Input / Hydrant Coupler Carriage / Donkey “Croc ” …a-s.yolasite.com/resources/CROC...

Transcript of Input / Hydrant Coupler Carriage / Donkey “Croc ” …a-s.yolasite.com/resources/CROC...

Parts & Maintenance Document Aviation Refuelling Equipment Specialists

CARRIAGE, Input Coupler “CROC” Parts Doc: M7102

Parts Doc: M7102 Section 4E Issue 5. 02 / 2014 © LIQUIP Page 1 of 3

*This Doc REPLACES Mdocs

M0187

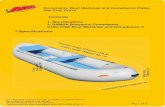

Input / Hydrant Coupler Carriage / Donkey

“Croc ®” (Crocodile)

APPLICATIONS

Input or hydrant Coupler carriages / trolleys are common to most Liquip aviation refuelling Hydrant Dispenser vehicles.

This new Liquip design, (dubbed “the Croc” due to the

crocodile-like open jaws appearance) came into initial

production late in 2007. A later production model, the 9000-55, appeared early 2008 and was then updated to the 6030* model in late 2009. This new design concept eliminated the rigid connection between the hydrant coupler and the carriage’s pipework and hose as required by coupler manufacturers such as Eaton Carter

® .

GENERAL

The function of the coupler carriage is one of efficiency and safety for employees. It allows the hydrant coupler to be easily wheeled from the vehicle to the hydrant pit with minimal effort by the operator / fuelling personnel and to then (pneumatically) lower the coupler into the hydrant pit for connection to the pit valve. On completion of fuelling, the coupler is (pneumatically) raised out of the hydrant pit and wheeled back to the vehicle. The carriage is then hooked onto the vehicle stabiliser which raises it off the ground for travelling. Some of the minor but noticeable differences between the models are the size of the wheels / castors, the shape of the pivoting raise / lower “jaws” plus some minor modifications to the handle.

PARTS & MAINTENANCE

There are some replaceable components incorporated in the assembly. Whilst considered low maintenance, normal inspection & lubrication of any moving parts is all that should be required as currently there is no maintenance data available. Parts Lists and drawings are on following pages:-

LIQUIP Part Nos:

6030-01-01 4" R.H. Version

6030-01-02 4" L.H. Version

6030-01-04 3" R.H. Version

Current Model 6030-01-00

(Above) Current R.H. 4" VERSION

Model 6030-01-00

_____________________________

(Above) VERSION 2 Model 9000-55-00

Parts & Maintenance Document Aviation Refuelling Equipment Specialists

Parts Doc: M7102 Section 4E Issue 5. 02 / 2014 © LIQUIP Page 2 of 3

6030-01-01 BOM (Refers to drawing on following page)

6030-01-01 std. 4" R.H. 'Croc' coupler carriage

Parts & Maintenance Document Aviation Refuelling Equipment Specialists

Parts Doc: M7102 Section 4E Issue 5. 02 / 2014 © LIQUIP Page 3 of 3