Innovative Roles of Laccase Mediator System in Nano ...ijrpb.org/pdf/v2-i8/5.pdfHuma Yaqoob et al....

Transcript of Innovative Roles of Laccase Mediator System in Nano ...ijrpb.org/pdf/v2-i8/5.pdfHuma Yaqoob et al....

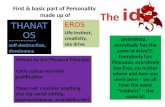

International Journal of Research in Pharmacy and Biosciences

Volume 2, Issue 8, September 2015, PP 23-34

ISSN 2394-5885 (Print) & ISSN 2394-5893 (Online)

*Address for correspondence

International Journal of Research in Pharmacy and Biosciences V2● I8 ● September 2015 23

Innovative Roles of Laccase Mediator System in Nano

Biotechnology, Bio Bleaching and Bioremediation

Huma Yaqoob, M. Kamran, Sikander Ali

Institute of Industrial Biotechnology (IIB), GC University Lahore, Pakistan

ABSTRACT

Laccases are blue copper containing oxidases present in fungi, bacteria, insects and plants. They have received

multi attention by research scientists in various fields from last decade due to their inimitable capability to

oxidize phenolic and non-phenolic compounds and environmental pollutants. Textile, paper pulp industry

produces many hazardous compounds. To detoxify those compounds these enzymes are discovered without

producing any harmful effect. Laccases are used for organic synthesis. Recently these are used in

biotransformation, nano biotechnology to catalyse electron transfer reactions without the use of cofactor, biosensing and bioremediation of food and soil. For biotechnological purposes these enzymes are used as

biocatalyst. Laccase has ability to delignify phenolic and aromatic compounds with the help of Laccase

mediator system (LMS) that is potential application of enzyme. Under different physiological conditions these

enzymes behave differently. Some inducers enhance the activity of enzymes.

Key words: Laccase mediator system, Bio bleaching, Bioremediation, Nanobio-technology.

INTRODUCTION

Laccases are large blue copper containing proteins also called blue copper oxidases, catalyze the

oxidation of all types of phenolic, aromatic, inorganic and organic compounds by reducing molecular

oxygen (by using as electron acceptor) into water molecule. Laccase, was discovered by Yoshida in

1883 from the sap of a tree Rhusvernicifera (Japanese lacquer tree) in the presence of air and its properties were discovered by Bertrand in 1985 (Giardina et al., 2010).In 1895 Bertrand and Laborde

demonstrated that laccases are fungal enzymes. The useful laccases in biotechnologies were

originated from fungi. White-rot fungi were reported as major source of laccases (Yaropolov et al., 1994). Species from genus pleurotus were discovered as main producers of laccases (Leonowicz et

al., 2001).Recently, it was studied that mostly aromatic and phenolic compounds having lignin or

lignin related compounds have ability to stimulate production of these enzymes by P. pulmonarius

(Soden and Dobson, 2001).This production of laccases from pulmonarius can be improved by using ferulic acid and vanillin inducers in combination (Malley et al., 1993).

Source of Production

These enzymes are widely studied in animals, insects, plants including vegetables and fruits, bacteria and fungi. The major source of laccases is fungi including ascomycetes, deuteromycetes and

basidiomycetes. The two main functions of laccases were seen as studied in fungi, first was lignin

degradation and second was pathogenesis in plant against fungus. These fungal laccases are 60-70 kD with pH 4 (Baldrian, 2006).Plant laccases are present in xylem, where they oxidize compound

monolignol into primary stage of lignifications and help in lignin polymerization (Hoopesand Dean,

2004). First bacterial laccase was reported in Azospirillumlipoferum that was responsible for

production of melanin (Faure et al., 1994). A thermostable cot A laccase was discovered in Bacillus subtilis that is involved in pigmentation in the coat of endospore. This bacillus laccase was also

responsible for phenolic degradation. In yeast laccase is tightly bound to the cell wall causing

resistance against fungicides (Martins et al., 2002).

Biochemical Features and Molecular Properties

Laccase is present in monomeric, dimeric and trimeric forms. Mostly they are said monomeric

extracellular enzymes having four copper atoms with three redox sites which are T1, T2 and T3.

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

24 International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015

These copper atoms are bound to redox sites as shown in Fig.1 (Palmieri et al., 2003). It is called blue

copper oxidase due to greenish blue colour of T1 site bound with copper atoms in its oxidized state which cause oxidation of reducing compounds. The cluster of Cu-T2 and Cu-T3 are present 12A˚ far

away from Cu-T1 and it is that place where reduction of oxygen into water is occurs (Alcalde et al.,

2007). This enzyme catalyses the oxidation of one electron of substrate by reducing four electrons of oxygen. In short it is said that laccase act as battery which store electrons for further oxidation of

substrate. Fungal laccase is actually a glycoprotein, containing 10-20% carbohydrates which are

responsible for its stability. The carbohydrates are mainly, mannose, N-acetyl glucosamine and galactose. It also contains amino acids chains having N-terminal secretary peptides (Yaver et al.,

1996).

Figure1. Structure of the Copper Coordination Network of Laccase Molecule

Plant and fungal laccases have different pH ranges due to difference in their physiological functions. The pH of fungal laccaseis about 3.9-5.2 whereas pH of plant laccase is within 6.8-7.4.Their

isoelectric points are also different. Fungal laccases are responsible for degradation of phenolic

compounds while plant laccases are responsible for lignin production (Benfield et al., 1964).

Mechanism of Action of Laccase

T1, T2 and T3 sites of laccase can be distinguished by UV light or electronic paramagnetic resonance

spectroscopy (EPR). When oxidation occurs,T1-Cu gives blue colour to enzymatic protein which

absorbs 610nm resonance that is EPR visible. T2-Cu does not absorb any light and colour but is EPR visible. T3-Cu having pair of atoms gives very weak absorbance of UV region but is not EPR visible.

T2-Cu and T3-Cu form trimeric centre where O2 molecule binds to restrict entrance of oxidizing

compounds (Gianfreda et al., 1999). As laccase enzyme act as battery for storage of electrons, it is necessary to oxidize four substrate molecules to complete reduction of oxygen molecule into water.

During oxidation of substrate, free radicals are produced. These radicals are responsible for the

degradation of lignin by breaking the bonds between alpha and beta carbons forming oxygen centred

free radical. This oxygen centred free radical is converted into quinone. Free radical and quinone can

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015 25

endure polymerization (Thurston et al., 1994). EPR study of laccase explained that T2-Cu has co-

ordination with two his-N regions and oxygen in form of OH while T3-Cu binds with three Histidine residues. Laccase cause oxidation of non-phenolic compounds by using some mediators. The system

is known as Laccase Mediator System (Zoppellaro et al., 2000).

Laccase catalyses phenolic group of lignin by cleaving carbon alpha-carbon beta bond, carbon-alpha oxidation and alkyl-aryl cleavage as described in Fig. 1. The activity of laccase consist on following

steps; reduction of substrate and T1-Cu, transfer of internal electrons from T1-Cu to T2-Cu and T3-

Cu, reduction of O2 into H2O at the sites of T2-Cu and T3-Cu as shown in Fig. 2 (Palmieri et al., 2003). The substrate oxidation involves the loss of one electron to form a radical that is unstable and

undergoes further oxidation to synthesize quinone from phenolic part of lignin (Xu et al., 1999). The

electron is transferred to T1-Cu from substrate which is controlled by redox potential. It appears that

stearic effect of T1-Cu is limited for phenol substrate. T2-Cu and T3-Cu seem to limit the contact with oxidizing agents rather than O2. The bond formation in tri-nuclear copper bunch is responsible

for activation of O2 and it was suggested that the transfer of electron from reducing substrate to T1-Cu

is actually rate determining step (Solomon et al,. 1996).Bourbonnais and Paice studied that laccase itself cannot degrade lignin. It can do degradation by using laccase mediator that is 2, 2’-azino-bis-[3-

ethylthiazoline-6-sulfonate] (ABTS) which helps to the study of laccase mediator system (LMS)

leading to degradation of lignin into pulp (Bourbonnais and Paice, 1990).

Figure2. Catalytic Cycle of Laccase

Laccase Mediator Systems

Mediators are low molecular weight organic compounds oxidized into free radicals by laccase and

undergo oxidation of non-phenolic compounds to which laccase itself cannot. Mediators mostly used

are 3-hydroxyanthranilic acid (3-HAA), N-hydroxyphthalimide (NHPI), p-coumaric acid, syringaldehyde, 1-hydroxy benzotriazole (HBT), 2, 2- azinobis-(3-ethylbenzthiazoline-6-sulfonate)

(ABTS), and 3 hydroxyanthranilic acid (GochevandKrastanov, 1993). As substrate molecule is unable

to enter into the active site of laccase due to its size, these mediators act as carrier of electrons between enzyme and substrate (Li et al., 1999).As the size of substrate increases, the activity of

laccases decreases.At the initial step, mediator is oxidized by laccase, due to its small size this

oxidized mediator enter into the pores of plant cell wall for the degradation of lignin and other aromatic compounds which do not have direct contact to laccase for degradation. After that the

mediator is reduced back into its original form (Bourbonnais et al., 1997).

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

26 International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015

Figure3. Mechanism of Substrate Oxidation by LMS

In 1990 Bourbonnais and Paice has explained the mechanism of action of ABTS mediator. Laccase-ABTS system can de-methylate and delignifykraft pulp. ABTS is oxidized by free radicals into

ABTS+˚

and further oxidized into ABTS 2+

. 1-Hydroxybenzotriazole (HBT) mediator is used in

biobleaching and lignin degradation of Kraft pulp.Some synthetic mediators are also used for laccase

like, violuric acid (VA), N-hydroxyacetanilide (NHA), N-hydroxyphthalimide (NHI), 2,2,6,6- etramethylpiperidin-1-yloxy (TEMPO) as in Fig.5 (Couto and Herrera, 2007). The structures of all

mediators contain N-OH group. The key steps which have to keep in mind while using synthetic

mediators are to take a compound having NH/OH groups in its structure. Then check its chemical properties other than LMS. Determine their optimum conditions for reaction and verify the product of

LMS degradation. The use of different mediators yields different products because oxidation of

substrate via mediators occurs in different mechanisms. ABTS and HBT behave differently, electron transfer in case of ABTS

+˚ and hydrogen transfer of nitroxyl radical in case of HBT as shown in Fig. 3

and 4 (Call and Mucke, 1997; Bourbonnais et al.,1997).

Figure4. Oxidation of ABTS by Laccase

In spite of all advantages of mediators there are some disadvantages to use them. These are cost

effective, can cause some serious toxic effects, during oxidation of mediators laccase can be

inactivated by radicals mediators and after all become an inactivated compounds with no more ability to oxidize mediators (Viswanath et al., 2014). Some natural mediator acetosyringone, syringaldehyde,

vanillin, acetovanillone, ferulic acid or pcoumaric acid are very efficient laccase mediators for dye

decolorization, removal of polycyclic aromatic hydrocarbons, bleaching of pulp and removal of pitch. These mediators are free of cost because they abundantly in nature and not produce any toxicity in the

environment (Vasconcelos et al., 2000). The Kmvalue of laccase mostly occurs in the range of

25,000μM. The difference in Km value explains that laccase is originated from different source and

have different substrate specificity (Arora et al., 2000).

Figure5. Some Synthetic Laccase Mediators

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015 27

There are some inhibitors which hinder the activity of laccase. Few anions like halides, azides,

cyanides and hydroxide bind with T2-Cu and T3-Cu of laccase and cause enzyme function inhibition by hindering electron transfer mechanism (Thiruchelvam et al., 2007).Hydroxide prevents oxidation

of substrate at alkaline pH and makes it stable at this pH. The hindrance via halides differs with

isoforms of laccase. Other inhibiting compounds are metal ions (Hg2+), cationic quaternary ammonium detergents, kojic acid, sulfhydril reagents, hydroxyglycine, fatty acids (Gianfreda and

Bollag,1999).

Classificationof Laccase on the Base of Substrate Specificity

Laccases are also called phenol oxidases. They are linked with three different activities; Catechol

oxidase (o-diphenol), Laccase (p-diphenol), Cresolase (mono-phenol mono-oxygenase). These are the

types based on substrate specificity (Walker and McCallion, 1980). Catechol oxidase also called

tyrosinase. It is very difficult to differentiate laccase on the base of substrate specificity because it has

overlapping with tyrosinase (Zadrazil et al., 1999). Catecholoxidase has o-diphenol and cresolase

activity whereas laccase have p-diphenol activity and only tyrosinase has cresolase activity. Other

problem to differentiate this enzyme on the base of substrate specificity is that it has variable range of

substrate from one organism to another (Papinutti et al., 2003).Laccase from Neurospora

crassaoxidizes p-diphenol except phloroglucinol. Laccase from Pyriculariaoryzaeoxidizes

phloroglucinol as substrate, from Carrenaunicolour prefer sp-substituted-phenol as substrate on the

other hand while from Trametes versicolor uses o-substituted-phenol for substrate. Those phenolic

compounds which are slowly oxidized by laccase are used to increase storage capacity of

laccase(Jolivalt et al., 1999).

Laccase Inducers

Xenobiotics have promoter regions of genes for laccase, whenever heavy metals binds to this region

they induce the production of laccase. The use of inducers can increase the production of laccase or it

can cause production of other isoforms of laccase (Minussi et al., 2007).Xylidine is an inducer which

in small amount can increase nine fold production of laccase in 24 hours. Use of ethanol can increase

laccase production greater than that of xylidine and veratryl alcohol and also it decreases melanin

concentration which induce laccase production (Chernykh et al., 2008). Addition of cellobiose and

lignin enhance the activity of laccase without increasing total protein contents (Levin et al., 2002).

Some metal ions such as copper, cadmium, cycloheximide, aromatic compounds and organic acids,

heavy metals, white rot fungi, xylidine, ethanol, melanin, cellobiose and lignin, veratric acid, ferulic

acid and addition of detergents and surfactants are able to induce production of laccase.

Veratrylalcohol acts as protectant against inactivation by hydrogen peroxide synthesized by fungus

(Janusz et al., 2006).

Nutritional Conditions for Production of Laccase

The activity of laccase with respect to optimum temperature differs from strain to strain. The enzyme

originated from Ganodermalucidem has optimum temperature 20-25˚C and is stable at 10-50˚C for

four hours (Ko et al., 2001).Same enzyme isolated from Marasmiusquercophilusis stable at 60˚C for

one hour (Farnet et al., 2000).It was also proposed that pre-incubation of this enzyme at 40-50˚C

enhance its activity. It is also noted that optimum temperature for production of laccase is 25˚C during

the incubation of culture in dark (Thurston et al., 1994). Fungal laccases are produce at 25-30˚C

(Minussiet et al., 2007). The highly thermo-stable isoforms of wood decaying basidiomycetes produce

three isoforms of laccase at 75-80˚C(Chernykh et al., 2008;Hilden et al., 2009).

Carbon is building block of living organisms. The sources of carbon generate energy on degradation.

In living organisms, the major source of carbon is glucose. In Coriolus versicolor 10g/L glucose

enhance the productivity of laccase while in Trametes versicolor the laccase production is increased at

20g/L concentration of glucose (Collinset et al., 1995; Levin &Forchiassin, 2002; Mussins et al.,

2007). In Ganodermalucidum 10g/Lglucose enhance the production of laccase (Perumal et al.,

1997).In Trametesgallica, maximum production of laccase occurs at 5g/L concentration of glucose in

liquid medium (Dong and Zhang, 2010). In Pleurotusflorida laccase is produced at 15.21g/L glucose.

In Botryospaeria sp. different carbon sources other than glucose such as fructose, galactose,

galacturonic acid, xylose, lactose, sucrose, mannitol, pectin, glucerol, starch and inulin were

discovered by D’Souza (D’Souza-Ticlo et al., 2006).

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

28 International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015

In white rot fungi, it was observed that the activity of laccase was increased by depletion of nitrogen.

In some other strains it was noted that production of laccase is not effected by nitrogen concentration

(Leatham et al., 1983; Janusz et al., 2006). Laccase production depends upon carbon to nitrogen ratio.

Nitrogen concentration at high level is required for laccase production but in case of white rot fungi

the limited level of nitrogen enhances the production of this enzyme (Baldrian and Gabrie,2002).In

Pycnoporussanguineussaccrose-asparagine medium having 5 times more asparagines than Kirk’s

medium increases the activity of laccase 2.5 times than Kirk’s medium (Eugenio and Carbajo, 2009).

Peptone was used as source of nitrogen for enzyme (Strong et al., 2011). Other nitrogen sources such

as potassium nitrate, glycine, glutamic acid, corn steep liquor, beef extract were found by Leatham

and Kent Kirk (LeathamandKirk, 1983).Copper is micronutrient for living organisms so it is required

in limited amount. Cupric ion in free form is highly toxic for microorganisms. The copper

supplemented cultures of Pleurotusostreatus showed increased production of laccase during northern

blot analysis (Gold and Glenn, 1988). Copper acts as very strong inducer for different species. Recent

study explains that the inoculation of copper into white rot fungi stimulates the production of

lignolytic enzyme and decolourization of polymeric dyes (Shraddha et al., 2011).

The effect of pH differs in case of different substrate. This effect is limited for enzyme production.

When the pH is very high, then oxidation of substrate also high and the difference between T1-Cu and

phenolic substrate also raise. On the other hand, hydroxyl ion binds with T2-Cu and T3-Cucentres

which hinder the activity of enzyme (Kunamneni et al., 2007). The optimum pH for isozymes of

laccase is different. For laccases, optimum pH is 3.0 to 5.0, but the enzyme from Trametes versicolor

is more active at pH 3.0 for 50˚C. The enzyme extracted from Stereumostrea is active at 6.0 for 40˚C

(Valeriano & Silva, 2009).Laccase originated from fungi is active at 3.9 to 5.2 but the optimum pH

for fungal laccase is from 4.5 to 6.0 (Thurston et al., 1994).The use of substrate ABTS cause acidic

condition and pH is lowered. When pH varies, bell-shaped sketch is formed. This variation is due to

oxygen, substrate and isozymes (Xu et al., 1997). Agitation is a factor that effects the production of

laccase. In fungus it was noted that the production of enzyme in stirred fermenter or reactor is decline.

Tavares said that agitation does not have any effect on enzyme production (Tavares et al., 2007).

In 1984, it was studied that azide, EDTA, diethyldithiocarbamic acid and thioglycolic acid are

inhibitors for enzyme activity as EDTA inhibits enzyme activity in less extent (Barreca et al., 2003).

Halides, hydroxides and cyanides interact with T2-Cu and T3-Cu and cause disturbance in enzymes

activity and interior electron shift. A few detergents, kojic acid, metal ions, fatty acids,

hydroxyglycine and few sulfhydryl reagents are also act as inhibitors for enzymes action (Christopher

et al., 2014).

Purification of Laccase

According to recent study major proficient methods for enzyme purification is precipitation of protein

by using ammonium sulfate, desalting, gel filtration chromatography and ion exchange

chromatography (Mayer et al., 2015). Laccase from Neurosporacrassacan be purified in single step

by using celite chromatography resulting 54 folds of enzyme. Laccase from T. versicolor is purified

by ethanol precipitation sephadex G100 and ion exchange chromatography by following gel filtration

(Dong et al., 2015). Stereumostrea and laccase from fruiting body is purified by ammonium sulphate

precipitation giving 70% purified protein. Laccase from fruiting body can also be purified by cellulose

chromatography with 3 fold purified protein (Viswanath et al., 2008).

Laccase was purified from natural fungus Lenzites sp. which was isolated from a live tree jujube

(Zizyphusmauritiana) by 70% ammonium sulphate precipitation. The cultural filtrate was fractionated

in ammonium sulphate saturation sequence starting from 0- 20%, 20-40%, 40-60%, and 60-80% and

80-100% saturations. The (NH4)2SO4 precipitate was then dissolved in 1M Na2HPO4/NaH2PO4buffer

and dialyzed against this buffer by changing the volume ratio in different time intervals. The dialyzed

enzyme was loaded on sephadex G-25 column. The enzyme was eluted by using the same buffer.

Fractions were collected and analysed for activity of enzyme (Table 1). Molecular weight of enzyme

was determined by SDS-PAGE (Pushkaraj and Gupta, 2015). Other than ammonium sulphate

precipitation various methods are used to purify laccase as described in Table 2.

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015 29

Table1. Laccase purification by ammonium sulphate precipitation

Ammonium Sulphate precipitated samples (%) Laccase activity (U/mL) References

20-40 % 2.029 Pushkaraj & Gupta, 2015

40-60 % 3.894 Dong et al., 2015

60-80 % 23.190 Mayer et al., 2015

80-100 % 2.91 Viswanath et al.,2015

Table2. Different methods for purification of laccase

Organism Purification step Yield and

purification fold

References

Trametes multicolour Ultrafiltration 100% - Leitner et al., 2002

Q-Sepharose 39.8%

Superdex-75 31.8%

Chaetomiumthermophilium Ultrafiltration 84 % 3 Chefetz et al., 1998

DEAE Sepharose 79 % 5

Concanavilin-A

Sepharose 4B

40 % 10

Ganodermalucidum DEAE Sepharose 74.9 % 2.6 Ko et al., 2001

Preparative

electrophoresis

28.6 % 32.4

Pycnoporuscinnabarinus Ultrafiltration 87 % 7 Eggert et al., 1996

DEAE M 75 % 20

Butyl Toyopearl 56 % 32

S-400 47 % 36

Trametessanguinea DEAD Toypearl 78 % - Nishiazawa et al., 1995

Phenyl Toyopearl 73 %

Polyporus versicolour Hydroxyl apatite 58 % - Mosbach, 1963

Zone electrophoresis 65 %

Coriolushirsutus DEAE cellulose - 17.5 Koroljova- Skoroboghat’ko

et al.,1998 DEAE Toyopearl 167.5

Pleurotusostreatus Ultrafiltration Sannia et al., 1986

DEAE Sepharose 18 %

Con-A Sepharose 12 % 27

Coriolushirsutus DEAE Sepharose 62.1 % 3.3 Shin & Lee, 2000

Sephacryl S-200 HR 57.2 % 3.7

Hitrap SP 45.4 % 8.2

Mono S 32.3 % 14.5

Trametesversicolour Sephadex-G 25 95 % 0.91 Rogalski et al., 1991

Syringyl- CPG 35.9 % 13.11

Vanillyl- CPG 9.2 % 109.19

Fomesfomentarius Sephadex-G 25 92.4 % 0.94 Rogalski et al., 1991

Syringyl- CPG 41 % 8.12

Vanillyl- CPG 15.6 % 41.4

Ceriporiopsissubvermispora Acel anion exchange 54 % - Fukushima & Kirk, 1995

Mono Q (L1) 34 %

Phenyl Superose 15 %

INDUSTRIAL APPLICATIONS OF LACCASES

Other than biotechnological applications, laccases are used in food industry, paper textile industry,

pulp industry, bio bleaching, medicinal and diagnostic purposes for making antibiotics and drugs,

water purification, in cosmetics to reduce their toxic effects, to remove xenobiotics compounds and

production of polymeric compounds acting as component of bioremediation (Couto and Herrera,

2006), biotransformation, organic compound synthesis and biosensing as in Fig. 6.(Morozova et al.,

2007).

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

30 International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015

Figure6. Scheme of Applications of Laccase

Laccase in Biobleaching

In pulp industry laccase is used as bio bleaching agent. Wood pulp is mainly composed of lignin,

cellulose and hemicelluloses. During pulping process almost 90% lignin that is insoluble compound is

solubilised and removed but the remaining lignin cause coloration in pulp and must be removed by

bio bleaching. The free radical of redox reaction is responsible for bond cleavage in lignin molecule as in Fig. 7 (Khammuang and Sarnthima, 2009).The bleaching process includes use of harsh oxidative

chemicals and conditions. The conventional methods used for bleaching are the use of chemical

oxidants which are based on chlorine or oxygen e.g. ClO2, O2. But the use of these chemicals causes degradation of cellulose and synthesis of harmful by-products (Bajpai et al., 1992).

Figure7. Schematic Mechanism of Laccase Used in Biotechnology

Traditional method of bio bleaching with Cl2 is replaced by elemental chlorine free (ECF) and total

chlorine free (TCF). ECF is more effective than TCF because of using chlorine chemicals (ClO2, ClO-

) in place of chlorine (Kunamneni et al., 2007). Filamentous fungi are efficiently used for the

degradation of lignin by producing their enzyme laccase (Eugenio et al., 2009). During degradation,

laccase enzyme act in response with phenolic fragments of lignin which bind with lignin polymer for

its degradation. The remaining lignin can be degraded by laccase. In Trametes versicolor the enzyme laccase delignifykraft pulp on pilot scales (Strong, 2011). Due to limited penetration of bulky laccase

into the cell wall of kraft pulp, biobleaching is carried out by LMS. The delignifying parts of laccase

are beta-1and beta-O-4 of lignin. Bourbonnais and Paice studied that laccase with ABTS degrade C-alpha and C-beta cleavage in beta-1 partin Fig.8 (Bourbonnais and Paice, 1990). In beta-O-4 part,

alpha-hydroxyl group is oxidized into alpha-carbonyl group studied by Barreca et al.,(2003). Kawai

studied that laccase with HBT on beta-O-4 undergo aromatic ring cleavage as in Fig. 9 (Kawai et al., 1999).

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015 31

Figure8. Degradation of beta-1 (top) and beta-O-4 (down) Parts of Lignin by Laccase with ABTS

Figure9. Degradation of beta-O-4 part of Lignin by Laccase with HBT

Laccase in Nanobiotechnology

Nanoscience is growing up rapidly from last decade. Nanotechnology has its role in all fields of human need. Nanofibres, nanotubes and nanoparticles are used as biosensing and biofueltransport

materials (Uematsu et al., 2001). Basically biosensor is a biological probe having electric transducer

that converts biochemical signal into electric signal which perceive, convey and trace the signal according to biochemical change. Today laccase is used for bioreporting and biosensing purpose

(D'Souza et al., 2001).The biosensing substances containing laccase are used for detecting aromatic

amines, phenolic compounds and glucose. Laccase bound covalently with biobinding molecules used as biosensor for histochemical assay, immunoassay, nucleic acid detection assay and cytochemical

assay (Saito et al., 2004).Laccase can also be used as immobilizer on cathode of biofuel cells that

provides power for electric transmitter system.Immobilized cell have an electrode consist on

immobilized anode and cathode enzyme that is deposited of metal nanowires of large surface area. Nanotubes can also be used instead of nanowires (Chen et al,. 1998). The anode enzyme consists on

immobilized glucose oxidase and cathode enzyme consists on immobilized laccase (Cabrita et al.,

2005). On the surface of anode glucose is oxidizes by glucose oxidase and on the surface of cathode reduction of oxygen occurs. Laccase can also be used as biocatalyst for electrode reactions as in Fig.

10(Caruso et al., 2000).

Figure10. Schematic Diagram of Biofuel Cell with Glucose Oxidase and Laccase

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

32 International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015

Laccase in Bioremediation

In bioremediation laccase is used to degrade undesirable contaminants, e.g. it is used to eliminate esynthetic wastes containing olefin units by oxidizing olefin via LMS system leading to degradation

of plastics. Laccase is also used to degrade fluorescent compounds and odour creating substances

from livestock and garbage (Uematsu et al., 2001; Saito et al., 2004). These enzymes decolorize water wastes in oilmils and home effluent by removing coloured compounds(Chakar et al., 2001; Nakatani

et al., 2003).Laccases are responsible for bioremediation of soil by eliminating chlorophenols, poly

aromatic hydrocarbons (PAHs) and xenobiotics. In industrial wastes laccases are used for refining of oil, organic compound synthesis, coal renovation and oil production. An herbicide Isoxaflutole in

plants and soil is converted from its activated form into acid (Duncan et al., 2004).Halogens

containing organic pesticides can also be degraded by laccase. LMS of laccase is used in enzymatic

bioremediation of soil, water and food. Laccase also use for dyeing of keratin fibres and bleaching of tooth enamel (Alcalde et al., 2006).

CONCLUSION

Laccase is ubiquitous and versatile enzyme originated from various sources as fungi, plants and

insects. The activity and properties of laccases differ from organism to organism. Due to unique

function to oxidize phenolic and non-phenolic compounds laccases are used in different

fields.Currently, laccase is used in pulp industry for bio bleaching, nanobiotechnology and bioremediation. In industry laccase or related enzymes are used for delignification, detoxification of

harmful chemicals, as biosensor and analytical purposes. Laccase acts on substrate to detoxify

pollutants in petrochemical industry. Moreover laccase will be used to degrade lignin for carbon source serving as biocatalyst.Instead of use of laccase in industry, few problems come in face. One

problem is the presence of insufficient enzyme stock. The future attempt is to overcome this drawback

by overproduction of cheap, active, healthier and efficient laccase in heterologus hosts. Another

drawback is cost and lethal effects of LMS. Further study will include the production of less toxic LMS like natural mediators of different and less polluting laccase.Laccase can also produce

peroxidase alternatives in future because this enzyme is economically viable and easily accessible.

ACKNOWLEDGEMENTS

Director of Institute of Industrial Biotechnology and Vice Chancellor of Government College

University Lahore are gracefully acknowledged for this publication.

REFERENCES

[1] Adinarayana, K., Camarero, S., Burgos, C. G., Plou, F. J., Ballesteros, A, &Alcalde, M. (2008) Engineering and applications of fungal laccases for organic synthesis. BioMed Cent.7, 32-40.

[2] Alcalde, M. (2007) Laccase: biological functions, molecular structure and industrial applications. Spring.6, 459-474.

[3] Alcalde, M., Ferrer, M., Plou, F. J, & Ballesteros, A. (2006) Environmental biocatalysis: from

remediation with enzymes to novel green processes. Trend Biotechnol.24, 281-287. [4] Arora, D. S, & Gill, P. K. (2000) Laccase production by some white rot fungi under different

nutritional conditions. Biores. Technol.12, 283-285.

[5] Baldrian, P. (2006) Fungal laccases – occurrence and properties. FEMS Microbiol.Lett.30, 215-

242. [6] Baldrian, P.& Gabriel, J. (2002) Copper and cadmium increase laccase activity in

Pleurotusostreatus. FEMS Microbiol.Lett.48, 69-74.

[7] Barreca, A. M., Fabbrini, M., Galli, C., Gentili, P.&Ljunggren, S. (2003) Laccase mediated oxidation of a lignin model for improved delignification procedures.J. Mol. Catalyt.Enzy.26,

105-10.

[8] Bourbonnais, R.&Paice, M. G. (1990) Oxidation of non-phenolic substrates, an expanded role for laccase in lignin biodegradation. FEBS Lett.267, 99-102.

[9] Chakar, F.&Ragauskas, S. (2001) Ligninolytic enzyme system of Phanerochaetechrysosporium synthesized in the absence of lignin in response to nitrogen starvation. J. Bacteriol. 135, 790-797.

[10] Chernykh, Myasoedova, N.&Kolomytseva, M. (2008) Laccase isoforms with unusual properties from the basidiomycete Steccherinumochraceumstrain 1833. J. App.Microbiol. 67, 2065-2075.

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015 33

[11] Christopher, L. P., Yao B. & Yun, J. (2014) Lignin biodegradation with laccase-mediator

systems. Front.Energ. Res. 10, 33-89.

[12] Collins, P. J.& Dobson, A. D. W. (1995) Extracellular lignin and manganese peroxidise production by the white-rot fungus Coriolus versicolour 290. Biotechnol.Lett. 90, 989-992.

[13] D’Souza-Ticlo, D., Verma, A. K., Mathew, M.&Raghukumar, C. (2006) Effect of nutrient nitrogen on laccase production, its isozyme pattern and effluent decolorization by the fungus

NIOCC # 2a, isolated from mangrove wood. Ind. J. Micro. Sci.34, 364-372.

[14] Dong, J. L., Zhang, Y. W., Zhang, R. H., Huang, W. Z.& Zhang, Y. Z. (2005) Influence of

culture conditions on laccase production and isozyme patterns in the white-rot fungus

Trametesgallica. J. Bas. Microbiol. 98, 190-198.

[15] D'Souza, S. F. (2001) Microbial biosensors. Biosens.Bioelec. 16, 337-353.

[16] Duncan, K. W. (2004) Novel application of coconut husk as growth support matrix and natural

inducer of fungal laccase production in a bubble column reactor. J. Mol. Bio. Biotechnol. 17, 47-52.

[17] Eugenio, M. E., Carbajo, J. M., Mart´ın, J. A., Gonz´alez, A. E.&Villar, J. C. (2009) Laccase production by Pycnoporussanguineusunder different culture conditions. J. Bas.Microbiol. 55,

433-440.

[18] Gianfreda, L., Xu F. &Bollag, J. M. (1999) Laccases: a useful group of oxidoreductive enzymes.

Bioremed.J.3, 1-25.

[19] Gold, M. H., Glenn, J. K.&Alic, M. (1988) Use of polymeric dyes in lignin biodegradation

assays. Meth.Enzy.44, 74-78.

[20] Hild´en, K., Hakala, T. K.&Lundell, T. (2009) Thermo tolerant and thermo stable laccases.

Biotechnol.Lett.76, 11, 17-1128.

[21] Janusz, G., Rogalski, J., Barwi´nska, M.&Szczodrak, J. (2006) Effect of culture conditions on

Production of extracellular laccase by Rhizoctoniapraticola.J. Microbiol. 35, 309-319.

[22] Leatham, G. A. & Kent Kirk, T. (1983) Regulation of ligninolytic activity by nutrient nitrogen in

white-rot basidiomycetes. FEMS Microbiol.Lett.21, 65-67.

[23] Levin, L., Forchiassin, F.& Ramos, A. M. (2002) Copper induction of lignin-modifying enzymes

in the white-rot fungus Trametestrogii. Mycol.89, 377-383.

[24] Maciel, M. J. M., Silva, A. C.& Ribeiro, H. C. T. (2010) Industrial and biotechnological applications of ligninolytic enzymes of the basidiomycota. Elec. J. Biotechnol.29, 0717-3458.

[25] Malley, D. M. O., Whetten, R., Bao, W., Chen, C. L.&Seedorf, R. R. (1993) The role of laccase in lignification. T. Plant J.4, 751-757.

[26] Mayer, A. M.& Staples, R. C. (2002) Laccase: new functions for an old enzyme. Phytochem. 98, 551-565.

[27] Minussi, R. C., Miranda, M. A.& Silva, J. A. (2007) Purification, characterization and

application of laccase from Trametes versicolor for colour and phenolic removal of olive mill

wastewater in the presence of 1-hydroxybenzotriazole. Afri. J. Biotechnol.16, 1248-1254.

[28] Morozova, O. V., Shumakovich, G. P., Shleev, S. V.&Yaropolov, Y. I. (2007) Laccase–mediator

systems and their applications.App. Biochem. Microbiol.80, 583-597.

[29] Palvannan, T. &Sathishkumar, P. (2010) Production of laccase from PleurotusfloridaNCIM

1243 using Plackett-Burman design and response surface methodology. J. Microbiol. 99, 325-335.

[30] Papinutti, V. L., Diorio, L. A.&Forchiassin, F. (2003) Production of laccase and manganese

peroxidase by Fomessclerodermeus grown on wheat bran. J. Ind. Microbiol. Biotechnol. 8, 157-160.

[31] Pushkaraj, V. P.& Das, G. D. (2015) Partial purification of laccase enzyme from a newly isolated

Lenzites sp. fungus and its use in decolorization of textile dye. Inter. J. Scien. Res. 4, 8-100.

[32] Saito, T., Kato, K.& Yokokawa, Y. (2004) A fungal metabolite mediates degradation of non-

phenolic lignin structures and synthetic lignin by laccase, FEBS Lett. 391, 144-148.

[33] Nakatani, Yoshida, M. (2003) Production of laccase by Pycnoporussanguineus using 2, 5-

xylidine and ethanol. Braz. J. Microbiol. 40, 790-794.

Huma Yaqoob et al. “Innovative Roles of Laccase Mediator Systemin Nano Biotechnology, Bio Bleaching

and Bioremediation”

34 International Journal of Research in Pharmacy and Biosciences V2 ● I8 ● September 2015

[34] Shraddha, Shekher, R., Sehgal, S., Kamthania, M.& Kumar, A. (2011) Laccase: microbial

sources, production, purification, and potential biotechnological applications. SAGE Hind. Acc. Res. 15, 217-861.

[35] Strong, P. J. (2011) Improved laccase production by Trametes pubescensMB89 in distillery

waste waters. Enzy. Res.3, 1-8.

[36] Thiruchelvam, A. T. & Ramsay, J. A. (2007) Growth and laccase production kinetics of

Trametes versicolor in a stirred tankreactor, App. Microbiol. Biotechnol.6, 547-554.

[37] Thurston, C. F. (1994) The structure and function of fungal laccases. Microbiol. J. 140, 19-26.

[38] Uematsu, H., Watanabe, Y., Isshiki, K.&Kurane, R. (2001) Production of laccase by Curvularia

sp. Microbiol. 36, 343-346.

[39] Valeriano, V. S., Silva, A. M. F., Santiago, M. F., Bara, M. T. F. & Garcia, T. A. (2009)

Production of laccase by Pycnoporussanguineususing 2,5-xylidine and ethanol. Braz.

J.Microbiol. 51, 790-794.

[40] Vasconcelos, A. F. D., Barbosa, A. M., Dekker, R. F. H., Scarminio, I. S. &Rezende, M. I.

(2000) Optimization of laccase production by Botryosphaeriasp. in the presence of veratryl alcohol by the response-surface method. Biochem.51, 1131-1138.

[41] Viswanath, B., Chandra, M. S., Pallavi, H.& Reddy, B. R. (2008) Screening and assessment of laccase producing fungi isolated from different environmental samples. Afri.J. Biotechnol.22,

1129-1133.

[42] Viswanath, B., Rajesh, B., Janardhan, A., Kumar, A. P.&Narasimha, G. (2014) Fungal laccases

and their applications in bioremediation. Hind.4, 163-242.

[43] Zadrazil, F., Gonser, A. & Lang, E. (1999) Influence of incubation temperature on the secretion

of extracellular ligninolytic enzymes of Pleurotussp. and Dichomitussqualens into soil, activity,

ecology and applications. J. Ind. Microbiol. Biotechnol.9, 12-16.

[44] Zoppellaro, G., Huang, H. W.& Sakurai, T. (2000) Kinetic studies on the reaction of the full reduced laccase with dioxygen. Inorg.Reac. Mech. 2, 79-84.