Installation and operating instructions - PPS Pumps · PDF fileLCD 107, LC, LCD 108, LC, LCD...

Transcript of Installation and operating instructions - PPS Pumps · PDF fileLCD 107, LC, LCD 108, LC, LCD...

SEG50 Hz

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

En

glish

(GB

)

2

English (GB) Installation and operating instructions

Original installation and operating instructions.

CONTENTSPage

1. Symbols used in this document

1. Symbols used in this document 2

2. General description 32.1 Product drawing 32.2 Applications 32.3 Operating conditions 3

3. Delivery and handling 43.1 Transportation 43.2 Storage 43.3 Lifting 4

4. Identification 54.1 Nameplate 54.2 Type key 6

5. Approvals 75.1 Approval standards 75.2 Explanation to Ex approval 7

6. Safety 86.1 Potentially explosive environments 8

7. Installation 97.1 Installation on auto coupling 97.2 Free-standing submerged installation 11

8. Electrical connection 118.1 Wiring diagrams 128.2 CU 100 control box 138.3 Pump controllers 148.4 Thermal switches 148.5 Frequency converter operation 15

9. Start-up 169.1 General start-up procedure 169.2 Operating modes 169.3 Direction of rotation 17

10. Maintenance and service 1710.1 Inspection 1710.2 Replacing the grinder system 1810.3 Cleaning the pump housing 1910.4 Checking/replacing the shaft seal 1910.5 Oil change 2010.6 Service kits 2110.7 Contaminated pumps 21

11. Fault finding 22

12. Technical data 23

13. Disposal 23

Warning

Prior to installation, read these installation and operating instructions. Installation and operation must comply with local regulations and accepted codes of good practice.

Warning

The use of this product requires experience with and knowledge of the product.Persons with reduced physical, sensory or mental capabilities must not use this product, unless they are under supervision or have been instructed in the use of the product by a person responsible for their safety.Children must not use or play with this product.

Warning

If these safety instructions are not observed, it may result in personal injury.

Warning

If these instructions are not observed, it may lead to electric shock with consequent risk of serious personal injury or death.

Warning

These instructions must be observed for explosion-proof pumps. We recommend that you also follow these instructions for standard pumps.

CautionIf these safety instructions are not observed, it may result in malfunction or damage to the equipment.

Note Notes or instructions that make the job easier and ensure safe operation.

En

glis

h (

GB

)

3

2. General description Grundfos SEG pumps are designed with a grinder system which grinds solid particles into small pieces so that they can be led away through pipes of a relatively small diameter.

SEG pumps are used in pressurised systems, e.g. in hilly areas.

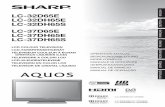

The pumps can be controlled via the Grundfos LC, LCD 107, LC, LCD 108, LC, LCD 110 pump controllers or the Grundfos CU 100 control box.See installation and operating instructions for the selected unit.

2.1 Product drawing

Fig. 1 SEG pump

2.2 Applications

SEG pumps are designed for pumping the following liquids:

• Domestic wastewater with discharge from water closets

• sewage from restaurants, hotels, camping sites, etc.

The compact design makes the pumps suitable for both temporary and permanent installation. The pumps can be installed on an auto-coupling system or stand freely on the bottom of the pit.

2.3 Operating conditions

The Grundfos SEG pumps are designed for intermittent operation (S3). When completely submerged, the pumps can also run continuously (S1). See section 9.2 Operating modes.

Installation depth

Maximum 10 metres below liquid level.

Operating pressure

Maximum 6 bar.

Number of starts per hour

Maximum 30.

pH value

Pumps in permanent installations can be used for pumping liquids with pH values between 4 and 10.

Liquid temperature

0 °C to +40 °C.

For short periods (maximum 15 minutes), a temperature of up to 60 °C is permissible (non-Ex versions only).

Density and viscosity of pumped liquid

When pumping liquids with a density and/or a kinematic viscosity higher than that of water, use motors with correspondingly higher outputs.

TM

02

53

99

45

02

Pos. Designation

1 Cable plug

2 Nameplate

3 Discharge flange DN 40

4 Discharge port

5 Lifting bracket

6 Stator housing

7 Oil screw

8 Clamp

9 Pump foot

10 Pump housing

5

6

8

9

10

1

2

3

4

7

Warning

Explosion-proof pumps must never pump liquids at a temperature higher than 40 °C.

En

glish

(GB

)

4

3. Delivery and handlingThe pump may be transported and stored in a vertical or horizontal position. Make sure that it cannot roll or fall over.

3.1 Transportation

All lifting equipment must be rated for the purpose and checked for damage before any attempts to lift the pump. The lifting equipment rating must under no circumstances be exceeded. The pump weight is stated on the nameplate.

The polyurethane-embedded plug prevents water from penetrating into the motor via the motor cable.

3.2 Storage

For long periods of storage, the pump must be protected against moisture and heat.

After a long period of storage, the pump should be inspected before it is put into operation. Make sure that the impeller can rotate freely. Pay special attention to the shaft seals and the cable entry.

3.3 Lifting

When lifting the pump, it is important to use the right lifting point to keep the pump balanced. Place the lifting chain hook in point A for auto-coupling installations and in point B for other installations. See fig. 2.

Fig. 2 Lifting points

Warning

Always lift the pump by its lifting bracket or by means of a fork-lift truck if the pump is fixed on a pallet. Never lift the pump by means of the motor cable or the hose/pipe.

TM

06

00

66

48

13

En

glis

h (

GB

)

5

4. Identification

4.1 Nameplate

The nameplate states the operating data and approvals applying to the pump. The nameplate is fixed with rivets to the side of the stator housing near the cable input to the motor.

Fix the additional nameplate supplied with the pump close to the pit.

Fig. 3 SEG nameplate

TM

05

88

71

28

13

98795230

Pos. Description Pos. Description

1 Ex description 15 Ex description

2 Ex certificate no 16 Product number of I&O

3 Type designation 17 Enclosure class

4 Production number 18 Max. installation depth (m)

5 Production code 19 Max. flow rate (l/s)

6 Max. head (m) 20 Max. liquid temperature (°C)

7 Phases 21 Rated power output (kW)

8 Rated power input (kW) 22 Cos φ, 1/1 load

9 Speed (rpm) 23 Rated current, Δ10 Rated voltage, Δ 24 Rated current, Y

11 Rated voltage, Y 25 Starting capacitor (µF)

12 Frequency (Hz) 26 Run capacitor (µF)

13 Net weight (kg) 27 Insulation class / temperature rise

14 Approval 28 Production country

En

glish

(GB

)

6

4.2 Type key

The type key covers the entire Grundfos SEG range of wastewater pumps. This is why the type key has a number of empty fields for the grinder pumps. Each SEG grinder pump is identified by means of the type key below. Please note that not all combinations are available.

Code Description SE G .40 .12 .Ex .2 .1 5 02

SEType rangeGrundfos sewage pumps

GImpeller typeGrinder system in the pump inlet

40Pump dischargeNominal diameter of discharge port [mm]

12Output power, P2P2 = Code number from type designation/10 [kW]

[ ]EquipmentStandard, without equipment

[ ]Ex

Pump versionStandard version of submersible wastewater pumpsPump designed according to the ATEX standard indicated or Australian standard, AS 2430.1

2Number of poles2-pole, 3000 min-1, 50 Hz

1[ ]

Number of phasesSingle-phase motorThree-phase motor

5Mains frequency50 Hz

020B0C

Voltage and starting method230 V, direct-on-line starting400-415 V, direct-on-line starting230-240 V, direct-on-line starting

[ ]AB

GenerationFirst generationSecond generationThird generationThe pumps belonging to the individual generations differ in design but are similar in terms of power rating.

[ ]Material in pumpStandard material

En

glis

h (

GB

)

7

5. ApprovalsThe standard version of SEG pumps has been tested by VDE. The explosion-proof version has been approved by DEKRA according to the ATEX directive.

5.1 Approval standards

The standard versions are approved by LGA according to EN 12050-1. See Declaration of Performance on page 39.

5.2 Explanation to Ex approval

The explosion protection classification of the pump is Europe CE 0344 II 2 G Ex d IIB T4 X.

5.2.1 Australia

Ex variants for Australia are approved as Ex nC II T3 according to IEC 79-15 (corresponding to AS 2380.9).

Directive/standard

Code Description

ATEX

CE 0344

=CE marking of conformity according to the ATEX directive 94/9/EC, Annex X.0344 is the number of the notified body which has certified the quality system for ATEX.

= Explosion protection marking.

II =Equipment group according to the ATEX directive, Annex II, point 2.2, defining the requirements applicable to the equipment in this group.

2 =Equipment category according to the ATEX directive, Annex II, point 2.2, defining the requirements applicable to the equipment in this category.

G = Explosive atmospheres caused by gases, vapours or mists.

Harmonised European standard EN 50014

Ex = The equipment conforms to harmonised European standard.

d = Flameproof enclosure according to EN 60079-1:2007.

II = Suitable for use in explosive atmospheres (not mines).

B =Classification of gases, see EN 60079-0:2006, Annex A.Gas group B includes gas group A.

T4 = Maximum surface temperature is 135 °C.

X =The letter X in the certificate number indicates that the equipment is subject to special conditions for safe use. The conditions are mentioned in the certificate and the installation and operating instructions.

Standard Code Description

IEC 79-15:1987

Ex = Area classification according to AS 2430.1

n = Non-sparking according to AS 2380.9:1991, section 3 (IEC 79-15:1987)

C = The environment is adequately protected against sparking components

II = Suitable for use in explosive atmospheres (not mines)

T3 = Maximum surface temperature is 200 °C

X =The letter X in the certificate number indicates that the equipment is subject to special conditions for safe use. The conditions are mentioned in the certificate and the installation and operating instructions.

En

glish

(GB

)

8

6. Safety

For safety reasons, all work in pits must be supervised by a person outside the pump pit.

Pits for submersible wastewater pumps contain wastewater with toxic and/or disease-causing substances. Therefore, all persons involved must wear appropriate personal protective equipment and clothing and all work on and near the pump must be carried out under strict observance of the hygiene regulations in force.

6.1 Potentially explosive environments

Use explosion-proof SEG pumps for applications in potentially explosive environments.Warning

Pump installation in pits must be carried out by specially trained persons.

Work in or near wastewater pits must be carried out according to local regulations.

Warning

Persons must not enter the installation area when the atmosphere is explosive.

Warning

It must be possible to lock the mains switch in position 0. Type and requirements as specified in EN 60204-1, 5.3.2.

Warning

When the pump has been installed, there must be at least 3 m free cable above the maximum liquid level.

NoteIt is advisable to make all maintenance and service work when the pump is placed outside the pit.

Warning

Make sure that the lifting bracket is tightened before attempting to lift the pump. Tighten if necessary. Carelessness during lifting or transportation may cause injury to personnel or damage to the pump.

Warning

SEG pumps must under no circumstances pump combustible or flammable liquids.

Warning

The classification of the installation site must be approved by the local firefighting authorities in each individual case.

Warning

The explosion protection classification of the pump is CE 0344 II 2 G Ex d IIB T4 X. The classification of the installation site must be approved by the local firefighting authorities in each individual case.

Warning

Special conditions for safe use of SEG explosion-proof pumps:

1. Bolts used for replacement must be class A2-70 or better according to EN/ISO 3506-1.

2. The level of pumped liquid must be controlled by two stop level switches connected to the motor control circuit. The minimum level depends on the installation type and is specified in these installation and operating instructions.

3. Make sure the permanently attached cable is suitably mechanically protected and terminated in a suitable terminal board placed outside the potentially explosive area.

4. The thermal protector in the stator windings has a nominal switch temperature of 150 °C and must guarantee the disconnection of the power supply; the power supply must be reset manually.

En

glis

h (

GB

)

9

7. Installation

Fit the extra nameplate supplied with the pump at the installation site or keep it in the cover of this booklet.

All safety regulations must be observed at the installation site, e.g. the use of blowers for fresh-air supply to the pit.

Prior to installation, check the oil level in the oil chamber. See section 10. Maintenance and service.

The SEG pumps are suitable for different installation types which are described in sections 7.1 and 7.2.

All pump housings have a cast DN 40, PN 10 discharge flange.

7.1 Installation on auto coupling

Pumps for permanent installation can be mounted on a stationary auto-coupling guide rail system or a hookup auto-coupling system.

Both auto-coupling systems facilitate maintenance and service as the pump can easily be lifted out of the pit.

Caution Prior to installation, make sure the pit bottom is even.

Warning

Before beginning the installation, switch off the power supply and lock the mains switch in position 0.

Any external voltage connected to the pump must be switched off before working on the pump.

Warning

Before installation and the first start-up of the pump, check the cable for visible defects to avoid short-circuits.

Note

The pumps are designed for intermittent operation. When completely submerged in the pumped liquid, the pumps can also run continuously. See section 12. Technical data.

Warning

Do not put your hands or any tool into the pump suction or discharge port after the pump has been connected to the power supply, unless the pump has been switched off by removing the fuses or switching off the mains switch. Make sure that the power supply cannot be accidentally switched on.

Caution

We recommend to always use Grundfos accessories to avoid malfunction due to incorrect installation.

Warning

Only use the lifting bracket for lifting the pump. Do not use it to hold the pump when in operation.

Warning

Before beginning installation procedures, make sure that the atmosphere in the pit is not potentially explosive.

Note

Make sure that the pipework is installed without the use of undue force. No loads from the pipework weight must be carried by the pump. We recommend the use of loose flanges to ease the installation and to avoid pipe tension at flanges and bolts.

Note

Do not use elastic elements or bellows in the pipework; these elements should never be used as a means to align the pipework.

En

glish

(GB

)

10

Auto-coupling guide rail system

See fig. A on page 24.

Proceed as follows:

1. Drill mounting holes for the guide rail bracket on the inside of the pit and fasten the guide rail bracket provisionally with two screws.

2. Place the auto-coupling base unit on the bottom of the pit. Use a plumb line to establish the correct positioning. Fasten the auto coupling with heavy-duty expansion bolts. If the bottom of the pit is uneven, the auto-coupling base unit must be supported so that it is level when being fastened.

3. Assemble the discharge pipe in accordance with the generally accepted procedures and without exposing the it to distortion or tension.

4. Insert the guide rails in the auto-coupling base unit and adjust the length of the rails accurately to the guide rail bracket.

5. Unscrew the provisionally fastened guide rail bracket, fit it on top of the guide rails, and finally fasten it firmly to the pit wall.

6. Clean out debris from the pit before lowering the pump into the pit.

7. Fit the guide claw to the discharge port of the pump.

8. Slide the guide claw down the guide rails and lower the pump into the pit by means of a chain fastened to the lifting bracket. When the pump reaches the auto-coupling base unit, the pump will automatically connect tightly.

9. Hang up the end of the chain on a suitable hook at the top of the pit and in such a way that the chain cannot come into contact with the pump housing.

10. Adjust the length of the motor cable by coiling it up on a relief fitting to ensure that the cable is not damaged during operation. Fasten the relief fitting to a suitable hook at the top of the pit. Make sure that the cables are not sharply bent or pinched.

11. Connect the motor cable and the monitoring cable, if any.

Hookup auto coupling

See fig. B on page 25.

Proceed as follows:

1. Fit a crossbar in the pit.

2. Fit the stationary part of the auto coupling on top of the crossbar.

3. Fit the adapted piece of pipe for the movable part of the hookup auto coupling to the pump discharge port.

4. Fasten a shackle and a chain to the movable part of the hookup auto coupling.

5. Clean out debris from the pit before lowering the pump.

6. Lower the pump into the pit by means of the chain fastened to the lifting bracket. When the movable part of the auto coupling reaches the stationary part, the two will automatically connect tightly.

7. Hang up the end of the chain on a suitable hook at the top of the pit and in such a way that the chain cannot come into contact with the pump housing.

8. Adjust the length of the motor cable by coiling it up on a relief fitting to ensure that the cable is not damaged during operation. Fasten the relief fitting to a suitable hook at the top of the pit. Make sure that the cables are not sharply bent or pinched.

9. Connect the motor cable and the monitoring cable, if any.

NoteThe guide rails must not have any axial play as this would cause noise during pump operation.

Caution

Grease the gasket of the guide claw before lowering the pump into the pit.

When the pump has reached the auto-coupling base unit, shake the pump by means of the chain to make sure that it is placed in the correct position.

NoteThe free end of the cable must not be submerged as water may penetrate through the cable into the motor.

NoteThe free end of the cable must not be submerged as water may penetrate through the cable into the motor.

En

glis

h (

GB

)

11

7.2 Free-standing submerged installation

Pumps for free-standing submerged installation can stand freely on the bottom of the pit or similar location. See fig. C on page 27.

The pump must be mounted on separate feet (accessory).

In order to facilitate service on the pump, fit a flexible union or coupling to the discharge pipe for easy separation.

If a hose is used, make sure that the hose does not buckle and that the inside diameter matches that of the discharge port.

If a rigid pipe is used, the union or coupling, non-return valve and isolating valve should be fitted in the order mentioned, when viewed from the pump.

If the pump is installed in muddy conditions or on uneven ground, we recommend you to support the pump on bricks or a similar support.

1. Fit a 90 ° elbow to the pump discharge port and connect the discharge pipe or hose.

2. Lower the pump into the liquid by means of a chain fastened to the lifting bracket of the pump. We recommend you to place the pump on a plane, solid foundation. Make sure that the pump is hanging from the chain and not the cable.

3. Hang up the end of the chain on a suitable hook at the top of the pit and in such a way that the chain cannot come into contact with the pump housing.

4. Adjust the length of the motor cable by coiling it up on a relief fitting to ensure that the cable is not damaged during operation. Fasten the relief fitting to a suitable hook. Make sure that the cables are not sharply bent or pinched.

5. Connect the motor cable and the monitoring cable, if any.

8. Electrical connection

NoteThe free end of the cable must not be submerged as water may penetrate through the cable into the motor.

Note

If several pumps are to be installed in the same pit, the pumps must be installed at the same level in order to allow for optimum utilization of pump alternation.

Warning

Connect the pump to an external mains switch which ensures all-pole disconnection with a contact separation according to EN 60204-1, 5.3.2.

It must be possible to lock the mains switch in position 0. Type and requirements as specified in EN 60204-1, 5.3.2.

The electrical connection must be carried out in accordance with local regulations.

Warning

The pumps must be connected to a control box with a motor protection relay with an IEC trip class 10 or 15.

Warning

The permanent installation must be fitted with earth leakage circuit breaker (ELCB) with a tripping current < 30 mA.

Warning

When the pump has been installed, there must be at least 3 m free cable above the maximum liquid level.

Warning

Pumps installed in hazardous locations must be connected to a control box with a motor protection relay with an IEC trip class 10.

En

glish

(GB

)

12

The supply voltage and frequency are marked on the pump nameplate. The permissible voltage tolerance is - 10 %/+ 6 % of the rated voltage. Make sure that the motor is suitable for the power supply available at the installation site.

All pumps are supplied with 10 metres of cable and a free cable end.

All pumps are supplied without a control box.

The pump must be connected to one of these two controller types:

• a control box with motor-protective circuit breaker, such as a Grundfos CU 100 control box

• a Grundfos LC, LCD 107, LC, LCD 108 or LC, LCD 110 pump controller.

See fig. 4 or 5 and the installation and operating instructions for the selected control box or pump controller.

Potentially explosive environments

In potentially explosive environments you have two options:

• Use float switches made for Ex environment and a safety barrier in combination with either DC, DCD or LC, LCD 108.

• Use air bells in combination with LC, LCD 107.

For more information about the function of the thermal switches, see section 8.4 Thermal switches.

8.1 Wiring diagrams

Fig. 4 Wiring diagram for single-phase pumps

Fig. 5 Wiring diagram for three-phase pumps

Warning

Do not install Grundfos control boxes, pump controllers, Ex barriers and the free end of the supply cable in potentially explosive environments.

The explosion protection classification of the pump is CE 0344 II 2 G Ex d IIB T4 X. The classification of the installation site must be approved by the local firefighting authorities in each individual case.

On explosion-proof pumps, make sure that an external earth conductor is connected to the external earth terminal of the pump via a lead with a secure cable clamp. Clean the surface for external earth connection, and fit the cable clamp.

The cross-section of the earth conductor must be at least 4 mm2, e.g. type H07 V2-K (PVT 90 °) yellow/green.

Make sure that the earth connection is protected from corrosion.

Make sure that all protective equipment has been connected correctly.

Float switches used in potentially explosive environments must be approved for this application. They must be connected to the Grundfos LC, LCD 108 pump controller via the intrinsically safe LC-Ex4 barrier to ensure a safe circuit.

Warning

If the supply cable is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons.

Caution

Set the motor-protective circuit breaker to the rated current of the pump. The rated current is stated on the pump nameplate.

Warning

If the pump has an Ex mark on the nameplate, make sure that the pump is connected in accordance with the instructions given in this booklet.

Warning

Before installation and the first start-up of the pump, check the cable for visible defects to avoid short circuits.

TM

02

55

87

43

02

TM

02

55

88

36

02

150˚C160˚C

PE 1 2 3 64 5

1

T3T2 T1

L NPE

150˚C170˚C

PE 1 2 3 64 5

3

T3T2 T1

L1PE L2 L3

En

glis

h (

GB

)

13

8.2 CU 100 control box

The CU 100 control box incorporates a motor-protective circuit breaker and is available with level switch and cable.

Single-phase pumps

A run capacitor must be connected to the control box.

For capacitor sizes, see the table below.

Start and stop levels

The difference in level between start and stop can be adjusted by changing the free cable length.

Long free cable = large difference in level

Short free cable = small difference in level.

• To prevent air intake and vibrations, install the stop level switch in such a way that the pump is stopped before the liquid level is lowered below the upper edge of the clamp on the pump.

• Install the start level switch in such a way that the pump is started at the required level; however, the pump must always be started before the liquid level reaches the bottom inlet pipe to the pit.

Fig. 6 Start and stop levels

Pump typeCS,

starting capacitor

CR,run capacitor

[kW] [μF] [V] [μF] [V]

0.9 and 1.2 150 230 30 450

1.5 150 230 40 450

Note Both the two following points must be observed.

Warning

The CU 100 control box must not be used for Ex applications.See section 8.3 Pump controllers.

Warning

The pump must not run dry.

An additional level switch must be installed to ensure that the pump is stopped in case the stop level switch is not operating. See fig. 6.

The pump must be stopped when the liquid level reaches the upper edge of the clamp on the pump.

Float switches used in potentially explosive environments must be approved for this application. They must be connected to the Grundfos DC, DCD and LC, LCD 107, LCD 108 and LCD 110 pump controller via an intrinsically safe barrier to ensure a safe circuit.

TM

05

83

33

22

13

Alarm

Start

Stop

En

glish

(GB

)

14

8.3 Pump controllers

The following LC and LCD pump controllers are available:

LC controllers are for one-pump-installations and LCD controllers are for two-pump-installations.

• LC 107 and LCD 107 with air bells.

• LC 108 and LCD 108 with float switches.

• LC 110 and LCD 110 with electrodes.

In the following description, "level switches" can be air bells, float switches or electrodes, depending on the pump controller selected.

Controllers for single-phase pumps incorporate capacitors.

LC: The controller is fitted with two or three level switches: One for start and the other for stop of pump. The third level switch, which is optional, is for high-level alarm.

LCD: The controller is fitted with three or four level switches: One for common stop and two for start of the pumps. The fourth level switch, which is optional, is for high-level alarm.

When installing the level switches, the following points should be observed:

• To prevent air intake and vibrations, install the stop level switch in such a way that the pump is stopped before the liquid level is lowered below the middle of the motor housing.

• The start level switch should be installed in such a way that the pump is started at the required level; however, the pump must always be started before the liquid level reaches the bottom inlet pipe to the pit.

• The high-level alarm switch, if installed, should always be installed about 10 cm above the start level switch; however, the alarm must always be given before the liquid level reaches the inlet pipe to the pit.

For further settings, see the installation and operating instructions for the pump controller selected.

8.4 Thermal switches

All SEG pumps have two sets of thermal switches incorporated in the stator windings.

Thermal switch, circuit 1 (T1-T3), breaks the circuit at a winding temperature of approx. 150 °C.

Thermal switch, circuit 2 (T1-T2), breaks the circuit at a winding temperature of approx. 170 °C (three-phase pumps) or 160 °C (single-phase pumps).

The maximum operating current of the thermal switches is 0.5 A at 500 VAC and cos φ 0.6. The switches must be able to break a coil in the supply circuit.

In the case of standard pumps, both thermal switches can (when closing the circuit after cooling) generate automatic restarting of the pump via the controller.

Warning

The pump must not run dry.

An additional level switch must be installed to ensure that the pump is stopped in case the stop level switch is not operating.

Stop the pump when the liquid level reaches the upper edge of the clamp on the pump.

Float switches used in explosive environments must be approved for this application. They must be connected to the Grundfos LC, LCD 108 LC 107, LC 110 pump controller via the intrinsically safe LC-Ex4 barrier to ensure a safe circuit.

Note This thermal switch must be connected for all pumps.

Warning

After thermal cutout, explosion-proof pumps must be restarted manually.The thermal switch (circuit 2) must be connected for manual restarting of these pumps.

Warning

The separate motor-protective circuit breaker/control box must not be installed in potentially explosive environments.

En

glis

h (

GB

)

15

8.5 Frequency converter operation

For frequency converter operation please observe the following information.

Requirements must be fulfilled.

Recommendations ought to be fulfilled.

Consequences should be considered.

8.5.1 Requirements

• The thermal protection of the motor must be connected.

• Peak voltage and dU/dt must be in accordance with the table below. The values stated are maximum values supplied to motor terminals. The cable influence has not been taken into account. See data sheet for the frequency converter used regarding the actual values and cable influence on the peak voltage and dU/dt.

• If the pump is an Ex-approved pump, check if the Ex certificate of the specific pump allows the use of frequency converter.

• Set the frequency converter U/f ratio according to the motor data.

• Local regulations/standards must be fulfilled.

8.5.2 Recommendations

Before installing a frequency converter, calculate the lowest allowable frequency in the installation in order to avoid zero flow.

• Do not reduce the motor speed to less than 30 % of rated speed.

• Keep the flow velocity above 1 m/sec.

• Let the pump run at rated speed at least once a day in order to prevent sedimentation in the piping system.

• Do not exceed the frequency indicated on the nameplate. In this case there is risk of motor overload.

• Keep the motor cable as short as possible. The peak voltage will increase with the length of the motor cable. See data sheet for the frequency converter used.

• Use input and output filters on the frequency converter. See data sheet for the frequency converter used.

• Use screened motor cable if there is a risk that electrical noise can disturb other electrical equipment. See data sheet for the frequency converter used.

8.5.3 Consequences

When operating the pump via a frequency converter, please be aware of these possible consequences:

• The locked-rotor torque will be lower. How much lower will depend on the frequency converter type. See the installation and operating instructions for the frequency converter used for information on the locked-rotor torque available.

• The working condition of bearings and shaft seal may be affected. The possible effect will depend on the application. The actual effect cannot be predicted.

• The acoustic noise level may increase. See the installation and operating instructions for the frequency converter used for advice as to how to reduce the acoustic noise.

NoteFrequency converter operation will influence the efficiency of the grinder system.

Max. repetitive peak voltage

[V]

Max. dU/dt UN 400 V[V/μ sec.]

650 2000

En

glish

(GB

)

16

9. Start-up

9.1 General start-up procedure

Proceed as follows:

1. Remove the fuses, and check that the impeller can rotate freely. Turn the grinder head by hand.

2. Check the condition of the oil in the oil chamber. See also section 10.5 Oil change.

3. Check whether the monitoring units, if used, are operating satisfactorily.

4. Check the setting of the air bells, float switches or electrodes.

5. Open the isolating valves, if fitted.Auto-coupling: It is important to grease the gasket of the guide claw before lowering the pump into the pit.

6. Lower the pump into the liquid and insert the fuses.Auto-coupling: Check that the pump is in right position on the auto-coupling base unit.

7. Check that the system has been filled with liquid and vented. The pump is self-venting.

8. Switch on the power supply to the pump. When power is on, the pump will start and pump down to the dry-running level. This process can be used to check that the pump functions correctly.

Check the condition of the oil in the chamber after one week of operation after replacement of the shaft seal. See section 10. Maintenance and service.

9.2 Operating modes

The pumps are designed for intermittent operation (S3). When completely submerged, the pumps can also operate continuously (S1).

Fig. 7 Operating levels

S3, intermittent operation

S3 operation is a series of identical duty cycles (TC) each with a constant load for a period, followed by a rest period. Thermal equilibrium is not reached during the cycle. See fig. 8.

Fig. 8 S3 operation

S1, continuous operation

In this operating mode, the pump can operate continuously without having to be stopped for cooling. Being completely submerged, the pump is sufficiently cooled by the surrounding liquid. See fig. 9.

Fig. 9 S1 operation

Warning

Before starting work on the pump, make sure that the fuses have been removed or the mains switch has been switched off. Make sure that the power supply cannot be accidentally switched on.

Make sure that all protective equipment has been connected correctly.

The pump must not run dry.

Warning

The pump must not be started if the atmosphere in the pit is potentially explosive.

Warning

Opening the clamp when the pump is started can lead to personal injury or death.

Caution

In case of abnormal noise or vibrations from the pump, other pump failure or power supply failure, stop the pump immediately. Do not attempt to restart the pump until the cause of the fault has been found and the fault corrected.

TM

04

71

26

15

10

TM

04

92

31

37

10

TM

04

45

28

15

09

S1

S3

P

Operation

StopTC

P

t

Operation

Stop

En

glis

h (

GB

)

17

9.3 Direction of rotation

All single-phase pumps are factory-wired for the correct direction of rotation.

Before starting up three-phase pumps, check the direction of rotation.

An arrow on the stator housing and an arrow at the pump inlet indicate the correct direction of rotation.

Correct direction of rotation is clockwise when viewed from above. When started, the pump will jerk in the opposite direction of the direction of rotation.

If the direction of rotation is wrong, interchange two phases. See fig. 4 or 5.

Checking the direction of rotation

Check the direction of rotation in one of the following ways every time the pump is connected to a new installation.

Procedure 1:

1. Start the pump and measure the quantity of liquid or the discharge pressure.

2. Stop the pump and interchange two phases.

3. Restart the pump and measure the quantity of liquid or the discharge pressure.

4. Stop the pump.

5. Compare the results taken under points 1 and 3. The connection which gives the larger quantity of liquid or the higher pressure is the correct direction of rotation.

Procedure 2:

1. Let the pump hang from a lifting device, e.g. the hoist used for lowering the pump into the pit.

2. Start and stop the pump while observing the movement (jerk) of the pump.

3. If connected correctly, the pump will jerk in the opposite direction of the direction of rotation.See fig. 10.

4. If the direction of rotation is wrong, interchange two phases. See fig. 4 or 5.

Fig. 10 Jerk direction

10. Maintenance and service

Flush the pump thoroughly with clean water before carrying out maintenance and service. Rinse the pump parts in water after dismantling.

10.1 Inspection

Pumps running normal operation should be checked every 3000 operating hours or at least once a year. If the dry-solids content of the pumped liquid is very high or sandy, check the pump at shorter intervals.

Check the following points:

• Power consumption See pump nameplate.

• Oil level and oil conditionWhen the pump is new or after replacement of the shaft seal, check the oil level after one week of operation.Use Shell Ondina X420 oil or similar type.See section 10.5 Oil change.

The table below states the quantity of oil in the oil chamber of SEG pumps:

NoteThe pump may be started for a very short period without being submerged to check the direction of rotation.

TM

02

53

93

28

02

Warning

Before starting work on the pump, make sure that the fuses have been removed or the mains switch has been switched off. Make sure that the power supply cannot be accidentally switched on.

All rotating parts must have stopped moving.

Warning

Except for service on the pump parts, all other service work must be carried out by Grundfos or a service workshop authorised by Grundfos.

Warning

When loosening the screws of the oil chamber, note that pressure may have built up in the chamber. Do not remove the screws until the pressure has been fully relieved.

Pump typeQuantity of oil in oil

chamber [l]

SEG up to 1.5 kW 0.17

SEG 2.2 to 4.0 kW 0.42

Note Used oil must be disposed of in accordance with local regulations.

En

glish

(GB

)

18

• Cable entryMake sure that the cable entry is watertight and that the cables are not sharply bent and/or pinched. See section 10.6 Service kits.

• Pump partsCheck the impeller, pump housing, etc. for possible wear. Replace defective parts. See section 10.6 Service kits.

• Ball bearingsCheck the shaft for noisy or heavy operation (turn the shaft by hand). Replace defective ball bearings.A general overhaul of the pump is usually required in case of defective ball bearings or poor motor function. This work must be carried out by Grundfos or a service workshop authorised by Grundfos.

• Grinder system/partsIn case of frequent choke-ups, check the grinder system for visible wear. When worn, the edges of the grinding parts are round and worn. Compare with a new grinder system.

10.2 Replacing the grinder system

For position numbers, see page 35.

Dismantling

1. Loosen screw (pos. 188a) in one of the pump feet.

2. Loosen grinder ring (pos. 44) and open the bayonet socket by knocking/turning the grinder ring 15 to 20 ° clockwise. See fig. 11.

Fig. 11 Removing the grinder ring

3. Carefully prise grinder ring (pos. 44) out of the pump housing with a screwdriver.Make sure that the grinder ring does not get stuck against the grinder head!

4. Insert a punch into the hole in the pump housing to hold the impeller.

5. Remove screw (pos. 188a) in the shaft end and lock ring (pos. 66).

6. Remove grinder head (pos. 45).

Adjusting the impeller clearance

See fig. 12.

1. Gently tighten adjusting nut (pos. 68) (spanner size 24) until impeller (pos. 49) cannot rotate any more.

2. Loosen the adjusting nut by 1/4 turn.

Fig. 12 Adjusting the impeller clearance

Warning

Before starting work on the pump, make sure that the fuses have been removed or the mains switch has been switched off. Make sure that the power supply cannot be accidentally switched on.

All rotating parts must have stopped moving.

Warning

Beware of the sharp edges on the impeller, grinder head and grinder ring.

CautionDuring service the painted surface may be damaged. Remember to restore the painted surface by applying new paint.

TM

02

53

92

28

02

TM

02

53

91

28

02

En

glis

h (

GB

)

19

Assembly

1. When fitting grinder head (pos. 45), the projections on the back of the grinder head must engage with the holes in the impeller (pos. 49).

2. Tighten screw (pos. 188a) in the shaft end to 20 Nm. Do not forget the lock washer.

3. Fit grinder ring (pos. 44).

4. Turn grinder ring (pos. 44) 15 to 20 ° anti-clockwise until it is tightened.

5. Check that the grinder ring does not touch the grinder head.

6. Tighten screw (pos. 188a) to 16 Nm.

7. Check that the grinder head rotates freely and noiselessly.

10.3 Cleaning the pump housing

For position numbers, see page 35.

1. Remove clamp (pos. 92).

2. Lift the motor part out of pump housing (pos. 50). The impeller and grinder head are removed together with the motor part.

3. Clean the pump housing and the impeller.

4. Place the motor part with impeller and grinder head in the pump housing.

5. Fit and tighten the clamp (pos. 92).

See also section 10.4 Checking/replacing the shaft seal.

10.4 Checking/replacing the shaft seal

The shaft seal is a complete unit for all SEG pumps.

To make sure that the shaft seal is intact, the oil should be checked.

If the oil contains more than 20 % water, it is an indication that the shaft seal is defective and must be replaced. If the shaft seal is still used, the motor will be damaged.

If the oil is clean, it can be reused. See also section 10. Maintenance and service.

For position numbers, see page 35.

To check the shaft seal, proceed as follows:

1. Remove grinder ring (pos. 44). See section 10.2 Replacing the grinder system.

2. Remove screw (pos. 188a) from the shaft end.

3. Loosen and remove clamp (pos. 92).

4. Lift the motor part out of pump housing (pos. 50). The impeller and grinder head are removed together with the motor part.

5. Remove grinder head (pos. 45).

6. Remove impeller (pos. 49) from the shaft.

7. Drain the oil from the oil chamber.See section 10.5 Oil change.

8. Remove screws (pos. 188a) securing shaft seal (pos. 105).

9. Lift shaft seal (pos. 105) out of the oil chamber according to the lever principle using the two dismounting holes in shaft seal carrier (pos. 58) and two screwdrivers.

10. Check the condition of the shaft where the secondary seal of the shaft seal touches the shaft. Bush (pos. 103) on the shaft must be intact. If the bush is worn and must be replaced, the pump must be checked by Grundfos or an authorised service workshop.

If the shaft is intact, proceed as follows:

1. Check/clean the oil chamber.

2. Lubricate the faces in contact with the shaft seal with oil (pos. 105a) (O-rings and shaft).

3. Insert new shaft seal (pos. 105) using the plastic bush included in the kit.

4. Tighten screws (pos. 188a) securing the shaft seal to 16 Nm.

5. Fit the impeller. Make sure that key (pos. 9a) is fitted correctly.

6. Fit pump housing (pos. 50).

7. Fit and tighten clamp (pos. 92).

8. Fill the oil chamber with oil.

For adjustment of impeller clearance, see section 10.2 Replacing the grinder system.

Note Used oil must be disposed of in accordance with local regulations.

Warning

When loosening the screws of the oil chamber, note that pressure may have built up in the chamber. Do not remove the screws until the pressure has been fully relieved.

En

glish

(GB

)

20

10.5 Oil change

Every 3000 operating hours or at least once a year, change the oil in the oil chamber as described below.

If the shaft seal has been changed, the oil must be changed as well. See section 10.4 Checking/replacing the shaft seal.

Draining of oil

1. Remove both oil screws to allow all the oil to drain from the chamber.

2. Check the oil for water and impurities. If the shaft seal has been removed, the oil will give a good indication of the condition of the shaft seal.

Oil filling, pump lying down

See fig. 13.

1. Place the pump in such a position that it is lying on the stator housing and the discharge flange and that the oil screws are pointing upwards.

2. Fill oil into the oil chamber through the upper hole until it starts running out of the lower hole. The oil level is now correct. See section 10.1 Inspection.

3. Fit both oil screws using the packing material included in the kit. See section 10.6 Service kits.

Fig. 13 Oil filling holes

Oil filling, pump in upright position

1. Place the pump on a plane, horizontal surface.

2. Fill oil into the oil chamber through one of the holes until it starts running out of the other hole. For oil quantity, see section 10.1 Inspection.

3. Fit both oil screws using the packing material included in the kit. See section 10.6 Service kits.

Warning

When loosening the screws of the oil chamber, note that pressure may have built up in the chamber. Do not remove the screws until the pressure has been fully relieved.

Note Used oil must be disposed of in accordance with local regulations.

TM

02

53

90

28

02

Oil fill

Oil level

Oil filling

Oil level

En

glis

h (

GB

)

21

10.6 Service kits

The service kits in the table below are available for all SEG pumps.

The kits can be ordered as required:

* For pumps produced in week 19, 2014: P.C. code 1419.

10.7 Contaminated pumps

If Grundfos is requested to service the pump, Grundfos must be contacted with details about the pumped liquid, etc. before the pump is returned for

service. Otherwise Grundfos can refuse to accept the pump for service.

Possible costs of returning the pump are paid by the customer.

However, any application for service (no matter to whom it may be made) must include details about the pumped liquid if the pump has been used for liquids which are injurious to health or toxic.

Before a pump is returned, it must be cleaned in the best possible way.

Warning

Before starting work on the pump, make sure that the fuses have been removed or the mains switch has been switched off. Make sure that the power supply cannot be accidentally switched on.

All rotating parts must have stopped moving.

Service kit Contents Pump type Material Product number

Shaft seal kit Shaft seal complete

SEG.40.09 - 15 BQQP 96076122

BQQV 96645160

SEG.40.26 - 40 BQQP 96076123

BQQV 96645275

O-ring kit O-rings and gaskets for oil screws

SEG.40.09 - 15

NBR9607612498682327*

FKM9664606198682329*

SEG.40.26 - 40NBR 96076125

FKM 96646062

Grinder systemGrinder head, grinder ring, shaft screw and locking screw

Heavy duty applications

96903344

Standard applications

96076121

ImpellerImpeller complete with adjusting nut, shaft screw and key

SEG.40.09 96076115

SEG.40.12 96076116

SEG.40.15 96076117

SEG.40.26 96076118

SEG.40.31 96076119

SEG.40.40 96076120

Oil

1 litre of oil, type Shell Ondina X420.See section 10. Maintenance and service for required quantity in oil chamber.

All types 96586753

Lifting bracket Lifting bracket and screwSEG.40.09 - 15 96690420

SEG.40.26 - 40 96690428

Note A possible replacement of the cable must be carried out by Grundfos or a service workshop authorised by Grundfos.

Warning

If a pump has been used for a liquid which is injurious to health or toxic, the pump will be classified as contaminated.

En

glish

(GB

)

22

11. Fault finding

Warning

All regulations applying to pumps installed in potentially explosive environments must be observed.

Make sure that no work is carried out in potentially explosive atmosphere.

Warning

Before attempting to diagnose any fault, make sure that the fuses have been removed or the mains switch has been switched off. Make sure that the power supply cannot be accidentally switched on.

All rotating parts must have stopped moving.

Fault Cause Remedy

1. Motor does not start. Fuses blow, or motor-protective circuit breaker trips immediately.Caution: Do not start again!

a) Supply failure; short-circuit; earth-leakage fault in cable or motor winding.

Have the cable and motor checked and repaired by a qualified electrician.

b) Wrong type of fuse. Install fuses of the correct type.

c) Impeller blocked by impurities. Clean the impeller.

d) Air bell, float switch or electrode out of adjustment or defective.

Check the air bells, float switches or electrodes.

2. The pump operates, but the motor-protective circuit breaker trips after a short while.

a) Low setting of thermal relay in motor-protective circuit breaker.

Set the relay in accordance with the specifications on the nameplate.

b) Increased current consumption due to large voltage drop.

Measure the voltage between two motor phases.Tolerance: - 10 %/+ 6 %.

c) Impeller blocked by impurities. Increased current consumption in all three phases.

Clean the impeller.

d) Impeller clearance incorrect. Readjust the impeller. See fig. 12 in section 10.2.

3. The pump's thermal switch trips when the pump has been operating for some time.

a) Too high liquid temperature. Reduce the liquid temperature.

b) Too high liquid viscosity. Dilute the liquid.

c) Wrong electrical connection.(If the pump is star-connected to a delta connection, the result will be very low undervoltage).

Check and correct the electrical installation.

4. The pump operates at below-standard performance and increased power consumption.

a) Impeller blocked by impurities. Clean the impeller.

Check the direction of rotation. If it is not correct, interchange two phases. See section 9.3 Direction of rotation.

b) Wrong direction of rotation.

5. The pump operates but delivers no liquid.

a) Discharge valve closed or blocked.

Check the discharge valve and possibly open and/or clean it.

b) Non-return valve blocked. Clean the non-return valve.

Vent the pump.c) Air in pump.

6. The pump is blocked. a) Grinder system is worn. Replace the grinder system.

En

glis

h (

GB

)

23

12. Technical data

Supply voltage

• 1 x 230 V - 10 %/+ 6 %, 50 Hz.

• 3 x 230 V - 10 %/+ 6 %, 50 Hz.

• 3 x 400 V - 10 %/+ 6 %, 50 Hz.

Winding resistances

* The table values do not include the cable.Resistance in cables: 2 x 10 m, approx. 0.28 Ω.

Enclosure class

IP68. According to IEC 60529.

Explosion protection classification

CE II 2 G, Ex d IIB T4 X. According to EN 60079-0:2006.

Insulation class

F (155 °C).

Pump curves

Pump curves are available via www.grundfos.com.

The curves are to be considered as a guide. They must not be used as guarantee curves.

Test curves for the supplied pump are available on request.

Sound pressure level

The sound pressure level of the pumps is lower than the limiting values stated in the EC Council Directive 2006/42/EC relating to machinery.

13. DisposalThis product or parts of it must be disposed of in an environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest Grundfos company or service workshop.

Subject to alterations.Motor size Winding resistance*

Single-phase motor

[kW] Starting winding Main winding

0.94.5 Ω 2.75 Ω

1.2

1.5 4.1 Ω 2.9 Ω

Three-phase motor

3 x 230 V 3 x 400 V

0.9

6.8 Ω 9.1 Ω1.2

1.5

2.6 3.4 Ω 4.56 Ω3.1

2.52 Ω 3.36 Ω4.0

Ap

pe

nd

ix

Appendix 1

One-pump installation on auto-coupling

Fig. A

TM

02

53

88

13

10

24

Ap

pe

nd

ix

One-pump installation on hookup auto-coupling

Fig. B

TM

02

53

86

13

10

25

Ap

pe

nd

ix

Free-standing installation

Fig. C

TM

02

53

87

13

10

/ T

M0

2 5

97

4 1

31

0

26

Ap

pe

nd

ix

Dimensions

Weights

Power[kW]

A B C D DN2 E F G1 H I M N O V1 Y2 Z3

0.9 and 1.2 466 100 255 99 DN 40 154 216 214 71 123 134 100

min. 600

510 116 115

1.5 (3 phase) 466 100 255 99 DN4 0 154 216 214 71 123 134 100 510 116 115

1.5 (1 phase) 471 100 255 99 DN 40 154 216 214 71 123 134 100 515 116 115

2.6 522 100 292 119 DN 40 173 256 215 60 143 134 100 582 115 115

3.1 and 4.0 562 100 292 119 DN 40 173 256 214 60 144 134 100 622 115 115

Power[kW]

Z4 Z6 Z6a Z7 Z9 Z10a Z11 Z12a Z15 Z16 Z18 Z19 ZDN1

0.9 and 1.2 118 424 365 374 70 3/4"-1" 546 68 90 221 271 120 Rp 11/2

1.5 (3 phase) 118 424 365 374 70 3/4"-1" 546 68 90 221 271 120 Rp 11/2

1.5 (1 phase) 118 424 365 374 70 3/4"-1" 551 68 90 221 271 120 Rp 11/2

2.6 118 460 365 410 70 - 614 80 90 221 271 120 Rp 11/2

3.1 and 4.0 118 460 365 410 70 - 652 80 90 221 271 120 Rp 11/2

Pump typeWeight

[kg]

SEG.40.09.2.1.502 40

SEG.40.09.2.50B/C 39

SEG.40.12.2.1.502 40

SEG.40.12.2.50B 40

SEG.40.12.2.50C 39

SEG.40.15.2.1.502 53

SEG.40.15.2.50B 40

SEG.40.15.2.50C 39

SEG.40.26.2.50B/C 62

SEG.40.31.2.50B/C 70

SEG.40.40.2.50B/C 40

27

Ap

pe

nd

ix

Appendix 1

Pos.Designation

GB

Описание

BG

Popis

CZ

Betegnelse

DK

6a Pin Щифт Kolík Stift

7a Rivet Нит Nýt Nitte

9a Key Фиксатор Pero Feder

37a O-rings О-пръстени O-kroužky O-ringe

44 Grinder ring Пръстен Řezací kolo Snittering

45 Grinder head Режеща глава Hlava mělnicího zařízení Snittehoved

48 Stator Статор Stator Stator

48a Terminal board Клеморед Svorkovnice Klembræt

49 Impeller Работно колело Oběžné kolo Løber

50 Pump housing Помпен корпус Těleso čerpadla Pumpehus

55 Stator housing Корпус на статора Těleso statoru Statorhus

58 Shaft seal carrier Носач на уплътнението при вала Unašeč ucpávky Akseltætningsholder

66 Locking ring Фиксиращ пръстен Pojistný kroužek Låsering

68 Adjusting nut Регулираща гайка Stavěcí matice Justermøtrik

76 Nameplate Табела Typový štítek Typeskilt

92 Clamp Скоба Fixační objímka Spændebånd

102 O-ring О-пръстени O-kroužek O-ring

103 Bush Втулка Pouzdro Bøsning

104 Seal ring Уплътняващ пръстен Těsnicí kroužek Simmerring

105105a

Shaft seal Уплътнение при вала Hřídelová ucpávka Akseltætning

107 O-rings О-пръстени O-kroužky O-ringe

112a Locking ring Фиксиращ пръстен Pojistný kroužek Låsering

153 Bearing Лагер Ložisko Leje

154 Bearing Лагер Ložisko Leje

155 Oil chamber Маслото в камерата Olejové komoře Oliekammer

158 Corrugated spring Гофрирана пружина Tlačná pružina Bølgefjeder

159 Washer Шайба Podložka Skive

172 Rotor/shaft Ротор/вал Rotor/hřídel Rotor/aksel

173 Screw Винт Šroub Skrue

173a Washer Шайба Podložka Skive

176 Inner plug part Вътрешна част на щепселаVnitřní část kabelové průchodky

Indvendig stikdel

181 Outer plug part Външна част на щепселаVnější část kabelové průchodk

Udvendig stikdel

188a Screw Винт Šroub Skrue

190 Lifting bracket Ръкохватка Zvedací rukojet' Løftebøjle

193 Oil screw Винт при камерата за масло Olejová zátka Olieskrue

193a Oil Масло Olej Olie

194 Gasket Гарнитура Těsnicí kroužek Pakning

198 O-ring О-пръстен O-kroužek O-ring

28

Ap

pe

nd

ix

Pos.Bezeichnung

DE

Seletus

EE

Περιγραφή

GR

Descripción

ES

6a Stift Tihvt Πείρος Pasador

7a Kerbnagel Neet Πριτσίνι Remache

9a Keil Kiil Κλειδί Chaveta

37a O-Ringe O-ringid ∆ακτύλιοι-Ο Juntas tóricas

44 Schneidring Purusti plaat ∆ακτύλιος άλεσης Anillo de corte

45 Schneidkopf Purusti pea Κεφαλή άλεσης Cabezal de corte

48 Stator Staator Στάτης Estator

48a Klemmbrett Klemmliist Κλέμες σύνδεσης Caja de conexiones

49 Laufrad Tööratas Πτερωτή Impulsor

50 Pumpengehäuse Pumbapesa Περίβλημα αντλίας Cuerpo de bomba

55 Statorgehäuse Staatori korpus Περίβλημα στάτη Alojamiento de estator

58 Dichtungshalter Võllitihendi alusplaat Φορέας στυπιοθλίπτη άξονα Soporte de cierre

66 Sicherungsring Lukustusrõngas Ασφαλιστικός δακτύλιος Anillo de cierre

68 Justiermutter Seademutter Ρυθμιστικό περικόχλιο Tuerca de ajuste

76 Leistungsschild Andmeplaat Πινακίδα Placa de identificación

92 Spannband Klamber Σφιγκτήρας Abrazadera

102 O-Ring O-ring ∆ακτύλιος-Ο Junta tórica

103 Buchse Puks Αντιτριβικός δακτύλιος Casquillo

104 Dichtungsring Tihend Στεγανοποιητικός δακτύλιος Anillo de cierre

105105a

Wellenabdichtung Võllitihend Στυπιοθλίπτης άξονα Cierre

107 O-Ringe O-ringid ∆ακτύλιοι-Ο Juntas tóricas

112a Sicherungsring Lukustusrõngas Ασφαλιστικός δακτύλιος Anillo de cierre

153 Lager Laager Έδρανο Cojinete

154 Lager Laager Έδρανο Cojinete

155 Ölsperrkammer Õlikamber Θάλαμος λαδιού Cámara de aceite

158 Gewellte Feder Vedruseib Αυλακωτό ελατήριο Muelle ondulado

159 Unterlegscheibe Seib Ροδέλα Arandela

172 Rotor/Welle Rootor/võll Ρότορας/άξονας Rotor/eje

173 Schraube Polt Βίδα Tornillo

173a Unterlegscheibe Seib Ροδέλα Arandela

176 Kabelanschluß,innerer Teil

Pistiku sisemine pool Εσωτερικό τμήμα φις Parte de clavija interior

181 Kabelanschluß,äußerer Teil

Pistiku välimine pool Εξωτερικό τμήμα φις Parte de clavija exterior

188a Schraube Polt Βίδα Tornillo

190 Transportbügel Tõsteaas Χειρολαβή Asa

193 Ölschraube Õlikambri kork Βίδα λαδιού Tornillo de aceite

193a Öl Õli Λάδι Aceite

194 Dichtung Tihend Τσιμούχα Junta

198 O-Ring O-ring ∆ακτύλιος-Ο Junta tórica

29

Ap

pe

nd

ix

Pos.Description

FR

Opis

HR

Descrizione

IT

Сипаттама

KZ

6a Broche nožica Perno Штифт

7a Rivet zarezani čavao Rivetto Тойтарма шеге

9a Clavette opruga Chiavetta Шпонка

37a Joints toriques O-prsten O-ring Тығыздағыш сақиналар

44 Anneau broyeur prsten za rezanje Anello trituratore Майдалау сақинасы

45 Tête de broyeur glava za rezanje Trituratore Майдалау бас бөлігі

48 Stator stator Statore Статор

48a Bornier priključna letvica Morsettiera Тақта терминалы

49 Roue rotor Girante Жұмыс дөңгелегі

50 Corps de pompe kućište crpke Corpo pompa Сорғы корпусы

55 Logement de stator kućište statora Cassa statore Статор корпусы

58 Support de garniture mécanique

držač brtveSupporto tenuta meccanica

Білік тығыздауышының негізгі бөлігі

66 Anneau de serrage sigurnosni prsten Anello di arresto Құлыптау сақинасы

68 Ecrou de réglage matica za justiranje Dado di regolazione Сомынды реттеу

76 Plaque signalétique natpisna pločicaTarghetta di identificazione

Зауыттық тақтайша

92 Collier de serrage zatezna traka Fascetta Қысқыш

102 Joint torique O-prsten O-ring Тығыздағыш сақина

103 Douille brtvenica Bussola Втулка

104 Anneau d'étanchéité brtveni prsten Anello di tenuta Сақиналы тығыздауыш

105105a

Garniture mécanique brtva vratila Tenuta meccanica Білік тығыздағышы

107 Joints toriques O-prsten O-ring Тығыздағыш сақиналар

112a Anneau de serrage sigurnosni prsten Anello di arresto Құлыптау сақинасы

153 Roulement ležaj Cuscinetto Подшипник

154 Roulement ležaj Cuscinetto Подшипник

155 Chambre à huile komora za ulje Camera dell'olio Май камерасы

158 Ressort ondulé valovita opruga Molla ondulata Серіппелі сақина

159 Rondelle podložna pločica Rondella Шайба

172 Rotor/arbre rotor/vratilo Gruppo rotore/albero Ротор/білік

173 Vis vijak Vite Бұранда

173a Rondelle podložna pločica Rondella Шайба

176 Partie intérieure de la fiche kabel. priključak, nutarnji dio

Parte interna del connettore

Электр қосқышының ішкі бөлігі

181 Partie extérieure de la fichekabel. priključak, vanjski dio

Parte esterna del connettore

Электр қосқышының сыртқы бөлігі

188a Vis vijak Vite Бұранда

190 Poignée de levage transportni stremen Maniglia Көтеру ілмегі

193 Bouchon d'huile vijak za ulje Tappo dell'olio Май тығыны

193a Huile ulje Olio Май

194 Joint d'étanchéité brtva Guarnizione Аралық қабат

198 Joint torique O-prsten O-ring Тығыздағыш сақина

30

Ap

pe

nd

ix

Pos.Apraksts

LV

Aprašymas

LT

Megnevezés

HU

Omschrijving

NL

6a Tapa Vielokaištis Csap Paspen

7a Kniede Kniedė Szegecs Klinknagel

9a Atslēga Kaištis Rögzítőék Spie

37a Apaļa šķērsgriezuma blīvgredzeni

O žiedai O-gyűrűk O-ring

44 Griezējgredzens Smulkintuvo žiedas Őrlőgyűrű Snijring

45 Griezējgalva Smulkintuvo galvutė Őrlőfej Snijkop

48 Stators Statorius Állórész Stator

48a Spaiļu plate Kontaktų plokštė Kapcsoló tábla Aansluitblok

49 Darbrats Darbaratis Járókerék Waaier

50 Sūkņa korpuss Siurblio korpusas Szivattyúház Pomphuis

55 Statora korpuss Statoriaus korpusas Állórészház Motorhuis

58 Vārpstas blīvējuma turētājs Riebokšlio lizdas Tengelytömítés-keret Dichtingsplaat

66 Sprostgredzens Fiksavimo žiedas Rögzítőgyűrű Borgring

68 Regulēšanas uzgrieznis Reguliavimo veržlė Beállítóanya Afstelmoer

76 Pases datu plāksnīte Vardinė plokštelė Adattábla Typeplaat

92 Apskava Apkaba Bilincs Span ring

102 Apaļa šķērsgriezuma blīvgredzens

O žiedas O-gyűrű O-ring

103 Ieliktnis Įvorė Tömítőgyűrű Bus

104 Blīvējošais gredzens Sandarinimo žiedas Tömítőgyűrű Oliekeerring

105105a

Vārpstas blīvējums Riebokšlis Tengelytömítés As afdichting

107 Apaļa šķērsgriezuma blīvgredzeni

O žiedai O-gyűrűk O-ringen

112a Sprostgredzens Fiksavimo žiedas Rögzítőgyűrű Borgring

153 Gultnis Guolis Csapágy Kogellager

154 Gultnis Guolis Csapágy Kogellager

155 Eļļas kamera Alyvos kamera Olajkamra Oliekamer

158 Viļņotā atspere Rifliuota spyruoklė Hullámrugó Drukring

159 Paplāksne Poveržlė Alátét Ring

172 Rotors/vārpsta Rotorius/velenas Forgórész/tengely Rotor/as

173 Skrūve Varžtas Csavar Schroef

173a Paplāksne Poveržlė Alátét Ring

176 Spraudņa iekšējā daļa Vidinė elektros jungties dalis Belső kábelbevezetésKabelconnector inwendig

181 Spraudņa ārējā daļa Išorinė elektros jungties dalis Külső kábelbevezetésKabelconnector uitwendig

188a Skrūve Varžtas Csavar Inbusbout

190 Rokturis Kėlimo rankena Emelőfül Ophangbeugel

193 Eļļas aizgrieznis Alyvos sraigtas Olajtöltőnyílás zárócsavarja Inbusbout

193a Eļļa Alyva Olaj Olie

194 Blīvslēgs Tarpiklis Tömítés Pakkingring

198 Apaļa šķērsgriezuma blīvgredzens

O žiedas O-gyűrű O-ring

31

Ap

pe

nd

ix

Pos.Opis

PL

Descrição

PT

Наименование

RU

6a Kołek Pino Штифт

7a Nit Rebite Заклепка

9a Klin Chaveta Шпонка

37a Pierścień O-ring O-rings Уплотнительное кольцо круглого сечения

44 Pierścień tnący Anilha da trituradora Кольцо режущего механизма

45 Głowica tnąca Cabeça da trituradora Головка режущего механизма

48 Stator Estator Статор

48a Listwa przyłączeniowa Caixa terminal Выходной щит

49 Wirnik Impulsor Рабочее колесо

50 Korpus pompy Voluta da bomba Корпус насоса

55 Obudowa statora Carcaça do estator Корпус статора

58 Mocowanie uszczelnienia wału

Suporte do empanque Корпус уплотнения вала

66 Pierścień mocujący Anilha de fixação Стопорная шайба

68 Nakrętkadopasowująca

Porca de ajuste Регулировочная гайка

76 Tabliczka znamionowa Placa de característicasФирменная табличка с номинальными техническими данными

92 Zacisk Gancho Стяжная скоба

102 Pierścień O-ring O-ring Уплотнительное кольцо круглого сечения

103 Tulejka Anilha Втулка

104 Pierścień uszczelniający

Anilha de empanque Уплотнительное кольцо

105105a

Uszczelnienie wału Empanque Уплотнение вала

107 Pierścień O-ring O-rings Уплотнительное кольцо круглого сечения

112a Pierścień mocujący Anilha de fixação Стопорная шайба

153 Łożysko Rolamento Подшипник

154 Łożysko Rolamento Подшипник

155 Komorze olejowej Compartimento do óleo Масляной камере

158 Sprężyna falista Mola Упорное нажимное кольцо

159 Podkładka Anilha Шайба

172 Rotor/wał Rotor/veio Ротор/вал

173 Śruba Parafuso Винт

173a Podkładka Anilha Шайба

176 Część zewn. wtyczki Parte interna do bujão Внутренние детали электросоединителя

181 Część wewn. wtyczki Parte externa do bujão Наружные детали электросоединителя

188a Śruba Parafuso Винт

190 Uchwyt Suporte de elevação Ручка

193 Śruba olejowa Parafuso do óleo Резьбовая пробка

193a Olej Óleo Масло

194 Uszczelka Junta Прокладка

198 Pierścień O-ring O-ring Уплотнительное кольцо круглого сечения

32

Ap

pe

nd

ix

Pos.Instalaţie fixă

RO

Popis

SK

Opis

SI

Naziv

RS

6a Pin Kolík Zatič Klin

7a Nit Nýt Zakovica Zakovica

9a Cheie Pero Ključ Klin

37a Inel tip O O-krúžky O-obroči O-prsten

44 Inel tocător Rezacie koleso Drobilni obroč Prsten seckalice

45 Cap tocătorHlava rezacieho zariadenia

Drobilna glava Glava seckalice

48 Stator Stator Stator Stator

48a Înveliş stator Svorkovnica Priključna letvica Priključna letva

49 Rotor Obežné koleso Tekalno kolo Propeler

50 Carcasă pompa Teleso čerpadla Ohišje črpalke Kućište pumpe

55 Carcasă stator Teleso statora Ohišje statorja Stator kućišta

58 Etanşare Unášač upchávky Nosilec tesnila osi Nosač zaptivanja osovine

66 Inel închidere Poistný krúžok Zaklepni obroček Prsten pričvršćivanja

68 Cap reglaj Stavacie matice Prilagoditvena matica Matica za podešavanje

76 Etichetă Typový štítok Tipska ploščica Pločica za obeležavanje

92 Şurub Fixačná objímka Sponka Obujmica spajanja

102 Inel tip O O-krúžok O-obroč O-prsten

103 Bucşă Púzdro Podloga ležaja Čaura

104 Inel etanşare Tesniaci krúžok Tesnilni obroč Zaptivni prsten

105105a

Etanşare Hriadeľová upchávka Tesnilo osi Zaptivka osovine

107 Inel tip O O-krúžky O-obroči O-prsten

112a Inel închidere Poistný krúžok Zaklepni obroček Prsten pričvršćivanja

153 Rulment Ložisko Ležaj Kuglični ležaj

154 Rulment Ložisko Ležaj Kuglični ležaj

155 Camera de ulei Olejovej komore Oljni komori Uljnoj komori

158 Arc canelat Tlačná pružina Vzmet Sigurnosni prste

159 Spălator Podložka Tesnilni obroč Podloška

172 Rotor/ax Rotor/hriadeľ Rotor/os Rotor/osovina

173 Filet Skrutka Vijak Zavrtanj

173a Spălător Podložka Tesnilni obroč Prsten podloške

176 Cablu conector intrareVnútorná čast' káblovej priechodky

Notranji vtični del Unutrašnji deo konektora

181 Cablu conector ieşireVonkajšia čast' káblovej priechodky

Zunanji vtični del Spoljni deo konektora

188a Filet Skrutka Vijak Zavrtanj

190 Mâner Dvíhacia rukovät' Ročaj Ručica

193 Şurub ulei Olejová zátka Oljni vijak Zavrtanj za ulje

193a Ulei Olej Olje Ulje

194 Spălător Tesniaci krúžok Tesnilni obroč Podloška

198 Inel tip O O-krúžok O-obroč O-prsten

33

Ap

pe

nd

ix

Pos.Beskrivning

SE

Kuvaus

FI

Tanım

TR

6a Stift Tappi Pim

7a Nit Niitti Perçin

9a Kil Kiila Anahtar

37a O-ringar O-rengas O-ringler

44 Skärring Repijärengas Parçalayıcı halka

45 Skärhuvud Repijä Parçalayıcı başlık

48 Stator Staattori Stator

48a Kopplingsplint Kytkentälevy Klemens bağlantısı

49 Pumphjul Juoksupyörä Çark

50 Pumphus Pumppupesä Pompa gövdesi

55 Statorhus Staattoripesä Stator muhafazası

58 Axeltätningshållare Akselitiivistekannatin Salmastra taşıyıcı

66 Låsring Lukkorengas Kilitleme halkası

68 Justermutter Säätömutteri Ayar somunu

76 Typskylt Arvokilpi Bilgi etiketi

92 Spännband Kiinnityspanta Kelepçe

102 O-ring O-rengas O-ring

103 Bussning Holkki Burç

104 Simmerring Tiivisterengas Sızdırmazlık halkası

105105a

Axeltätning Akselitiiviste Salmastra

107 O-ringar O-renkaat O-ringler

112a Låsring Lukkorengas Kilitleme halkası

153 Lager Laakeri Rulman

154 Lager Laakeri Rulman

155 Oljekammare Öljytila Yağ miktarı

158 Fjäder Aaltojousi Oluklu yay

159 Bricka Aluslevy Pul

172 Rotor/axel Roottori/akseli Rotor/mil

173 Skruv Ruuvi Vida

173a Bricka Aluslevy Pul

176 Kontakt, inre del Sisäpuolinen tulppaosa İç fiş kısmı

181 Kontakt, yttre del Ulkopuolinen tulppaosa Dış fiş kısmı

188a Skruv Ruuvi Vida

190 Lyftbygel Nostosanka Kaldırma kolu

193 Oljeskruv Öljytulppa Yağ vidası

193a Olja Öljy Yağ

194 Packning Tiiviste Conta

198 O-ring O-rengas O-ring

34

Ap

pe

nd

ix

Fig. D

TM

02

56

16

37

02

104

105107

105a

58

188a

103176

173173a

55

7a76

48

159

48a

6a

198

188a

66

26a

181

194

193

194193a

9a

188a

190

158

154

172

37a

155

153

188a

49

92

37

50

68

45

66

188a

44

188a

150a

153a

153b

105a

112a

107

58

188a

102

102

35

De

cla

ratio

n o

f co

nfo

rmity

Declaration of conformity 2

GB: EC declaration of conformityWe, Grundfos, declare under our sole responsibility that the product SEG, to which this declaration relates, is in conformity with these Council directives on the approximation of the laws of the EC member states:

BG: EC декларация за съответствиеНие, фирма Grundfos, заявяваме с пълна отговорност, че продукта SEG, за който се отнася настоящата декларация, отговаря на следните указания на Съвета за уеднаквяване на правните разпоредби на държавите членки на ЕС:.

CZ: ES prohlášení o shoděMy firma Grundfos prohlašujeme na svou plnou odpovědnost, že výrobek SEG, na nějž se toto prohlášení vztahuje, je v souladu s ustanoveními směrnice Rady pro sblížení právních předpisů členských států Evropského společenství v oblastech:

DK: EF-overensstemmelseserklæringVi, Grundfos, erklærer under ansvar at produktet SEG som denne erklæring omhandler, er i overensstemmelse med disse af Rådets direktiver om indbyrdes tilnærmelse til EF-medlemsstaternes lovgivning:

DE: EG-KonformitätserklärungWir, Grundfos, erklären in alleiniger Verantwortung, dass die Produkte SEG, auf die sich diese Erklärung bezieht, mit den folgenden Richtlinien des Rates zur Angleichung der Rechtsvorschriften der EG-Mitgliedstaaten übereinstimmen:

EE: EL vastavusdeklaratsioonMeie, Grundfos, deklareerime enda ainuvastutusel, et toode SEG, mille kohta käesolev juhend käib, on vastavuses EÜ Nõukogu direktiividega EMÜ liikmesriikide seaduste ühitamise kohta, mis käsitlevad:

GR: ∆ήλωση συμμόρφωσης ECΕμείς, η Grundfos, δηλώνουμε με αποκλειστικά δική μας ευθύνη ότι τα προϊόντα SEG, στα οποία αναφέρεται η παρούσα δήλωση, συμμορφώνονται με τις εξής Οδηγίες του Συμβουλίου περί προσέγγισης των νομοθεσιών των κρατών μελών της ΕΕ:

ES: Declaración CE de conformidadNosotros, Grundfos, declaramos bajo nuestra propia responsabilidad que el producto SEG, al cual se refiere esta declaración, está conforme con las Directivas del Consejo en la aproximación de las leyes de los Estados Miembros del EM:

FR: Déclaration de conformité CENous, Grundfos, déclarons sous notre seule responsabilité, que le produit SEG, auquel se réfère cette déclaration, est conforme aux Directives du Conseil concernant le rapprochement des législations des Etats membres CE relatives aux normes énoncées ci-dessous :

HR: EZ izjava o usklađenostiMi, Grundfos, izjavljujemo pod vlastitom odgovornošću da je proizvod SEG, na koji se ova izjava odnosi, u skladu s direktivama ovog Vijeća o usklađivanju zakona država članica EU:

IT: Dichiarazione di conformità CEGrundfos dichiara sotto la sua esclusiva responsabilità che il prodotto SEG, al quale si riferisce questa dichiarazione, è conforme alle seguenti direttive del Consiglio riguardanti il riavvicinamento delle legislazioni degli Stati membri CE:

KZ: EO сəйкестік туралы мəлімдемеБіз, Grundfos компаниясы, барлық жауапкершілікпен, осы мəлімдемеге қатысты болатын ХХХ бұйымы ЕО мүше елдерінің заң шығарушы жарлықтарын үндестіру туралы мына Еуроодақ кеңесінің жарлықтарына сəйкес келетіндігін мəлімдейміз:

LV: EK atbilstības deklarācijaSabiedrība GRUNDFOS ar pilnu atbildību dara zināmu, ka produkts SEG, uz kuru attiecas šis paziņojums, atbilst šādām Padomes direktīvām par tuvināšanos EK dalībvalstu likumdošanas normām:

LT: EB atitikties deklaracijaMes, Grundfos, su visa atsakomybe pareiškiame, kad gaminys SEG, kuriam skirta ši deklaracija, atitinka šias Tarybos Direktyvas dėl Europos Ekonominės Bendrijos šalių narių įstatymų suderinimo:

HU: EK megfelelőségi nyilatkozatMi, a Grundfos, egyedüli felelősséggel kijelentjük, hogy a SEG termék, amelyre jelen nyilatkozik vonatkozik, megfelel az Európai Unió tagállamainak jogi irányelveit összehangoló tanács alábbi előírásainak:

NL: EC overeenkomstigheidsverklaringWij, Grundfos, verklaren geheel onder eigen verantwoordelijkheid dat het product SEG waarop deze verklaring betrekking heeft, in overeenstemming is met de Richtlijnen van de Raad in zake de onderlinge aanpassing van de wetgeving van de EG lidstaten betreffende:

PL: Deklaracja zgodności WEMy, Grundfos, oświadczamy z pełną odpowiedzialnością, że nasze wyroby SEG, których deklaracja niniejsza dotyczy, są zgodne z następującymi wytycznymi Rady d/s ujednolicenia przepisów prawnych krajów członkowskich WE:

PT: Declaração de conformidade CEA Grundfos declara sob sua única responsabilidade que o produto SEG, ao qual diz respeito esta declaração, está em conformidade com as seguintes Directivas do Conselho sobre a aproximação das legislações dos Estados Membros da CE:

RU: Декларация о соответствии ЕСМы, компания Grundfos, со всей ответственностью заявляем, что изделия SEG, к которым относится настоящая декларация, соответствуют следующим Директивам Совета Евросоюза об унификации законодательных предписаний стран-членов ЕС:

RO: Declaraţie de conformitate CENoi, Grundfos, declarăm pe propria răspundere că produsele SEG, la care se referă această declaraţie, sunt în conformitate cu aceste Directive de Consiliu asupra armonizării legilor Statelor Membre CE: