldbus has proven its merit in bringing projects on-line ear-

lier and more efficiently, allowing advanced digital feed-back and control to processing plants previously stuck in the analog age. This allowed far more exacting process con-trol, greater autonomy of control loops, accurate trending, greater centralized monitoring, and lower installation costs through easier wiring and faster commissioning. However, when it came to the hazardous environments often encoun-tered in many chemical, pharmaceutical, plastics and pe-troleum plants, fieldbus initially fell short when intrinsically safe (IS) techniques were required.

Users of intrinsically safe devices in conventional control schemes have been used to the flexibility and ease of use af-forded by the Entity Concept since the late 1980s. FM in the U.S. led the way in simplifying the process of confirming the safety of intrinsically safe loops and the Entity Concept now governs how every non-fieldbus IS loop is designed and documented.

Initially, fieldbus implementations went the same way: use a conventional IS interface, apply the industry-standard En-tity Concept and the loop (now a segment) would be safe. The problem was conventional IS interfaces under the En-tity Concept allowed only 80mA or so, barely enough to drive four devices at an average draw of 20mA per device. Fieldbus segments with only 4 devices somewhat defeated the point of early fieldbus justifications; plants still had lots of cable, and hardware costs went up.

Technology stepped up to the challenge in the form of FISCO (Fieldbus Intrinsically Safe Concept) which was de-

veloped in the late 1990s. Work in Germany had established that if cables and device parameters were defined by bound-ary values, modern electronic current-limiting designs could allow more current and still remain intrinsically safe. By taking advantage of this new technology, FISCO succeed in making more current available in hazardous locations-a full 115mA in worst-case (hydrogen) areas, enough to com-fortably drive five devices, rather than the 80mA (4 devices) allowed by the Entity Concept.

Improvement, indeed. Yet FISCO makes this incremental gain at the expense of operational limitations because these units are complex pieces of electronics, generally based on switch-mode power supplies with duplicated current-limit-ing networks. This complex circuitry creates more heat and reduces unit reliability (complexity = more components = lower MTBF). Furthermore, a primary requirement of FISCO design is that the maximum allowable trunk and spur lengths fall from 1900m to 1000m, and from 120m to 30m, respectively. In addition, all devices and cable must be FISCO-compatible, further limiting choices in installing fieldbus networks.

For some time then, many I&C engineers have been searching for a new solution that would allow them to max-imize intrinsically-safe segment capacity and operational ease within hazardous applications to the same level cur-rently enjoyed within non-hazardous implementations.

The split architecture solutionAt last, technology has come through once again with a solution. The capacity barrier of FISCO has now been sig-nificantly surpassed by a novel split architecture design that

15

Back to Basics

has already proven itself in the field.Engineers at MooreHawke, a division of Moore Indus-

tries-International in North Hills, California, developed this new technology by reexamining traditional approaches to pushing the capacity limits of intrinsically safe segments.

It quickly became evident that the primary cause of low segment power in fieldbus applications was the placement of the main current-limiting resistor at the point of highest current: the IS interface between the safe area and the haz-ardous area.

In response, MooreHawke developed a split architecture approach using a field-mounted device coupler, and an asso-ciated power supply with a safe-area interface. Here, the to-tal resistance requirement is obtained via a split resistance; a small resistor is used in the IS interface and a larger resistor is placed in the field device coupler. The small (trunk) re-sistor ‘sees’ a large current (sum of all devices), but only gen-erates a small voltage drop. The larger (spur) resistor ‘sees’ a small current (single device) and so only generates a small

voltage drop.Subsequently approved by the FM (US) and SIRA (ATEX)

certifying organizations, this design enables intrinsically safe fieldbus segments to support up to 350mA, enough to power 16 devices at 500m, while still being intrinsically safe for hydrogen at the individual spur connection.

In terms of reliability, the split-architecture power supply steps around the complexity associated with FISCO circuits by the use of a conventional wire-wound resistor which, in IS terms, is deemed to be infallible. To further augment the overall systems reliability, the MooreHawke design also in-corporates full AC/DC power conversion, simple linear power supply, and full galvanic isolation, with built in re-dundant supplies. Here again, fewer components translate into greater reliability. MTBFs (AKA MTTF) rise.

Entity parametersOne of the advantages claimed for FISCO systems is that if the design uses a FISCO Power Supply, FISCO-approved devices, and FISCO-marked cable within the FISCO length limitations, then the segment meets the FISCO re-quirements and no Entity Parameter calculations need be done--a previously laborious process employed to confirm that the inherent energy storage in any device, plus its con-necting cable, were within the allowable parameters in that particular hazardous environment.

At first glance, the split-architecture system, being an En-tity design, seems to fall back into requiring new calcula-tions per segment whenever additions are made. However, the unique MooreHawke design has intrinsically safe cur-rent limiting resistors per spur, making each spur an inde-pendent IS loop.

Also, IS fieldbus devices all have the same minimum En-tity parameters as a requirement of their Foundation field-bus approval. This means that while Entity calculations are indeed required, they only have to be done once. This is nor-mally documented for the longest (worst case) spur length, 120m. After that, no device or spur can be any more “worse,”

A unique I.S. split-architecture system supports up to 350mA per

segment to provide safe and reliable installation and operational

advantages in hazardous locations.

16

Back to Basics

so no more calculations are required. Considering all of the above, I&C engineers get to have

the best of all worlds: the digital efficiencies of fieldbus; the long cable lengths, reduced documentation, and unre-stricted device (non proprietary) benefits of the Entity Con-cept; and vastly increased power (350 mA).

Increased flexibility during installationHaving access to the full 1900meters/120meters per spur (limited only by Ohm’s law) allows systems designers to ap-ply the operational advantages of fieldbus to all hazardous areas of a plant, inside or out, almost as if they were looking at a non-hazardous plant. This simplifies installation when facility engineers wire their DCS system, whether retrofit-ting an older plant or building one up from a “greenfield.”

While a collective experience is growing in fieldbus imple-mentation, many installation contractors are still learning the process. One of the issues that frequently causes prob-lems during installation is the fieldbus requirement to have a ‘terminator’ at each end of the segment. Operationally, these terminators prevent reflection of the high frequency communications signal and subsequent interference. How-ever, correctly determining the right amount of terminators, and where to place them, can prove challenging, leading to a common situation of having too many or too few.

Once again, technology came up with a solution. To re-duce any resultant communication errors during segment commissioning, a unique auto-terminator feature was incor-porated into the MooreHawke device couplers.

Reducing downtime and easing maintenanceThe new circuits that help propel fieldbus to increased func-tionality also work to improve the reliability of hazardous plant operations. As it is, MooreHawke’s ROUTE-MASTER system has 99.99993% availability because of the use of pas-sive components, simple design and power redundancy.

Installing a series fuse per spur is a well-proven tech-nique and many such installations exist today. When a fuse

“blows,” the fault is isolated quickly, no segment-loading ef-fects can occur, and adjacent devices are completely unaf-fected. Simple fuses have enormous MTBF and are gener-ally inexpensive. On the other hand, blown fuses must be physically replaced and though this can be done with the segment on line, it can still be a maintenance nuisance.

In keeping with a theme of making fieldbus systems work for the benefit of the plant, technology managed to come up with a simple solution for spur protection when accessing a fuse proves difficult. MooreHawke, for one, offers a fea-ture that provides spur protection via a fold-back technique which locks in a small 2 mA load, just enough to turn on an LED light, and then removes the device from the segment.

This approach is distinctly different from earlier cur-rent-limiting designs which, as the name implies, simply hold the fault current on the segment at a fixed (and always higher-than-normal) value. A fixed current of 60mA is com-mon, and this can quickly overload power supplies and crash the segment. On the other hand, the fold-back technique completely eliminates any and all fault loads from the seg-ment and allows the rest of the system to remain up and running.

Modern device couplers can also ease the maintenance of control systems through diagnostic capabilities in excess of what Foundation fieldbus or Profibus has to offer by them-selves. Some couplers contain LED indicators to provide sta-tus checks at a glance. Built-in access points for hand-held communicators such as fieldbus trouble-shooting devices also save time.

A promise fulfilledFor plants that process chemicals, pharmaceuticals, petro-leum and other products whose production may involve hazardous environments, it appears that recent technolog-ical improvements in split architecture systems design have finally delivered what FISCO promised: Intrinsically-safe segment capacity virtually indistinguishable from non-haz-ardous fieldbus implementations.

17

Back to Basics

Power Supplies Get In On The Reliability ActThe demand for increased reliability and global application for process control

is driving evolution of power supply design

by Jim Montague, Executive Editor

Just as large electricity producers and consumers are us-ing smart devices and software to improve power qual-ity and operating efficiency, developers of device-level

power supplies are employing many of the same strategies.Mike Garrick, power supply manager at Phoenix Contact,

reports that demand for increased reliability and global appli-cation for process control is driving evolution of power supply design. “Process designers are looking for power supplies with increased diagnostic/monitoring ability,” says Garrick. “The application becomes more robust when a power supply can report when its connected field devices are drawing too much current, while the integrity of the DC bus is still intact.

“For example, if the system is designed for 10 amps, it’s be-come a reasonable expectation for the power supply to provide a signal to the process controller when the load starts to draw more than 10 amps. This signal is an early warning indication that the load is drawing too much current, and maintenance should be scheduled. When this early warning signal is re-ceived, the process controller knows the process is still running at the proper voltage at a current beyond the nominal rating of the supply. The reason for this could be a field device, such as a pump, that’s getting old and requires service.”

If this hypothetical application continues to draw more and more current, Garrick explains, then its power supply voltage will eventually start to drop (load down). “The pro-cess controller should expect to receive a second indication when the voltage has dropped 10% down from the adjusted/required application voltage,” he adds. “At 10% down in voltage, the application should be tolerant, and continue to maintain the process, but this second indication is the fi-

nal warning. Any further reduction in voltage will threaten the fidelity of the process. With the reception of the second warning, maintenance must be considered. Depending on what’s at stake with the application, an organized safe shut-down or an acceptable idling point should be considered.”

Garrick adds that global process applications must con-sider various other dynamics to meet all requirements for power supply installation, and these firms will standardize on power supplies that meet these needs. “Approvals for haz-ardous location are the first step to determine the suitability of a power supply to be applied anywhere in the world,” he explains. “Power supplies listed for use in Class I Division 2, ATEX and IEC Ex suit the need for most installations worldwide. Temperature is the next consideration for an ap-plication. Temperature can vary greatly depending on the location of the installation. Global process integration com-panies need power supplies rated for -40 °C to 70 °C to meet their design specifications.

“Finally, the last important, but commonly overlooked fac-tor is choosing a power supply with printed circuit boards (PCBs) that have been dipped in conformal coating. Confor-mal-coated power supplies provide resistance from moisture, such as salt spray, corrosive gases, conductive dust and other contaminants that could influence the life of the power sup-ply. Please know that all coated supplies are not created equal. Techniques range from hand painting, spray and dip coating the PCB. Perfect coverage can only be obtained by dipping the entire PCB in conformation coating. When evaluating the sup-plies, the extent of the coverage can be determined by analyz-ing the PCBs under an ultraviolet light source.”

18

Back to Basics

Wire, Cable and Connectors Are CrucialAs the use of wire and connectors increases with added networking functions and interoperabil-

ity–and decreases, as networks simplify–cabling has become forever crucial in industrial network-

ing applications.

by Jim Montague, Executive Editor

With all the cool stuff happening in industrial network-ing, hardware can be easy to overlook. Wireless and Ethernet seem to be taking over the world. Interop-

erability is advancing everywhere. Fieldbuses are reaching into intrinsically safe areas. Sensors and transmitters are get-ting their own web servers. Plant floor and enterprise sys-tems are linking up.

Wires and related components just lie there. Not very exciting.

So, who cares about cables, connectors, and cordsets? Everyone. That is, everyone who knows networking hard-ware still forms the backbone of their control, automa-tion, and manufacturing applications, and quietly will continue to enable every rookie networking method that emerges in the future. Point-to-point 4-20 mA still dwarfs all other industrial networking methods, though twist-ed-pair fieldbuses and industrial Ethernet have scratched its surface lately. And, truth to tell, there are some pretty historic shifts occurring among the cable and connector sectors themselves.

Tailoring cordsetsFaced with smaller, aging staffs and high labor costs, many end users are asking cable and connector manufacturers, sys-tems integrators, or assembly houses to build more and more complex cordsets for them. As a result, more assembly work reportedly is being outsourced to lower-cost labor centers worldwide. Frank Koditek, Belden CDT’s industrial market manager, says his company has seen a big increase in user de-mand for pre-made cables and connector sets, and that more assembly businesses have grown up to serve that need.

In fact, Jack Gayara, Lapp USA’s connector products man-ager, claims that his firm’s custom cordset and wiring har-ness division has seen double-digit growth in the past couple of years, though business has leveled off in the past several months. “This is a very cyclic business,” says Gayara. “When business is booming, then OEMs keep their cordset build-ing in house. When the economy is down a little, they out-source that work.”

Five or 10 years ago, adds Gayara, there was a lot of relay logic in control panels, so the wires going to the machine had higher pin counts. “Then PLCs combined a lot of that wiring, and pin counts went down,” he says. “Next, newer technologies allowed users to control more functions, and pin counts when up again, until they were reduced by users implementing fieldbuses, Ethernet, and wireless technologies. It seems that cable and connectors’ contacts increase; someone finds a way to simplify, and they decrease for awhile; and future technology allows more monitoring and control functions, and pin counts

Most industrial networks use one or more of the following three con-

nector technologies:

• Mini: These connectors are based on a 7/8-in wide barrel with a 16

pitch. They usually consist of two through seven-pin connectors.

• Euro or Micro (DC): These are based on M12 threads, and have a

coupling unit that’s about 14 mm wide. They include two through

six-pin connectors.

• 9DB: These include D-shell, subminiature connectors typically with

nine pins.

COnnECtOR MEthOdS fOR nEtWORkS

19

Back to Basics

go up again. These two forces really do seem to balance off each other.”

Ed Nabrotzky, industrial communication general man-ager at Woodhead Industries, says increasing use of tai-lor-made cordsets is part of a trend it calls “connector-ization.” “Hardwiring usually requires a skilled, union electrician to pull wire, screw on connectors, and address many power and compatibility issues, ” says Nabrotzky. “Preassembled cabling and connectors, or ‘softwiring,’ means less skilled labor is needed, enables more modular design practices, and allows worldwide shipping and servic-ing far from where components were originally sourced.”

In the past, machines often were designed as one unit. “Now, we can break designs into sub-machines and/or sub-assemblies, and mix and match components as needed by the recipe for the product being produced,” adds Nabrot-zky. “We can build a machine in Kentucky, and reassemble it in Eastern Europe.”

This increased use of customized, modular technologies doesn’t stop at the cable. Individual connectors also are mul-tiplying the variety of inserts and contacts to meet increas-ingly varied demands. “People are using more rectangular connectors with different housing or hoods on the ends, but now we even have modular inserts within them, so we can custom configure for specific applications,” says Gayara. “It’s a lot like Legos. Many users seem to enjoy doing their own inserts. We’ve even added Ethernet to these modular inserts, which gives some flexibility, but maintains a reliable, shielded connection.”

Though much cordset assembly is outsourced, some man-ufacturers are finding they can do it themselves economi-cally. “We do a lot of assembly work here, rather than send-ing components to two or three other companies before they reach the end user,” says Kirk Larson, Turck’s project engi-

neering manager. “We’re also seeing work come back from Asia because of quality and lead time. We’re finding we can be competitive in this area.”

Ethernet and M12Though its presence is still small compared to legacy indus-trial networks, Ethernet is gaining nodes quickly, and this is fueling demand for Ethernet-based cable, connectors and components that can survive and serve long-term in harsh industrial settings with high temperatures, corrosive fluids, electrical noise, extreme heat or cold, high vibrations, or a combination of these factors.

“Presently, Ethernet only makes up 3% of our cable and connector businesses, but that’s up from zero just a couple of years ago,” says Nabrotzky. “For example, we have the global contract for General Motors’ networking, and they’ve speci-fied having Ethernet in all applications by 2007.”

Despite this push, Nabrotzky adds, automotive production suppliers such as robotics and transfer line manufacturers are still having some problems getting all their devices up and working on Ethernet. “The big vendors say they have a work-ing network safety standard in place, but the drives and ro-botics guys still are asking how to build these standards into their devices,” says Nabrotzky. “When they try to do it, they find that everything isn’t defined, there are a lot of gray areas, and they have to guess when they try to format a data packet or interpret a signal. There are still a lot of incompatibilities.”

For a new standard or safety technology to be effective, it must have broad support from vendors to enable interoper-ability and a stable supply chain for end users. “My view is that Ethernet will be very well accepted as a future technol-ogy because vendors are building now, though there aren’t enough products yet to allow it to be more widely imple-mented,” concludes Nabrotzky.

Similarly, as safety functions migrate from redundant hardwiring to join the rest of the operating network, some difficulties persist. “The design is to have safe PLCs and ver-ifications, but all the Ethernet safety standards aren’t fully

“It’s amazing how much wire and cable it takes to go wireless.”

20

Back to Basics

developed yet,” adds Zabrotzky. “However, there’s already harmonizing going on between Europe and the U.S. and between the IEC 61508 and EN 954 standards. They’re al-ready referencing each other, and they have common provi-sions now. For example, the Profibus Trade Organization is putting harmonized standards into Profisafe, and ODVA is releasing its CIP Safety standard.

One trend expected to hasten Ethernet’s adoption is that its users have generally gathered around two connector types. RJ45 is already the most-used Ethernet connector worldwide, mostly in the usual office settings, but now these connectors are being made more rugged for industrial settings, and even acquiring over-molding for especially harsh applications.

Users also are adopting traditional, round M12 and M8 four and eight-pole connectors for installing Ethernet on the plant floor. This has triggered an increase in demand for two-pair Ethernet cable, which M12 connectors require, rather than the four-pair Ethernet cables that don’t match these connectors.

Turck’s Larson says users want more pins and sockets in smaller packages. “M12 used to have just four pins, but now people increasingly want the 12-pin maximum that these connectors can handle,” he states. “It’s a challenge, but it also opens new markets for us. For example, users are adding IP67 ruggedized RJ45 cables to on-board systems on off-road construction vehicles.”

Ethernet education essentialKoditek reports that Ethernet can only keep growing on the plant floor if users are educated about industrially hardened cabling and switches that will help them be successful in the long term.

“With all the oil, solvents, and fumes in many applica-tions, degradation can take place, and failures can occur,” says Koditek. “Process engineers certainly know their own environments, but they may not know the industrial compo-nents they’ll need to get Ethernet into these areas. Similarly, when the IT department is asked to extend Ethernet into a factory, it often doesn’t know that a commercial Ethernet

product isn’t good enough. The walls and cabinets where Ethernet historically exists are much more benign, with a much narrower temperature range, and so the jackets on these cables work at the beginning. However, they can dete-riorate quickly because they can’t withstand the abrasion, oil

exposure, sunlight, cold, crushing forces, and other factors on the plant floor. That’s when intermittent problems start, and downtime costs begin to come in.”

In fact, some of this message might be getting through be-cause, after experiencing slow growth in Ethernet for several years, Koditek reports that Belden has seen strong double-digit growth in Ethernet cabling for the past two or three years.

Wireless needs wiresAfter years of worrying that wireless technologies were going to eliminate hardware, suppliers and users realized sensors and transmitters often need new wires to send wireless sig-nals, and that receivers and PLCs also need cabling to relay that data. Grant Bistram, also of Turck, sums up the industry’s favorite punch-line about the new technology, saying, “It’s amazing how much wire and cable you need to go wireless.”

Woodhead’s Nabrotzky adds, “We’re not seeing wireless in the discrete automation platform at all. No car plant I know of uses it. Some retailers use wireless technology such as RFID for sorting, handling and logisitics, but they still cable all their automation. Wireless is being used in the process industries in remote telemetry units (RTUs) that collect and control I/O data slowly, over long distances, and in wide open spaces.”

In the end, Koditek says wireless and wire likely will co-ex-

“Safety automation that gets rid of hardwired stops, but the cable

market accelerates anyway because now you need cables devoted

to this new technology.”

21

Back to Basics

ist peacefully on the plant floor with each doing the jobs it does best. “Wired infrastructures are more secure and sta-ble, but wireless is more flexible, and more easily can ad-vance performance to where it’s needed, such as hooking up and accessing remote sensors,” he adds.

Do you RoHS?Perhaps the most substantive physical change in wire and ca-bling in recent years was driven by the Europe-based RoHS regulations requiring lead-free, non-heavy-metal composi-tion in a variety of hardware and other components. Major manufacturers already have spent several years gearing up to comply with the new rules, which officially take effect in July 2006, and already are getting rid of non-RoHS-com-pliant inventories. This process reportedly hasn’t been easy because many cable manufacturers have had to find substi-tutes for the heavy-metal additives that often helped make their cables more flexible and durable.

“We spent a couple of years working on this technical chal-lenge, but we haven’t had to change specifications, we hav-en’t lost any capabilities, and we’ve been able to mitigate most of the cost impacts, so there’s minimal if any effect on our customers,” says Koditek. “Now that most of the compound changes are pretty well set, we can continue looking at getting higher performance from these cables, whether it’s increased system speed, more data capacity, or better quality signals.”

Coming attractionsNabrotsky adds another reason for softwire’s growth is that the National Fire Protection Association (NFPA) revised its rules in 2002 to allow higher-voltage power, typically 30 A and 600 V, to be supplied via softwiring with factory-ap-plied, molded connectors. Again, this design simplification reduces labor and potential errors, but it also fits with how cables and connectors have evolved in recent decades.

“Simple tool cords began to be used in the 1970s, and these branched into networking in the 1990s and softwired power in 2002,” says Nabrotzky. “Next, we’re seeing safety

automation that gets rid of hardwired stops. This means you no longer need cables for that task, but the cable market ac-celerates anyway because you do need new cables devoted to the new safety automation.”

Nabrotzky adds that future developments also will include more data and power combined in the same system, espe-cially when a Power over Ethernet (PoE) standard is com-pleted. He also expects DeviceNet and AS-i to tie power and data onto the same cable.

The following terms are some the basic instruction included in

Belden CDT’s Cable 101: The Basics of Wire & Cable.

• Attenuation: A measure of a cable’s loss of electrical energy;

expressed in dB/unit length

• Breaking strength: The pulling force, in pounds, that will cause a

conductor to fracture.

• Capacitance: A measure of insulation’s ability to store electrical

energy; expressed in picofarads per foot.

• Dielectric constant: Electrical property that determines capaci-

tance, propagation velocity, impedance, and insulation perfor-

mance.

• Dielectric strength: Material’s ability to withstand voltage break-

down; expressed in volts (V) or kilovolts (KV).

• Flexibility: Ease with which a conductor can be bent.

• Flex life: Ability of the conductor to bend repeatedly without

breaking.

• Insulation: Substances that electrically and physically separate

conductors in a cable.

• Length of lay: The number of twists in a conductor.

• Propagation velocity: Transmission speed of an electrical signal

through a length of cable; compared to light speed in a vacuum.

• Skin effect: As its frequency increases, the flow of electrons move

to the surface or skin of the conductor.

• Working voltage: Maximum voltage allowable by UL to be applied

to cable; expressed as AC Volts (V) or kilovolts (KV).

• Shielding: Contains electrical energy so signal on cable doesn’t

radiate and interfere with other nearby signals.

CAbLE And COnnECtOR GLOSSARY

22

Back to Basics

Power Supplies & Circuit ProtectionAn overload on any circuit that increases the total current to more than 11A will cause

the power supply to go into its shutdown or hiccup mode

by Dan Hebert, Senior Technical Editor

Electromechanical and analog technologies once dom-inated the world of automation and electrical systems. Automation systems migrated to electronic digital tech-

nologies a few decades ago as PLCs and DCSs replaced re-lays, timers and analog instruments.

The electrical systems that power and protect process plant automation systemsfollowed suit. Among the first to transi-tion was the power supply. Switch-mode power supplies have now replaced transformer-based power supplies in many ap-plications, but in some instances switch-mode power sup-plies don’t work well with thermal and thermal-magnetic circuit breakers. E-T-A Circuit Breakers illustrates why in a white paper summarized below.

When a transformer-based power supply sees a load change, it reacts based on basic electrical principles. A cur-rent overload due to an increase in load will cause a gradual drop in voltage output. A voltage drop may disable control components powered by the supply, as they typically require at least 18 volts to operate.

Switch-mode power supplies, on the other hand, are de-signed to shut down when the total load current reaches 110% of nominal current. Shutdown is typically via a quick-operating electronic switch.

Most of the components that make up the power supply load have capacitive behavior when switching on, so initial current inrush can easily exceed the range of nominal current, causing the power supply to shut down. Switch-mode power supplies can handle this condition. If a power supply is supplying mul-tiple circuits, an overload condition on just one circuit that is not cleared quickly will cause the power supply to shut down. To protect individual circuits fed from one power sup-ply, the system designer will often place a thermal or ther-

mal-magnetic circuit breaker between each individual cir-cuit under load and the power supply.

Let’s look at the behavior of a typical 10-A, 24-VDC switch-mode power supply. Let’s say it has four circuits draw-ing 2A each for a base load of 8A. The maximum current the switch-mode power supply will provide is 11A or 110% of nominal current. Therefore, an overload on any circuit that increases the total current to more than 11A will cause the power supply to go into its shutdown or hiccup mode.

Conventional circuit breakers are effective in many appli-cations. But because a switch-mode DC power supply out-put is current limiting, no conventional circuit breaker is able to limit the current to a safe value that avoids shutting down the power supply while distinguishing between a mo-mentary inrush and a short circuit.

Electronic switches overcome the limitations of thermal and thermal magnetic breakers in this and many other ap-plications. These switches give more control in defining which current overload conditions trigger a trip.

For example, E-T-A’s smart electronic circuit protectors tolerate a momentary inrush and at the same time limit the maximum current to no more than 1.8 times their rating. These circuit protectors can provide advanced circuit pro-tection of automation components, such as sensors, actua-tors and fieldbus couplers.

Electronic circuit protectors use a mechanical circuit breaker in series with an electronic switch. This allows isola-tion of a faulty circuit while still aggressively protecting con-trol system components.

Precise trip-current monitoring, remote operation capabil-ity and remote status indication make electronic circuit pro-tectors a good match for modern automation and systems.

23

Back to Basics

Maintaining ConnectionsThere are plenty of issues that cause network headaches, but never assume your electrical

subcontractor is familiar with routing and terminating network connector cables, even if they

do it all the time.

by Mark Lamendola, Contributor

You’ve probably never counted the number of connectors in your network. However, you

might be surprised at just how many there are. You might be even more surprised,unpleasantly so,if you’ve been treating signal wire connectors as mere commod-ity items. Why? Because doing so leads to some of the stealthiest per-formance and downtime problems a network can experience.

We might not think much about the technology behind each con-nector, such as which style (see sidebar on next page) or termina-tion method to use, but all can af-fect bandwidth, reliability, and total cost of ownership.

The Right StuffA sound strategy for preventing connector-related problems begins with using the right connectors. At the very least, these must be industrial-grade rather than consumer-grade.

“Home network devices are meant for conditioned en-vironments,” says David LaBree, CTO of Prime Telecom in Tampa, Fla. “They use inexpensive components to keep prices down. Placing home devices into industrial environ-ments is asking for problems.” Prime Telecom provides net-work engineering, integration, and maintenance services to municipal and ISP networks.

Manufacturers agree that your first line of defense is to

go with industrial devices. Weid-müller is one of many industri-al-component suppliers that make connectors suited for harsh envi-ronmental conditions, including solvents, fumes, vibration, abra-sion, oil exposure, sunlight, cold, crushing forces, corrosive fluids, electrical noise, and extreme heat or cold.

Andre Jordao, Weidmüller’s business development manager for advanced connectivity in North America, says, “One of the biggest problems with Ether-net for industrial applications is that many customers chose to use

common, small-office/home-office (SOHO) equipment. The pricing and availability are tempting, but those de-vices were designed for a clean office environment. These products were never designed to work in harsh environ-ments. The products might work for a while, but inter-mittent problems or complete failures are guaranteed. It’s only a matter of time.”

You also need to provide the proper protection for each connection. (See Figure 1) You must ask what contaminants (e.g., oil, water, or solvents) are present, and to what degree? Do you need to protect from spraying, dripping, immersion, or high concentrations? Your choice of protection devices and methods will affect the reliability of the connection. Ex-pect tradeoffs in cost and accessibility.

Figure 1: Notice the protective boots on these connec-

tors. Your choice of protection devices and methods

can affect the reliability of the connection. Expect trade-

offs in cost and accessibility.

thESE bOOtS ARE MAdE fOR WALkInG

24

Back to Basics

Better MethodsInstallation matters. “Installation errors can undermine even the best design,” LaBree says. One reason errors oc-cur is complexity. Communication Planning Corp. (CPC), Jacksonville, Fla., is a full-service system integrator serving industrial and commercial markets. Frank Bisbee, CPC’s president, says, “The technology involved in connector hardware can be mind-boggling.” So, if you use outside in-stallers, it’s also good advice to be certain that they know their stuff.

“Never assume your electrical subcontractor is familiar with routing and terminating network cables, even if they

do it all the time,” says Chip Schaible, senior engineer at A&E Engineering. “Sit down with them and go through a few example connectors.” Based in Greer, S.C., A&E pro-vides complete industrial automation and information ser-vices, from design through integration, to many industries.

A consensus view of the major factors for a good installa-tion includes:

• Certification of the installers. Look for a relevant BICSI designation.

• Compliance with the relevant standards, available from BICSI and the IEEE.

These are the more common connector styles used in networks:

• Mini connectors have a 0.875-in (about 23 mm) barrel and 16

threads per inch. They have two to seven pins. Best application:

Where space is at a premium and cables are thin.

• Micro connectors are smaller than mini connectors, and follow

European standards: They have a 14-mm (0.55 in) barrel and

use M12 threads. Typically, they have two to six pins, but an M12

connector might have up to 12 pins. Best application: Where the

equipment being connected adheres to metric standards rather

than SAE. Also useful for two-pair Ethernet.

• DB connectors come in a variety of sizes. Most common are

DB-9, DB-15, DB-19, DB-25, DB-37, and DB-50. The number

after the DB indicates the number of active lines the connector

has, and not the number of pins. Network applications typically

use a nine-pin DB-9 connector. Most computer monitors have a

DB-9 connector. Best application: Serial connections. They�re

commonly used for “snap-on” connectors, rather than plug-in

or threaded.

• IP67 RJ45 connectors are an industrialized version of the ubiq-

uitous RJ45 connector, the most common Ethernet connector.

Two problems with RJ45 are the small contact size and the weak

clips–neither of which were originally intended for industrial use.

Best application: Where standardizing factory floor Ethernet with

the office Ethernet is desirable and failure is tolerable.

• Narrow-tongue compression lugs provide high-quality, safe, re-

liable terminations, if you have the correct die for a given con-

nector. Best application: Accommodating limited-space applica-

tions where you want lug-style connections.

• Pluggable connectors for I/O modules simplify installation,

speed up maintenance, and reduce wiring errors. Common

features include built-in test points, tool-free operation, in-

tegrated coding, and industrial-grade (vibration-resistant or

vibration-proof, thermal cycling resistant, and corrosion-re-

sistant) secure mechanical connection. Best application:

Reduce construction time via pre-manufactured wiring har-

nesses (in house or outsourced), or to simplify replacement

of I/O modules.

Custom cable/connector assemblies (made at the factory or by a

specialty shop) allow elimination of tedious connector assembly

in the field, where it’s tougher to get right. This can result in se-

rious cost-savings up-front, plus increased reliability for the life

of the installation. Consider this for projects that you can plan in

sufficient detail to know the needed cable lengths and which con-

nectors to use with each one.

Custom connectors with modular inserts can solve oddball prob-

lems. Depending on the scope of your project, you might find it

cost-effective to “mix and match” the housing of one connector

with the guts of another rather than doing a major redesign.

COnnECtOR StYLES

25

Back to Basics

• Post-installation testing with a professional-quality net-work analyzer.

In addition, “Always go back with a network validation tool, no matter who does the connections,” adds Schaible.

LaBree agrees. “The client assumes the design is poor if the network isn’t running optimally,” he adds. “Optimiza-tion usually requires each leg or section of the network be tested in its parts, and then tested as a whole. Poor installa-tion will be found in testing.”

The quality of the test also is important. “Those doing the testing need to use the right test equipment and correctly in-terpret the results,” Bisbee cautions.

There’s a school of thought that says you save money by conducting your first round of testing after the system has been operational for a few months. Bisbee says don’t include him in that school. “It’s more economical to test as part of the installation procedure than it is to haggle later over who’s responsible for that 18-hour downtime incident caused by a faulty connector termination that should have been discov-ered before system turnover,” he says.

Mark Lamendola is a f requent con tr ibu tor to Control design and Indus tr ial ne t work ing, You can reach Mark a t comments@mindconnec t ion.com

A fiberoptic installation normally requires field terminations. Here

are some tips your installer should know:

• See if an anaerobic connector system will work for your applica-

tion. If so, you can skip the curing oven and eliminate one more

source of error.

• Understand that “feel” is important when inserting the fiber

into the connector. You can develop feel by setting up a prac-

tice station and doing several test runs on spare cable and

connectors, and evaluating the results. This also is true for

the polishing.

• Set aside the notion that “if a little is good, then more is better”

when using the epoxy. Too much is just as bad as not enough.

Follow specifications precisely.

• Use a microscope to inspect the polished connector. The flaws

you don’t catch with the unaided eye will degrade the system.

• Use a fiberoptic test set. Don’t rely on visual inspection alone,

which can evaluate only the surface finish of the fiber. Other de-

fects such as micro-bending or fiber breaks inside the connec-

tor need correction, too.

• Obviously, dirt interferes with fiber signal transmission. But

so can ordinary condensation, chemical cleaners, and sol-

vents. When planning your fiberoptic system, ask connector

providers about protection methods. Note that some methods

make it difficult to undo a connection. Look for an industri-

al-grade optical connector with an IP67-rated seal.

fIbER MEthOdS

Pho

to c

our

tesy

Flu

ke

Figure 2: When you appreciate the value of testing and the right

equipment, one person can test runs point to point and end to end.

Proper testing isn’t expensive, but the cost of inadequate testing can

be exorbitant.

A tEStY AttItUdE

26

technology in action

Cordsets Survive a Great FloodThis case history demonstrates how cabling and connectors simplified networking

for engineers at an upstate N.Y. wastewater plant, and aided the plant’s recovery

following a devastating deluge.

by Jim Montague, Executive Editor

Many engineers believe that water, in all its various forms, is the most insidious force in nature.

Sure, it’s tasty and essential for life. Yes, we’re three-quarters water ourselves. Some, yawn, astronomers think liquid H2O might be the most precious substance in the universe because of the relatively tiny temperature win-dow it needs to exist.

However, this is small comfort to anyone who’s ever had to mop up a flooded basement, keep moisture out of delicate instruments, or clean up an inundated neighborhood or city. Whether pulled down by gravity or condensing out of the air, water literally gets in everywhere.

Ironically, though they make their living cleaning up wastewater or supporting those that do, several engineers in upstate New York this summer had far more cause than they expected to sympathize with folks in New Orleans and along the Gulf Coast. That’s because these municipal, elec-trical, and construction professionals had to cope with and recover from a devastating, late-June flood at their wastewa-ter plant. And, as if this wasn’t enough, these engineers had to deal with the extra tragic twist that they were within five weeks of finishing a major retrofit of their plant.

Renovation innovationAbout two years ago, the Binghamton-Johnson City Joint Sewage Treatment Plant in Vestal, N.Y., started a $55-60 million retrofit project to improve its capability and capac-ity for treating wastewater. The plant also needed to com-ply with U.S. Environmental Protection Agency and New York State Department of Environmental Conservation reg-ulations, according to Art Van Gelder, project manager for

C&S Engineers, Syracuse, N.Y., which is the project’s de-sign, build, and construction management firm.

The original plant had six primary settling tanks, four secondary settling tanks, three thickeners, three digesters, a belt filter press, a composting facility, and equipment for grit handling and other tasks.

However, because its 18.5-acre site is hemmed in by neigh-bors, a road, and two rivers, the plant’s construction and electrical engineers had to find a way to increase its capac-ity without increasing its footprint. The designers eventually settled on plans to implement an innovative biological aer-ated filter (BAF) system. Though this technology is gaining popularity in Europe, where riverfront space also is scarce, Van Gelder says there are less than a half dozen of these in-stallations in the U.S. The Binghamton-Johnson City plant eventually bought its BAF system from Norway-based IDI Systems.

The initial reconfiguration involved converting the plant’s four secondary settling tanks into primary settling tanks, which typically have slower flow rates. New tanks added to the facility included eight carbonaceous filters, eight nitrification filters, and four de-nitrification filters, as well as backwash pumps, a second inflow pump station, and fine-screen rooms.

To monitor and manage all of the plant’s new equipment and systems, C&S and Matco Electric, Vestal, N.Y., net-worked pneumatic control valves on the plant’s 21 motors with Foundation fieldbus (FF) and DeviceNet protocols via Turck’s molded cables, connectors and cordsets. These mo-tors average 200-300 hp, but include a few 450-hp units.

The new network also controls the plant�s level, flow,

27

technology in action

and pressure transmitters, as well as its analyzers and level switches. This twisted-pair networking topography, enabled by FF and DeviceNet, reduced the plant’s hardwiring by thousands of feet (See Figure 1). The plant previously relied on a point-to-point architecture that filled its existing cable trays. When it’s installed, FF’s cable usually contains one pair of wires for data, and one drain wire. DeviceNet cable usually has five total wires, including one pair for data, one pair for power, and one drain wire or shielded conductor.

Dan Dvorsky, Matco’s general foreman, says DeviceNet gen-erally is used to control valves and pumps, while FF monitors the flow and level transmitters. The supplier provided cus-tom-length cables and ends for a total of 200 valves on 20 tanks.

These improvements and the BAF system are designed to increase the plant’s capacity from 18.5 mgd average flow, with a peak of 23-25 mgd, up to 60 mgd. It was IDI’s develop-ers that advised the plant to adopt FF and DeviceNet.

Flood and recoveryBecause water treatment plants are situated near channels that can accept their effluent, the Binghamton-Johnson City facility is located at the confluence of the Susquehanna and Chenango rivers, which both feed the greater Delaware wa-tershed (See Figure 2 below). “All of the surrounding com-munities are higher than the plant,” says Van Gelder.

Because its location is necessarily hazardous, the plant was in a vulnerable position when extremely heavy rains and resulting floodwaters arrived over a three-day period be-ginning on June 28. Most of the facility and its new con-struction ended up under about 8 ft of water. The rivers re-portedly reached 4-5 ft above their estimated 100-year flood level. This is the level that water treatment plants are usually designed to withstand.

New construction damaged or otherwise affected by the flood is estimated at $10.3 million, which is what it would re-portedly cost to get the plant back to its pre-renovation state. Total damage to the plant was reportedly $15-25 million.

In fact, this was the fourth flood that has occurred during the two-year renovation project. The first two didn’t affect the plant or the project, but the third in the spring of 2005

Figure 1: Installing twisted-pair Foundation fieldbus and DeviceNet

terminated with molded cordsets reduced the amount of hardwiring

used at the wastewater treatment plant. These waterproof cables and

connectors survived a late-June flood without needing the decon-

struction, drying, and rebuilding that a regular wire-in-conduit job

would have required.

MOStLY EMPtY tRAY

Figure 2: The Binghamton-Johnson City Joint Sewage Treatment Plant

is located next to (and occasionaly in) the confluence of the Susque-

hanna and Chenango rivers.

dOWn bY thE RIVER

28

technology in action

reached the 100-year level and delayed the renovation by about five weeks.

The treatment plant has continued to treat sewage from its customers, even while its staff carries out flood-related re-pairs. However, it’s still not known how many more months it will take to completely repair the plant, or when its new capacity will come online.

Cordsets eclipsing conduitWhen a catastrophe like a flood happens, people often find that few of their usual, sophisticated tools have survived. One of the very few bright spots for the plant’s staff and consulting engineers is that Turck’s over-molded, IP-67-rated cordsets used in the renovation and the BAF system survived the flood pretty much unscathed. This meant that the plant’s staff didn’t have to clean and rebuild these net-work components.

“A lot of the new installation was underwater,” says Dvorsky. “However, our new cables and cordsets were wa-terproof enough that they survived. We didn’t even have to clean and dry them out like we did with all of our other elec-trical conduit.”

Van Gelder adds, “If we’d had regular electrical conduit instead of these molded cordsets, then we would”ve had to take it all apart, clean out the water and silt, and rebuild them.” Also, the fact that the plant converted from point-to-point hardwiring to twisted-pair FF and DeviceNet meant that there were far fewer networking paths, cable runs, and other equipment to clean out.