Intent to Issue Air Individual Permit Major Amendment ... · Air Individual Permit . Major...

-

Upload

hoangnguyet -

Category

Documents

-

view

220 -

download

0

Transcript of Intent to Issue Air Individual Permit Major Amendment ... · Air Individual Permit . Major...

Air Individual Permit

Major Amendment

14700012-101 Permittee: Crown Cork & Seal Co Inc - Owatonna

Facility name: Crown Cork & Seal Co Inc - Owatonna 2929 West Bridge Street Owatonna, MN 55060 Steele County

Operating permit issuance date: September 10, 2014 Expiration date: September 10, 2019 * All Title I Conditions do not expire Major Amendment: August 23, 2016 Stage 1 issuance date – Authorization to Construct and Operate: August 3, 2016 Stage 2 issuance date – Major Amendment: August 23, 2016 Permit characteristics: Federal; Part 70/ Major for NSR; Limits to avoid NSR; Limits to avoid NESHAP The emission units, control equipment and emission stacks at the stationary source authorized in this permit amendment are as described in the Permit Applications Table. The conditions included in Stage 1 of this permit action are effective on the Stage 1 Issuance Date shown above. Stage 1 conditions authorize construction and modification of the facility and the operation of the modified emissions units at the address listed above until final action is taken on Stage 2. Air Emission Permit No. 14700012- 004 remains effective until the Stage 2 Issue Date. Beginning on the Stage 2 Issue date Air Emission Permit No. 14700012-101 supersedes Air Emission Permit No. 14700012- 004 and authorizes the Permittee to operate, construct, and modify the stationary source at the address listed above unless otherwise noted in the permit. The Permittee must comply with all the conditions of the permit. Any changes or modifications to the stationary source must be performed in compliance with Minn. R. 7007.1150 to 7007.1500. Terms used in the permit are as defined in the state air pollution control rules unless the term is explicitly defined in the permit. Unless otherwise indicated, all the Minnesota rules cited as the origin of the permit terms are incorporated into the SIP under 40 CFR § 52.1220 and as such as are enforceable by U.S. Environmental Protection Agency (EPA) Administrator or citizens under the Clean Air Act.

Stage 1 Issuance Approval:

Signature: Steven S. Pak This document has been electronically signed. for the Minnesota Pollution Control Agency

for Don Smith, P.E., Manager Air Quality Permits Section Industrial Division

Stage 2 Issuance Approval:

Signature: Toni Volkmeier This document has been electronically signed. for the Minnesota Pollution Control Agency

for Don Smith, P.E., Manager Air Quality Permits Section Industrial Division

Table of Contents

Page

1. Permit applications table ............................................................................................................................................. 4 2. Where to send submittals ............................................................................................................................................ 5 3. Facility description ....................................................................................................................................................... 6 4. Amendment description .............................................................................................................................................. 6 5. Summary of subject items ........................................................................................................................................... 7 6. Limits and other requirements .................................................................................................................................... 9 7. Submittal/action requirements ................................................................................................................................. 34 8. Appendices ................................................................................................................................................................. 40

Appendix A. Insignificant Activities and General Applicable Requirements ............................................................ 40 Appendix B. Maximum Content of Materials and Capacity Information ................................................................ 41

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 4 of 41

1. Permit applications table Subsequent permit applications: Title description Application receipt date Action number Part 70 Reissuance 08/13/2010 14700012- 004 Part 70 Reissuance (Supplemental Information)

01/21/2011 14700012- 004

Major Amendment 10/08/2015 14700012-101

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 5 of 41

2. Where to send submittals

Send submittals that are required to be submitted to the U.S. EPA regional office to: Chief Air Enforcement Air and Radiation Branch EPA Region V 77 West Jackson Boulevard Chicago, Illinois 60604

Each submittal must be postmarked or received by the date specified in the applicable Table. Those submittals required by Minn. R. 7007.0100 to 7007.1850 must be certified by a responsible official, defined in Minn. R. 7007.0100, subp. 21. Other submittals shall be certified as appropriate if certification is required by an applicable rule or permit condition.

Send submittals that are required by the Acid Rain Program to:

U.S. Environmental Protection Agency Clean Air Markets Division 1200 Pennsylvania Avenue NW (6204N) Washington, D.C. 20460

Send any application for a permit or permit amendment to:

Fiscal Services – 6th Floor Minnesota Pollution Control Agency 520 Lafayette Road North St. Paul, Minnesota 55155-4194

Also, where required by an applicable rule or permit condition, send to the Permit Document Coordinator notices of:

a. Accumulated insignificant activities b. Installation of control equipment c. Replacement of an emissions unit, and d. Changes that contravene a permit term

Unless another person is identified in the applicable Table, send all other submittals to:

AQ Compliance Tracking Coordinator Industrial Division Minnesota Pollution Control Agency 520 Lafayette Road North St. Paul, Minnesota 55155-4194

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 6 of 41

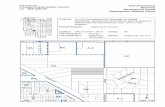

3. Facility description

The Crown Cork & Seal Co Inc - Owatonna (Facility) is located at 2929 W Bridge St in Owatonna, MN, Steele County, Minnesota. Crown Cork and Seal Co Inc - Owatonna (Crown) is a metal can manufacturer which consists of two identical lines for the production of two-piece steel food cans. The two manufacturing lines have an individual maximum production capacity of 1725 cans per minute each. Primarily Volatile Organic Compound (VOC) emissions are generated from the protective coatings applied to the inside (spray line) and outside (washcoat) of the cans. Coatings also contain hazardous air pollutant (HAP) emissions for which the facility has accepted limits to avoid triggering major source status under 40 CFR Section 63.2. Particulate matter (PM), particulate matter less than 10 microns (PM10), and particulate matter less than 2.5 microns (PM2.5) are also emitted from both inside spray lines and are controlled by lacquer spray machine (LSM) control boxes. The LSM control boxes work by using a series of panels that act as a baffling system and are capable of achieving an overall control efficiency of 95%. This facility is an existing major source under New Source Review (NSR) regulations.

4. Amendment description Crown is installing a regenerative thermal oxidizer (RTO) to control VOC and HAP emissions from coating lines EQUI 8 and EQUI 9 for the production of two-piece steel food cans. The RTO will also control emissions from EQUI 4 (oven) and EQUI 5 (oven). Oven emissions are included to ensure the RTO receives gases and emissions at the appropriate temperature for operation. The RTO shall achieve a capture efficiency of 75% and a control efficiency of 95% for VOC and HAP emissions. Crown will conduct performance tests to show compliance with both efficiencies. Crown is also adding a new coating to their operations. A change in coating is a change in operation and emission increases from the coating change were evaluated. Crown accepted a VOC limit of 100 tons per year for EQUIs 8 and 9 coating lines to avoid major modification status under 40 CFR 52.21. This limit is found in COMG 8 of the permit. In addition, Crown accepted a limit of 240 hour per year of uncontrolled hours of operation for EQUIs 4, 5, 8, and 9. Crown expects time is needed for repair and maintenance of the RTO, but Crown wants the ability to continue coating operations during downtime for RTO repair and maintenance. A limit on uncontrolled hours of operation allows Crown operational flexibility and to take credit for RTO operation when calculating future emission increases for EQUIs 4, 5, 8, and 9. Moreover, Crown is installing a fabric filter (baghouse). EQUIs 8 and 9 will vent emissions from the LSM control boxes to the baghouse before emissions are vented to the RTO. Crown is installing this baghouse for fire prevention reasons only and is not taking credit for this unit as a control device. Therefore, the baghouse is not included in the permit.

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 7 of 41

5. Summary of subject items

SI ID: Description

Relationship Type

Related SI ID: Description

ACTV3: All IAs COMG2: HAP Limits has

members EQUI6, EQUI7, EQUI8, EQUI9

COMG8: EQUIs 8 and 9

has members

EQUI8, EQUI9

COMG9: EQUIs controlled by TREA 5

has members

EQUI4, EQUI5, EQUI8, EQUI9

EQUI10: Inside Spray

EQUI11: Inside Spray

EQUI12: Wash Coat EQUI13: Inside Spray

EQUI1: Boiler sends to STRU16 EQUI2: Dryer, unknown firing method - Line 1

sends to STRU3

EQUI2: Dryer, unknown firing method - Line 1

sends to STRU4

EQUI3: Dryer, unknown firing method - Line 2

sends to STRU6

EQUI3: Dryer, unknown firing method - Line 2

sends to STRU7

EQUI4: Oven, unknown firing method - Line 1

sends to STRU10

EQUI4: Oven, unknown firing method - Line 1

sends to STRU17: RTO Stack

EQUI4: Oven, unknown firing method - Line 1

sends to STRU8

EQUI4: Oven, unknown firing method - Line 1

sends to STRU9

EQUI4: Oven, unknown firing method - Line 1

is controlled by

TREA5: Regenerative Thermal Oxidizer

EQUI5: Oven, unknown firing method - Line 2

sends to STRU12

EQUI5: Oven, sends to STRU13

SI ID: Description

Relationship Type

Related SI ID: Description

unknown firing method - Line 2 EQUI5: Oven, unknown firing method - Line 2

sends to STRU14

EQUI5: Oven, unknown firing method - Line 2

sends to STRU17: RTO Stack

EQUI5: Oven, unknown firing method - Line 2

is controlled by

TREA5: Regenerative Thermal Oxidizer

EQUI6: Wash coat 1 sends to STRU2 EQUI7: Wash coat 2 sends to STRU5 EQUI8: Spray Booth - Line 1

sends to STRU11

EQUI8: Spray Booth - Line 1

sends to STRU17: RTO Stack

EQUI8: Spray Booth - Line 1

is controlled by

TREA1: LSM Collection Box

EQUI8: Spray Booth - Line 1

is controlled by

TREA5: Regenerative Thermal Oxidizer

EQUI9: Spray Booth - Line 2

sends to STRU15

EQUI9: Spray Booth - Line 2

sends to STRU17: RTO Stack

EQUI9: Spray Booth - Line 2

is controlled by

TREA2: LSM Collection Box

EQUI9: Spray Booth - Line 2

is controlled by

TREA5: Regenerative Thermal Oxidizer

STRU10: STRU11: STRU12: STRU13: STRU14: STRU15: STRU16: STRU17: RTO Stack STRU1: Warehouse STRU2: STRU3: STRU4: STRU5: STRU6:

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 8 of 41

SI ID: Description

Relationship Type

Related SI ID: Description

STRU7: STRU8: STRU9: TFAC1: Crown Cork & Seal Co Inc - Owatonna

TREA1: LSM Collection Box

is controlled in series by

TREA5: Regenerative Thermal Oxidizer

SI ID: Description

Relationship Type

Related SI ID: Description

TREA2: LSM Collection Box

is controlled in series by

TREA5: Regenerative Thermal Oxidizer

TREA5: Regenerative Thermal Oxidizer

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 9 of 41

6. Limits and other requirements Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation TFAC 1 14700012 Crown Cork &

Seal Co Inc - Owatonna

5.1.1 Permit Appendices: This permit contains appendices as listed in the permit Table of Contents. The Permittee shall comply with all requirements contained in Appendices [Appendix A. Insignificant Activities and General Applicable Requirements; Appendix B. Maximum Content of Materials and Capacity Information]. [Minn. R. 7007.0800, subp. 2]

5.1.2 PERMIT SHIELD: Subject to the limitations in Minn. R. 7007.1800, compliance with the conditions of this permit shall be deemed compliance with the specific provision of the applicable requirement identified in the permit as the basis of each condition. Subject to the limitations of Minn. R. 7007.1800 and 7017.0100, subp. 2, notwithstanding the conditions of this permit specifying compliance practices for applicable requirements, any person (including the Permittee) may also use other credible evidence to establish compliance or noncompliance with applicable requirements. This permit shall not alter or affect the liability of the Permittee for any violation of applicable requirements prior to or at the time of permit issuance. [Minn. R. 7007.1800, (A)(2)]

5.1.3 These requirements apply if a reasonable possibility (RP) as defined in 40 CFR Section 52.21(r)(6)(vi) exists that a proposed project, analyzed using the actual-to-projected-actual (ATPA) test (either by itself or as part of the hybrid test at Section 52.21(a)(2)(iv)(f)) and found to not be part of a major modification, may result in a significant emissions increase (SEI). If the ATPA test is not used for the project, or if there is no RP that the proposed project could result in a SEI, these requirements do not apply to that project. The Permittee is only subject to the Preconstruction Documentation requirement for a project where a RP occurs only within the meaning of Section 52.21(r)(6)(vi)(b). Even though a particular modification is not subject to New Source Review (NSR), or where there isn't a RP that a proposed project could result in a SEI, a permit amendment, recordkeeping, or notification may still be required by Minn. R. 7007.1150 - 7007.1500. [Minn. R. 7007.0800, subp. 2, Title I Condition: 40 CFR 52.21(r)(6) and Minn. R. 7007.3000]

5.1.4 Preconstruction Documentation -- Before beginning actual construction on a project, the Permittee shall document the following: 1. Project description 2. Identification of any emission unit whose emissions of an NSR pollutant could be affected

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 10 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation 3. Pre-change potential emissions of any affected existing emission unit, and the projected post-change potential emissions of any affected existing or new emission unit. 4. A description of the applicability test used to determine that the project is not a major modification for any regulated NSR pollutant, including the baseline actual emissions, the projected actual emissions, the amount of emissions excluded due to increases not associated with the modification and that the emission unit could have accommodated during the baseline period, an explanation of why the amounts were excluded, and any creditable contemporaneous increases and decreases that were considered in the determination. The Permittee shall maintain records of this documentation. [Minn. R. 7007.0800, subps. 4-5, Minn. R. 7007.1200, subp. 4, Title I Condition: 40 CFR 52.21(r)(6) and Minn. R. 7007.3000]

5.1.5 The Permittee shall monitor the actual emissions of any regulated NSR pollutant that could increase as a result of the project and that were analyzed using the ATPA test, and the potential emissions of any regulated NSR pollutant that could increase as a result of the project and that were analyzed using potential emissions in the hybrid test. The Permittee shall calculate and maintain a record of the sum of the actual and potential (if the hybrid test was used in the analysis) emissions of the regulated pollutant, in tons per year on a calendar year basis, for a period of 5 years following resumption of regular operations after the change, or for a period of 10 years following resumption of regular operations after the change if the project increases the design capacity of or potential to emit of any unit associated with the project. [Minn. R. 7007.0800, subps. 4-5, Title I Condition: 40 CFR 52.21(r)(6) and Minn. R. 7007.3000]

5.1.6 The Permittee must submit a report to the Agency if the annual summed (actual, plus potential if used in hybrid test) emissions differ from the preconstruction projection and exceed the baseline actual emissions by a significant amount as listed at 40 CFR Section 52.21(b)(23). Such report shall be submitted to the Agency within 60 days after the end of the year in which the exceedances occur. The report shall contain: a. The name and ID number of the Facility, and the name and telephone number of the Facility contact person. b. The annual emissions (actual, plus potential if any part of the project was analyzed using the hybrid test) for each pollutant for which the preconstruction projection and significant emissions increase are exceeded. c. Any other information, such as an explanation as to why the summed emissions differ from the preconstruction projection. [Minn. R. 7007.0800, subps. 4-5, Title I Condition: 40 CFR 52.21(r)(6) and Minn. R. 7007.3000]

5.1.7 The Permittee shall comply with National Primary and

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 11 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation Secondary Ambient Air Quality Standards, 40 CFR pt. 50, and the Minnesota Ambient Air Quality Standards, Minn. R. 7009.0010 to 7009.0080. Compliance shall be demonstrated upon written request by the MPCA. [Minn. R. 7007.0100, subp. 7(A), 7(L), & 7(M), Minn. R. 7007.0800, subp. 4, Minn. R. 7007.0800, subps. 1-2, Minn. R. 7009.0010-7009.0080, Minn. Stat. 116.07, subd. 4a, Minn. Stat. 116.07, subd. 9]

5.1.8 Circumvention: Do not install or use a device or means that conceals or dilutes emissions, which would otherwise violate a federal or state air pollution control rule, without reducing the total amount of pollutant emitted. [Minn. R. 7011.0020]

5.1.9 Air Pollution Control Equipment: Operate all pollution control equipment whenever the corresponding process equipment and emission units are operated. [Minn. R. 7007.0800, subp. 16(J), Minn. R. 7007.0800, subp. 2]

5.1.10 Operation and Maintenance Plan: Retain at the stationary source an operation and maintenance plan for all air pollution control equipment. At a minimum, the O & M plan shall identify all air pollution control equipment and control practices and shall include a preventative maintenance program for the equipment and practices, a description of (the minimum but not necessarily the only) corrective actions to be taken to restore the equipment and practices to proper operation to meet applicable permit conditions, a description of the employee training program for proper operation and maintenance of the control equipment and practices, and the records kept to demonstrate plan implementation. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 16(J)]

5.1.11 Operation Changes: In any shutdown, breakdown, or deviation the Permittee shall immediately take all practical steps to modify operations to reduce the emission of any regulated air pollutant. The Commissioner may require feasible and practical modifications in the operation to reduce emissions of air pollutants. No emissions units that have an unreasonable shutdown or breakdown frequency of process or control equipment shall be permitted to operate. [Minn. R. 7019.1000, subp. 4]

5.1.12 Fugitive Emissions: Do not cause or permit the handling, use, transporting, or storage of any material in a manner which may allow avoidable amounts of particulate matter to become airborne. Comply with all other requirements listed in Minn. R. 7011.0150. [Minn. R. 7011.0150]

5.1.13 Noise: The Permittee shall comply with the noise standards set forth in Minn. R. 7030.0010 to 7030.0080 at all times during the operation of any emission units. This is a state only requirement and is not enforceable by the EPA Administrator or citizens under the Clean Air Act. [Minn. R. 7030.0010-7030.0080]

5.1.14 Inspections: The Permittee shall comply with the inspection procedures and requirements as found in Minn. R. 7007.0800, subp. 9(A). [Minn. R. 7007.0800, subp. 9(A)]

5.1.15 The Permittee shall comply with the General Conditions listed in Minn. R. 7007.0800, subp. 16. [Minn. R. 7007.0800,

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 12 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation subp. 16]

5.1.16 Performance Testing: Conduct all performance tests in accordance with Minn. R. ch. 7017 unless otherwise noted in this permit. [Minn. R. ch. 7017]

5.1.17 Performance Test Notifications and Submittals: Performance Tests are due as outlined in this permit. Performance Test Notification (written): due 30 days before each Performance Test Performance Test Plan: due 30 days before each Performance Test Performance Test Pre-test Meeting: due 7 days before each Performance Test Performance Test Report: due 45 days after each Performance Test Performance Test Report - Microfiche Copy: due 105 days after each Performance Test The Notification, Test Plan, and Test Report may be submitted in an alternative format as allowed by Minn. R. 7017.2018. [Minn. R. 7017.2018, Minn. R. 7017.2030, subps. 1-4, Minn. R. 7017.2035, subps. 1-2]

5.1.18 Limits set as a result of a performance test (conducted before or after permit issuance) apply until superseded as stated in the MPCA's Notice of Compliance letter granting preliminary approval. Preliminary approval is based on formal review of a subsequent performance test on the same unit as specified by Minn. R. 7017.2025, subp. 3. The limit is final upon issuance of a permit amendment incorporating the change. [Minn. R. 7017.2025, subp. 3]

5.1.19 Monitoring Equipment Calibration - The Permittee shall either: 1. Calibrate or replace required monitoring equipment every 12 months; or 2. Calibrate at the frequency stated in the manufacturer's specifications. For each monitor, the Permittee shall maintain a record of all calibrations, including the date conducted, and any corrective action that resulted. The Permittee shall include the calibration frequencies, procedures, and manufacturer's specifications (if applicable) in the Operations and Maintenance Plan. Any requirements applying to continuous emission monitors are listed separately in this permit. [Minn. R. 7007.0800, subp. 4(D)]

5.1.20 Operation of Monitoring Equipment: Unless noted elsewhere in this permit, monitoring a process or control equipment connected to that process is not necessary during periods when the process is shutdown, or during checks of the monitoring systems, such as calibration checks and zero and span adjustments. If monitoring records are required, they should reflect any such periods of process shutdown or checks of the monitoring system. [Minn. R. 7007.0800, subp.

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 13 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation 4(D)]

5.1.21 Recordkeeping: Retain all records at the stationary source, unless otherwise specified within this permit, for a period of five (5) years from the date of monitoring, sample, measurement, or report. Records which must be retained at this location include all calibration and maintenance records, all original recordings for continuous monitoring instrumentation, and copies of all reports required by the permit. Records must conform to the requirements listed in Minn. R. 7007.0800, subp. 5(A). [Minn. R. 7007.0800, subp. 5(C)]

5.1.22 Recordkeeping: Maintain records describing any insignificant modifications (as required by Minn. R. 7007.1250, subp. 3) or changes contravening permit terms (as required by Minn. R. 7007.1350, subp. 2), including records of the emissions resulting from those changes. [Minn. R. 7007.0800, subp. 5(B)]

5.1.23 If the Permittee determines that no permit amendment or notification is required prior to making a change, the Permittee must retain records of all calculations required under Minn. R. 7007.1200. These records shall be kept for a period of five years from the date the change was made or until permit reissuance, whichever is longer. The records shall be kept at the stationary source for the current calendar year of operation and may be kept at the stationary source or office of the stationary source for all other years. The records may be maintained in either electronic or paper format. [Minn. R. 7007.1200, subp. 4]

5.1.24 Shutdown Notifications: Notify the Commissioner at least 24 hours in advance of a planned shutdown of any control equipment or process equipment if the shutdown would cause any increase in the emissions of any regulated air pollutant. If the owner or operator does not have advance knowledge of the shutdown, notification shall be made to the Commissioner as soon as possible after the shutdown. However, notification is not required in the circumstances outlined in Items A, B and C of Minn. R. 7019.1000, subp. 3. At the time of notification, the owner or operator shall inform the Commissioner of the cause of the shutdown and the estimated duration. The owner or operator shall notify the Commissioner when the shutdown is over. [Minn. R. 7019.1000, subp. 3]

5.1.25 Breakdown Notifications: Notify the Commissioner within 24 hours of a breakdown of more than one hour duration of any control equipment or process equipment if the breakdown causes any increase in the emissions of any regulated air pollutant. The 24-hour time period starts when the breakdown was discovered or reasonably should have been discovered by the owner or operator. However, notification is not required in the circumstances outlined in Items A, B and C of Minn. R. 7019.1000, subp. 2.

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 14 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation At the time of notification or as soon as possible thereafter, the owner or operator shall inform the Commissioner of the cause of the breakdown and the estimated duration. The owner or operator shall notify the Commissioner when the breakdown is over. [Minn. R. 7019.1000, subp. 2]

5.1.26 Notification of Deviations Endangering Human Health or the Environment: As soon as possible after discovery, notify the Commissioner or the state duty officer, either orally or by facsimile, of any deviation from permit conditions which could endanger human health or the environment. [Minn. R. 7019.1000, subp. 1]

5.1.27 Notification of Deviations Endangering Human Health or the Environment Report: Within 2 working days of discovery, notify the Commissioner in writing of any deviation from permit conditions which could endanger human health or the environment. Include the following information in this written description: 1. the cause of the deviation; 2. the exact dates of the period of the deviation, if the deviation has been corrected; 3. whether or not the deviation has been corrected; 4. the anticipated time by which the deviation is expected to be corrected, if not yet corrected; and 5. steps taken or planned to reduce, eliminate, and prevent reoccurrence of the deviation. [Minn. R. 7019.1000, subp. 1]

5.1.28 Application for Permit Amendment: If a permit amendment is needed, submit an application in accordance with the requirements of Minn. R. 7007.1150 through Minn. R. 7007.1500. Submittal dates vary, depending on the type of amendment needed. Upon adoption of a new or amended federal applicable requirement, and if there are more than 3 years remaining in the permit term, the Permittee shall file an application for an amendment within nine months of promulgation of the applicable requirement, pursuant to Minn. R. 7007.0400, subp. 3. [Minn. R. 7007.0400, subp. 3, Minn. R. 7007.1150 - 7007.1500]

5.1.29 Extension Requests: The Permittee may apply for an Administrative Amendment to extend a deadline in a permit by no more than 120 days, provided the proposed deadline extension meets the requirements of Minn. R. 7007.1400, subp. 1(H). Performance testing deadlines from the General Provisions of 40 CFR pt. 60 and pt. 63 are examples of deadlines for which the MPCA does not have authority to grant extensions and therefore do not meet the requirements of Minn. R. 7007.1400, subp. 1(H). [Minn. R. 7007.1400, subp. 1(H)]

5.1.30 Emission Inventory Report: due on or before April 1 of each calendar year following permit issuance, to be submitted on a form approved by the Commissioner. [Minn. R. 7019.3000-7019.3100]

5.1.31 Emission Fees: due 30 days after receipt of an MPCA bill.

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 15 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation [Minn. R. 7002.0005-7002.0095]

COMG 2 GP007 HAP Limits 5.2.1 The Permittee shall limit emissions of HAPs - Total <= 22.0

tons per year 12-month rolling sum to be calculated by the 15th day of each month for the previous 12-month period. HAP contents for each HAP-containing material (i.e. coatings, gun cleaner, etc.) shall be determined as described under the Material Content requirement in COMG 2. [Minn. R. 7011.7000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.2.2 The Permittee shall limit emissions of HAPs - Single <= 9.0 tons per year 12-month rolling sum to be calculated by the 15th day of each month for the previous 12-month period. HAP contents for each HAP-containing material (i.e. coatings, gun cleaner, etc.) shall be determined as described under the Material Content requirement in COMG 2. [Minn. R. 7011.7000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.2.3 Daily Recordkeeping. On each day of operation, the Permittee shall calculate, record, and maintain the total quantity of all coatings and other HAP-containing materials used at the facility. This shall be based on delivery records. [Minn. R. 7007.0800, subps. 4-5, Minn. R. 7011.7000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.2.4 HAPs: Monthly Recordkeeping. By the 15th of the month, the Permittee shall calculate and record the following using the formulas specified in this permit: 1) The total HAP-containing materials used in the previous calendar month using the daily usage records. This record shall also include the individual and total HAP contents of each HAP-containing material used in the previous month, as determined by the Material Content requirement of this permit; 2) The total and individual HAP emissions for the previous month using the formulas specified in this permit; and 3) The 12-month rolling sum total and individual HAP emissions for the previous 12-month period by summing the monthly emissions data for the previous 12 months. [Minn. R. 7007.0800, subps. 4-5]

5.2.5 HAPs: Monthly Calculation -- HAP Emissions. The Permittee shall calculate each individual HAP and total HAP emissions using equations specified in this permit for EQUIs 6, 7, 8, and 9. Each individual HAP and total HAP emissions from EQUIs 6, 7, 8, and 9 shall be summed to determine the previous month and 12-month rolling sum HAP emissions for the previous 12-month period for COMG 2 emissions.

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 16 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation HAP Emissions (tons/month) = Sum of [H] Where: H = the amount of each pollutant (total HAP or each individual HAP), used, in tons/month, as calculated for EQUIs 6, 7, 8, and 9 in this permit. [Minn. R. 7007.0800, subps. 4-5]

5.2.6 Material Content. HAPs contents in coating materials shall be determined by the Safety Data Sheet (SDS) or the Material Safety Data Sheet (MSDS) provided by the supplier for each material used. If a material content range is given on the SDS or the MSDS, the highest number in the range shall be used in all compliance calculations. If information is provided in the Regulatory Section of the SDS, the highest number in the range of that section may be used. Other alternative methods approved by the MPCA may be used to determine the HAPs contents. The Commissioner reserves the right to require the Permittee to determine the HAP contents of any material, according to EPA or ASTM reference methods. If an EPA or ASTM reference method is used for material content determination, the data obtained shall supersede the SDS or the MSDS. [Minn. R. 7007.0800, subps. 4-5]

5.2.7 Maximum Contents of Materials: The Permittee assumed certain worst-case contents of materials when determining the short term potential to emit of units in COMG 2. These assumptions are listed in Appendix B of this permit. Changing to a material that has a higher content of any of the given pollutants is considered a change in method of operation that must be evaluated under Minn. R. 7007.1200, subp. 3 to determine if a permit amendment or notification is required under Minn. R. 7007.1150. [Minn. R. 7005.0100, subp. 35a]

COMG 8 EQUIs 8 and 9 5.3.1 The Permittee shall limit emissions of Volatile Organic

Compounds <= 100 tons per year 12-month rolling sum to be calculated by the 15th day of each month for the previous 12-month period as described later in this permit. VOC contents for each VOC-containing material shall be determined as described under the Material Content requirement in COMG 8. [Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.3.2 Daily Recordkeeping. On each day of operation, the Permittee shall calculate, record, and maintain the following: -total quantity (tons) of all coatings and other VOC, solids, and HAP-containing materials used when COMG 8 EQUIs vented to TREA 5 and TREA 5 was in operation. This shall be based on written usage logs. -total quantity (tons) of all coatings and other VOC, solids, and HAP-containing materials used when COMG 8 EQUIs did not vent to TREA 5 or during periods of non-operation of

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 17 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation TREA 5. This shall be based on written usage logs. [Minn. R. 7007.0800, subps. 4-5, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.3.3 Material Content. VOC, HAPs, and Solids (PM, PM<10 microns, and PM<2.5 microns) contents in coating materials shall be determined by the Safety Data Sheet (SDS) or the Material Safety Data Sheet (MSDS) provided by the supplier for each material used. If a material content range is given on the SDS or the MSDS, the highest number in the range shall be used in all compliance calculations. If information is provided in the Regulatory Section of the SDS, the highest number in the range of that section may be used. When using the MSDS as the basis of calculating particulate emissions, the conservative assumption is made that PM consists entirely of PM less than 10 microns or less than 2.5 microns. Other alternative methods approved by the MPCA may be used to determine the VOC, HAPs, and solids contents. The Commissioner reserves the right to require the Permittee to determine the VOC, HAP, and solids contents of any material, according to EPA or ASTM reference methods. If an EPA or ASTM reference method is used for material content determination, the data obtained shall supersede the SDS or the MSDS. [Minn. R. 7007.0800, subps. 4-5]

5.3.4 Maximum Contents of Materials: The Permittee assumed certain worst-case contents of materials when determining the short term potential to emit of units in COMG 8. These assumptions are listed in Appendix B of this permit. Changing to a material that has a higher content of any of the given pollutants is considered a change in method of operation that must be evaluated under Minn. R. 7007.1200, subp. 3 to determine if a permit amendment or notification is required under Minn. R. 7007.1150. [Minn. R. 7005.0100, subp. 35a]

5.3.5 Volatile Organic Compounds: Monthly Recordkeeping: By the 15th of the month, the Permittee shall calculate and record the following: 1a) The total usage of VOC-containing materials used in EQUI 8 when EQUI 8 vented to TREA 5 and TREA 5 was in operation for the previous calendar month using the daily usage records. This record shall also include the VOC and solids contents of each material as determined by the Material Content requirement of this permit; 1b) The total usage of VOC-containing materials used in EQUI 9 when EQUI 9 vented to TREA 5 and TREA 5 was in operation for the previous calendar month using the daily usage records. This record shall also include the VOC and solids contents of each material as determined by the Material Content requirement of this permit; 2a) The total usage of VOC-containing materials used in EQUI 8 when EQUI 8 did not vent to TREA 5 or during periods of

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 18 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation non-operation of TREA 5 for the previous calendar month using the daily usage records. This record shall also include the VOC and solids contents of each material as determined by the Material Content requirement of this permit; 2b) The total usage of VOC-containing materials used in EQUI 9 when EQUI 9 did not vent to TREA 5 or during periods of non-operation of TREA 5 for the previous calendar month using the daily usage records. This record shall also include the VOC and solids contents of each material as determined by the Material Content requirement of this permit; 2) The VOC emissions for the previous month using the formulas specified in this permit; and 3) The 12-month rolling sum VOC emissions for the previous 12-month period by summing the monthly VOC emissions data for the previous 12 months. [Minn. R. 7007.0800, subps. 4-5]

5.3.6 Volatile Organic Compounds: Monthly Calculation -- VOC Emissions. The Permittee shall calculate VOC emissions using the following equations: 1) VOC Emissions (tons/month) = V = V1 + V2 2) Use the following equations to calculate VOC emissions when EQUI 8 or EQUI 9 vents to TREA 5, TREA 5 is in operation, and credit for capture and control can be taken. V1 = UE + CE UE = [(A1 x B1) + (A2 x B2) + (A3 x B3) + ....] * (1 - CAE) CE = [(A1 x B1) + (A2 x B2) + (A3 x B3) + ....] * CAE * (1 - COE) Where: V1 = the amount of VOC, in tons/month when EQUI 8 or EQUI 9 operated controlled. UE = uncaptured emissions CE = captured and controlled emissions A# = amount of each VOC-containing coating used in the previous month, in tons/month. B# = weight percent of VOC in A#, as a fraction (e.g., 50% is 0.50). CAE = capture efficiency as determined under TREA 5, as a fraction (e.g., 50% is 0.50). COE = control efficiency as determined under TREA 5, as a fraction (e.g., 50% is 0.50). 2) Use the following equation to calculate VOC emissions when EQUI 8 or EQUI 9 is not vented to TREA 5, TREA 5 is not in operation, or when credit for capture and control cannot be taken.

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 19 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation V2 = [(A1 x B1) + (A2 x B2) + (A3 x B3) + ....] Where: V2 = the amount of VOC, in tons/month when EQUI 8 or EQUI 9 operated uncontrolled. A# = amount of each VOC-containing coating used in the previous month, in tons/month. B# = weight percent of VOC in A#, as a fraction (e.g., 50% is 0.50). [Minn. R. 7007.0800, subps. 4-5]

COMG 9 EQUIs

controlled by TREA 5

5.4.1 The Permittee may operate EQUIs 4, 5, 8, and 9 without venting to TREA 5 for a period of uncontrolled Hours <= 240 hours per year 12-month rolling sum to be calculated by the 15th day of each month for the previous 12-month period as described later in this permit. [Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.4.2 Daily Recordkeeping. On each day of operation, the Permittee shall calculate, record, and maintain a record of the total hours of controlled and uncontrolled operation for EQUI 8 and EQUI 9. The Permittee shall document periods of operation and non-operation of TREA 5 when EQUI 8 and EQUI 9 are in operation. This shall be based on written logs. [Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.4.3 Monthly Recordkeeping. By the 15th of the month, the Permittee shall calculate and record the following: 1) The total hours of uncontrolled operation for the previous calendar month using the daily records; and 2) The 12-month rolling sum hours of uncontrolled operation for the previous 12-month period by summing the monthly hours of uncontrolled operation for the previous 12 months. [Minn. R. 7007.0800, subps. 4-5]

EQUI 1 EU010 Boiler 5.5.1 Fuel type: Natural gas and propane only by design. [Minn. R.

7005.0100, subp. 35a] 5.5.2 The Permittee shall submit a notification of any physical or

operational change which increases emission rate: due 60 days (or as soon as practical) before the change is commenced. [40 CFR 60.7(a)(4), Minn. R. 7019.0100, subp. 1]

5.5.3 Recordkeeping: The Permittee shall maintain records of the occurrence and duration of any startup, shutdown, or malfunction in the operation of the facility including; any malfunction of the air pollution control equipment; or any periods during which a continuous monitoring system or monitoring device is inoperative. [40 CFR 60.7(b), Minn. R. 7019.0100, subp. 1]

5.5.4 Recordkeeping: The Permittee shall maintain a file of all

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 20 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation measurements, maintenance, reports and records for at least five years. This requirement is more stringent than 40 CFR Section 60.7(f), which specifies two years. [40 CFR 60.7(f), Minn. R. 7007.0800, subp. 5(C), Minn. R. 7019.0100, subp. 1]

5.5.5 No owner or operator shall build, erect, install, or use any article, machine, equipment or process, the use of which conceals an emission which would otherwise constitute a violation of an applicable standard. [40 CFR 60.12, Minn. R. 7011.0050]

5.5.6 Recordkeeping: By the last day of each calendar month, the Permittee shall record the amount of natural gas and propane combusted in the boiler during the previous calendar month. These records shall consist of purchase records, receipts, or fuel meter readings. [40 CFR 60.48c(g), Minn. R. 7011.0570]

EQUI 2 EU002 Dryer, unknown

firing method - Line 1

5.6.1 Opacity <= 20 percent opacity except for one six-minute period per hour of not more than 60 percent opacity. [Minn. R. 7011.0610, subp. 1(A)(2)]

5.6.2 Total Particulate Matter <= 0.30 grains per dry standard cubic foot of exhaust gas unless required to further reduce emissions to comply with the less stringent limit of either Minn. R. 7011.0730 or Minn. R. 7011.0735. [Minn. R. 7011.0610, subp. 1(A)(1)]

5.6.3 Fuel type: Natural gas and propane only by design. [Minn. R. 7005.0100, subp. 35a]

EQUI 3 EU004 Dryer, unknown

firing method - Line 2

5.7.1 Opacity <= 20 percent opacity except for one six-minute period per hour of not more than 60 percent opacity. [Minn. R. 7011.0610, subp. 1(A)(2)]

5.7.2 Total Particulate Matter <= 0.30 grains per dry standard cubic foot of exhaust gas unless required to further reduce emissions to comply with the less stringent limit of either Minn. R. 7011.0730 or Minn. R. 7011.0735. [Minn. R. 7011.0610, subp. 1(A)(1)]

5.7.3 Fuel type: Natural gas and propane only by design. [Minn. R. 7005.0100, subp. 35a]

EQUI 4 EU006 Oven, unknown

firing method - Line 1

5.8.1 Opacity <= 20 percent opacity except for one six-minute period per hour of not more than 60 percent opacity. [Minn. R. 7011.0610, subp. 1(A)(2)]

5.8.2 Total Particulate Matter <= 0.30 grains per dry standard cubic foot of exhaust gas unless required to further reduce emissions to comply with the less stringent limit of either

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 21 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation Minn. R. 7011.0730 or Minn. R. 7011.0735. [Minn. R. 7011.0610, subp. 1(A)(1)]

5.8.3 Fuel type: Natural gas and propane only by design. [Minn. R. 7005.0100, subp. 35a]

EQUI 5 EU008 Oven, unknown

firing method - Line 2

5.9.1 Opacity <= 20 percent opacity except for one six-minute period per hour of not more than 60 percent opacity. [Minn. R. 7011.0610, subp. 1(A)(2)]

5.9.2 Total Particulate Matter <= 0.30 grains per dry standard cubic foot of exhaust gas unless required to further reduce emissions to comply with the less stringent limit of either Minn. R. 7011.0730 or Minn. R. 7011.0735. [Minn. R. 7011.0610, subp. 1(A)(1)]

5.9.3 Fuel type: Natural gas and propane only by design. [Minn. R. 7005.0100, subp. 35a]

EQUI 6 EU001 Wash coat 1 5.10.1 Opacity <= 20 percent opacity. [Minn. R. 7011.0715, subp.

1(B)] 5.10.2 Total Particulate Matter <= 0.30 grains per dry standard cubic

foot of exhaust gas unless required to further reduce emissions to comply with the less stringent limit of either Minn. R. 7011.0730 or Minn. R. 7011.0735. [Minn. R. 7011.0715, subp. 1(A)]

5.10.3 Daily Recordkeeping. On each day of operation, the Permittee shall calculate, record, and maintain the total quantity of all coatings and other HAP-containing materials used in EQUI 6. This shall be based on delivery records. [Minn. R. 7007.0800, subp. 4-5, Minn. R. 7011.7000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.10.4 Monthly Recordkeeping: By the 15th day of each month, the Permittee shall calculate and record the following information: 1) Tons of each type of coating used in EQUI 6 for the previous month and previous 12 months. This record shall also include the individual and total HAP contents of each HAP-containing material used in the previous month, as determined by the Material Content requirement of this permit; 3) The total and individual HAP emissions for the previous month using the formulas specified in this permit; and 4) The 12-month rolling sum total and individual HAP emissions for the previous 12-month period by summing the monthly emissions data for the previous 12 months. [Minn. R. 7007.0800, subp. 4-5]

5.10.5 HAPs: Monthly Calculation -- HAP Emissions. The Permittee shall calculate each individual HAP and total HAP emissions

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 22 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation using the following equation: HAP Emissions (tons/month) = H H = (A1 x B1) + (A2 x B2) + (A3 x B3) + .... Where: H = the amount of each pollutant (total HAP or each individual HAP), used in EQUI 6, in tons/month. A# = amount of each HAP-containing material used in the previous month, in tons/month. B# = weight percent of each individual or total HAP in A#, as a fraction (e.g., 50% is 0.50). [Minn. R. 7007.0800, subp. 4-5]

EQUI 7 EU003 Wash coat 2 5.11.1 Opacity <= 20 percent opacity. [Minn. R. 7011.0715, subp.

1(B)] 5.11.2 Total Particulate Matter <= 0.30 grains per dry standard cubic

foot of exhaust gas unless required to further reduce emissions to comply with the less stringent limit of either Minn. R. 7011.0730 or Minn. R. 7011.0735. [Minn. R. 7011.0715, subp. 1(A)]

5.11.3 Daily Recordkeeping. On each day of operation, the Permittee shall calculate, record, and maintain the total quantity of all coatings and other HAP-containing materials used in EQUI 7. This shall be based on delivery records. [Minn. R. 7007.0800, subp. 4-5, Minn. R. 7011.7000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.11.4 Monthly Recordkeeping: By the 15th day of each month, the Permittee shall calculate and record the following information: 1) Tons of each type of coating used in EQUI 7 for the previous month and previous 12 months. This record shall also include the individual and total HAP contents of each HAP-containing material used in the previous month, as determined by the Material Content requirement of this permit; 3) The total and individual HAP emissions for the previous month using the formulas specified in this permit; and 4) The 12-month rolling sum total and individual HAP emissions for the previous 12-month period by summing the monthly emissions data for the previous 12 months. [Minn. R. 7007.0800, subp. 4-5]

5.11.5 HAPs: Monthly Calculation -- HAP Emissions. The Permittee shall calculate each individual HAP and total HAP emissions using the following equation: HAP Emissions (tons/month) = H H = (A1 x B1) + (A2 x B2) + (A3 x B3) + .... Where:

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 23 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation H = the amount of each pollutant (total HAP or each individual HAP), used in EQUI 7, in tons/month. A# = amount of each HAP-containing material used in the previous month, in tons/month. B# = weight percent of each individual or total HAP in A#, as a fraction (e.g., 50% is 0.50). [Minn. R. 7007.0800, subp. 4-5]

EQUI 8 EU005 Spray Booth -

Line 1

5.12.1 The Permittee shall limit emissions of Total Particulate Matter <= 1.30 pounds per hour 3-hour average from EQUI 8 and associated pollution control equipment (TREA 1). The emission rate is equal to the 3-Hour average of solids applied and that are not collected on the can surfaces and the LSM Collection Box. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 2, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.12.2 The Permittee shall limit emissions of PM < 10 micron <= 1.30 pounds per hour 3-hour average from EQUI 8 and associated pollution control equipment (TREA 1). The emission rate is equal to the 3-Hour average of solids applied and that are not collected on the can surfaces and the LSM Collection Box. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 2, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.12.3 The Permittee shall limit emissions of PM < 2.5 micron <= 1.30 pounds per hour 3-hour average from EQUI 8 and associated pollution control equipment (TREA 1). The emission rate is equal to the 3-Hour average of solids applied and that are not collected on the can surfaces and the LSM Collection Box. [Minn. R. 7007.0800, subp. 2]

5.12.4 Opacity <= 20 percent opacity. [Minn. R. 7011.0715, subp. 1(B)]

5.12.5 Total Particulate Matter <= 0.30 grains per dry standard cubic foot of exhaust gas unless required to further reduce emissions to comply with the less stringent limit of either Minn. R. 7011.0730 or Minn. R. 7011.0735. [Minn. R. 7011.0715, subp. 1(A)]

5.12.6 Daily Recordkeeping. On each day of operation, the Permittee shall calculate, record, and maintain the following: -tons of each type of coating used in EQUI 8 when EQUI 8 vented to TREA 5 and TREA 5 was in operation. This shall be based on delivery records. -tons of each type of coating used in EQUI 8 when EQUI 8 did not vent to TREA 5 or during periods of non-operation of TREA 5. This shall be based on delivery records. [Minn. R. 7007.0800, subp. 4-5, Minn. R. 7011.7000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.12.7 Monthly Recordkeeping: By the 15th day of each month, the Permittee shall calculate and record the following

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 24 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation information: 1) Tons of each type of coating used in EQUI 8 when EQUI 8 vented to TREA 5 and TREA 5 was in operation for the previous month. This record shall also include the individual and total HAP contents of each HAP-containing material used in the previous month, as determined by the Material Content requirement of this permit; 2) Tons of each type of coating used in EQUI 8 when EQUI 8 did not vent to TREA 5 or during periods of non-operation of TREA 5 for the previous month. This record shall also include the individual and total HAP contents of each HAP-containing material used in the previous month, as determined by the Material Content requirement of this permit; 3) The total and individual HAP emissions for the previous month using the formulas specified in this permit; and 4) The 12-month rolling sum total and individual HAP emissions for the previous 12-month period by summing the monthly emissions data for the previous 12 months. [Minn. R. 7007.0800, subp. 4-5]

5.12.8 HAPs: Monthly Calculation -- HAP Emissions. The Permittee shall calculate each individual HAP and total HAP emissions using the following equations: 1) HAP Emissions (tons/month) = H = H1 + H2 2) Use the following equations to calculate total and individual HAPs when EQUI 8 vents to TREA 5, TREA 5 is in operation, and credit for capture and control can be taken. H1 = UE + CE UE = [(A1 x B1) + (A2 x B2) + (A3 x B3) + ....] * (1 - CAE) CE = [(A1 x B1) + (A2 x B2) + (A3 x B3) + ....] * CAE * (1 - COE) Where: H1 = the amount of each pollutant (total HAP or each individual HAP), used, in tons/month when EQUI 8 operated controlled. UE = uncaptured emissions CE = captured and controlled emissions A# = amount of each coating used in the previous month, in tons/month. B# = weight percent of each individual or total HAP in A#, as a fraction (e.g., 50% is 0.50). CAE = capture efficiency as determined under TREA 5, as a fraction (e.g., 50% is 0.50). COE = control efficiency as determined under TREA 5, as a fraction (e.g., 50% is 0.50).

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 25 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation 2) Use the following equation to calculate total and individual HAPs when EQUI 8 is not vented to TREA 5, TREA 5 is not in operation, or when credit for capture and control cannot be taken. H2 = [(A1 x B1) + (A2 x B2) + (A3 x B3) + ....] Where: H2 = the amount of each pollutant (total HAP or each individual HAP), used, in tons/month when EQUI 8 operated uncontrolled. A# = amount of each coating used in the previous month, in tons/month. B# = weight percent of each individual or total HAP in A#, as a fraction (e.g., 50% is 0.50). [Minn. R. 7007.0800, subp. 4-5]

EQUI 9 EU007 Spray Booth -

Line 2

5.13.1 The Permittee shall limit emissions of Total Particulate Matter <= 1.30 pounds per hour 3-hour average from each inside spray machine (EQUI 9) and associated pollution control equipment (TREA 2). The emission rate is equal to the 3-Hour average of solids applied and that are not collected on the can surfaces and the LSM Collection Box. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 2, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.13.2 The Permittee shall limit emissions of PM < 10 micron <= 1.30 pounds per hour 3-hour average from each inside spray machine (EQUI 9) and associated pollution control equipment (TREA 2). The emission rate is equal to the 3-Hour average of solids applied and that are not collected on the can surfaces and the LSM Collection Boxes. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 2, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.13.3 The Permittee shall limit emissions of PM < 2.5 micron <= 1.30 pounds per hour 3-hour average from each inside spray machine (EQUI 9) and associated pollution control equipment (TREA 2). The emission rate is equal to the 3-Hour average of solids applied and that are not collected on the can surfaces and the LSM Collection Boxes. [Minn. R. 7007.0800, subp. 2]

5.13.4 Opacity <= 20 percent opacity. [Minn. R. 7011.0715, subp. 1(B)]

5.13.5 Total Particulate Matter <= 0.30 grains per dry standard cubic foot of exhaust gas unless required to further reduce emissions to comply with the less stringent limit of either Minn. R. 7011.0730 or Minn. R. 7011.0735. [Minn. R. 7011.0715, subp. 1(A)]

5.13.6 Daily Recordkeeping. On each day of operation, the Permittee shall calculate, record, and maintain the following:

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 26 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation -tons of each type of coating used in EQUI 9 when EQUI 9 vented to TREA 5 and TREA 5 was in operation. This shall be based on delivery records. -tons of each type of coating used in EQUI 9 when EQUI 9 did not vent to TREA 5 or during periods of non-operation of TREA 5. This shall be based on delivery records. [Minn. R. 7007.0800, subp. 4-5, Minn. R. 7011.7000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.13.7 Monthly Recordkeeping: By the 15th day of each month, the Permittee shall calculate and record the following information: 1) Tons of each type of coating used in EQUI 9 when EQUI 9 vented to TREA 5 and TREA 5 was in operation for the previous month. This record shall also include the individual and total HAP contents of each HAP-containing material used in the previous month, as determined by the Material Content requirement of this permit; 2) Tons of each type of coating used in EQUI 9 when EQUI 9 did not vent to TREA 5 or during periods of non-operation of TREA 5 for the previous month. This record shall also include the individual and total HAP contents of each HAP-containing material used in the previous month, as determined by the Material Content requirement of this permit; 3) The total and individual HAP emissions for the previous month using the formulas specified in this permit; and 4) The 12-month rolling sum total and individual HAP emissions for the previous 12-month period by summing the monthly emissions data for the previous 12 months. [Minn. R. 7007.0800, subp. 4-5]

5.13.8 HAPs: Monthly Calculation -- HAP Emissions. The Permittee shall calculate each individual HAP and total HAP emissions using the following equations: 1) HAP Emissions (tons/month) = H = H1 + H2 2) Use the following equations to calculate total and individual HAPs when EQUI 9 vents to TREA 5, TREA 5 is in operation, and credit for capture and control can be taken. H1 = UE + CE UE = [(A1 x B1) + (A2 x B2) + (A3 x B3) + ....] * (1 - CAE) CE = [(A1 x B1) + (A2 x B2) + (A3 x B3) + ....] * CAE * (1 - COE) Where: H1 = the amount of each pollutant (either total HAP or each individual HAP), used, in tons/month when EQUI 9 operated

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 27 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation controlled. UE = uncaptured emissions CE = captured and controlled emissions A# = amount of each coating used in the previous month, in tons/month. B# = weight percent of each individual or total HAP in A#, as a fraction (e.g., 50% is 0.50). CAE = capture efficiency as determined under TREA 5, as a fraction (e.g., 50% is 0.50). COE = control efficiency as determined under TREA 5, as a fraction (e.g., 50% is 0.50). 2) Use the following equation to calculate total and individual HAPs when EQUI 9 is not vented to TREA 5, TREA 5 is not in operation, or when credit for capture and control cannot be taken. H2 = [(A1 x B1) + (A2 x B2) + (A3 x B3) + ....] Where: H2 = the amount of each pollutant (either total HAP or each individual HAP), used, in tons/month when EQUI 9 operated uncontrolled. A# = amount of each coating used in the previous month, in tons/month. B# = weight percent of each individual or total HAP in A#, as a fraction (e.g., 50% is 0.50). [Minn. R. 7007.0800, subp. 4-5]

EQUI 10 TK001 Inside Spray 5.14.1 The tank shall be equipped with a submerged fill pipe; or be

equipped with a floating roof, vapor recovery system or its equivalent. The tank has been equipped with a permanent submerged fill pipe. [Minn. R. 7011.1505, subp. 3(B)]

EQUI 11 TK002 Inside Spray 5.15.1 The tank shall be equipped with a submerged fill pipe; or be

equipped with a floating roof, vapor recovery system or its equivalent. The tank has been equipped with a permanent submerged fill pipe. [Minn. R. 7011.1505, subp. 3(B)]

EQUI 12 TK003 Wash Coat 5.16.1 The tank shall be equipped with a submerged fill pipe; or be

equipped with a floating roof, vapor recovery system or its equivalent. The tank has been equipped with a permanent submerged fill pipe. [Minn. R. 7011.1505, subp. 3(B)]

EQUI 13 TK004 Inside Spray 5.17.1 The tank shall be equipped with a submerged fill pipe; or be

equipped with a floating roof, vapor recovery system or its equivalent. The tank has been equipped with a permanent submerged fill pipe. [Minn. R. 7011.1505, subp. 3(B)]

TREA 1 CE002 LSM Collection

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 28 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation Box

5.18.1 The Permittee shall vent emissions from EQUI 8 to TREA 1 whenever EQUI 8 operates, and operate and maintain TREA 1 at all times that any emissions are vented to TREA 1. The Permittee shall document periods of non-operation of the control equipment. [Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.18.2 The Permittee shall operate and maintain the LSM Collection Box (TREA 1) such that it achieves an overall control efficiency, for Total Particulate Matter >= 95 percent. [Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.18.3 The Permittee shall operate and maintain the LSM Collection Box (TREA 1) such that it achieves an overall control efficiency, for PM < 10 micron >= 95 percent. [Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.18.4 The Permittee shall operate and maintain the LSM Collection Box (TREA 1) such that it achieves an overall control efficiency, for PM < 2.5 micron >= 95 percent. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 2]

5.18.5 Daily Inspections: Once each operating day, the Permittee shall visually inspect the condition of TREA 1 with respect to alignment, saturation and any other condition that may affect the performance of the LSM Collection box. The Permittee shall maintain a daily written record of TREA 1 inspections. [Minn. R. 7007.0800, subps. 4-5, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.18.6 Periodic Inspections: At least once per calendar quarter, or more frequently as required by the manufacturer's specifications, the Permittee shall inspect the control equipment components. The Permittee shall maintain a written record of these inspections. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subps. 4-5]

5.18.7 Corrective Actions: If the LSM Collection box or any components are found during the inspections to need repair, the Permittee shall take corrective action as soon as possible. Corrective actions shall include completion of necessary repairs identified during the inspection, as applicable. Corrective actions include, but are not limited to, those outlined in the O & M Plan for the LSM Collection box. The Permittee shall keep a record of the type and date of any corrective action taken for TREA 1. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subps. 4-5]

5.18.8 Operation and Maintenance of LSM Control Box: The Permittee shall operate and maintain TREA 1 in accordance with the Operation and Maintenance (O & M) Plan. The Permittee shall keep copies of the O & M Plan available onsite for use by staff and MPCA staff. [Minn. R. 7007.0800, subp. 14]

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 29 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation TREA 2 CE004 LSM Collection

Box

5.19.1 The Permittee shall vent emissions from EQUI 9 to TREA 2 whenever EQUI 9 operates, and operate and maintain TREA 2 at all times that any emissions are vented to TREA 2. The Permittee shall document periods of non-operation of the control equipment. [Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.19.2 The Permittee shall operate and maintain the LSM Collection Box (TREA 2) such that it achieves an overall control efficiency, for Total Particulate Matter >= 95 percent. [Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.19.3 The Permittee shall operate and maintain the LSM Collection Box (TREA 2) such that it achieves an overall control efficiency, for PM < 10 micron >= 95 percent. [Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.19.4 The Permittee shall operate and maintain the LSM Collection Box (TREA 2) such that it achieves an overall control efficiency, for PM < 2.5 micron >= 95 percent. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 2]

5.19.5 Daily Inspections: Once each operating day, the Permittee shall visually inspect the condition of TREA 2 with respect to alignment, saturation and any other condition that may affect the performance of the LSM Collection box. The Permittee shall maintain a daily written record of inspections. [Minn. R. 7007.0800, subps. 4-5, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.19.6 Periodic Inspections: At least once per calendar quarter, or more frequently as required by the manufacturer's specifications, the Permittee shall inspect the control equipment components. The Permittee shall maintain a written record of these inspections. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subps. 4-5]

5.19.7 Corrective Actions: If the LSM Collection box or any components are found during the inspections to need repair, the Permittee shall take corrective action as soon as possible. Corrective actions shall include completion of necessary repairs identified during the inspection, as applicable. Corrective actions include, but are not limited to, those outlined in the O & M Plan for the LSM Collection box. The Permittee shall keep a record of the type and date of any corrective action taken for TREA 2. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subps. 4-5]

5.19.8 Operation and Maintenance of LSM Control Box: The Permittee shall operate and maintain each LSM Collection Box in accordance with the Operation and Maintenance (O & M) Plan. The Permittee shall keep copies of the O & M Plan available onsite for use by staff and MPCA staff. [Minn. R. 7007.0800, subp. 14]

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 30 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation TREA 5 Regenerative

Thermal Oxidizer

5.20.1 The Permittee is authorized to construct and operate TREA 5 meeting the following design requirements; 1400 degrees Fahrenheit inlet temperature, 250 degree Fahrenheit outlet temperature, 1.5 second residence time, and 4.00 MMBtu/hr burner capacity, within 18 months after permit issuance of Permit No. 14700012-101. The units shall meet all the requirements of this permit. [Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.20.2 The Permittee shall operate and maintain control equipment such that it achieves an overall control efficiency for Volatile Organic Compounds >= 95 percent control efficiency. [Minn. R. 7007.0800, subp. 2, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.20.3 The Permittee shall operate and maintain control equipment such that it achieves an overall capture efficiency for Volatile Organic Compounds >= 75 percent capture efficiency. [Minn. R. 7007.0800, subp. 2, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000]

5.20.4 The Permittee shall operate and maintain control equipment such that it achieves an overall control efficiency for HAPs - Total >= 95 percent control efficiency. [Minn. R. 7007.0800, subp. 2, Minn. R. 7011.7000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.20.5 The Permittee shall operate and maintain control equipment such that it achieves an overall capture efficiency for HAPs - Total >= 75 percent capture efficiency. [Minn. R. 7007.0800, subp. 2, Minn. R. 7011.7000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.20.6 Temperature >= 1400 degrees Fahrenheit 3-hour rolling average at the combustion chamber outlet, unless a new limit is required to be set pursuant to Minn. R. 7017.2025, subp. 3. If a new minimum is required to be set it will be based on the values recorded during the most recent MPCA-approved performance test where compliance was demonstrated. The new limit shall be implemented upon receipt of the Notice of Compliance letter granting preliminary approval. The limit is final upon issuance of a permit amendment incorporating the change. If the 3-hour rolling average temperature is below the minimum temperature limit, the VOC emitted during that time shall be considered uncontrolled until the average temperature is above the minimum temperature limit. This shall be reported as a deviation. [Minn. R. 7007.0800, subp. 2, Minn. R. 7011.7000, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000, Title I Condition: Avoid major source under 40 CFR 63.2]

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 31 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation 5.20.7 The Permittee shall vent emissions from EQUIs 4, 5, 8, and 9

to TREA 5 whenever EQUIs 4, 5, 8, and 9 operate, and operate and maintain TREA 5 at all times that any emissions are vented to TREA 5, except for a period of less than or equal to 240 hours per year the Permittee may operate EQUIs 4, 5, 8, and 9 without venting to TREA 5. The Permittee shall document periods of non-operation of the control equipment, TREA 5, whenever EQUIs 4, 5, 8, and 9 are operating. [Minn. R. 7007.0800, subp. 2, Minn. R. 7011.7000, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.20.8 The Permittee shall operate and maintain the thermal oxidizer in accordance with the Operation and Maintenance (O & M) Plan. The Permittee shall keep copies of the O & M Plan available onsite for use by staff and MPCA staff. [Minn. R. 7007.0800, subp. 14]

5.20.9 Temperature Monitoring: The Permittee shall maintain and operate a thermocouple monitoring device that continuously indicates and records the combustion chamber temperature of the thermal oxidizer. The monitoring device shall have a margin of error less than the greater of +/- 0.75 percent of the temperature being measured or +/- [2.5 degrees Celsius][4.5 degrees Fahrenheit]. The recording device shall also calculate the three-hour rolling average combustion chamber temperature. Recorded values outside the range specified in this permit are considered Deviations as defined by Minn. R. 7007.0100, subp. 8a. [Minn. R. 7007.0800, subps. 4-5, Minn. R. 7011.7000, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.20.10 Daily Monitoring: The Permittee shall physically verify the operation of the temperature recording device at least once each operating day to verify that it is working and recording properly. The Permittee shall maintain a written record of the daily verifications. [Minn. R. 7007.0800, subps. 4-5, Minn. R. 7011.7000, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.20.11 Monitoring Equipment: The Permittee shall install and maintain thermocouples to conduct temperature monitoring required by this permit. The monitoring equipment must be installed, in use, and properly maintained whenever operation of the monitored control equipment is required. [Minn. R. 7007.0800, subps. 4-5]

5.20.12 The Permittee shall maintain a continuous hard copy readout or computer disk file of the temperature readings and calculated three hour rolling average temperatures for the combustion chamber. [Minn. R. 7007.0800, subps. 4-5, Minn. R. 7011.7000, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000, Title I Condition: Avoid major source under 40 CFR 63.2]

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 32 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation 5.20.13 Annual Calibration: The Permittee shall calibrate the

temperature monitor at least once every 12 months and shall maintain a written record of the calibration and any action resulting from the calibration. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 4-5]

5.20.14 Quarterly Inspections: At least once per calendar quarter, or more frequently if required by the manufacturer's specifications, the Permittee shall inspect the control equipment internal and external system components, including but not limited to the refractory, heat exchanger, and electrical systems. The Permittee shall maintain a written record of the inspection and any corrective actions taken resulting from the inspection. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 4-5]

5.20.15 Annual Inspection: At least once per calendar year, the Permittee shall conduct an inspection that includes all operating systems of the control device. The Permittee shall maintain a written record of the inspection and any action resulting from the inspection. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 4-5]

5.20.16 For periods when the thermal oxidizer is operated above the minimum combustion chamber temperature, the Permittee shall use either one of the following when completing calculations as required elsewhere in this permit: 1a. The overall control efficiency limit specified in this permit for this equipment (x%); or 1b. The overall control efficiency determined during the most recent MPCA approved performance test. If the tested efficiency is less than the efficiency limit in this permit, the Permittee must use the tested value in all calculations until the efficiency is demonstrated to be above the permit limit through a new test. 2a. The overall capture efficiency limit specified in this permit for this equipment (x%); or 2b. The overall capture efficiency determined during the most recent MPCA approved performance test. If the tested efficiency is less than the efficiency limit in this permit, the Permittee must use the tested value in all calculations until the efficiency is demonstrated to be above the permit limit through a new test. [Minn. R. 7007.0800, subps. 4-5, Minn. R. 7011.7000, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.20.17 For periods when the thermal oxidizer is operated below the minimum combustion chamber temperature, the Permittee shall use a 0% control efficiency and 0% capture efficiency when completing calculations as required elsewhere in this permit. [Minn. R. 7007.0800, subp. 2, Minn. R. 7011.7000, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000, Title I Condition: Avoid major source under 40 CFR 63.2]

Permit issued: August 23, 2016 14700012-101 Permit expires: September 10, 2019 Page 33 of 41

Subject Item Sec. SI.Regt SI des:SI desc Requirement & Citation 5.20.18 For periods when the thermal oxidizer is not operated, the

Permittee shall use a 0% control efficiency and 0% capture efficiency when completing calculations as required elsewhere in this permit. [Minn. R. 7007.0800, subp. 2, Minn. R. 7011.7000, Title I Condition: Avoid major modification under 40 CFR 52.21(b)(2) and Minn. R. 7007.3000, Title I Condition: Avoid major source under 40 CFR 63.2]

5.20.19 Corrective Actions: If the temperature is below the minimum specified by this permit or if the thermal oxidizer or any of its components are found during the inspections to need repair, the Permittee shall take corrective action as soon as possible. Corrective actions shall return the temperature to at least the permitted minimum and/or include completion of necessary repairs identified during the inspection, as applicable. Corrective actions include, but are not limited to, those outlined in the O & M Plan for the thermal oxidizer. The Permittee shall keep a record of the type and date of any corrective action taken. [Minn. R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 4-5]