Influencia de PH

-

Upload

david-santiago -

Category

Documents

-

view

7 -

download

1

description

Transcript of Influencia de PH

Enzyme and Microbial Technology 31 (2002) 685–697

Influence of pH conditions on metabolic regulations in serine alkalineprotease production byBacillus licheniformis

Pınar Çalıka, Esra Bilirb,c, Güzide Çalıkb,c, Tunçer H. Özdamarb,c,∗a Department of Chemical Engineering, Middle East Technical University, 06531 Ankara, Turkey

b Department of Industrial Biotechnology, Biotechnology Research Center, Ankara University, Tandogan, 06100 Ankara, Turkeyc Department of Chemical Engineering, Ankara University, Tandogan, 06100 Ankara, Turkey

Received 16 December 2001; received in revised form 23 May 2002; accepted 7 June 2002

Abstract

The effects of the controlled and uncontrolled pH conditions, as well as of the value of initial pH in the range of 7–7.5, on serine alkalineprotease (SAP) production byBacillus licheniformis were investigated on a defined medium with the single carbon source glucose inbatch bioreactors. Besides uncontrolled pH operations, growth phase, production phase, and entire process control strategies were alsoapplied. The concentrations of the product (SAP) and by-products, i.e. neutral protease, amylase, amino acids, and organic acids weredetermined in addition to SAP activities. For SAP production, uncontrolled pH operation was more favourable than the controlled pHoperations; and pH0 = 7.25 was optimum for SAP production where maximum enzyme activity was obtained as 390 U cm−3, while,the highest cell concentration was obtained at pH0 = 7 in uncontrolled operation. Thereafter, by using the experimental data obtained atpH0 = 7, 7.25 and 7.5 uncontrolled pH operations, perturbation effects of pH on the intracellular flux distributions were investigated forthe growth (0< t < 20 h) and SAP production (20< t ≤ 43 h) periods. In the growth phase the fluxes of the glycolysis pathway and theTCA cycle increased with the increase in pH0; further, due to the difference in proton electrochemical gradients generated, the lowest andthe highest energies were produced at pH0 = 7 and 7.5 conditions, respectively. In the SAP production period, at pH0 = 7.5 and 7 theglycolysis pathway fluxes were, respectively, the lowest and the highest. However, the TCA cycle fluxes, amino acid synthesis fluxes andSAP synthesis flux were the highest at pH0 = 7.25 condition. The diversions in the pathways and certain metabolic reactions and potentialstrategies for improving SAP production are also discussed.© 2002 Elsevier Science Inc. All rights reserved.

Keywords: Serine alkaline protease; pH; Intracellular fluxes; Metabolic flux analysis; By-products

1. Introduction

The state of a bioprocess depends primarily on thebiomolecule synthesis capacity of either the wild-type orrecombinant organism, based on its genetic structure and

Abbreviations: GP, growth phase; PP, production phase; EP, entire process; C-GP, growth phase pH controlled operation; C-PP, production phasepH controlled operation; C-EP, entire process pH controlled operation; UC:7, uncontrolled pH operation starting at pH0 = 7; UC:7.25, uncontrolledpH operation starting at pH0 = 7.25; UC:7.5, uncontrolled pH operation starting at pH0 = 7.5; pH0, initial pH; Ac, acetate; AcCoA, acetyl coen-zyme A; ADP, adenosine-5′-diphosphate; Ala,l-alanine; Arg,l-arginine; Asn,l-asparagine; Asp,l-aspartate; AspSa, aspartate semialdehyde; ATP,adenosine-5′-triphosphate; Chor, chorismate; Cit, citrate; Citr, citruline; Cys,l-cysteine; DC,l,2,3-dihyrodipicolinate; E4P, erythrose-4-phosphate; F6P,fructose-6-phosphate; FADH, flavine adenine dinucleotide (reduced); Fum, fumarate; G6P, glucose-6-phosphate; Glc, glucose; Gln,l-glutamine; Glu,l-glutamate; Glx, glyoxlate; Gly,l-glycine; His, l-histidine; Hser, homoserine; Icit, isocitrate; IGP, indoleglycerolphosphate; Ile,l-isoleucine;�KG,�-ketoglutarate; Kval, ketovaline; Lac, lactate; Leu,l-leucine; Lys,l-lysine; Mal, malate; mDAP, meso-diaminopimelate; Met,l-methionine; NADH, nicoti-namide adenine dinucleotide (reduced); NADPH, nicotinamide adenine dinucleotide phosphate (reduced); OA, oxaloacetate; Orn, ornithine; PEP, phospho-enolpyruvate; PG3, glycerate-3-phosphate; Phe,l-phenylalanine; PPP, pentose phosphate pathway; Pro,l-proline; PRPP, 5-phospo-d-ribosylpyrophosphate;Pyr, pyruvate; R5P, ribulose-5-phosphate; Rib5P, ribose-5-phosphate; S7P, sedoheptulose-7-phosphate; SAP, serine alkaline protease; Ser,l-serine; Suc, suc-cinate; SucCoA, succinate coenzyme A; Xyl5P, xylulose-5-phosphate; T3P, triose-3-phosphate; TCA, tricarboxylic acid; Tet,l,2,3,4,5-tetrahydrodipicolinate;Thr, l-threonine; Trp,l-tyrptophan; Tyr,l-tyrosine; Val,l-valine

∗ Corresponding author. Tel.:+90-312-2126720x1354; fax:+90-312-2232395.E-mail address: [email protected] (T.H. Özdamar).

genetic control mechanism whereupon the regulation ofthe intracellular bioreaction network. An industrial mi-croorganism as the microbioreactor, function with stronginteractions within its microenvironment in an aerobic fer-mentation, which should be properly formed by the design

0141-0229/02/$ – see front matter © 2002 Elsevier Science Inc. All rights reserved.PII: S0141-0229(02)00162-X

686 P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697

Nomenclature

A SAP activityCDO dissolved oxygen concentration (mol m−3)CG glucose concentration (kg m−3)CSAP serine alkaline protease concentration (kg m−3)CX microorganism concentration (kg dry cell m−3)DO dissolved oxygenKLa overall liquid film mass transfer

coefficient (s−1)N agitation rate (min−1)Qo volumetric air feed rate (m3 min−1)SAP serine alkaline proteaset bioreactor cultivation time (h)T bioreaction medium temperature (◦C)V volume of the bioreactor (m3)VR volume of the bioreaction media (m3)Y(P/S) overall specific product yield on substrate

(g g−1)Y(P/X) overall amount of SAP produced per amount

of cell generated (g g−1)Y(X/S) overall specific cell yield on substrate (g g−1)

of the medium with the oxygen transfer and pH conditions.These bioreactor operation conditions affect product andby-product formations in aerobic fermentation processesby influencing metabolic pathways and changing metabolicfluxes. On the basis of these interactions some bioprocessesrequire high oxygen transfer rates, while others requirecontrolled oxygen transfer rates to regulate oxygen uptakerates[1,4]; similarly, some bioprocesses require controlledpH conditions, while others might require uncontrolled pHoperations, in order to increase the product yield and se-lectivity. The interactions between the bioreactor operationconditions and the intracellular bioreaction network encour-age the investigation of characteristic strategies in order tofine-tune bioreactor performance.

Publications on alkaline protease related with pH gen-erally reported the application of controlled pH conditionswithout any discussion[5–9]. Two research groups, i.e.Hübner et al.[10] and van Putten et al.[11] (pH0 = 6.8),and Çalık et al.[1,4] (pH0 = 7.25), however, applied un-controlled pH operations. Frankena et al.[5,6] conductedprotease production at pH0 = 7; Wright et al.[8], at pH0 =7.5. Among these controlled pH operations only Moon andParulekar[9] investigated the controlled pH effect and re-ported the optimum as pH= 7.7. On the other hand, thereis no publication in the literature that reported the influenceof the operation parameter pH on the intracellular reactionrates.

Interactions between the metabolic reactions and geneticregulatory mechanisms, and product and by-product forma-tions in the bioprocess for the SAP production are dependent

on pH conditions and enable introduction of well-definedperturbations. The present work reports the effects of thepH controlled conditions and for the first time the effectsof uncontrolled pH conditions byBacillus licheniformis onSAP (EC 3.4.21.14) production in a defined medium withglucose as sole carbon source, and the variations in productand by-product concentrations, and SAP activity in connec-tion with pH. Thereafter, by using the experimental data,the effects of the bioreactor operation condition pH on theintracellular flux distributions were investigated in order todetermine the perturbation effect of initial pH on the intra-cellular metabolic reactions.

2. Experimental methods

2.1. Microorganism and culture maintenance

B. licheniformis DSM 1969 (Deutsche Sammlung vonMikroorganismen und Zellkulturen GmbH) was used asproducer of serine alkaline protease (SAP) enzyme. Stockcultures were maintained on agar slants that contained(kg m−3): peptone, 5; azocasein, 2.5; MnSO4·2H2O, 0.010;and agar, 15.

2.2. Media and bioreactors

Cells from newly prepared slants were inoculated into thepreculture medium for preparation of inocula that contained(kg m−3): soytryptone, 15; peptone, 5; MnSO4·2H2O, 0.010;Na2HPO4, 0.25; and CaCl2, 0.100 and grown at 37◦C for6 h. The composition of SAP production medium for batchbioreactor fermentations was designed as (kg m−3): glucose,6; (NH4)2HPO4, 4.7; and KH2PO4, 2 and 0.04 M Na2HPO4and 0.04 M NaH2PO4. The laboratory-scale 3.5 dm3 batchbioreactors (Chemap, CF 3000, Volketswil, Switzerland)consisted of a system of working volume 1× 10−3–2.5 ×10−3 m3, each with temperature, pH, foam, stirring rateand dissolved oxygen control, which were stirred with twofour-blade Rushton turbines[3].

2.3. Analyses

Proteolytic activity was measured by hydrolysis of casein.The culture broth was harvested by centrifugation (SorvallRC 285, Dupont, Wilmington, DE, USA) at 7000× g and+4◦C for 15 min. Two millilitre of 0.5% (w/v) Hammerstencasein in borate buffer (50 mM, pH= 10) was mixed with1 ml of diluted bacterial broth and hydrolysed underT =37◦C, pH= 10 andt = 20 min conditions. The reaction wasstopped by adding 2 ml of 10% (w/v) trichloroacetic acid, themixture was centrifuged at 28,700× g for 10 min at+4◦C,and absorbance of the supernatant was measured at 275 nmwith a UV–VIS spectrophotometer (Shimadzu UV-160A,Tokyo, Japan). One unit protease activity was defined as theactivity that liberates 4 nmol of tyrosine per minute[1].

P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697 687

Cell concentrations based on dry weights (DWs) weremeasured with a UV–VIS spectrophotometer (SchimadzuUV-160A, Tokyo, Japan), using a calibration curve obtainedat 600 nm[1].

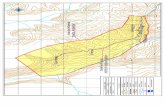

Fig. 1. Metabolic pathway map ofB. licheniformis.

SAP, neutral protease (NP), and amylase concentra-tions were measured using a high performance capillaryelectrophoresis (Waters HPCE, Quanta 4000E, Milford,MA, USA). The samples were analysed at 12 kV and

688 P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697

15◦C with a positive power supply as described elsewhere[1].

Amino acid concentrations were measured with an aminoacid analysis system (Waters, HPLC, Milford, MA, USA),using the Pico Tag method. The method is based on reversedphase HPLC that uses a precolumn derivation technique witha gradient program developed for amino acids[1].

Organic acid concentrations were determined with a highperformance capillary electrophoresis at 254 nm (WatersHPCE, Quanta 4000E, Milford, MA, USA). The sampleswere analysed at 20 kV and 15◦C with a negative powersupply by hydrostatic pressure injection, using an electrolytecontaining 5 mM potassium hydrogen phtalate and 0.5 mMOFM Anion Bt (Waters, Milford, MA, USA) as the flowmodifier at pH= 5.6 (for �-ketoglutaric, acetic, malic, fu-maric, succinic, lactic, oxaloacetic and gluconic acids) andat pH= 7 (for pyruvic, citric, lactic, and gluconic acids)[1].

2.4. Mass flux balance-based analysis

The metabolic reaction network ofB. licheniformis [12]that contains 105 metabolites and 147 intracellular reactionsis used by the addition of the, anaplerotic reaction:

R 148 : Pyr+ CO2 → OA

catalysed by pyruvate carboxylase, which connects the gly-colysis pathway to the TCA cycle. Consequently, the massflux balance-based stoichiometric model[12] is extendedto 105 metabolites and 148 reaction fluxes; and, the simpli-fied metabolic pathway map ofB. licheniformis is shownin Fig. 1. The details of the metabolic flux analysis aredescribed elsewhere[2,12,13]. In this study, as SAP is anextracellular enzyme that is excreted to the broth when thepolypeptide chain synthesis is completed, for the theoreticaldata-based intracellular flux analysis the model was solvedby minimising the SAP accumulation rate in the cell, asdescribed elsewhere in detail[12].

3. Results

SAP fermentations were accomplished in batch bioreac-tors equipped with dissolved oxygen, pH, foam, agitationrate and air flow rate measurements, and controls; andproduct and by-product distributions and oxygen transfercharacteristics of the bioprocess for SAP production wereinvestigated atT = 37◦C, optimum initial glucose con-centrationCG = 6 kg m−3, agitation rateN = 750 min−1

and air inlet rateQo/VR = 0.5 vvm conditions[4] withuncontrolled and controlled pH strategies. The uncontrolledpH experiments were carried out within the initial pH range7–7.5; and the three controlled strategies namely growthphase, production phase, and entire process controls wereapplied. The abbreviations of these six different pH opera-tions were given inTable 1.

Table 1Abbreviations of applied pH strategies

pH0 Uncontrolledoperation

Controlled operation

Growth Production Entirephase (GP) phase (PP) process (EP)

7 UC:7 – – –7.25 UC:7.25 C-GP C-PP C-EP7.5 UC:7.5 – – –

3.1. Effects of uncontrolled pH operation

3.1.1. Glucose and biomass concentration profilesThe variations of the glucose—that enters to the carbon

metabolism from the beginning of the glycolysis pathway—and biomass concentrations with the cultivation time and ini-tial medium pH are given inFig. 2. Considering the biomassconcentration profiles, the bioprocess can be divided simplyinto two periods. Period I (0< t ≤ 20 h) covers the growthphase and, period II (20< t < 43 h) covers the stationaryphase of the fermentation. In period I, the consumption rateof the substrate increases with the increasing initial pH andit was the highest at pH0 = 7.5 and the lowest at pH0 = 7;however, in period II glucose consumption rate decreaseswith the increasing initial pH most probably due to the de-creased glucose concentration. The highest and the lowestcell concentrations and overall specific cell yields on sub-strate (YX/S) were the highest at pH0 = 7, (YX/S = 0.38),and the lowest at pH0 = 7.5, (YX/S = 0.26); while YX/Svalue was 0.28 at pH0 = 7.25.

3.1.2. Dissolved oxygen concentration and pH profilesThe variations of the medium pH and dissolved oxygen

concentration with the cultivation time and initial mediumpH are shown inFig. 3. As it is seen inFig. 3, dissolvedoxygen concentration exhibited a sudden drop at the earlyhours of the fermentation; and it did not change considerablyafter ca.t = 12 h due to the high oxygen transfer rate. At allthe investigated pH0 values, medium pH has a tendency todecrease with the cultivation time untilt = 16–20 h; then itincreased until the end of the fermentation. The locus of pHversust profiles obtained at all the initial pH values do notdiffer from each other significantly in period I; nevertheless,no substantial increase was obtained at pH0 = 7 in periodII due to the influence of higher hydrogen ion concentrationon the metabolic network.

3.1.3. SAP activity profilesThe variations of the SAP activity with the cultivation

time and initial medium pH are shown inFig. 4. It is clearfrom the figure that SAP concentration started to increasesubstantially att = 20 h; moreover high production ratesof SAP corresponds to the stationary phase of the growth(Fig. 2) due to the nongrowth associated synthesis of theenzyme. As there was no SAP production beforet = 20 h,period II (20 < t < 43 h) can be regarded as the SAP

P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697 689

Fig. 2. The variations in the biomass and glucose concentrations with the cultivation time and the initial pH.T = 37◦C, CG = 6 kg m−3, Qo/VR = 1 vvm,N = 750 min−1, VR = 2 × 10−3 m3. pH0: (�, �) 7; (�, �) 7.25; (�, �) 7.5.

Fig. 3. The variations in the dissolved oxygen concentration (% air saturation) and medium pH with the cultivation time and the initial pH.T = 37◦C,CG = 6 kg m−3, Qo/VR = 1 vvm, N = 750 min−1, VR = 2 × 10−3 m3. pH0: (– · – · –) 7; (—) 7.25; (- - -) 7.5.

690 P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697

Fig. 4. The variations in the SAP enzyme activity with the cultivation time and the initial pH rate.T = 37◦C, CG = 6 kg m−3, Qo/VR = 1 vvm,N = 750 min−1, VR = 2 × 10−3 m3. pH0: (�) 7; (�) 7.25; (�) 7.5.

production phase. The regulation of protease synthesis hasnot been studied inB. licheniformis yet, but its pattern islikely to be similar to that found forBacillus subtilis; andthe biosynthesis of SAP is dependent on the induction ofsporulation, and on the concentration of carbon and nitrogensources. At the end of the fermentations, under pH0 = 7.25condition SAP activity was the highest and its value wasU = 390 U cm−3 (230 U mg−1).

3.1.4. Organic acid concentrationsAs glucose enters to the carbon metabolism from the be-

ginning of the glycolysis pathway for the biomass gener-ation and SAP synthesis, all the central pathways, i.e. theglycolysis, the pentose phosphate pathway (PPP), and theTCA cycle and the routes going through the nucleotides, co-factors, fatty acids, biomass components, and amino acidsshould be active. However, due to the differences in enzymesyntheses and activities in the metabolic network resultingfrom the perturbation effect of pH some of the organic acidsare produced more than the demand of the cells. Thus, atpH0 = 7 citric and succinic acids; and at pH0 = 7.25�-ketoglutaric, citric, succinic, lactic and pyruvic acids; andat pH0 = 7.5 �-ketoglutaric, citric, succinic and gluconicacids were observed in the fermentation broth. Excreted to-tal organic acid concentration increased untilt = 24 h at alloperation conditions and then decreased slowly. The total or-ganic acid concentration increased with the increasing initialpH; and, at pH0 = 7 varied between 0.03 and 0.85 kg m−3, at

pH0 = 7.25 between 0.05 and 1.2 kg m−3 and at pH0 = 7.5between 0.06 and 1.45 kg m−3.

3.1.5. Amino acid concentrationsAt all operation conditions,l-aspartate (Asp),l-arginine

(Arg), l-glycine (Gly), andl-methionine (Met) were notdetected in the fermentation broth. On the other hand,l-asparagine (Asn) that was not observed in the fermen-tation broth with the sole carbon source citrate[1] wasobserved at trace levels at the beginning of the fermenta-tion, with the carbon source glucose. Furthermore,l-lysine(Lys) that was the amino acid having the highest concen-tration in the fermentation with citrate[1] was at low levelswith glucose. Thus, besides organic acids, amino acid pro-duction rates were also affected by the initial pH whichconsequently affected the SAP production. The total aminoacid concentration at pH0 = 7 varied between 0.06 and0.30 kg m−3, at pH0 = 7.25 between 0.02 and 0.50 kg m−3,and at pH0 = 7.5 between 0.03 and 0.45 kg m−3. At all theuncontrolled pH operations excreted amino acid concentra-tions increased untilt = 12 h and then decreased slowlytill t = 24 h and aftert = 24 h decreased considerably, dueto their consumption as carbon/energy source as glucoselevels were reduced.

3.1.6. Oxygen transfer characteristicsThe dynamic method was applied[14] to find the oxygen

uptake rate and oxygen transfer coefficientKLa values during

P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697 691

the cultivation times corresponding to the characteristic re-gions of the batch bioprocess. At all the uncontrolled pHoperation conditionsKLa was between 0.040 and 0.055 s−1,and oxygen uptake rate decreased with the cultivation timeafter t = 8–12 h.

3.2. Effects of controlled pH operation

3.2.1. pH profilesThree control strategies namely growth phase, production

phase, and entire process controls were applied at initialpH0 = 7.25 that was found as the best in terms of SAPproduction among the uncontrolled operations. pH controlswere conducted with 5 M KOH and 5 M H2SO4 solutions.Variation of pH with the cultivation time for the controlledpH operations are presented inFig. 5 together with theuncontrolled pH profile of pH0 = 7.25. As it is seen inFig. 5, at the end of the bioprocess, medium pH was thehighest at the growth phase controlled operation (C-GP)and the lowest at the production phase controlled operation(C-PP).

3.2.2. Glucose and biomass concentration profilesEffect of controlled pH operations on biomass and glu-

cose concentrations are presented inFig. 6together with the

Fig. 5. pH profiles under different pH strategies.T = 37◦C, CG = 6 kg m−3, Qo/VR = 1 vvm, N = 750 min−1, VR = 2 × 10−3 m3. (—) UC:7.25;(– · – · –) C-GP; ( ) C-PP; (- - -) C-EP.

cell and glucose concentration profiles of uncontrolled pHoperation of pH0 = 7.25. As it is seen inFig. 6, the highestbiomass concentration was obtained under C-PP which hadno significant difference than the uncontrolled pH operationat pH0 = 7.25 (UC:7.25); where the lowest cell concen-trations were obtained at the C-GP and entire process pHcontrolled (C-EP) operations. Glucose consumption of C-PPand uncontrolled pH operation at pH0 = 7.25 (UC:7.25)were similar until t = 24 h, as expected; however, aftert = 24 h glucose consumption was lower at C-PP than theuncontrolled pH operation. On the other hand, in the first24 h of the fermentation the glucose consumption profiles ofC-GP and C-EP operations were similar, as expected. How-ever, aftert = 24 h the glucose consumption rate increasedin C-GP (Fig. 6).

3.2.3. SAP activity profilesEffect of controlled pH operations on SAP activity is pre-

sented inFig. 7together with the SAP activity profile of un-controlled pH operation at pH0 = 7.25 (UC:7.25). As it isseen inFig. 7, there was almost no SAP production when theentire process was pH controlled (C-EP) probably due to theinhibition caused by the high amount of sulphate ions usedfor the pH control. On the other hand, glucose was utilisedand the cell was generated (Fig. 6). For SAP production,

692 P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697

Fig. 6. The variations in glucose and cell concentrations with the cultivation time under different pH strategies.T = 37◦C, CG = 6 kg m−3, Qo/VR = 1 vvm,N = 750 min−1,VR = 2 × 10−3 m3. (�, �) UC:7.25; (�, �) C-GP; (�, �) C-PP; (�, �) C-EP.

Fig. 7. The variations in the SAP enzyme activity with the cultivation time under different pH strategies.T = 37◦C, CG = 6 kg m−3, Qo/VR = 1 vvm,N = 750 min−1, VR = 2 × 10−3 m3. (�) UC:7.25; (�) C-GP; (�) C-PP; (�) C-EP.

P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697 693

Table 2Variations in metabolic flux distributions with the initial hydrogen ion concentration (reaction rows having zero flux values have been eliminated)

Reaction number Period I (mmol g−1DW h−1) Period II (mmol g−1DW h−1)

7 (t = 9 h) 7.25 (t = 9 h) 7.5 (t = 9 h) 7 (t = 33 h) 7.25 (t = 33 h) 7.5 (t = 33 h)

1 1.154 1.6 2.354 0.176 0.125 0.063 1.133 1.539 2.361 0.176 0.125 0.068 1.065 1.548 2.353 0.157 0.12 0.065

10 2.066 3.095 4.697 0.301 0.233 0.1312 1.884 3.095 4.697 0.286 0.224 0.11814 0.616 1.469 2.318 0.095 0.075 0.04616 1.354 2.459 0 0.135 0.429 0.07117 0 0.055 0 0 0 018 0.046 0 0.011 0 0 0.01519 0.046 0 0.011 0 0 0.01520 0.046 0.055 0.011 0 0 0.01521 0 0.13 0 0 0 0.00522 0.057 0 0.006 0.019 0.005 0.01123 0 0.013 0.00047 0 0.004 0.00624 0 0 0 0.005 0 025 0 0.013 0.00047 0 0.004 0.00626 0 0 0 0.005 0 028 0.057 0 0.007 0.013 0.008 0.00016429 0 0.012 0 0 0.004 0.00630 0.003 0 0 0.005 0 031 0 0.15 0 0 0 034 0.154 0.056 0.032 0.041 0.059 0.0335 0 0 0 0 0 037 0.618 2.365 4.31 0.128 0.351 0.03838 0.594 2.365 4.31 0.128 0.351 0.03839 0.206 2.365 4.187 0.128 0.275 0.00440 0.056 2.004 4.036 0.109 0.271 041 0.056 2.004 4.036 0.109 0.742 043 0.469 2.004 4.224 0.109 0.347 0.03444 0.55 2.027 4.237 0.133 0.349 0.0445 0.938 2.027 4.360 0.133 0.425 0.07446 0.389 0 0.123 0 0.076 0.03447 0.389 0 0.123 0 0.076 0.03448 0.182 0 0 0.015 0.009 0.01349 0.099 0.028 0.016 0.013 0.003 0.00650 0.026 0.027 0.013 0.000225 0.00075 0.00351 0.067 0.004 0.161 0.005 0.006 0.00952 0.124 0.024 0.016 0.014 0.007 0.00553 0.075 0.014 0.008 0.006 0.005 0.00454 0.049 0.01 0.008 0.008 0.002 0.00255 0.099 0.028 0.016 0.024 0.00090 0.00456 0.007 0.003 0.001 0.024 0.00075 0.00457 0.32 0.083 0.05 0.067 0.074 0.03558 0.027 0.008 0.004 0.00081 0.003 0.00259 0.132 0.029 0.02 0.042 0.069 0.02660 0.05 0.007 0.007 0.04 0.056 0.01961 0.05 0.007 0.007 0.04 0.056 0.01962 0.05 0.007 0.007 0.04 0.056 0.01963 0.047 0.006 0.006 0.04 0.056 0.01964 0.081 0.022 0.013 0.001 0.013 0.00865 0.064 0.017 0.01 0.001 0.012 0.00566 0.034 0.009 0.005 0.0002 0.001 0.00167 0.017 0.005 0.003 0.000225 0.00075 0.00368 0.054 0.012 0.007 0.008 0.012 0.00669 0.031 0.006 0.003 0.007 0.001 0.00270 0.016 0.005 0.002 0.00058 0.002 0.00371 0.006 0.002 0.001 0.00045 0.00015 0.00011572 0.006 0.002 0.001 0.00045 0.00015 0.00011573 1.025 0 0.405 0.193 0.170 0.09874 0.262 0.252 0.042 0.026 0.005 0.00975 0.025 0 0.134 0.004 0.001 0.001

694 P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697

Table 2 (Continued )

Reaction number Period I (mmol g−1DW h−1) Period II (mmol g−1DW h−1)

7 (t = 9 h) 7.25 (t = 9 h) 7.5 (t = 9 h) 7 (t = 33 h) 7.25 (t = 33 h) 7.5 (t = 33 h)

76 0.042 0.012 0.007 0.00018 0.00060 0.00277 0.035 0.01 0.006 0.00018 0.00060 0.00278 0.035 0.01 0.006 0.00018 0.00060 0.00284 0 0.178 0 0 0 097 0.04 0.012 0.007 0.024 0.00075 0.00498 0.027 0.008 0.004 0 0 099 0.027 0.008 0.004 0 0 0

100 0.038 0.011 0.006 0.024 0.00075 0.004102 0.002 0.0007 0.0004 0 0 0103 0.002 0.0007 0.0004 0 0 0104 0.013 0.004 0.002 0.024 0.00075 0.004105 0.246 0.068 0.04 0.05 0.00 0.019106 0.053 0.015 0.008 0 0 0107 0.053 0.015 0.008 0 0 0108 0.05 0.014 0.008 0 0 0109 0.023 0.007 0.004 0 0 0110 0.002 0.0007 0.0004 0 0 0112 0.002 0.0007 0.0004 0 0 0113 0.002 0.0007 0.0004 0 0 0114 0.002 0.0007 0.0004 0 0 0115 0 0 0 0.011 0 0.002116 0.017 0.005 0.003 0.000225 0.00075 0.003117 0.073 0.021 0.012 0.024 0.00075 0.004118 0.073 0.021 0.012 0.024 0.00075 0.004119 0.006 0.001 0.000855 0 0.002 0120 2.014 0 0 0.157 0.063 0.172121 0 2.005 3.341 0 0 0122 2.782 11.481 20.96 0.605 1.308 0.145123 0.469 2.004 4.224 0.109 0.347 0.034124 1.757 6.475 12.736 0.377 1.042 0.114126 1.265 0.224 0.435 0.207 0.175 0.101128 0.044 0.01 0.007 0.00045 0.001 0.007129 0.263 0.073 0.043 0.05 0.006 0.019130 0.268 0.075 0.043 0 0 0132 0.016 0.005 0.003 0 0 0133 0.003 0.000822 0.00047 0 0 0134 0.003 0.000822 0.00047 0 0 0135 0.032 0.009 0.005 0 0 0136 0.088 0.025 0.014 0.00018 0.00060 0.002137 0.009 0.002 0.001 0 0 0138 0.003 0.000966 0.000552 0 0 0139 0.003 0.000822 0.00047 0 0 0140 0.003 0.000822 0.00047 0 0 0141 0.003 0.000822 0.00047 0 0 0142 0.021 0.006 0.003 0 0 0144 0.002 0.000549 0.000314 0 0 0145 0.125 0.035 0.02 0 0 0146 0 0 0 4.5E−5 0.00015 1.15E−4147 0.469 27.801 53.544 1.419 3.244 0.289148 0 0.421 0 0.062 0 0

C-GP was better than C-PP but worse than the uncontrolledpH operation (UC:7.25).

3.3. pH influence on intracellular metabolicflux distributions

Interactions between the metabolic reactions and ge-netic regulatory mechanism, and product and by-product

formations in the bioprocess for the SAP production aredependent on the pH strategies applied in the bioreactor andenable introduction of well-defined perturbations. Metabolicflux analyses were conducted for the three uncontrolledpH operations namely pH0 = 7, 7.25 and 7.5. Consideringthe biomass and SAP concentrations and activity profilesat pH0 = 7, 7.25, and 7.5 conditions, the bioprocess wasdivided into two periods. Period I (0< t ≤ 20 h) and

P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697 695

period II (20< t < 43 h) were regarded as the cell growthand SAP synthesis periods, respectively. The experimentaldata att1 = 9 h andt2 = 33 h were used to calculate theintracellular metabolic flux distributions in period I andperiod II, respectively. The extensive analysis of the brothdid not reveal any pools of metabolic products that are notincluded in the mass balance-based stoichiometric modelof the bioreaction network. The data obtained throughoutSAP fermentation were exploited, using a linear optimisa-tion approach, to calculate the specific growth rate and theuptake and excretion rates of the metabolites, i.e. the aminoacids, the organic acids, and the secretion rate of SAP. Themeasured net-output rates of metabolites that are derivedfrom the data points of the batch bioreactor experimentswere used in the model in order to calculate the intracellularflux distributions, as described elsewhere[2,12]. The biore-action network rates were calculated at pH0 = 7, 7.25, and7.5 uncontrolled pH operation conditions, and reaction ratedistributions were obtained from the solution of the model,based on the minimum in vivo SAP accumulation rate incombination with the elaborate experimental data for thegrowth phase (att = 9 h) and for the SAP synthesis phase (att = 33 h), and the fluxes for the selected reactions are givenin Table 2.

3.3.1. Period I: cell growth phaseThe sole carbon source in the defined medium was glucose

that enters to the bioreaction network from the beginningof the glycolysis pathway, the rate of which is influencedby the pH0 condition. The fluxes of the glycolysis pathwayand the TCA cycle (R38–R45), increased with the increasein pH0; they were the lowest at pH0 = 7 and the highest atpH0 = 7.5, in period I. On the other hand, the gluconeo-genesis pathway reactions were inactive at these three op-eration conditions, as expected, while the glyoxylate shunt(R46–R47) was considerably active at pH0 = 7; however, itwas either inactive or poorly active at other pH values. Withthe increase in the initial pH, the CO2 flux increased thus,in period I the rate of CO2 evolution (R124) was the highestand the lowest, respectively, at pH0 = 7.5 and 7.

The fluxes through the nucleotides (R93–R113), cofactors(R114–R119), fatty acids (R132–R136) and biomass com-ponents (R137–R144) were active; and they were the high-est and the lowest, respectively, at pH0 = 7, and 7.5. Con-sequently, the specific growth rate (R145) was the highestat pH0 = 7 and the lowest at pH0 = 7.5. The SAP syn-thesis rate was zero for these three conditions. The reactionR16 that connects the glycolysis pathway to the TCA cy-cle, was active; furthermore, at pH0 = 7 and pH0 = 7.25the connection of the glycolysis pathway to the TCA cyclewas also achieved by the anaplerotic reaction R148 catal-ysed by pyruvate carboxylase. The glycolysis pathway fluxvalues of pH0 = 7.5 are approximately two-fold higher thanthose of the pH0 = 7. At all the operation conditions thePPP was active; nevertheless, at pH0 = 7.25 the oxidativereactions (R17–R20) and also the interconversion reactions

(R21–R30) were active while at pH0 = 7 and pH0 = 7.5only the interconversion reactions were active.

The total ATP generation rate (R10, R14, R41, R122,R123) increased with the increase in pH0 and it was thelowest at pH0 = 7 and the highest at pH0 = 7.5. The ATPrequirement for the transportation, translocation and mainte-nance of the gradients stated in the model as the hydrolysisof ATP (R147) to ADP increased with the increase in pH0.

3.3.2. Period II: SAP synthesis phaseIn the SAP synthesis period, the glycolysis pathway fluxes

were decreased due to the decrease in glucose concentration.Further, the TCA cycle fluxes were the highest at pH0 =7.25 and the lowest at pH0 = 7.5 On the other hand, rateof CO2 evolution (R124) was the lowest and the highest,respectively, at pH0 = 7.5 and 7.25 conditions. However, asexpected, the TCA cycle fluxes and CO2 evolution in periodII were much lower than those of period I. In period II, thebiomass formation flux (R145) was zero.

The flux partitioning at�KG (R73) towards glutamategroup and at OA (R57) towards aspartic acid group aminoacids are dependent on the pH0 condition. The maxima ofboth R73 and R57 were obtained in period I at pH0 = 7condition; but in the SAP synthesis phase while the maxi-mum of R57 was obtained at pH0 = 7.25, the maximum ofR73 was obtained at pH0 = 7. Moreover, at pH0 = 7.25the amino acidsl-serine (Ser, R48), Gly (R49),l-cysteine(Cys, R50),l-alanine (Ala, R51),l-histidine (His, R56),Asp (R57), Asn (R58),l-threonine (Thr, R65),l-isoleucine(Ile, R66), Met (R67), tryptophan (Trp, R72),l-glutamate(Glu, R73),l-proline (Pro, R76), and Arg (R78) biosynthe-sis rates were the highest that yielded the highest SAP syn-thesis rate (R146). Although the total amino acid fluxes ofpH0 = 7.5 were lower than that of pH0 = 7, the lowest SAPsynthesis flux was obtained at pH0 = 7.

4. Discussion and conclusions

Since the phases of a bioprocess are dynamic and arethe consequences of directed functioning of the bioreactionnetwork interacting strongly with the microenvironmentof the cell, the influence of the operational variable pHon the overall bioreaction is indeed important and needsclarification in order to develop an operational strategy.Membrane-bound respiratory chains of the bacilli that catal-yse the transfer of reducing equivalents from a reducedsubstrate to an oxidant is spontaneous, and is based onthe differences in oxidation-reduction potential among themembers of the chain. A release of free energy is associ-ated with transfer of reducing equivalents, and energy isconserved as a transmembrane electrochemical gradient ofprotons [15]. In Bacillus species this gradient is used todrive energy-requiring reactions, including solute transport,ATP synthesis via oxidative phosphorylation and motility[16]. Microbial cells have a remarkable ability to maintain

696 P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697

the intracellular pH at a constant level even with largevariations in the pH of the extracellular medium, but onlyat the expense of a significant increase in the maintenancedemands, since Gibbs free energy has to be used for main-taining the proton gradient across the cell membrane[17].Under the influence of the operational conditions pH andoxygen transfer including the designed medium, the cellpumps H+ ions in or out through the membrane. Where-upon, the pH of the environment has a natural tendencyto change along with the bioprocess despite the fact thatintracellular pH is kept constant.

The effects of the controlled and uncontrolled pH con-ditions and hydrogen ion concentration on SAP productionby B. licheniformis on a defined medium with a single car-bon source, i.e. glucose, were investigated in the range ofinitial pH0 = 7–7.5 in batch bioreactors. Considering thebiomass, SAP activity, glucose and H+ concentration pro-files the bioprocess can be divided into two typical periodsnamely growth (t = 0–20 h: period I) and SAP production(t = 20–43 h: period II) periods. The results showed thatthe glucose consumption rate depended significantly on theinitial pH in period I, and consequently the proton electro-chemical gradient that is related to the proton concentrationsin the bulk extracellular and intracellular aqueous phases andthe membrane potential (adjusted to compensate for changesin the extracellular–intracellular pH difference) produced byB. licheniformis whose intracellular aqueous (cytoplasmic)pH is 7.5. In period I, the glucose consumption rate was thehighest at pH0 = 7.5 condition where the proton electro-chemical gradient was the lowest. On the other hand, glu-cose consumption rate was the lowest at pH0 = 7 wherethe proton electrochemical gradient was the highest. Underall uncontrolled operations pH of the broth decreased untilt = 18 h and aftert = 20 h medium pH started to increasedue to H+ transport into the cells. Under uncontrolled ex-periments, in the first 20 h of the process as the pH of thebroth decreased, proton electrochemical gradient increased.The higher or lower proton electrochemical gradient resulteddifferences in the metabolism; thus, although the glucoseconsumption was the highest at pH0 = 7.5 the biomass pro-duced was the lowest, and at pH0 = 7 the glucose consump-tion was the lowest; however, the biomass production wasthe highest.

In SAP production period, at uncontrolled pH opera-tion the glucose consumption and biomass production ratesdecreased, SAP concentration increased, and proton elec-trochemical gradient decreased. Uncontrolled pH operationstarting at pH0 = 7.25 was optimum for SAP production;however, pH0 = 7 was optimum for biomass generation. Asincreasing the concentration of SAP producing cells mightimprove SAP production and the optimum initial pH mightbe between 7 and 7.25.

pH profile depends also on the carbon source used; when aTCA cycle intermediate such as citrate is used pH showed acontinuous increase throughout the bioprocess[1,4] owing tothe transfer of citrate to the cell. When the results of different

substrates used for SAP fermentations are compared onecan conclude that SAP production is nongrowth associatedwith glucose, while it is growth associated with citrate[1,4].Although the activity obtained with citrate was higher thanthat of glucose and the corresponding cultivation time (t =37 h) was lower, the enzyme was not able to maintain itshigh activity[1,4]. Nevertheless, with glucose either a slightdecrease or no decrease was observed after the maximumactivity was reached.

Metabolic flux analysis results show that with glucose asthe carbon source, energy is generated first in the glycolysispathway by the substrate level phosphorylation and then inthe TCA cycle by the oxidative phosphorylation reactions.During energy generation by the oxidative phosphoryla-tion reactions electrochemical gradient is indeed important.Since the proton electrochemical gradient was the lowestat pH0 = 7.5 conditions, the highest energy is generated(R10, R14, R41, R122, R123) and the energy is probablyused as maintenance energy (R147) to maintain the con-centration gradients and a fraction of the carbon should bedirected to energy production reactions to ensure properfunctioning of the cell. Consequently lowest biomass wasgenerated. Furthermore, due to the energy demand glucosewas consumed earliest at pH0 = 7.5 conditions. On theother hand, as the proton electrochemical gradient was thehighest at pH0 = 7, instead of using the carbon source togenerate energy for maintenance glucose was used for thesynthesis of building blocks of the biomass.

Lastly, during SAP synthesis period the TCA cycle fluxesand the amino acid synthesis fluxes were the highest atpH0 = 7.25; thus, addition of TCA cycle organic acids andthe addition of controlling amino acids to the fermentationbroth at limiting levels during SAP production might in-crease SAP synthesis and the addition of organic acids andthe controlling amino acids is currently being investigated.

Acknowledgments

This work was supported by the State Planing Organisa-tion-TÜBITAK (Turkey) grant 97K120590. The infras-tructure used in the experimental research provided bySPO-TÜBITAK (Turkey) grants 89K120390 and 95K120290are also gratefully acknowledged. E. Bilir was awarded aM.S. Scholarship by TÜBITAK (BAYG).

References

[1] Çalık P, Çalık G, Özdamar TH. Oxygen transfer effects in serinealkaline protease fermentation byBacillus licheniformis: use of citricacid as the carbon source. Enzyme Microb Technol 1998;23:451–61.

[2] Çalık P, Çalık G, Takaç S, Özdamar TH. Metabolic flux analysis forserine alkaline protease fermentation byBacillus licheniformis in adefined medium: effects of oxygen transfer rate. Biotechnol Bioeng1999;64:151–67.

P. Çalık et al. / Enzyme and Microbial Technology 31 (2002) 685–697 697

[3] Çalık P, Çalık G, Takaç S, Özdamar TH. Metabolic flux analysesfor serine alkaline protease production. Enzyme Microb Technol2000;27:793–805.

[4] Çalık P, Çalık G, Özdamar TH. Oxygen transfer strategy and itsregulation effects in serine alkaline protease production byBacilluslicheniformis. Biotechnol Bioeng 2000;69(3):301–11.

[5] Frankena J, van Verseveld HW, Stouthamer AH. A continuousculture study of the bioenergetic aspects of growth and productionof exocellular protease inBacillus licheniformis. Appl MicrobiolBiotechnol 1985;22:169–76.

[6] Frankena J, Koningstein GM, van Verseveld HW, Stouthamer AH.Effect of different limitations in chemostat cultures on growth andproduction of exocellular protease byBacillus licheniformis. ApplMicrobiol Biotechnol 1986;24:106–12.

[7] Kole MM, Draper I, Gerson DF. Protease production byBacillussubtilis in oxygen controlled, glucose fed-batch cultivation. ApplMicrobiol Biotechnol 1988;28:404–8.

[8] Wright CP, Whitney GK, Dauglis AJ, White BN. Enhancement andregulation of extracellular protein production byBacillus brevis 47through manipulation of cell culture conditions. Biotechnol Bioeng1992;40:46–52.

[9] Moon SH, Parulekar SJ. Some observations on protease productionin continuous suspension cultures ofBacillus firmus. BiotechnolBioeng 1993;41:43–54.

[10] Hübner U, Bock U, Schügerl K. Production of alkaline serineprotease subtilisin Carlsberg byBacillus licheniformis on complex

medium in a stirred tank reactor. Appl Microbiol Biotechnol 1993;40:182–8.

[11] van Putten AB, Spitzenberger F, Kretzmer G, Hitzmann B, Dors M,Simutis K, Schügerl K. Improvement of the production of subtilisinCarlsberg alkaline protease byBacillus licheniformis by on-lineprocess monitoring and control in a stirred tank reactor. J Biotechnol1996;49:83–93.

[12] Çalık P, Özdamar TH. Mass flux balance-based model and metabolicpathway analysis for serine alkaline protease synthesis byBacilluslicheniformis. Enzyme Microb Technol 1999;24:621–35.

[13] Çalık P, Özdamar TH. Carbon sources affect metabolic capacities ofBacillusspecies for the production of industrial enzymes: theoreticalanalyses for serine alkaline and neutral proteases and alpha-amylase.Biochem Eng J 2001;8:61–81.

[14] Rainer BW. Determination methods of the volumetric oxygentransfer coefficientKLa in bioreactors. Chem Biochem Eng 1990;4:185–96.

[15] Çalık P, Çalık G, Özdamar TH. Bioprocess development for serinealkaline protease production: a review. Rev Chem Eng 2001;17(SupplS):1–62.

[16] Taber HW. Respiratory chains. In: Sonenshein AL, Hoch JA,Lorich R, editors.Bacillus subtilis and other gram-positive bacteria:biochemistry, physiology, and molecular genetics. Washington, DC:American Society for Microbiology, 1993. p. 199–212.

[17] Nielsen J, Villadsen J. Bioreaction engineering principles. New York:Plenum Press, 1994. p. 55–83.