Investigation of the Flow in Pelton Turbines andthe...

Transcript of Investigation of the Flow in Pelton Turbines andthe...

International Journal of Rotating Machinery1997, Vol. 3, No. 4, pp. 239-247

Reprints available directly from the publisherPhotocopying permitted by license only

(C) 1997 OPA (Overseas Publishers Association)Amsterdam B.V. Published under license

under the Gordon and Breach SciencePublishers imprint.

Printed in India.

Investigation of the Flow in Pelton Turbinesand the Influence of the Casing

HEINZ-BERND MATTHIAS a, JOSEF PROST a’* and CHRISTIAN ROSSEGGER b

Institute for Waterpower and Pumps, Vienna University of Technology, Karlsplatz 13, 1040 Wien, Austria,"Ingersoll Dresser Pumps, Industriestrafle B Nr.6, 2345 Brunn/Geb, Austria

(Received 25 March 1997; In finalform 11 April 1997)

At the institute for waterpower and pumps at the University of Technology Vienna we do alot of research work observing the flow in the casing and the buckets of Pelton turbines. Oneinterest of our research is to find criteria to estimate the influence of the splash waterdistribution in the casing on the turbine efficiency. Knowing the splash water distribution itis further possible to develop methods to provide visual documentation of the flow in andaround the buckets from the beginning to the end of interaction.Our measurements have been done on a single jet Pelton turbine with a runner pitch

diameter of 420 mm. Our research shows that the casing has great influence to the operationof a Pelton turbine and so it is very important to include the casing as an important factor inall investigations. Aluminum honeycombs have been successful to bring the splashing waterunder control and to make good visual documentations of the flow.

Keywords." Flow in Pelton turbines, Influence of the casing, Visual documentation, Outline of thecasing, Turbine efficiency

1. INTRODUCTION

At the test rig for Pelton turbines at the Institutefor Waterpower and Pumps all kinds of operatingconditions can be researched. A main interest ofour research is to observe the flow in the casing ofthe turbine and to find criteria to estimate theinfluence of the splash water distribution in thecasing on the turbine efficiency. Knowing the splashwater distribution it is further possible to developmethods to provide visual documentation of the

flow in and around the buckets from the beginningto the end of interaction.

2. THE TEST RIG

At our test rig the research of multi-jet Peltonturbines with a pitch diameter up to 500mm byheads up to 260m is possible. The head for theturbine is produced by three pumps (parallel and/or serial operation). They are powered by speed

*Corresponding author. Tel." +43 58801-3211. Fax: +43 504 1148.

239

240 H.-B. MATTHIAS et al.

regulated DC-motors, which allow an optimaladjustment of the pumps with respect to the headand flow of a defined operation point of the Peltonturbine.The DC-motor-generator for the Pelton turbine

allows a real 4-quadrant operation. He can beregulated by speed or current and has the followingcharacteristics:

P 87kW,

n +O-3000 min- 1.

To measure the frictional force the turbine shaftis equipped with a hydrostatic bearing. The shaft isconnected with the DC-motor-generator by anRSG-torquemeter and a gearing.

All kinds of data are recorded by electro-mechanical measuring instruments. The outputsignals of the amplifiers are digitized. So the mea-sured data can be treated by a personal computer.For more details of the test rig see Rossegger et al.(1990) or Rossegger (1991).

The reported measurements have been done on

a single jet Pelton turbine with a runner pitchdiameter of 420 mm.

3. SPLASH WATER DISTRIBUTION IN ARECTANGULAR CASING

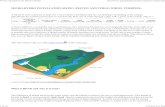

To get basic knowledge of the flow distribution thefirst tests were made with a rectangular casing withtransparent walls, see Fig. 1. The only installationswere a splash-guard to protect the wall opposite to

the nozzle and a bucket-plate to reduce the splashwater in the upper part of the casing.

Photos and videos were made and analyzed. Animportant factor to get usable pictures was theposition of the camera and optimal illuminationconditions (brightness, position of the lamps). Theshutter speed of the camera system was controlledby the generator speed.For the given geometric and hydraulic config-

uration we found four criteria to classify the flow

1200-618 -’! I [.--600 --/ bucket-plate

*L’ I’

: nozz,e A ’"

splash-guarcasing

tailwater chanel

-///////////////////

570

1260

/

900

FIGURE Rectangular casing.

INVESTIGATION FLOW IN PELTON TURBINES 241

distribution (Wurm, 1990):

(1) Classification of the splash water distributionby observing how the normal projection of thePelton runner to the casing is covered bysplash water. The splash water distribution atthe transparent wall of the casing can be clas-sified into four groups, which are dependenton the operation point of the turbine:

Group 1 (Fig. 2(a)) is independent of theflow and can only be observed at low gen-erator speed. It shows the trend from theoptimal operation point to low unit speed.Group 2 (Fig. 2(b)) is independent of theflow and can only be observed in the optimalrange of operating conditions. It shows thetrend from the optimal operation point tohigh unit speed.Group 3 (Fig. 2(c)) is dependent on the flowand is located above the optimal range ofoperating conditions.Group 4 is the field near and above therunaway speed of the turbine. No coveringof the turbine with. splash water can beobserved in this field.

(2) Angle of contact of the splash water to thecasing. The angle of contact (’a’ in Fig. 1) isa function of the buckets geometry, the flowand the speed. In the optimal operation rangethe angle of contact gets to a minimum andis about 45-50 Besides no lateral flow canbe observed in the optimal operating range.

(3) Area ofjlood in the casing. Flood means thatthe water falls back from the casing to the

(4)

runner and impinges on the runner at therear of the buckets. This depends only on thegeometry of the casing. In our case the waterimpinges on the vertical side walls of the cas-

ing, flows to the rear upper edge and is re-

flected there. In the turbine characteristic thearea of flood is located at low unit speed andhigher unit discharge.Water transport around the circuit of the Peltonrunner (’b’ in Fig. 1). The water transport isdependent on flow and generator speed andcan be estimated to nearly 250 measuredfrom jet contact. The point of full emptyingof the bucket depends mainly on the unitspeed.

4. INFLUENCE OF THE CASING TO THEPERFORMANCE OF THE TURBINE

The next step of our research work was the varia-tion of the casing in order to analyze the influenceof the casing to the performance of the turbine,(Rossegger, 1991). For the given geometrical andhydraulic configuration we did research on the flowin different dome-shaped and rectangular casingsin the regular and off-design operation range of theturbine. Finally we made an analysis of the lossesto determine a ’casing-efficiency’.The tests were made on 9 different casings.

Figure 3 shows one of the casings with cylindricaldome. The radius and the width of the dome havebeen varied. Figure 4 shows an example of a tested

a) b)FIGURE 2 Splash water distribution at the wall of the rectangular casing.

242 H.-B. MATTHIAS et al.

casing with a rectangular dome. Modifications weremade on the width of the dome.

Table I shows the list of the tested casings.For each casing we determined the characteristic

of the turbine. For a constant position of the needle

35

FIGURE 3 Casing with cylindrical dome.

of the nozzle and a constant head (constant unitdischarge Qll) the best efficiency point and thecorresponding unit speed nil can be located"

QQll

D2. x/- (1)

n.Dn- v/H (2)

The connecting line of these Q11/nl -values is theuseful operation range of the turbine. The analysisshows that all lines (except the line of casingNo. 121) are very close. The gradients rise sharply,the n-values range from 36.75 to 38 min-1 (from37.2 to 38.3 min-1 for No. 121). So it seems to bepermissible to use a mean unit speed of rill37.5 min- for the further considerations.For this value of nil the graph of/T as a function

of Q can be estimated. Figure 5 shows the graph

750

35

FIGURE 4 Casing with rectangular dome.FIGURE 5 Efficiency versus unit discharge.

TABLE Dimension of the tested casings

Type Width (mm) Rg (mm) Bucket-plate

No. lllNo. 121No. 211No. 221No. 222No. 321No. 322No. 431No. 430

Cylindrical dome 150 275 Type ACylindrical dome 235 275 Type ACylindrical dome (Fig. 3) 150 370 Type ACylindrical dome (Fig. 3) 235 370 Type ACylindrical dome 235 370 Type BRectangular dome (Fig. 4) 235 Type ARectangular dome 235 Type BRectangular casing (Fig. 1) 600 Type ARectangular casing 600

INVESTIGATION FLOW IN PELTON TURBINES 243

60 85

50 84

o 40 83

20 81

0 79

111 121 211 221 222 321 322 431 430

unit discharge [] efficiency behaviour factor [] efficiency

FIGURE 6 Effect of the casing on unit discharge, efficiency and efficiency behavior factor.

for casing No. 111. The best efficiency and the cor-

responding unit discharge now can be estimated.The results for all casings are presented in Fig. 6.High values of Ql are a result of a casing design

which prevents flow to fall back into the runner. Agood casing design for high Q ll is a casing with a

very small slit between the wall and the runner

(No. 111) or a casing with a great radial and axialexpanse of the dome (No. 321). The so-calledbucket-plate is useful for high Qll too as water isdisabled to enter the dome.The turbine efficiency is nearly equal for each

casing. Exception is the casing with a cylindricaldome with a small radial and a great axial slit

(No. 121). Because of the great axial slit the domeof the casing is full of water which could not leavethe dome. Although the best efficiencies of theother casings are almost the same the casings withcylindrical dome seem to be better as less water is inthe casing. So the flow depends less on the reflec-tions of the casing.

In order to rate the performance of the turbine inpartial load and overload conditions (variation ofdischarge Q res. unit discharge Q11) we defined anefficiency behavior factor. This factor is the radiusof curvature at the vertex of the efficiency char-acteristic. High values of this factor mean highefficiency out of the optimum.The determined factors are presented in Fig. 6.

The casings with a small radius of the cylindrical

dome (No. 111 and No. 121) have the minor

efficiency behavior factor. Leaving the best effi-ciency point the efficiency of the turbine decreaserather quick. The best efficiency out of theoptimum is detectable with casing No. 211 (smallaxial and great radial slit of the cylindrical dome).At off design conditions (above and below the

optimal unit speed) a significant change of the flowin the casing can be observed. Below the optimumof nil there is more splash water in the casingbecause the relation of the geometry of the bucketand flow velocity is out of order. Above theoptimum of rill some part of the flow is no moreinvolved in energy transformation and so there isless water in the upper casing parts. The deter-mined best efficiencies at nl 35 min- and nl40.4min-1 are presented in Fig. 7. The behaviorr/T=f(Qll) represented by the efficiency behaviorfactor differs too, see Fig. 8.

5. ANALYSIS OF THE LOSSES

The losses in a Pelton turbine may be split up intothe following losses:

-losses in the jet because of friction, highturbulence, jet-divergence and gravitation,losses in the runner because of friction in thebuckets, entrance losses,...,

244

85

83- 82

gl

H.-B. MATTHIAS et al.

8O

79

111 121 211 221 222 321 322 431 430

tt n =35min- t n 11 =37,5min- n 11=40,4min-

FIGURE 7 Effect of the unit speed on the efficiency.

9O- 80

70

60

40

,a 30

20

o

111 121 211 221 222 321 322 431 430

I111 nl l=35min-1 Ii nl l=37,5min-1 n 11=40,4min-

FIGURE 8 Effect of the unit speed on the efficiency behavior factor.

losses in the casing because of ventilation andsplash water falling into the runner and/or thejet,mechanical losses in the generator, bearings,...

In our investigation we only have to recognizethe system jet-runner-casing. The efficiency of theturbine can be determined from the turbinecharacteristic. The efficiency of the jet (res. of thenozzle) can be obtained knowing the velocity of thejet by measuring the jet diameter at a knowndischarge. We measured the diameter of the jetusing a Digital Image Processing System (DIP). A

good approximate value of the efficiency of therunner can be estimated from the geometry of thebucket and the velocity triangles at the inlet andthe outlet. The losses in the bucket are consideredusing experience values published in literature (e.g.Raabe, 1970).The losses in the nozzle and in the runner

estimated in this way come to approximately13.2%, see Fig. 9. The efficiency of the casing nowcan be estimated by

(3)f/N

2O

18% 16

1,9

111

INVESTIGATION FLOW IN PELTON TURBINES

121

2,6

211

2,8 2,7 2,62,7 2,2 2,3

221 222 321 322 431 430

casingI1 nozzle and runner

FIGURE 9 Efficiencies for the tested casings.

245

The efficiencies of the casings estimated in thisway for nl 37.5 min-1 are presented in Fig. 9. Thevalues range from 1.9% to 2.8% except No. 121.

In summary it may be said that casing No. 211seems to be the best compromise regarding effi-ciency and efficiency behavior both in design andoff-design conditions. Other casings certainly showbetter efficiencies, but the efficiency behavior insome cases is much worse than in No. 211.

6. DOCUMENTATION OF THE FLOW INTHE BUCKET

Knowing the splash water distribution in the casingit seems obvious to use this knowledge for thevisual documentation of the flow in the runner.

Catching the splash water it is possible to makevideos without reduction of quality. The rectan-gular casing (Fig. 1) was the basis.For the regular catch and drain of the splashing

water two elements with aluminum honeycombswere constructed (Eckert, 1993). The hexagonalgrid made of thin aluminumfoils has the task tocatch the splashing water from different directionswithout reflection of droplets. The function of thesurrounding construction is the stable support ofthe honeycombs and the drain of the water. Theelement opposite to the shaft was narrow and

FIGURE 10 Catch of the splash water in the casing.

adjustable in height (see Fig. 10). So the reductionof the view angle from the side can be minimized.A normal 50Hz video-camera with a tele-

objective was used to observe from the outsidethrough the open casing. There were two positionsfor the camera, see Fig. 11. To provide a stableimage the stroboscopic light was triggered exter-nally by an optical speed sensor. With the phase

246 H.-B. MATTHIAS et al.

adjuster the image of the bucket could be adjustedby hand or moved continuously.

Figure 12 shows one example of the recordedpictures. You can see the entrance of the bucketinto the jet and the flow in the bucket.The stages of the beginning entrance of the

bucket into the jet are visible in detail in Fig. 13.

k--Posl+/-lon

FIGURE ll Positions for the camera.

In the upper left picture the outline of the jet issmooth. Drops of water are still leaving the bucketafter a full rotation of the runner. When the tip ofthe bucket comes up to the jet the outline of the jetbecomes rough. According with literature there aretwo possible reasons:

-The buckets have the effect of a radialcompressor and the air leaving the runnerinterferes with the jet (Bachmann et al., 1990).The drops coming out from the bucket slowdown and dissolve the boundary surface of thejet (Grein, 1990).

Following there is a summary of the observedphenomena:

-Perturbation of the surface of the jet andseparation of droplets when the cutout of thebucket approaches the jet (Fig. 13).Detachment of the jet by the bucket not in aclean matter; the cut off part of the jet tears offin a very irregular structure; the part adhering

F|GURE 12 Flow in the buckets of a Pelton runner.

INVESTIGATION FLOW IN PELTON TURBINES 247

FIGURE 13 Entrance of the buckets into the jet.

on the backside of the bucket moves radial outof the runner.The flow out of the bucket forms sheets of water;the sheets fuse to a wall of splash water.Water from the cutout region on the backside ofthe bucket fans out towards the ribs of thebucket and splashes off.

NOMENCLATURE

Qll/711

QHD

TT

unit discharge, 1/s (10-3 m3/s)unit speed, min-discharge, 1/s (10-3 m3/s)head, mpitch diameter, mefficiency of the turbine, %efficiency of the casing, %efficiency of the nozzle (jet), %efficiency of the runner, %

References

Bachmann, P. et al. (1990) Experimental flow studies on a 1-jetmodel Pelton turbine, Proceedings of the 15th I.A.H.R.Symposium, Vol. 2, Article R3.

Eckert, F. (1993) Realisierung und erste Anwendung einesSystems zur visuellen Dokumentation der Str6mungsvor-g/inge in den Schaufeln einer Peltonturbine, Diploma thesis,Vienna University of Technology.

Grein, H. (1990) Cavitation pitting and rain erosion on Peltonrunners, Proceedings of the 15th I.A.H.R. Symposium, Vol. 1,pp. H6.1-10.

Rossegger, Ch. et al. (1990) Computeraided measurementsystem for hydro turbines, International Water Power &Dam Construction, 42(3), 28-33.

Rossegger, Ch. (1991) Ein Beitrag zur Untersuchung desGeh/iuseeinflusses auf das Betriebsverhalten einer Modellpel-tonturbine unter besonderer Berticksichtigung der Automa-tisierung des Versuchsstandes, Doctoral thesis, ViennaUniversity of Technology.

Raabe, J. (1970) Hydraulische Maschinen und Anlagen Teil 2Wasserturbinen, VDI-Verlag, Dtisseldorf.

Wurm, L. (1990) Dokumentation und Analyse verschiedenenBetriebszust/inde einer Peltonturbine, Diploma thesis, ViennaUniversity of Technology.

EENNEERRGGYY MMAATTEERRIIAALLSSMaterials Science & Engineering for Energy Systems

Economic and environmental factors are creating ever greater pressures for theefficient generation, transmission and use of energy. Materials developments arecrucial to progress in all these areas: to innovation in design; to extending lifetimeand maintenance intervals; and to successful operation in more demandingenvironments. Drawing together the broad community with interests in theseareas, Energy Materials addresses materials needs in future energy generation,transmission, utilisation, conservation and storage. The journal covers thermalgeneration and gas turbines; renewable power (wind, wave, tidal, hydro, solar andgeothermal); fuel cells (low and high temperature); materials issues relevant tobiomass and biotechnology; nuclear power generation (fission and fusion);hydrogen generation and storage in the context of the ‘hydrogen economy’; andthe transmission and storage of the energy produced.

As well as publishing high-quality peer-reviewed research, Energy Materialspromotes discussion of issues common to all sectors, through commissionedreviews and commentaries. The journal includes coverage of energy economicsand policy, and broader social issues, since the political and legislative contextinfluence research and investment decisions.

SSUUBBSSCCRRIIPPTTIIOONN IINNFFOORRMMAATTIIOONNVolume 1 (2006), 4 issues per year Print ISSN: 1748-9237 Online ISSN: 1748-9245Individual rate: £76.00/US$141.00Institutional rate: £235.00/US$435.00Online-only institutional rate: £199.00/US$367.00For special IOM3 member rates please emailssuubbssccrriippttiioonnss@@mmaanneeyy..ccoo..uukk

EEDDIITTOORRSSDDrr FFuujjiioo AAbbeeNIMS, Japan

DDrr JJoohhnn HHaalldd, IPL-MPT,Technical University ofDenmark, Denmark

DDrr RR VViisswwaannaatthhaann, EPRI, USA

FFoorr ffuurrtthheerr iinnffoorrmmaattiioonn pplleeaassee ccoonnttaacctt::Maney Publishing UKTel: +44 (0)113 249 7481 Fax: +44 (0)113 248 6983 Email: [email protected] Publishing North AmericaTel (toll free): 866 297 5154 Fax: 617 354 6875 Email: [email protected]

For further information or to subscribe online please visitwwwwww..mmaanneeyy..ccoo..uukk

CCAALLLL FFOORR PPAAPPEERRSSContributions to the journal should be submitted online athttp://ema.edmgr.com

To view the Notes for Contributors please visit:www.maney.co.uk/journals/notes/ema

Upon publication in 2006, this journal will be available via theIngenta Connect journals service. To view free sample contentonline visit: wwwwww..iinnggeennttaaccoonnnneecctt..ccoomm//ccoonntteenntt//mmaanneeyy

NNEEWW

FFOORR 22000066

Maney Publishing on behalf of the Institute of Materials, Minerals and Mining

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttp://www.hindawi.com Volume 2010

RoboticsJournal of

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Hindawi Publishing Corporation http://www.hindawi.com

Journal ofEngineeringVolume 2014

Submit your manuscripts athttp://www.hindawi.com

VLSI Design

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation http://www.hindawi.com

Volume 2014

The Scientific World JournalHindawi Publishing Corporation http://www.hindawi.com Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Modelling & Simulation in EngineeringHindawi Publishing Corporation http://www.hindawi.com Volume 2014

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttp://www.hindawi.com Volume 2014

DistributedSensor Networks

International Journal of

![Pelton Turbines [Compatibility Mode]](https://static.fdocuments.us/doc/165x107/55cf92f8550346f57b9ab6bd/pelton-turbines-compatibility-mode.jpg)