Installation Instructions – Vertical Application · 1 ˜ ˜ ˜D ˜A ˜B ˜C B B B B ˜ B h-c ˜-c...

Transcript of Installation Instructions – Vertical Application · 1 ˜ ˜ ˜D ˜A ˜B ˜C B B B B ˜ B h-c ˜-c...

-

1

2

4

3D

3A 3B

3C

B

B

B

B

1

B

hh-c1-c2

c2

c1≥ l0 5

≥ 15M @250 mm≥ 10M

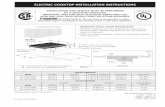

① + ② ▶ Before installation, check products for conformity with purchase or-

der and that no Isokorb® parts are missing. ▶ Check products for visible damages. ▶ Check the product for correct type conforming to the design draw-

ings of the structural engineer. ▶ Ensure that the materials required to install Schöck Isokorb® for the

construction project are complete including a tape measure, rebar tie-wires, wire cutters, a hammer and a hand saw as required.

③ These images demonstrate the general position for installing the Schöck Isokorb® Type CPA in the vertical orientation with various parapet wall types. Follow the layout drawings of the approved Schöck Technical Proposal to con� rm the exact position of the ther-mal break.

④ + ⑤Additional reinforcement is required to tie in the loops of the Schöck Isokorb® Type CPA. The outside vertical loops of the CPA product need to be tied to a horizontal U-bar (sized 10M) in the slab provided on site. Longitudinal rebar is required at the top and bot-tom corners of the in-slab U-bars. This is to ensure a sti� slab edge and proper transition of forces in compliance with the design draw-ings of the structural engineer.

Installation Instructions – Vertical Application

Schöck Isokorb® Type CPA

TH Schöck Isokorb®/CA-en/2018.1/January

CPA

Inst

alla

tion

-

2

6

7a

8

9

l0

l0

⑥ Note the locations where the Schöck Isokorb® Type CPA are speci-� ed in the design drawings and place the additional reinforcement into the slab as required.

⑦ + ⑧Position each Schöck Isokorb® Type CPA into the roof slab formwork and tie the outside vertical loops from the product to the in-slab horizontal U-bars provided on site. The bottom surface of the Schöck Isokorb® Type CPA insulation block should be � ush with the � nal top surface of the roof slab.

⑨ The horzontal in-slab connectors must be long enough to provide the required lap-length to the primary slab rebar speci� ed by the engineer of record (EOR).

Before placing the concrete, check the alignment of the Schöck Isokorb® Type CPA with the slab and connecting reinforcement. Con� rm all is in accordance with the approved Schöck Technical Proposal and the design drawings of the EOR.

Installation Instructions – Vertical Application

Schöck Isokorb® Type CPA

TH Schöck Isokorb®/CA-en/2018.1/January

CPA

Inst

alla

tion

-

3

10

11

12

l0 l0

13

≥ 10M @250 mm

≥ 10M

⑩ + ⑪Place the concrete in the slab vibrating evenly around the rebar of the Schöck Isokorb® Type CPA. Once the concrete slab has cured, position insulation spacers (Schöck Isokorb® Type ZXT) between the CPA units.

⑫ + ⑬Additional reinforcement is required to tie in the vertical bars of the Schöck Isokorb® Type CPA. The parapet wall requires vertical U-bars sized 10M spaced at minumum 250 mm. Longitudinal rebar is re-quired at the bottom corners of the parapet wall U-bars, and spaced up the height of the wall as speci� ed by the engineer of record.

Installation Instructions – Vertical Application

Schöck Isokorb® Type CPA

TH Schöck Isokorb®/CA-en/2018.1/January

CPA

Inst

alla

tion

-

4

15

14

⑭ Tie the vertical bars of the Schöck Isokorb® Type CPA to the parapet wall longitudinal rebar.

⑮ Once the parapet formwork has been built, place concrete up the parapet wall and ensure it is evenly vibrated.

Installation Instructions – Vertical Application

Schöck Isokorb® Type CPA

TH Schöck Isokorb®/CA-en/2018.1/January

CPA

Inst

alla

tion

-

5

2

3A 3B

3C 3D

≥ 150 mm

≥ 150 mm

≥ 150 mm

≥ 150 mm

1

4

a

① + ② ▶ Before installation, check products for conformity with purchase or-

der and that no Isokorb® parts are missing. ▶ Check products for visible damages. ▶ Check the product for correct type conforming to the design draw-

ings of the structural engineer. ▶ Ensure that the materials required to install Schöck Isokorb® for the

construction project are complete including a tape measure, rebar tie-wires, wire cutters, a hammer and a hand saw as required.

③ These images demonstrate the general position for installing the Schöck Isokorb® Type CPA in the horizontal orientation with various supporting wall types under the roof slab. Follow the layout draw-ings of the approved Schöck Technical Proposal to con� rm the exact position of the thermal break.

④ Position each Schöck Isokorb® Type CPA into the roof slab formwork and tie each horizontal bar provided in the product to the upper and lower in-slab reinfocement bars provided on site. The height of the Schöck Isokorb® Type CPA should match the slab height, with the insulation � ush to the outer edge of the roof slab.

Installation Instructions – Horizontal Application

Schöck Isokorb® Type CPA

TH Schöck Isokorb®/CA-en/2018.1/January

CPA

Inst

alla

tion

-

6

8

5

7

6

l0≥ 10M @125 mm

≥ 10M

⑤ + ⑥Additional reinforcement is required to tie in the loops of the Schöck Isokorb® Type CPA with the parapet wall. Every loop joining into the parapet wall requires a vertical U-bar size 10M to be provid-ed in the wall. Longitudinal rebar is required at the bottom corners of the in-wall U-bars. This is to ensure a proper transition of forces from the parapet wall to the roof slab in compliance with the Schöck Technical Proposal and the design drawings of the engineer of record (EOR).

⑦ + ⑧Once the parapet wall reinforcement has been installed with the loops of the Schöck Isokorb® Type CPA completely tied in, insulation spacers (Schöck Isokorb® Type ZXT) are positioned between the Isokorb® CPA units.

Installation Instructions – Horizontal Application

Schöck Isokorb® Type CPA

TH Schöck Isokorb®/CA-en/2018.1/January

CPA

Inst

alla

tion

-

7

9

11

12

l0

l0

h-c1-c2

c2

c1≥ l0

10

h

≥ 10M @250 mm≥ 10M

⑨ + ⑩Additional reinforcement is required to tie the horizontal bars of the Schöck Isokorb® Type CPA into the slab reinforcement. The roof slab requires additional edge U-bars sized 10M spaced at minumum 250 mm. Longitudinal rebar is required at the top and bottom cor-ners of the slab edge U-bar as recommended by the approved Schöck Technical Proposal and speci� ed by the engineer of record.

⑪ Tie the upper and lower bars of the Schöck Isokorb® Type CPA to the roof slab longitudinal rebar.

⑫ The horzontal in-slab connectors must be long enough to provide the required lap-splice length to the primary slab rebar as speci� ed by the engineer of record (EOR).

Before placing the concrete, check the alignment of the Schöck Isokorb® Type CPA with the slab edge and that all reinforcement is well connected. Con� rm all is in accordance with the approved Schöck Technical Proposal and design drawings of the EOR.

Installation Instructions – Horizontal Application

Schöck Isokorb® Type CPA

TH Schöck Isokorb®/CA-en/2018.1/January

CPA

Inst

alla

tion

-

8

13

14

⑬ Place the concrete in the slab vibrating evenly around the rebar of the Schöck Isokorb® Type CPA.

⑭ Once the parapet formwork has been built, place concrete up the parapet wall and ensure it is evenly vibrated.

Installation Instructions – Horizontal Application

Schöck Isokorb® Type CPA

TH Schöck Isokorb®/CA-en/2018.1/January

CPA

Inst

alla

tion