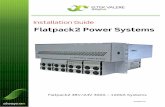

Installation Guide Flatpack2 PS System Outdoor v4

description

Transcript of Installation Guide Flatpack2 PS System Outdoor v4

35

1476

.033

Installation Guide

DC Power Supply System, 16kW, 48VDC Outdoor 2.0m Fan Cooled Cabinet

1 Welcome

2 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Information in this document is subject to change without notice and does not represent a commitment on the part of Eltek Energy. No part of this document may be reproduced or transmitted in any form or by any means — electronic or mechanical, including photocopying and recording — for any purpose without the explicit written permission of Eltek Energy.

Copyright ©: Eltek Energy, Norway 2007

Certificate no: 900005E

Certificate no: 900005Q

Power Distribution Centre for

Communications Equipment

35KS

NS-EN ISO 14001:

1996 Certificate No: 900005E

NS-EN ISO 9001: 1994 Certificate No: 900005Q

This product is CE marked and complies with all current requirements for relevant

standards and directives. This product is made according to EU directive 2002/95/EC (RoHS) and 2002/96/EC (WEEE).

EMC EN61000-6-2 Industrial Environment EN61000-6-3 Residential, Commercial and Light Industry ETS 300386 Telecommunication Equipment

LVD LVD73/23/EEC Low Voltage Directive EN60950 Safety of Technology Equipment UL60950,UL1801

“FP2 PRSB 16KW/48V OD fan 2.0m” has part no. CF1032.006.

351476.033 Issue 4, 2007 June Published 2007-06-19 Mfm

1 Welcome

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 3

Table of Contents

1. Welcome 4

About this Guide ............................................................................................................. 4

2. System Description 4

Location of Components ~ General Arrangement .............................................. 5 External AC Fuses ~ Recommended Ratings ................................................................ 6 Mains Reconfiguration ~ AC Terminal Block .................................................................. 6 Terminals & Pin-out Location, GMT Fuses ..................................................................... 7 Alarm Relays & Digital Inputs .......................................................................................... 7

Terminals & Pin-out Location, Alarm Interface Card ................................................................ 8 Terminals & Pin-out Location, System Interface Card .............................................................. 9

LVD Latching Contactors ................................................................................................ 9 Monitoring, Control and Signal Interface .......................................................... 10

System Monitoring ........................................................................................................ 10 Fan and Heater Operation................................................................................... 10 System Specification .......................................................................................... 11

3. Installation 12

Safety Precautions ........................................................................................................ 12 General Safety Precautions .......................................................................................... 13 Electrical Safety ............................................................................................................ 13 Mechanical Safety ......................................................................................................... 14 Battery Safety ............................................................................................................... 14

Installing the Modules ......................................................................................... 15 Mounting or Removing Smartpack and Flatpack2 Modules ................................................... 15 Mounting and Removing Blind Panels .................................................................................... 16 Correct Rectifier Position in Power Shelves ........................................................................... 16

System Installation .............................................................................................. 17 Site Preparation ............................................................................................................ 17 Mechanical Installation .................................................................................................. 17 Electrical Installation ..................................................................................................... 18

4. Commissioning 23

Pre-Start Check ................................................................................................... 23 Commissioning Steps, Startup .......................................................................... 24

Startup and No-Load Adjustments .......................................................................................... 24 Load Adjustments ................................................................................................................... 25

5. Maintenance 26

Replacement of Door Filter ........................................................................................... 27 Replacement of Fan Filter ............................................................................................. 27

6. Forms, Schematics & Drawings 28

Installation Check List ....................................................................................................... 28 Commissioning Procedure ................................................................................................. 28 Maintenance Procedure ...................................................................................................... 28 General Arrangement Drawing .......................................................................................... 28 Cabinet’s Neoprene Mat Table, Drilling Template, Plinth’s fastening holes .................... 28 Cabinet Clearance Drawing ............................................................................................... 28 System Schematic Drawing ............................................................................................... 28 Configuration Settings ~ Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m ........ 28 Load Distribution List ........................................................................................................ 28

1 Welcome

4 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

1. Welcome The Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m is a DC power supply for telecom equipment suitable for outdoor fan cooled applications.

About this Guide This booklet provides users of the Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m with the required information to perform system installation, commissioning and maintenance. The booklet also describes the system’s technical specifications, and includes check lists, arrangement and schematic drawings. Read also the generic documentation included in the system’s documentation set, Art. No. 351476.003

2. System Description The Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m is a DC power supply system based on the Flatpack2 2000W 48V rectifier. The system contains AC termination blocks, DC distribution, Flatpack2 Power Rack, Flatpack2 2000W rectifier modules and the Flatpack2 Smartpack control unit. The system is designed for cable entry from top and the cabinet size is 770x820x2030 mm (30.3x32.3x80”) (WxDxH).

2 System Description

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 5

Location of Components ~ General Arrangement

Figure 1 General Arrangement Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m

Battery DC (+) terminalsBus bar, 35mm2, AWG 2

Smartpack controllerand CON 4 (monitoring terminals on the controller’s rear panel)

DC (+) Load TerminalsCommon positive bus bar, 70 mm2, AWG 2/0

DC (-) Load Terminals(BTS MCBs) 25mm2, AWG 4, 70mm2, AWG 2/0 (on top of each load breaker)

Battery DC (-) terminalsBus bar, 35mm2, AWG 2

Alarm Terminals1.5mm2, 16AWG

(Front access)

Terminals forGMT 10A Load

Fuses, 1.5mm2, AWG 16

AC MainsTerminals

AC EarthMains Protective Earth (PE)

Connection(Cabinet main ground bar)

DC EarthTelecom Earth (TE) Connection

Smartpackcontroller unit Flatpack2

rectifier modules

Battery strings and fusesin the lower part of the

cabinet

DC DistributionMCB Load, Alarm and

Signal Terminals

AC Input & EarthTerminals

AUX.AC MCB(heater, AC socket, air-conditioner)

Door Filter Outlet

Fan Filter Inlet

2 System Description

6 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

External AC Fuses ~ Recommended Ratings

The site’s AC supply quality is of great importance. In general, a site with better AC supply quality (stable nominal voltage) may use smaller breakers. Use the type of external AC fuses recommended in the table below.

Mains Reconfiguration ~ AC Terminal Block The AC terminal block is factory configured for mains supply type: 400VAC, 3 phase & N. To reconfigure the system’s AC mains feed, perform the following:

1. Switch OFF the AC supply fuses in external fuse boards

2. Connect the AC Mains wires to the AC terminal block, and mount the fish plate(s) shipped with the cabinet, according to the type of AC mains to be used, as shown in the actual example in this section

External AC Fuses ~ Recommended Ratings

AC Mains Type External Fuse Type 400VAC +N, 3 ph 50A – C-char. 230VAC, 1 ph 100A – C-char. 230VAC, 3 ph 63A – C-char. 208VAC, 1 ph 70A. Note: An external AC breaker is required on all sites, and it must be switched off under installation.

N N L1 L2 L3

Υ Mains, TN Three-phase & N, 400VAC

AC Mains Cable

AC Mains wires

AC Mains Terminal Block

Flatpack2 DC Power System

(To internal connections)

Fish Plate

Factory configured AC Mains terminal block.

L1 L2 L3 N

Δ Mains, ITThree-phase, 230VAC/208VAC

AC MainsCable

AC Mains wires

AC Mains Terminal Block

Flatpack2 DC Power System

(To internal connections)

Fish Plate

L1 L2 L3

N NL1 L2 L3 N NL1 L2 L3

MainsOne-phase, 230VAC/208VAC

AC MainsCable

AC Mains wires

AC Mains Terminal Block

Flatpack2 DC Power System

(To internal connections)

Fish Plate

WiresLinks L1 L2

2 System Description

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 7

Terminals & Pin-out Location, GMT Fuses

Figure 2 GMT fuse board (max. cable size 1.5mm2, AWG 16)

The table below shows the pin-out location for the GMT load fuse card:

Alarm Relays & Digital Inputs The alarm outputs in Flatpack2 systems use the Fail-Safe Operation Mode (relay coils energized in the system’s normal operation mode). When the system is in alarm mode, the alarm relay coils are de-energized.

The figure shows the position of the relay contacts when the relay coils are de-energized (PS system in alarm mode)

In order to implement monitored fail-safe digital inputs circuits, the external relay coil must be energized and the contacts closed in the system’s normal mode of operation.

Pin Assignment for GMT Fuse Pin Signal Function Pin Signal Function 1 2

+ —

GMT fuse 1 (F5) 9 10

+ —

GMT fuse 5 (F9)

3 4

+ —

GMT fuse 2 (F6) 11 12

+ —

GMT fuse 6 (F10)

5 6

+ —

GMT fuse 3 (F7) 13 14

+ —

GMT fuse 7 (F11)

7 8

+ —

GMT fuse 4 (F8) 15 16

+ —

GMT fuse 8 (F12) (fan fuse)

Alarm Relays & Digital Inputs

Correct Use of Digital Inputs (example)

Normal ModeExternal Relay Y(Energized coil)

+—

Digital Input X (Normal mode)

Alarm ModeExternal Relay Y

(De-energized coil) +

—Digital Input X (Activated)

Flatpack2 PS System

Correct Use of Alarm Outputs (example)Flatpack2 PS System

—

+

NC

NOCom

Normal ModeRelay X

(Energized coil)

+—

Alarm Mode

Relay X(De-energized coil) NC

NOCom

Alarm Relay Specification 30 VDC, 2A Nominal switching capacity 60W (resistive load) Maximum switching power 220 VDC Maximum switching voltage 2A DC Maximum switching current

GMT fuses Max. 10A each

Pin 16 Pin 1

F5

F12

F8

2 System Description

8 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Terminals & Pin-out Location, Alarm Interface Card The Smartpack controller’s alarm and digital input monitoring signals are accessible from the controller’s rear panel, on mini power connector CON1 (2 outputs & 2 inputs) and on D-Sub connector CON2 (4 outputs & 4 inputs).

Using the Alarm Interface Card (Art. 105954) – located on top of the controller; see page 5 -- and two interface cables, you can make the signals on CON1 & 2 accessible at any suitable location inside your system.

For detailed information about the card’s pin-out location and terminal block connections, refer to the figures in this section.

The figure shows the position of the relay contacts when the relay coils are de-energized (PS system in alarm mode. Factory Settings in bold).

Terminals & Pin-out Location

Alarm Outputs & Digital Inputs Card, Art. 105954

CON2A CON1A

1 10 20 1

*X1 *X2

Alarm Outputs & Digital Inputs Card, Art. 105954

System Connections Card, Art. 200625

Smartpack

Battery Connections Card, Art. 200576

Battery Connections Card, Art. 200576

CON1A

CON2A

CON2

CO

N1

4 3 2 1

5

9 8 7 6

10

*X1:

(Customer Connections)

Input Circuit 1

Input Circuit 2

Alarm Circuit 1

Alarm Circuit 2

OutIn

(To

and

from

ex

tern

al e

quip

men

t) 1.5 mm2, max.

wire section

Relay 2High Battery Alarm

Relay 1OVP & Door Alarm

+−

NOCOM

NC

NOCOM

NC

+−

Digital Input 1

Digital Input 2

Alarm Outputs & Digital InputsVoltage free relay outputs and Configurable monitoring digital inputs

FUNCTION SIGNAL PIN-OUT

Input Circuit 3

Alarm Circuit 3

Input Circuit 4

Input Circuit 5

Input Circuit 6

Alarm Circuit 4

Alarm Circuit 5

Alarm Circuit 6

4 3 2 1

5

9 8 7 6

10

14 13 12 11

15

*X2:

16 17 18 19 20

+−

+−

+−

+−

NOCOM

NC

NOCOM

NC

NOCOM

NC

NOCOM

NC

Digital Input 3

Digital Input 4

Digital Input 5

Digital Input 6

Relay 3Low Battery Alarm

(To

exte

rnal

equ

ipm

ent)

(Fro

m e

xter

nal e

quip

men

t)

Card Art.105954 1

To S

mar

tpac

k,C

ON

2To

Sm

artp

ack,

CO

N1

Relay 5Battery Alarm: -10°C >Temp>50°C

& Rectifier Alarm

Relay 4Fuse Alarm

Load & Battery

Relay 6Mains Alarm &

Mains Low & High Alarms

2 System Description

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 9

Terminals & Pin-out Location, System Interface Card Flatpack2 systems are shipped from factory with the CON5 signals already connected. Some of the Smartpack controller’s internal system signals are accessible on D-Sub connector CON5, on the controller’s rear panel. Using the System Interface Card (Art. 200625) and a standard 15 pins D-Sub cable, the signals on CON5 may be accessible at any suitable location inside your system. For detailed information about the card’s pin-out location and terminal block connections, refer to the figures in this section.

LVD Latching Contactors Flatpack2 systems’ LVBD and LVLD1 functionality is implemented by the Smartpack controlling magnetically latching contactors.

The coil of latching contactors is not energized in any state. They change state from open to close, or vice versa, when a reversed pulse is applied to the coil.

1 LVBD, Low Voltage Battery Disconnect; LVLD, Low Voltage Load Disconnect

Latching Contactors, LVD1 & LVD2

A latching contactor changes state only when a reversed pulse voltage is applied to its coil

+ Pulse

ON

- Pulse

OFF

Correct Use of Latching Contactors (example)

PCB Art. 200625

10

8 9

X:*****

+

—

LVD1A

LVD2A LVD Common

Smartpack Unit

Flatpack2 PS System (internal)

11

LVD Common

Latching Contactor LVD2

Y

X

Latching Contactor LVD1

Y

X

Latching Contactor

Y

X

Bidirectional diode

Warning! The bidirectionaldiode must always bemounted to avoid dam-aging the controller.

+

4321

5

9876

1011

X:*****Power Input

−+−+−

10156

712

139+, Neg.D.

11−,Pos.D.1+/−3+/−

2+/−

Batt. Fuse Fail 1 Load Fuse Fail 1

Batt. Current 1

LVD1A LVD Common LVD1

OutIn

Term

inal

Boa

rd, A

rt. 2

0062

5 (T

o S

mar

tpac

k, C

ON

5)

(Internal Connections)Sy

stem

Con

nect

ions

JP2

LVD2ALVD Common LVD2(To latching contactors LVD1 & LVD2)

JP1 and JP2 are used to configure thesystem for Negative DC distribution (48 and60V systems) or Positive DC distribution(24V systems)

System Connections Card, Art. 200625 111 CON5A

JP1 JP2

X*****

Terminals & Pin-out Location

JP1

2 3

1 JP2

21

3

Neg. Distr.Pos. Distr.

Neg. Distr.Pos. Distr.

Alarm Outputs & Digital Inputs Card, Art. 105954

System Connections Card, Art. 200625

Smartpack

Battery Connections Card, Art. 200576

Battery Connections Card, Art. 200576

CO

N5A

CON5

For I

nter

nal U

se O

nly!

2 System Description

10 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Monitoring, Control and Signal Interface The Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m is available with basic functionality for monitoring and control of the system, and is equipped with:

o Relay outputs, 6 pcs o Digital inputs, 6 pcs

System Monitoring The Smartpack Control Unit monitors and controls the entire rectifier system including distribution and batteries, as well as other equipment on site. The unit also incorporates a communication port for connecting computers via the USB interface. The Flatpack2 system can be operated and configured locally via the keypad on the Smartpack unit, by selecting commands from set-up menus in a hierarchical menu system. Remote system monitoring and configuration may also be performed using PowerSuite -- a Windows-based program that runs on a connected PC. Following configuration tasks require the use of a PC:

o Installation settings o System calibration o Battery configuration o Alarm setup o Alarm log retrieval o Site information o Site specific configuration

Please, refer to the Smartpack controller’s User’s Guide --Art. No. 350003.013 – and to the PowerSuite program’s online help (press function key F1) for detailed information about system monitoring and functionality.

Fan and Heater Operation The fan runs as soon as the temperature in the cabinet passes 25oC (77°F). Hysteresis is 1°C (1.8°F). The heater is controlled through a thermostat and it starts up at cabinet temperature of 5°C (41°F).

2 System Description

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 11

System Specification

Technical Specification

Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m Max. number of rectifiers

8

AC INPUT Voltage 1 phase 230VAC (max 3

rectifiers, 6kW) 3 phase 208VAC ( Δ ) 3 phase 230VAC ( Δ ) 3 phase 400VAC+N ( Y )

Frequency 45 to 66Hz Maximum Current

See Flatpack2 48VDC datasheet (241115.001.DS3)

OVP (Optional)

Live – surge arrestor Neutral – spark gap Class C, type II In(8/20) – 40kA

MONITORING Monitoring Unit Smartpack Local operation Menu driven software via keypads

and LCD, USB or PC (PowerSuite) Remote operation PowerSuite via modem or Web

NMS via SNMP-agent Alarm relays 6 relays are standard Visual indications Green LED – System ON

Amber LED – Minor Alarm Red LED – Active alarm(s) LCD – system status

Digital inputs 6 (for monitoring of external equipment)

Current measurements

Battery current Rectifier current Load current

Alarms Load fuse alarm Battery fuse alarm Low Battery Voltage High Battery Voltage Temperature alarm Door switch alarm Mains detect alarm OVP Alarm

DC OUTPUT Voltage 48VDC Current Up to 16 KW – 340A CONNECTIONS Battery connections Battery cable, M8 bolts Load MCB connections

Negative distribution, Negative load cable, 70mm2 cable clamps Common positive bus bar, 70mm2 cable clamps

Alarm connections Plug-in wire connectors front access DISTRIBUTION OPTIONS No. of DC Load breakers

Up to 4 x 3pole 150A

No. of Battery breakers

Up to 4 x 150A MCBs mount next to each battery shelf

No. of Aux. fuses 8 x 10A GMT type Programmable LVD Standard: 1 LVBD (max. 300A) OTHER SPECIFICATIONS Isolation 3.0 KVAC – input and output

1.5 KVAC – input earth 1.0 KVDC – output earth

Operating temp -40 to +50°C (-40 to +122°F) *** Storage temp -40 to +85°C (-40 to +185°F) Dimensions 770 x 820 x 2030 mm (WxDxH) (30.3

x 32.3 x 79.9”) Weight Cabinet: 150 kg excl. optional plinth,

rectifiers and batteries Flatpack2 rectifiers: 1.9 kg

per rectifier Batteries: Max. 250 kg

per battery shelf APPLICABLE STANDARDS Electrical safety EN 60950

UL 60950 EMC ETSI EN 300 386 (telecommunication

network) EN 61000-6-3 (emission, light industry) EN 61000-6-2 (immunity, industry)

Environment ETSI EN 300 019-2 ETSI EN 300 132-2 2002/95/EC RoHS Compliant

*** Note that the cabinet’s operating temperature range does not apply to batteries. Refer to the manual for used batteries.

Rectifier Input Voltages Type VAC Note Nominal 230 Range 185 – 275 Full output power Low voltage 1 0 – 85 Shutdown Low voltage 2 85 – 185 Linear between 850W and 2000W

Type VAC Note High voltage 1 185 – 275 Full output power High voltage 1 275 –300 Full power, reduced power factor High voltage 2 300 – 350 Shutdown High voltage 3 350 – 420 Shutdown* (see note below)

* Note: If the input voltage is > 300Vac the rectifier will go into self protective mode. At no load, the rectifier will survive 350Vac. With load or battery connected, it will survive 420Vac.

Specifications are subject to change without notice

3 Installation

12 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

3. Installation This section describes how to install the Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m. Step-by-step procedures will guide you through the installation. Read also the generic documentation included in the system’s documentation set, Art. No. 351476.003

Safety Precautions To be installed only in restricted access areas or the like, in accordance with

articles 110-16, 110-17, and 110-18 of the National Electrical Code, ANSI/NFPA 70 For supply connectors use wires suitable for at least 75˚C (167˚F) Type: FEPW, RH, RHW, THHW, THW, THWN, ZHHW, USE, ZX or similar. Use copper conductors only

The equipment described in this manual must only be operated by

Eltek Energy personnel or by persons who have attended a suitable Eltek Energy training course

CAUTION: Even though the product incorporates protection circuitry and other safeguards, it can be damaged, perform poorly or have a reduced lifecycle if it is exposed to incorrect treatment during transport, installation or service.

The equipment represents an energy hazard and failure to observe this could cause terminal injury and invalidate our warranty

There are hazardous voltages inside the power system. As the modules incorporate large charged capacitors, it is dangerous to work inside the system even if the mains supply is disconnected

Products into which our components are incorporated have to comply with a number of requirements. Installation is to be in accordance with the recommendations herein

Please read the manual carefully before using the equipment

3 Installation

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 13

General Safety Precautions Please read and follow all safety instructions or warnings before installing or maintaining the power system. Review any supporting documentation regarding the power system and its components prior to installation.

The enclosure must be installed, serviced, maintained, and operated by a qualified technician who is familiar with electrical wiring, electrical equipment, and enclosure deployment techniques and best practices for safety

The enclosure must remain locked at all times, except when authorized service personnel are present

Remove all conductive jewelry or personal equipment prior to servicing equipment, parts, connectors, wiring, or batteries

Read and follow all installation, equipment grounding, usage, and service instructions included in this manual

Use proper lifting techniques whenever handling the enclosure, equipment, parts, or batteries

Do not roll the cabinets on their sides

Do not store anything on top of the cabinet

Electrical Safety Lethal voltages are present within the power supply and electrical boxes. Never assume that an electrical

connection or conductor is not energized. Check the circuit with a volt meter with respect to the grounded portion of the enclosure (both AC and DC) prior to any installation or removal procedure

An external electrical service disconnect must be used that is properly sized as required by the NEC and/or local codes

The supply neutral conductor must be bonded to earth ground at the disconnect panel

Do not work alone under hazardous conditions

A licensed electrician is required to install permanently wired equipment

Ensure that utility power is disabled before beginning installation or removal

Ensure no liquids or wet clothes contact internal components

Hazardous electrically live parts inside the enclosure are energized by batteries even when the AC input power is disconnected. Make sure the power is removed via the battery disconnect breaker before servicing any of the equipment

The internal equipment may be powered by AC circuits. Make sure power is removed via the appropriate breaker before servicing any of the equipment

Prior to installation, verify that the AC input voltage to the enclosure and its equipment with respect to voltage and frequency

Prior to installation, verify that the output voltage from the enclosure or its equipment match the voltage requirements of the connected equipment loads

Prior to installation, verify that the enclosure’s utility service panel is equipped with a properly rated circuit breaker for use with the equipment inside. Refer to the manufacturer’s recommendations

Prior to installation, contact local utilities, local building maintenance departments, and cable/piping locating services to ensure that installation does not interfere with existing utilities or building cables/piping

Fuses/circuit breakers may not be provided with the equipment. Refer to the documentation for the proper hardware. Use only the parts specified in the documentation. Installing fuses or circuit breakers not specified for use in this equipment may result in injury to service personnel or equipment damage

Where required for installations in the United States or Canada, use listed/certified compression connectors to terminate listed/certified field-installed conductors. If the proper connector for the country of installation is not provided, obtain the appropriate connectors and follow all manufacturer and local requirements for proper connections

Torque the electrical connections to the values specified on labels or in the product documentation

The DC distribution is considered a Safety Extra Low Voltage (SEL V) with the return side connected to the chassis (earth ground) inside the enclosure

The supply neutral conductor must be grounded at the external service supply disconnect panel

3 Installation

14 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Do not use other methods for cable entry than what is specified in the documentation for this product

Ensure proper cable support is used to support the weight of cables and cable conduits that enter/exit the cabinet

Do not drill new holes or use other methods for cable entry than what is described in the product documentation

Mechanical Safety Keep hands, hardware and tools clear of the fans. Fans are thermostatically controlled and will turn on

automatically as a function of temperature

Rectifiers can reach extreme temperatures under load and normal operation

Use caution around sheet metal components and sharp edges

Do not climb on the enclosure to access the cable entrance. Always use the proper ladder and safety precautions as dictated by the site conditions

Battery Safety Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove

all metallic objects from hands, wrists, and neck

Batteries contain dangerous voltages and current, as well as corrosive material. Battery maintenance, service, and replacement must be performed by authorized personnel only

Never use non-insulated tools or other conductive materials when installing, maintaining, servicing, or replacing batteries

Use special caution when connecting or adjusting battery cables. An improperly connected battery cable can result in arcing, fire, or possibly an explosion

A battery showing signs of cracks, swelling or leaking must be replaced immediately by authorized personnel using a battery of identical type and make

Do not smoke or introduce sparks in the vicinity of a battery

Follow the battery manufacturer’s approved transportation and storage instructions

Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may have developed in your body

Batteries contain or emit chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. Battery post terminals and related accessories contain lean and lead compounds. Wash hands after handling

If any battery emission contacts the skin, wash immediately and thoroughly with water. Follow your company’s approved chemical exposure procedures

Neutralize any spilled battery emission with a special solution contained in an approved spill kit or with a solution of 1 lb bicarbonate of soda to 1 gallon of water. Report a chemical spill using your company’s spill reporting procedures and seek medical attention, if necessary

Each individual battery should have at least 0.25 inches of space between it and surrounding surfaces, or per the battery manufacturer’s specification to allow for convective cooling

Battery cables must be dressed to avoid damage to the conductors. Damage or stress can be caused by routing around sharp edges or in areas where wires could get pinched

Follow battery manufacturer’s approved instructions to set all battery related parameters accordingly

3 Installation

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 15

Installing the Modules

Mounting or Removing Smartpack and Flatpack2 Modules Note that cables are plugged to the Smartpack’s rear panel. When mounting the controller, you must plug the cables before step 2. When removing it, unplug the cables during step 2.

1. Unlock the handles by

inserting a screwdriver into the holes to release the spring mechanism

2. Insert or remove the module by sliding it fully into the power shelf, so that the module makes proper contact (for Smartpack, plug cables first) or using both handles to pull the module loose. Support from underneath before the unit is completely free. Unplug the cables, when removing the Smartpack module

3. Lock the handles by pushing the handles up into their housings (locked position). Then, the module will be securely locked in the shelf, or ready for transport

4. Mount blind panels in unused module locations

Device hazard

CAUTION: - The modules may be warm, but do not hand-carry them by their handles - Open the handles before inserting them into the power shelves (hot-pluggable)

The rectifier incorporates a Mains fuse in each line. Double Pole / Neutral Fusing

Handle in unlocked position

Flatpack2rectifier

Smartpack controller

Handle in locked position

Hole to release the handle’s spring mechanism

Electric shock

3 Installation

16 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Mounting and Removing Blind Panels

To remove blind panels, carry out the following:

1. Release the panel’s upper left and right corners by inserting a small screwdriver into the panel’s upper left gap and carefully press down and out to release the locking tabs. Repeat on the upper right gap.

2. Remove the blind panel by using you hand to pull the panel loose

To mount blind panels, carry out the following:

1. Insert the panel’s upper edge by pressing gently so that its upper locking tabs engage

2. Lock the panel’s lower edge by pressing with your hand so that the blind panel’s lower tabs lock into position.

Correct Rectifier Position in Power Shelves Flatpack2 DC power systems are normally shipped from factory with empty power shelves. The rectifier modules are shipped in separate packaging, and you have to install the modules in the correct position in the power shelves, with respect to their ID number (or CAN bus address). Do not relocate already pre-installed rectifiers.

Follow the scheme below to install the Flatpack2 rectifier modules:

o Insert & hot-plug the rectifiers in the indicated power shelf positions, one module at a time, allowing a 2s delay between them and starting with ID number 1, 2, 3, and so on. (indifferent after ID# 6)

Screwdriver to release the locking tabs

Blind panel’s upper locking tabs

Correct Rectifier Position in the Power Shelves Dual AC feed: 2 AC inputs per shelf, each feeding 2 rectifiers

Δ Mains Three-phase, 230VAC

Υ MainsThree-phase & N, 400VAC

and

01 04

03 06

--- ---

02 05

--- ---

--- ---------------

Position 1

Position 4

Flatpack2rectifier

Position 8

Position 9

Smartpackcontroller

ID number (Assigned CAN bus address)

Phase 1

Phase 2

Phase 3

3 Installation

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 17

System Installation Check off in the Installation Check List, that you find in the last section of this folder.

Site Preparation Refer also to chapter “Location of Components ~ General Arrangement” on page 5. Step - Site Preparation Action Power is OFF! OK 1. Organize the

installation site o Check min. clearances for cabinet access:

front access, 100 cm, top access, 60 cm, rear clearance 100 cm * See page 36 * Note, The minimum rear clearance is only needed if Flexi kit 2 will be installed

o The floor construction must be capable of supporting the equipment, refer to System Specification, page 11

2. Prepare the installation tools

Check that insulated tools suitable for telecom installations are used

3. Prepare AC Supply: AC input cable(s) and fuses

Check the AC supply is the correct type, and that the external AC fuses and AC input cable(s) are suitably rated. Refer to page 6

Mechanical Installation Step - Mechanical Installation Action Power is OFF! OK 4. Remove packaging

and check equipment CAUTION: Do not step nor walk on the cabinet’s roof.

o Check you have received all the parts, correct cabinet, documentation, batteries (if applicable), etc

o Inspect the equipment for physical damage (report any damages)

o Leave rectifier modules in their packaging or in the selves, if factory installed. (commissioning task)

5. Use the Neoprene Mat Note: Only to be used when the cabinet is placed directly on concrete floor and a cabinet plinth is not mounted. o Use the attached neoprene mat between the

cabinet and the concrete floor. See Table 1, page 35 for specifications

3 Installation

18 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Step - Mechanical Installation Action Power is OFF! OK 6. Position and fasten

the cabinet

Note: If Flexi kit 2 will be installed, ensure a minimum clearance of 1m between the cabinet rear wall and any obstacle. See also Figure 7, page 36

o Drill holes on the floor or support beams, See Figure 5, page 35 and Perform Alt. A OR Alt. B

Alt. A: Cabinet Plinth Option NOT Used o Bolt the cabinet to the ground or support

beams Alt. B: Cabinet Plinth Option Used

o Fasten the plinth to the ground or support beams using M10 bolts. See Figure 6, page 35

o Bolt the cabinet to the plinth, using the “2m Cabinet-to-Plinth Fastening Holes”. See Figure 6, page 35

7. Mount the batteries on the shelves

o Start (if applicable) mounting them on the lower shelf first, and continue upwards. Use the battery kits, if supplied

Do not terminate the battery cables yet! Do not remove Condensation Stopper yet! The condensation stopper (yellow plastic) prevents humidity from entering the cabinet and must therefore not be removed until the system is powered up during commissioning. Humidity before powering up the system may cause serious damage to the system. The condensation stopper is attached to the filter on the inside of the door.

Electrical Installation Refer also to chapter “Location of Components ~ General Arrangement” on page 5. Step - Electrical Installation Action Power is OFF!OK 8. Make the system

completely voltage free Switch OFF or remove ALL load fuses (F1, Fx), battery fuses (Fb1, Fbx) and external AC supply fuses

9. Open the cabinet’s roof

The cabinet roof is locked with 2 screws in the front, from inside the door opening.

o Open these screws and lift up the roof o Secure the roof during installation with the

rod on the right side under the roof

..

3 Installation

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 19

Step - Electrical Installation Action Power is OFF!OK 10. Insert the cables

Marcon 25 multigate

.

Note! Other optional cable entry solutions are available for larger size cables and/or cable conduit. Please contact you local representative for details if the cable entry solution provided is not sufficient for your needs.

Cable (all phases in one cable) max 6mm2 each Single phase cable (one cable per phase) max 35mm2

CAUTION: Do not use the metal blind plates as cable entry plates.

o Use a screw driver to puncture the appropriate grommet(s) of the Marcon 25 multigate. Do not use a knife! The cut must be smaller than the cable diameter. The pictures show how to cut the grommets.

o Push cable(s) through the grommet(s):

o Then pull the cable(s) back out of the

grommet, approx. 10mm. This will lock the cable in the grommet and ensure full IP protection

o Ensure that the fixing screws of all Marcon 25 multigate cable entry plates and metal blind plates are properly tightened

Note! Ensure that any blind plates that are refitted to the cabinet are mounted with the gasket joint (spline) facing downwards.

Gasket joint/spline must face downwards when plate is

mounted back to cabinet

11. AC Connections o Check AC configuration: The AC terminals are correct configured to the external AC supply

o Connect the AC Earth wire (PE) to the terminals AC Earth (PE) - Terminal AC Earth (PE) is mechanically connected to cabinet chassis. Refer to page 5

o Connect the AC input cable(s) to the terminals. Cable and terminal block labelling are to correspond. Read pages 5 and 6.

3 Installation

20 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Step - Electrical Installation Action Power is OFF!OK 12. AC Socket Connection

The system is prepared for an AC socket, located to the right side of the cabinet. This AC outlet is intended for optional equipment. Due to the many different socket types all over the world, no socket is delivered with the system.

o Turn OFF the AC breaker. Connect the cables L, N and PE (not part of the cabinet) to the preferred socket type and mount the socket to the bracket.

o Mount the cables from AC socket to the AC breaker.

o Turn ON the AC Breaker

3 Installation

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 21

Step - Electrical Installation Action Power is OFF!OK 13. DC Connections

Load Circuits

3-pole link for CBI MCB

2-pole link for CBI MCB

o Terminate DC Earth (TE) - Terminals DC Earth (TE) is mechanically connected to cabinet chassis. Refer to page 5. - The Common Positive Bus bar is internally cabled to DC Earth (TE); thus the positive output of the rectifiers is connected to ground (TE), and the negative output represents the –48VDC supply voltage. Refer to Figure 1 General Arrangement Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m, on page 5. The Common DC Output Rail is to be connected to TE at only one place. - If required, you can remove the internal cable that connects the positive bus bar to local TE.

o Terminate DC Load Circuits The kit includes two copper links. One for 100 A (two pins) and one for 150 A (three pins). If the load current is larger than 50 A use the two pin copper link. Then the 3rd hole in the breaker cannot be used. If the load current is larger than 100 A, use the three pin copper link. Insert the chosen copper link on to the top of the MCB. - Connect the orange alarm wire to the copper links with a screw, if the links are used. - Connect the positive cable(s), max 70 mm sq (AWG 2/0), to the common positive bus bar on the top of the power core.2 - Connect the negative (-48V) cables, max 25 mm sq each (AWG 3), to the top of the MCBs or the copper links.

o Terminate GMT Fuse Load Circuits Connect the adequate cables, 1.5 mm sq (AWG 16), to the GMT fuse card according to the table on page 7

14. DC Connections Alarm & Signal Circuits

o Terminate Alarm Circuit cables to the relay output terminals. Refer to chapter “Terminals & Pin-out Location, Alarm Interface Card” on page 8.

2 The bus bar is prepared for connection of cables with lugs or ferrules. M8 bolts are fitted at delivery.

3 Installation

22 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Step - Electrical Installation Action Power is OFF!OK 15. DC Connections

Battery Cables The positive and negative (-48V) battery cables are connected from factory to the common positive bus bar and to the battery MCBs (does not apply for additional battery string kits). The battery temperature sense cable is also pre wired to CON4, and temporally fixed to the cabinet’s wall.

o Connect all battery inter-cell links o Connect the loose end of the battery cables

to the battery terminals; blue cable to the negative terminal and black cable to the positive terminal.

o Place the temperature sensor, located at the end of the battery temperature sense cable, on top of the topmost battery string

4 Commissioning

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 23

4. Commissioning The commissioning of Flatpack2 PS System consists of following stages:

I. Perform a pre-start check before the PS system is switched ON II. Switch ON the system with disconnected load; adjust output voltage

III. Adjust the nominal output voltage with connected batteries and load

Pre-Start Check Check off in the Commissioning Procedure, that you find in the last section of this folder. If you have just finished the system installation successfully and filled in the Installation Check List, jump over the Pre-Start Check and continue with stage II.

Before you switch ON the Flatpack2 PS system, verify the following:

1. System installation is completed o Ensure a correctly performed system installation, with correct polarity on

all connections, has been carried out (Installation Check List filled in) o All cabling and copper bars are securely terminated and supported o All components, terminal blocks, MCBs/ fuses, etc. are clearly labeled

2. Battery and load fuses are disconnected o Verify that all battery and load MCBs/ fuses are switched OFF or removed

3. AC input cable(s) and AC Earth wire (PE) are terminated o Make sure that the AC input cable(s) are connected to correctly configured

AC terminals o Verify that the AC input cable(s) and external AC fuses are sized and rated

as specified o Check that AC Earth (PE) is terminated, and electrically connected to

chassis (Link 1)

4. Site specific parameters and settings are known o Read the system specific drawings and documentation

5. AC supply and all MCBs, fuses are switched OFF o Make sure that all external AC fuses and internal MCBs/ fuses are switched

OFF

Device hazard

I Power is

OFF!

4 Commissioning

24 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Commissioning Steps, Startup Check off in the Commissioning Procedure, that you find in the last section of this folder. After the ”Pre-start Check” is performed, you can begin with stage II. During the stage, you will switch ON the Flatpack2 PSS — while the batteries and load are disconnected ⎯ then measure the output voltage, and adjust it if required. Carry out the following:

Startup and No-Load Adjustments 1. Disconnect all rectifier modules, without removing them (keep original location)

o Read how to install modules, on page 15. Also, read about the correct rectifier position on page 16, and then,

o If Flatpack2 rectifier modules are installed, unlock the handles and pull the modules partially out (fan housing visible), but do NOT physically remove them from the power shelves

o If Flatpack2 rectifier modules are not yet mounted, release their handles and insert them partially into the correct position in the shelves

2. Remove the Condensation Stopper o Remove the Condensation Stopper placed in front of both filters, inside the

door and in front of the fan. Read more about the Condensation Stopper on page 18

3. Switch ON the system o Switch ON the AC input supply (external AC fuses) to the PS cabinet

4. Measure and verify that the AC input voltage is correct o Measure the AC input voltage at the cabinet’s mains connection box o Verify the AC voltage is within range

5. Mount all Flatpack2 rectifier modules in the power shelves (keep original location)

o Push all rectifiers firmly inwards ⎯ one module at a time, allowing a 2s delay ⎯ to plug them in the same shelf location. Lock their handles. Refer also to page 15

o Mount blanking panels over unused positions

6. Ensure that the Smartpack and all rectifier modules are working: LEDs are ON o Verify correct operation, by monitoring the modules’ LED lamps and

display: No alarms are present on rectifiers; The Smartpack displays fuse alarms

7. Connect a PC to the PS system (to facilitate operation) o Plug a standard USB A-B cable between the PC and the Smartpack

controller o Start PowerSuite on the PC by selecting:

Start > All Programs > Eltek > PowerSuite o On the toolbar, click the “Connect” button to establish connection

8. Measure and adjust DC output voltage o Read the DC output voltage on the controller’s display o With a multi-meter, measure the DC output voltage at the most accessible

point, e.g. between the common DC rail and the lower connection of one of the priority load MCBs

o If required, adjust the voltage using the controller’s front keys or via PowerSuite

Device hazard

II Power is

ON!

4 Commissioning

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 25

9. Verify the alarm relays are working correctly (alarm relay test) o Run the alarm relay test using the controller’s front keys or via PowerSuite

(select the menu Go > Output Test)

10. Make sure the System Setup is in accordance with configuration o Verify system settings using the controller’s front keys or via PowerSuite o Use the opportunity to enter site related information, number of used AC

phases, type of batteries, etc.

Load Adjustments

Now, you can begin with stage III, where you will adjust again the output voltage to the battery voltage, and connect the batteries and the load. Carry out the following:

11. Adjust DC output voltage to equal measured battery voltage

o Measure the battery voltage is within range (check connections have correct polarity)

o Adjust DC output voltage — using the controller’s front keys or via PowerSuite— to equal the measured battery voltage. (Important adjustment to avoid arcing when connecting the batteries)

12. Unplug all rectifiers but one, and connect the battery fuses /MCBs (CAUTION: Have only one rectifier connected, when switching ON the battery fuses. Thus, avoiding damaging all rectifiers, due to possible incorrect polarity connections, etc.)

o Disconnect all rectifiers but one, by unlocking the handles and pulling them partially out (fan housing visible). Do NOT physically remove them from the power shelves

o Switch ON all battery fuses or MCBs

13. Adjust DC output voltage again to equal the nominal battery voltage o Adjust DC output voltage — using the controller’s front keys or via

PowerSuite — to equal the nominal battery voltage (or the nominal load voltage, when not using batteries)

14. Plug in again all rectifiers, and verify the rectifiers’ current sharing o Connect all rectifiers again by pushing them firmly inwards ⎯ Repeat step

4, in stage II o Wait for about 2 min., and check — using the PowerSuite application —that

each of the rectifiers delivers the same output current. A deviation of 1A is acceptable.

15. Connect the load breakers and verify that no alarms are displayed o Switch ON all load MCBs/ fuses o Verify correct operation: rectifiers and controller display no alarms

Devicehazard

Devicehazard

III Power is

ON!

5 Maintenance

26 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

5. Maintenance You can carry out the DC power system maintenance, by following the steps in the Maintenance Procedure that you find in the last section of this manual. This chapter describes how to perform filter maintenance. WARNING: You are operating in a live system. Precaution must be taken when changing filter in front of the fan.

Lower Door Filter (Fan Filter) Locations: Pollution degrees: Car park/road side: City roof top: Non central: Low 1 year 2 years 3-4 years Medium 1 year 2 years 3-4 years High 6 months 1 year 2 years

* Note! The filter replacement intervals listed in the above table are only guidelines. Shorter intervals may be required, depending on the level of air pollution on site. Eltek recommend bi-monthly site checks during the first year of operation, to establish actual filter replacement intervals for each individual site

Upper Door Filter Locations: Pollution degrees: Car park/road side: City roof top: Non central: Low 4 year 8 years 12 years Medium 4 year 8 years 12 years High 2 years 4 year 8 years

* Note! The filter replacement intervals listed in the above table are only guidelines. Shorter intervals may be required, depending on the level of air pollution on site. Eltek recommend bi-monthly site checks during the first year of operation, to establish actual filter replacement intervals for each individual site

Figure 3 Location of the cabinet’s door filter and fan filter

Door Filter, Outlet(The filter’s rough side facing

inwards)

Fan Filter Door

Filter frame’sfastening screws

Filter frame’sfastening screws

Fan Filter, Inlet(The filter’s smooth side

facing inwards)

Fastening knobs forfan filter door

Open fan filter door

5 Maintenance

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 27

Replacement of Door Filter Step Action OK 1. Remove

filter Refer to “Figure 3 Location of the cabinet’s door filter and fan filter”, on page 26. o Remove the Air baffle plate(s) that cover the filter grid on the

inside of the cabinet door (plates not shown in Figure 3). o Remove the filter grid

by loosening the screws around it. Pull the grid towards you when loose

2. Exchange filter

o Exchange the old filter with a new. Make sure that the rough side of the filter faces the inside of the cabinet

3. Mount the frame

o Mount the grid to the door again, fastening the screws around it

o Mount the Air baffle plate(s) back on again and tighten the screws

Replacement of Fan Filter Step Comments OK 1. Disconnect

the fan o Remove the fan fuse,

located at the GMT fuse card (fuse 8). Refer to “Terminals & Pin-out Location, GMT Fuses” on page 7

2. Open the Fan Filter Door

Refer to “Figure 3 Location of the cabinet’s door filter and fan filter”, on page 26. o Open the fan filter door

by turning the two knobs on the door (upper and lower right side)

3. Remove the filter grid

o Remove the filter grid by loosening the screws around it. Pull the grid towards you when loose

4. Exchange the filter

o Exchange the old filter with a new. Make sure that the smooth side of the filter faces the inside of the cabinet

5. Mount the grid

o Mount the grid again, fastening the screws around it

6. Close the Fan Filter door

o Close the fan filter door, and turn the knobs closed

7. Connect the fan

o Replace the fan fuse, and verify that the system is operating normally

6 Forms, Schematics & Drawings

28 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

6. Forms, Schematics & Drawings This section includes following forms and schematic drawings:

Installation Check List

Commissioning Procedure

Maintenance Procedure

General Arrangement Drawing

Cabinet’s Neoprene Mat Table, Drilling Template, Plinth’s fastening holes

Cabinet Clearance Drawing

System Schematic Drawing

Configuration Settings ~ Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m

Load Distribution List

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 29

INSTALLATION CHECK LIST System Data Flatpack2 PS System Flatpack2 Power Supply System, type: Article No.:

Site, name:

Serial No.: Software, version No.: Rectifiers, type & number of:

AC Input Voltage, measured: Battery Type: Battery Capacity: Installation carried out by, name:

Site Preparations Power is OFF! CARRY OUT FOLLOWING: OK

1. Organize the installation site

2. Prepare the installation tools

3. Prepare AC Supply: AC input cable(s) and fuses

Mechanical Installation Power is OFF! CARRY OUT FOLLOWING: OK

4. Remove packaging and check equipment

5. Use the Neoprene Mat

6. Position and fasten the cabinet

7. Mount the batteries on the shelves o Do not terminate the battery cables yet! o Do not remove the Condensation Stopper!

Electrical Installation Power is OFF! CARRY OUT FOLLOWING: OK

8. Make the system completely voltage free

9. Open the cabinet’s roof

10. Insert the cables

11. AC Connections o Check AC configuration: The AC terminals are correct configured to the external AC supply o Connect the AC Earth wire (PE) to the terminals AC Earth (PE) o Connect the AC input cable(s) to the terminals. Cable and terminal block labeling are to correspond

12. AC Socket Connection

13. DC Connections ⎯ Load Circuits o Terminate DC Earth (TE): Common DC Output Rail is connected to TE at only one place o For each DC load, connect one of the cables to the common DC output rail, and the other directly to the MCB o Terminate the GMT load circuits

14. DC Connections ⎯ Alarm & Signal Circuits

15. DC Connections ⎯ Battery Cables Careful! Use correct polarity. For each battery shelf,

o Mount 3 intercell links to connect in series 4 battery blocks, (In 24V systems: 1 link and 2 blocks) o Connect battery cables to fuses and common DC rail, and to the shelf’s outer terminals; black (+); blue (-) o Connect the temperature sensor cable, if applicable, to the D-Sub plug or input terminal, and fix the sensor (at the

end of the cable) to a suitable place in the middle of the installed battery bank

Approval Responsible of installation, sign.: Date: Approved by customer, sign.:

EMC regard

Electric shock

Device hazard

Electric shock

30 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 31

COMMISSIONING PROCEDURE System Data Flatpack2 PS System Supplier’s Order No.: Flatpack2 Power Supply System, type: Article No.:

Site, name:

Serial No.: Software, version No.: Rectifiers, type & number of:

AC Input Voltage, measured: Battery Type: Battery Capacity: Commissioning carried out by, name:

Pre-Start Check Power is OFF! CHECK FOLLOWING: OK 1. Flatpack2 system installation is completed; The Flatpack2 Installation Check List is filled in.

All cabling is securely terminated with correct polarity 2. All battery and load MCBs/ fuses are disconnected

3. AC input cable(s) and AC earth wire (PE) are terminated

4. Site specific parameters and settings are known

5. AC supply and all MCBs/ fuses are switched OFF

Start-up, No-Load & Load Adjustments Power is ON! CARRY OUT FOLLOWING: OK 1. Disconnect all rectifier modules, without removing them (keep original location) 2. Remove the Condensation Stopper

3. Switch ON the system (external AC fuses ON) 4. AC input voltage is correct; Measure and verify

5. Insert all Flatpack2 rectifiers in their original locations in the power shelves 6. The Smartpack and all rectifier modules are working, LEDs are ON; Verify

7. Connect a PC to the PS system Install the PowerSuite software, if required

8. DC output voltage; Measure and adjust

9. Alarm relay test; Verify all alarm relays are working correctly 10. System Setup is in accordance with configuration Enter site spec. info in PowerSuite 11. Adjust DC output voltage to equal measured battery voltage Check correct polarity! 12. Unplug all rectifiers but one, and connect all battery fuses/ MCBs 13. Adjust DC output voltage to equal nominal battery or load voltage 14. Plug in again all rectifiers, and verify the rectifiers’ current sharing 15. Connect all load MCBs/ fuses, and verify no alarms are displayed

Approval Responsible of commissioning, sign.: Date: Approved by customer, sign.:

Device hazard

I

II

Device hazard

III

Device hazard

32 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 33

WARNING: Maintenance work on live equipment is only to be performed by authorized and qualified persons using insulated tools. Hazardous voltages inside may cause terminal injury.

Electric shock

MAINTENANCE PROCEDURE System Data Flatpack2 PS System Flatpack2 Power Supply System, type: Article No.:

Site, name:

Serial No.: Software, version No.: Rectifiers, type & number of:

AC Input Voltage, measured: Battery Type: Battery Capacity: Maintenance carried out by, name:

System Inspection Power is ON! CARRY OUT FOLLOWING: OK 1. Site specific parameters and settings are known.

User manuals and site specific connection & arrangement drawings are available.

2. The battery bank has been fully charged in advance. At least for 12 hours since start-up or mains failure. Enables correct measurements & calibration

3. The equipment and door filters are free from damage, dust or dirt; verify. Carefully vacuum clean or remove any accumulation of dust, corrosion or dirt. Perform filter maintenance.

4. All cabling and copper bars are securely terminated and supported. Correct any loose connections, excessive cable temperature, defective insulation, etc.

5. The Smartpack & all rectifier modules are ON, no alarm present; verify. Otherwise, correct and put the PS system in normal mode of operation.

6. All rectifier’s functionality & Smartpack’s keys and display work OK; verify Correct possible abnormalities before continuing.

7. Connect the PS system to a PC (install the PowerSuite application if required) The PowerSuite program in the PC enables system configuration from the PC.

8. Rectifiers’ load current sharing; verify. Use the PowerSuite PC application to check all rectifiers output the same amount of current (±1A)

9. Display the stored log of Alarm Messages. Using the keypad on the Smartpack controller or from the PC.

System Adjustment CARRY OUT FOLLOWING: OK 1. DC Output Voltage Calibration; ensure correct display readings.

If measured DC output voltage at the load terminals deviates more than ±1% from the display reading, calibrate the output voltage from the Smartpack’s keypad or the PC.

2. Load & Battery Current Calibration; verify correct display readings. Measure with a clip-on ammeter the battery current & every load circuit current. Calculate the total load & battery current. If the calculated total values deviate more than ±1% from the display readings, calibrate the current from the PC (calibration value>50% of system’s max. capacity)

3. DC Output Voltage Adjustment; measure and adjust. Measure and, if required, adjust the output voltage to the nominal voltage recommended by the battery manufacturer. (Voltage measurements to be done at the DC rail, with little load current)

4. Alarm Relay Test; verify all alarm relays are working correctly. From the Smartpack’s keypad or PC use the Relay Test function; verify activation of external equipment

5. Battery bank control; measure and verify battery specifications. Follow the recommendations of the actual battery manufacturer.

Approval Responsible of maintenance control, sign.: Date: Approved by customer, sign.:

34 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Figure 4 General Arrangement Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m Doc, 24nnnn.yy, XvX

1944

.420

0

7U

14U

21U

29U

35U

41U

770.0000

AC Mains Terminals

Battery MCBFB4*

Battery MCBFB3*

Battery MCBFB2*

Battery MCBFB1

* Optional

AUX.AC MCB (heater, AC socket, air-conditioner)

Cabinet main ground barAC Earth (PE) and DC Earth (TE) connection On cabinet’s side wall

Flatpack2rectifiers

Smartpackcontroller

Door Switch

DC Distribution

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 35

Table 1 Neoprene Mat Specifications

Note: The mat is only to be used when the cabinet is placed directly on concrete floor and a cabinet plinth is not mounted.

Figure 5 Drilling Template, top view of the cabinet’s bottom plate. For cabinet fastening directly to the floor or to a plinth

Figure 6 Cabinet’s plinth, top and 3D view. Cabinet’s and plinth’s fastening holes

Cabinet’s Neoprene Mat Specifications Feature Value Test Standard Shore hardness A 65±5 DIN 53 505 Tensile strength 0,45 N/mm² DIN 53 571 Elongation at rupture 45% DIN 53 571 Density 730 kg/m³ Mass per unit area 730g/m²/mm Compression stress at 30% deformation 0,75 N/mm² DIN 53 577 Operational temperature -40 to +155°C Flammability Class B 2din 4102

2m Cabinet-to-Plinth Fastening Holes Plinth-to-Floor Fastening Hole (4x)

One hole in each corner

2m Cabinet-to-Plinth Fastening Hole (4x)One hole in each corner

1.3m Cabinet-to-Plinth Fastening Hole (4x)One hole in each corner

FRO

NT

125 mm

75 mm

120 mm

75 mm

620 mm

575 mm

620

mm

75 mm

125

mm

575

mm

120

mm

75 mm

Fron

t

36 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Figure 7 Cabinet Clearance, side and top view Doc No. 14990 - 109, 23.02.07

Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06 37

Figure 8 System Schematic Flatpack2 PS System, 16kW, 48VDC, OCab, FanC 2.0m Doc, 2020335, 4v0

1:O

ptio

nal 9

pin

D-s

ub R

S232

con

nect

ion.

Can

be

mou

nted

in fr

ont o

r on

rear

sid

e of

Sm

artp

ack.

Rep

lace

s”E

xt. B

atte

ry C

onne

ctio

ns”

whe

n m

ount

ed o

n th

e re

ar s

ide

of S

mar

tpac

k

2:O

ptio

nal W

eb/S

NM

P (E

NET

) con

nect

ion.

R

epla

ces

”Ext

. Ala

rm I/

O C

onne

ctio

ns”

Cus

tom

er

conn

ectio

ns

C

ON

5Sy

stem

Con

nect

ions

CO

N4

Bat

tery

con

nect

ions

CO

N2

Ext.

Ala

rm I/

O C

onne

ctio

ns2:

Opt

iona

l: W

eb/S

NM

P (E

NE

T)

CO

N1

Ala

rm I/

O C

onne

ctio

ns

USB

2.0

type

B p

ort

(PC

con

nect

ion)

91:

Opt

iona

l: R

S232

Smar

tpac

k m

onito

ring

and

cont

rol u

nit

10

CA

N p

ort

1515

9/15

CO

N3

Ext.

Bat

tery

con

nect

ions

1: O

ptio

nal:

RS

232

8/26

CA

N p

ort

USB

Rea

r con

nect

ions

Fron

t con

nect

ions

88

SH1

-+

-FB1

-FB2

*

-FB3

*

-F1

CU

-bar

com

mon

+0V

Customer connections

Battery Strings Circuits -48Vdc

Load circuits -48Vdc

YX

LVB

D

The

Sch

emat

ic/C

onne

ctio

n D

raw

ing

show

s th

e po

sitio

n of

the

rela

y co

ntac

ts w

hen

the

Pow

er S

yste

m is

in it

s al

arm

mod

e of

op

erat

ion

(rel

ay c

oils

are

then

de-

ener

gize

d). T

he re

lay

outp

uts

are

prep

rogr

amm

ed fr

om fa

ctor

y (F

acto

ry S

ettin

gs).

DC

Ear

th (T

E)

Con

5A

*Sy

stem

Con

nect

ions

Sys

tem

Con

nect

ion

Boar

d20

0625

151 2 3 4 5 6 7 8 9 10 11

*X5

Syst

em C

onne

ctio

n

21

32

13

JP1

JP2

NEG. DIST.

POS. DIST.

NEG. DIST.

POS. DIST.

+ -Po

wer

Inpu

t

Batte

ry C

urre

nt

Bat

tery

Fus

e Fa

il

Load

Fus

e Fa

il 1

LVD

1A

LVD

Com

mon

LVD

2A

+ -+ -

LVD

Com

mon

CO

MNO NC

1

Alar

m O

utpu

ts a

nd

Dig

ital I

nput

s10

5954

2610

2 3 4 5 6 7 8 9 10

+

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

- + -

Dig

ital I

nput

1

Dig

ital I

nput

2

Rel

ay 1

CO

MNO NC

Rel

ay 2

+ -D

igita

l Inp

ut 3

+ -D

igita

l Inp

ut 4

+ -D

igita

l Inp

ut 5

+ -D

igita

l Inp

ut 6

CO

MNO NC

Rel

ay 3

CO

MNO NC

Rel

ay 4

CO

MNO NC

Rel

ay 5

CO

MNO NC

Rel

ay 6

Con

1A

*A

larm

I/O

Con

nect

ions

Con

2A

*Ex

t. A

larm

I/O

Con

nect

ions

*X1

Ala

rm I/

O C

onne

ctio

ns *X2

Ext.

Ala

rm I/

O C

onne

ctio

ns

Customer connections

NA

whe

n W

eb/S

NM

P (E

NET

) kit

inst

alle

d in

Sm

artp

ack

L1L2

L3N

AC

term

inal

co

nnec

tions

Sta

r (40

0Vac

) 3-

phas

e

Back

wiri

ng F

P2

Low

Cur

rent

2AC

4 re

ctifi

er p

ositi

ons

1055

81

8 8Sm

artp

ack

Pow

er

-/C

AN b

us

inte

rcon

nect

ions

Con

8, p

in 1

-8

Con

8, p

in 9

-16+ -

PE

CO

N13

L1 C

ON

9L1

CO

N11

L2 C

ON

10L2

CO

N12

PS 1

Back

wiri

ng F

P2

Low

Cur

rent

2AC

4 re

ctifi

er p

ositi

ons

1055

81

8 8Sm

artp

ack

Pow

er

-/C

AN b

us

inte

rcon

nect

ions

Con

8, p

in 1

-8

Con

8, p

in 9

-16+ -

PE

CO

N13

L1 C

ON

9L1

CO

N11

L2 C

ON

10L2

CO

N12

PS 2

-FB4

*

-F2

-F3*

-F4*

LTE

Cus

tom

er c

onne

ctio

ns*

12

9

J1

TERM 1TERM 2TERM 3

Diode Matrix

101526

12

9

J1

TERM 1TERM 2TERM 3

Diode Matrix

101526

203929

9 8 7 6 5 4 3 2 1

+ -

Load Alarm

F12

F11

F10

F9 F8 F7 F6 F5

Load Alarm

1016 15 14 13 12 11

GMT Load circuits -48Vdc

-F13

-F14

-F15

-F16

-F17

-F18

-F19

-F20

Bat

tery

Hea

ter*

PE

AC

soc

ket*

PE*

OV

P k

it

LTE

EQ

UIP

ME

NT*

*OP

TIO

N

-+

A2T

A1

Blue

Red

Yellow

White

Tem

pse

nsor

6295

0-42

1

-F5 GMT

Zene

r dio

de 5

,6V

6295

0 -7

31

FAN

6295

0-42

0

11

Red

Bro

wn

14

Rel

ay

6295

0-73

4

A1A2

1114

Doo

r Sw

itch

2

4

Brown

Yellow

White

N

38 Installation Guide Flatpack2 PS System, 16kW, 48VDC, Outdoor 2.0m Fan Cooled Cabinet 351476.033, v4-2007-06

Note! The values in this table are default factory settings. The settings of a Smartpack controller in an installed system may be different from the above settings, depending on the system’s final configuration of optional kits, number/type of batteries, alarm setup and/or any other changes done to the system and/or the Smartpack controller after the system was shipped from the factory.

LOAD DISTRIBUTION LIST System Data Flatpack2 PSS, type: Article No.:

Site, name:

FUSE ID

FUSE TYPE LOAD DESCRIPTION

RATING

AMPERE

CABLE SIZE mm2

CABLE SIZE AWG BTS

MCB GMT FUSE

LTE MCB

F1 X

F2 X

F3*

F4*

F5 X 10

F6 X 10

F7 X 10

F8 X 10

F9 X 10

F10 X 10

F11 X 10

F12 X 10

F13* 10

F14* 10

F15* 10

F16* 10

F17* 10

F18* 10

F19* 10

F20* 10

*Optional fuses/breakers.

F3 & F4 are only fitted if optional BTS breaker kit(s) are installed in the cabinet. F13-F20 are only fitted if optional LTE kit is installed in the cabinet Breakers F1, F2 and GMT fuses F5-F12 are always part of cabinet

BTS MCB`s For details, see chapter

“Location of Components General arrangement”

GMT FUSES For details, see chapter

“Terminals and pin-out location GMT fuse”

LTE MCB`s(Optional)

For details, see installation manual for LTE kit (351480.033)

Eltek Energy AS Tel. +47 32 20 32 00

Internet: www.eltekenergy.com E-Mail: [email protected]

Form

xxx

-gb-

v1-C

01_3

5147

6-03

3_in

stgd

e_fp

2-ps

s-16

kw-4

8vdc

-oca

b-fa

nc-2

m0.

doc_

ts/m

fm_2

007-

06-1

9

www.eltekenergy.com

ELTEK Energy P-O- BOX 2340 StØmsØ N-3003 DRAMMEN NORWAY Phone: +47 32203200 Telefax: +47 32203210 Internet: http://www.eltekenergy.com e-mail: [email protected]

Location Company Telephone Fax Norway Eltek Energy AS +47 32 20 32 00 +47 32 20 32 10 Americas Eltek Energy, LLC +1 815 459 9100 +1 815 459 9118 Asia/Pacific Eltek Energy Pte Ltd. +65 6 7732326 +65 6 7753602 China Eltek Energy Ltd. +769 22651108 Europe Eltek Energy UK Ltd. +44 1442 219355 +44 1442 245894 Middle East Eltek Middle East +971 4 887 1176 +971 4 887 1175