Industrial operations at saft – a review of the quality, lcc and logistical processes

-

Upload

serkan-alan -

Category

Technology

-

view

138 -

download

0

Transcript of Industrial operations at saft – a review of the quality, lcc and logistical processes

I N D U S T R I A L O P E R A T I O N S A T S A F T

– A R E V I E W O F T H E Q U A L I T Y , L C C A N D L O G I S T I C A L

P R O C E S S E S

Course: 1SE001 – Introduction to industrial operations

Authors: Martin Skogmalm, Charlotte Håkansson, Petter Dahllöf Ek, Serkan Alan

Datum: 2012-10-11

2 (33)

Abstract

Introduction to industrial operations, Linnaeus School of Mathematics and Engineering, Course code: 1SE001, Fall 2012

AUTHORS: Martin Skogmalm, Charlotte Håkansson, Petter Dahllöf Ek, Serkan Alan

SUPERVISOR: Anders Ingwald and Åsa Gustafsson

TITLE: Industrial operations at SAFT – a review of the Quality, LCC and Logistical processes

KEYWORDS: Quality, LCC, Logistics, ERP, Maintenance, 5S, Lean production.

3 (33)

Table of Contents

1 Introduction ................................................................................................................. 4 1.1 Background ................................................................................................................................................................ 4 1.1.1 Production process .............................................................................................................................................. 6

1.2 Problem discussion ................................................................................................................................................ 8 1.3 Research questions ................................................................................................................................................ 8 1.4 Purpose ........................................................................................................................................................................ 8 1.5 Limitation ................................................................................................................................................................... 8 1.6 Definitions .................................................................................................................................................................. 9 1.7 Method ....................................................................................................................................................................... 10

2 Literature review ....................................................................................................... 11 2.1 Quality ........................................................................................................................................................................ 11 2.1.1 Management's role ............................................................................................................................................ 11 2.1.2 Different methods in order to increase quality work ......................................................................... 12

2.2 LCC ............................................................................................................................................................................... 13 2.3 Logistics ..................................................................................................................................................................... 15 2.4 ERP .............................................................................................................................................................................. 16 2.5 Maintenance ............................................................................................................................................................ 16

3 Empirical ................................................................................................................... 19 3.1 Quality ........................................................................................................................................................................ 19 3.1.1 Background .......................................................................................................................................................... 19 3.1.2 Quality work today ............................................................................................................................................ 19 3.1.3 Leadership ............................................................................................................................................................. 20 3.1.4 Education ............................................................................................................................................................... 20 3.1.5 Results ..................................................................................................................................................................... 20 3.1.6 The Future ............................................................................................................................................................. 20

3.2 LCC ............................................................................................................................................................................... 20 3.3 Logistics ..................................................................................................................................................................... 21 3.4 ERP .............................................................................................................................................................................. 21 3.5 Maintenance ............................................................................................................................................................ 22 3.5.1 Suppliers ................................................................................................................................................................. 23

4 Analysis ..................................................................................................................... 24 4.1 Quality ........................................................................................................................................................................ 24 4.2 LCC ............................................................................................................................................................................... 24 4.3 Logistics ..................................................................................................................................................................... 25 4.4 ERP .............................................................................................................................................................................. 25 4.5 Maintenance ............................................................................................................................................................ 26

5 Conclusions ................................................................................................................ 27

6 Works Cited ................................................................................................................ 29

Appendices ...................................................................................................................... 31

Pictures Picture 1: The turnover for the 21st century………………………………………………………………………….. 5 Picture 2: Own created production process picture……………………………………………………...……….. 6 Picture 3 & 4: The production process from SAFTs factory……………………………….............................. 7 Picture 5: Bathtub curve……………………………………………………………………................................................ 17

4 (33)

1 INTRODUCTION

In the introduction to this task a background is presented. The background together with the problem discussion defines the purpose of this task. Limitation, definitions and method are also presented here.

1.1 BACKGROUND

SAFT is a French-owned Swedish company that fabricates nickel-cadmium batteries. The company was founded by a Swedish engineer named Waldemar Jungner in 1910, but back in the day the batteries were based on nickel and iron. However, across the Atlantic Ocean, an American scientist named Benjamin Franklin tried to create a similar battery but Waldemar beat him to it and was first with the patent.1

When he got his patent for the batteries he could not imagine that new batteries would be manufactured with the same principal over a hundred years later. One of the most important characteristics with his batteries was the quality; a battery made in 1926 had 70% left of its full capacity after 50 years.2

Throughout the history the company has had some name changes due to change of ownership and battery mix. Originally the company was called Svenska Ackumulator AB Jungner and 1974 it was changed to NIFE Jungner AB and 1991 the company changed name to NIFE AB due to the change of ownership to the French company SAFT Group S.A and is today it is called SAFT AB.3

SAFT is currently the leading company in the manufacturing of nickel-cadmium batteries and have business partners and customers all over the globe. The batteries are used in trains, military defense, space projects, power backups etc. in fact it can be used wherever the need of a reliable power source backup is needed. The batteries are capable of providing cities with backup power for approximately 15 minutes with 27 MW, they have a long lifetime and a warranty for 20 years and they can withstand extreme temperatures, +60 to -40 degrees Celsius.4

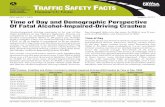

The turnover for the 21st century has been more than profitable so far.

1 (Toftrup, 2012) 2 (Engström & Toftrup, 2012:5) 3 (Engström & Toftrup, 2012:6) 4 (Engström & Toftrup, 2012:4--14)

5 (33)

Picture 1. The turnover for the 21st century5

The strategy of SAFT is “We are determined upon being a leading supplier of high quality Ni-Cd industrial batteries for reserve power and energy storage to the entire world market ” – SAFT AB.6

5 (Engström & Toftrup, 2012:12) 6 (Saftbatteries, 2009)

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011

MSEK

Salesvolume inMSEK

6 (33)

1.1.1 PRODUCTION PROCESS

This is a general chart over the production process to show how products are produced in theory.

Picture 2: Own created production process picture

The production process of the nickel-cadmium batteries is basically the following:

The first step is to make metal stripes that will be welded into a plate. Later those plates will be mounted in side frames that will hold the plates in place in the complete battery. Then two plates, complete with side frames, will be attached to each other. Now that they have a plate group it’s time to weld the nickel one together with the cadmium and place a plastic grid between them so the battery will work. The final step is to put down the nickel-cadmium group into a plastic container and add water and you will have a battery cell.

7 (33)

Picture 3: The production process from SAFTs factory

Picture 4: The production process from SAFTs factory

8 (33)

1.2 PROBLEM DISCUSSION

In recent decades, the industry has increasingly begun to use commercial models in quality, Life Cycle Cost (LCC) and the logistics that relate to mass production and economies of scale. This demands higher efficiency and improved methods of working without jeopardizing the quality of the product. However, an implementation of these methods and to constantly renew oneself is not always problem-free. Staff can easily experience a threat to efficiency improvements because it might result in cutbacks. This shows the importance that these models are clearly rooted in the whole organization. It is therefore interesting to study how these models work at SAFT?

Quality work, LCC and logistics are based on reducing lead times, how will this work in an organization that places high demands on quality? Is it possible to engage staff to improve access to the goods and reach the goals SAFT has set?

To succeed with the implementation of the models requires strong commitment from management and that stable structures are created to deal with the changes that occur in the organization. Implementation of the models also requires a more interdisciplinary work and various professional groups must cooperate. It is therefore interesting to study the effects of the implementation of the different models?

1.3 RESEARCH QUESTIONS

These questions are a summary of the above problem discussion, which concludes the following three questions.

1. How do the models work at SAFT? 2. Is it possible to engage staff to improve access to the goods and reach the goals you

have set? 3. What effects have the implementation of the models given?

1.4 PURPOSE

The purpose of the study is to describe the practice and implementation of quality, LCC and logistical processes at the company SAFT. Further, the purpose is to examine if the usage of the models have engaged the personal in the access to the goods in order to reach the goals and what effects the implementation of the models have had.

1.5 LIMITATION

Because of the delay in our study visits and the limited time of the course we were forced to keep some parts of how the company really works very shallow. Our knowledge and experience of SAFT is also something that has to be taken into concern. Another shortcoming of our work is that although SAFT was incredibly helpful and courteous so were our contact person employed by the Quality Department, which has resulted in that the most detailed information is naturally focused on quality. We have therefore a smaller proportion of relevant facts about the other elements that our report is based on.

9 (33)

1.6 DEFINITIONS

Quality: Many companies define quality as the product/service to achieve and preferably exceed customer expectations. Other companies see it more as a degree to which the product is produced correctly. Many different techniques and concepts have evolved to improve product or service quality in the business. One concept is TQM, which according to Bergman and Klefsjö is defined as "A constant striving to meet, and preferably exceed customer needs and expectations at the lowest cost through continuous improvement where everyone is involved and has a focus on the organization's processes."7

Life Cycle Cost: Life Cycle Cost Analysis is a useful method to collect and treat all costs that occur over the full life span or a specified period of services or goods. Aim of the Life Cycle Cost Analysis method show possibilities of minimizing the costs and maximizing the turnover. The Life Cycle Cost Analysis includes the entire life cycle regarding raw material manufacture, distribution, transportation and maintenance. LCC also provides important inputs in the decision making process.

The Life Cycle Cost Model is a method to calculate the Life Cycle Costs in a company. “Life Cycle Costs are summations of cost estimates from inception to disposal for both equipment and projects as determined by an analytical study and estimate of total costs experienced during their life.”8

Logistics: The term logistics comes from the late 19th century: from French logistique, from loger 'to lodge9. Logistics can, quite humorously, be defined as: “Logistics is nothing but having the right item in the right quantity at the right time at the right place for the right price in right condition to the right customer”.10

All those, quite different aspects, play an important role if a factory has the possibility to deliver a product within the criteria that is considered good service.

Maintenance: Maintenance is mostly all actions that are demanded to retain or restore materiel to a specified condition. It requires all the supplies and reparations that are needed to keep the device in such a condition that it is able to carry out its intended purpose. Maintenance is not only important on devices, equipment and machines, but also on the entire plant, structure, ground facility etcetera.11

ERP: A system that can transfer all kind of information electronically through the organization is called Enterprise Resource Planning systems (ERP). ERP is a complete information system that supports and reflects all of the company’s business models. An ERP

7 (Bergman & Klefsjö, 2001) 8 (Barringer & Weber, 1996) 9 (Oxford University Press, 2012) 10 (Aron, 2011) 11 (The American Heritage® Dictionary of the English Language, 2009)

10 (33)

system is therefore intended to control all of the organization’s internal and external information flows that are included in the business model.12

1.7 METHOD

We have, during a period of nine weeks, taken part of different seminaries, which has given us the foundations of knowledge to write this report.

We have also made two study visits at our chosen company, where the first one provided us with basic information and comprehension about what the company was producing.

We have, based on that, made a qualitative interview with one of the responsible employers on the company. This gave us a deeper insight and we could thereby make use of the knowledge we have gained to an analysis of the company. As a further aid, we have also been using books regarding the subject, as well as discussions with our teachers.

12 (Olve & Samuelsson, 2008)

11 (33)

2 LITERATURE REVIEW

2.1 QUALITY

Quality has evolved and expanded as a concept. According to Bergman and Klefsjö, the quality of the development is generally said to have followed four phases13:

1. Quality improvement - constant improvements before, during and after production 2. Quality security - before production 3. Quality management - under production 4. Quality control - after production

The development of quality basically means that quality work is increasingly implemented earlier in the production process then before.

Today is quality used as a competitive mean, more so then before. Several studies have been conducted to examine the quality of work impact on corporate competitiveness and profitability. According Lakhal14, who conducted a study of 74 different organizations, quality improvements lead to increased competitiveness and profitability. His study shows that the quality primarily generates competitive advantages for the company and the competitive advantages in turn leads to increased profitability. Other studies indicate that quality improvement does not always lead to increased profitability but rather the opposite. Iaquinto15 believe that negative results may occur when companies become too focused on their quality work. This may mean that other, critical for the company, activities and abilities are set aside, which reduces firm value. In addition, it helps the bureaucratic approach that quality work means that employees feel barriers to creativity and spontaneity - qualities that are essential for business innovation. For getting quality work to function, it requires management.

2.1.1 MANAGEMENT'S ROLE

According to Nilsson16 it rests on the management board to decide how the organization should be controlled and to ensure that operations are conducted in accordance with the business idea. This means ensuring that all the company’s processes work and that they support the company’s business. The processes include financial management, human resource development, competitor monitoring, computer systems, information management and more.

Management's role is according to Nilsson17 also to drive the business forward and ensure that the company's activities and processes are controlled in a way that creates commitment competitiveness that benefits that benefits customers and the organization. It also means that

13 (Bergman & Klefsjö, 2001:93) 14 (Lakhal, 2009) 15 (Iaquinto, 1999) 16 (Nilsson, Att integrera ledningssystem, 2000) 17 (Nilsson, Utveckla kvalite, 1994)

12 (33)

is the management's task to develop the business so that it achieves the intended quality thereby to contribute to customer satisfaction. This task also involves responsibility that clearly states objectives for quality and to establish a quality policy.18

Nilsson19 suggests that what management says or otherwise formulate in words also must be consistent with management's actions. He goes on to describe that the most effective way to communicate the quality policy and approach to quality is to be an example to the rest of the organization. In other words, management should take an active role in the development of quality. Bergman and Klefsjö emphasizes that the management's understanding of and participation in the process of quality development is a prerequisite for success. 20

According to Bergman and Klefsjö, it is generally accepted that a company must have a highly decentralized organization to be able to adapt to customer requirements. This means that the organization must be managed decentralized and the manager must act as a leader. The role is thus not to sit at the top of the organizational pyramid since the operational knowledge is needed at the level where the operations are performed. Management's role is to decide on the whole and thus let middle managers a greater role.21

Sashkin and Kiser also describes that for the implementation to be sustainable over long empowerment is required. It means giving employees the authority because it is the employees who need to identify and solve problems and improve work processes. In order to decentralize the organization training is required. In addition, the corporate culture may need to be modified which include looking over the policies and practices to promote a certain type of behavior from employees.22

2.1.2 DIFFERENT METHODS IN ORDER TO INCREASE QUALITY WORK

There are today a mass amount of different methods to be used in order to increase quality work, 5 S, Six, Sigma, A3-report, Kaizen, PDCA-cycle, Just-in-time, so on and so forth. One thing that they all have in common is that they build on the concept of Lean.

Lean requires a process-oriented approach. A process can be defined as "a chain of activities with a clear starting point and a clear end point, consisting of several steps, both scheduled and repetitive and has clear objectives and expected results."23 Lean is about focusing on value creation processes, as well as minimizing waste. It therefore means that you shouldn't do anything that does not add customer value, or in a systematic and carefully planned way can lead to reduced waste of resources within the organization and thus concentrate on the clients.24 Lean is not just a toolbox, but also a philosophy that must permeate the entire organization. It is a long-term project that is based on everyone's involvement.25 Lean is a

18 (Womack & Jones, 2003) 19 (Nilsson, Utveckla kvalite, 1994) 20 (Bergman & Klefsjö, 2001: 388) 21 (Bergman & Klefsjö, 2001: 388) 22 (Sashkin & Kiser, 1993) 23 (Aronsson, Abrahamsson, & Spens, 2011) 24 (Bergman & Klefsjö, 2001; (Meland & Meland, 2006) 25 (Liker, 2009)

13 (33)

major change that requires dedication and motivation of everyone in the company for the desired results to be achieved.

Lean philosophy is based on theory that if you over time implement small changes in the way one works, this should provide a new and improved attitude among employees. The idea is that an employee shall in addition to his daily routine always consider how the work they do can be developed and better contribute to the organization as a whole. This trend in the daily work, says Liker, can eliminate one of the wastages i.e. the employees’ untapped creativity, which means that the organization does not take advantage of the expertise and ideas to the full.26 According to Jones and Mitchell the philosophy leads to a more efficient organization through small changes over time. Best results are obtained in a decentralized organization where employees are allowed more responsibility, because employees feel that they have the control and power to change their work environment. Taken into account should also be the employees' self-esteem. No one should be singled out for dereliction when inefficiency is detected. The errors lie in the system and no individual should be charged for this.27

One important aspect within lean is a standardized way of working. One method that aims to standardize the way of working is 5S, which stands for sorting, straightening, systematic cleaning, standardizing and sustaining 28 . A basis of continuous improvement is standardization, which means that activities must be conducted in the same way every time. This means that before any problems can be identified, the process must be constant and stable. The standardized approach should provide examples of what works best right now. Improvements in the organization shall be carried out in conjunction with the ones that carry out the work process.29 A well-functioning organization that is based on safety and efficiency require orderliness. The 5S method is a tool for a consistent way, with small and simple steps, to create a safe and efficient workplace.30

In order to create safe and efficient workplace organizations should incorporate quality and environmental standards. International Organization for Standardization (ISO) is an international quality standard, which requires demands of an organizations quality system and how it should be built. Johansson et al. (1993:9)31 defines a quality system as a tool to control and improve the quality of an organization's activities. This includes everything from practices and methods to list of responsibilities. There are several hundred different ISO standards where 9000 deals with quality system and the ISO 14000 series cover the environmental systems.

2.2 LCC

Life Cycle Cost is an economic model, which shows and summarizes all the costs for a project, investment or a product. The LCC method is a useful method to analyze the total cost

26 (Liker, 2009) 27 (Jones & Mitchell, 2006) 28 (Liker, 2009; Westwood, Moore, & Cooke, 2007) 29 (Meland & Meland, 2006) 30 (Meland & Meland, 2006) 31 (Johansson, Lindgren, & Lissgärde, 1993)

14 (33)

for a project and compare it against other projects. LCC is the summation of all costs and cost estimations when considering the time value of money. A LCC analysis includes all the costs that are recurring costs and none recurring costs about specific investment during products whole life cycle. Some cost that are mentioned in the LCC model are; purchase price, installation costs, operating costs, maintenance and upgrade costs and residual or salvage value at the end of the useful life.32

Life Cycle Costs consist of recurring costs and non-recurring costs for operation and support of a product until nothing remains. Life cycle cost analysis is needed to create cost breakdown structure. When developing a cost breakdown structure, the entire cost type should be considered. The cost breakdown structure consists of four types of costs. These are listed below.

• Research and Development Costs (Cr) • Production and Construction Costs (Cp) • Operation and Maintenance Costs (Co) • Retirement and Disposal Costs (Cd)

All these costs are a part of the total cost of a products and can be calculated by using the

C = Cr + Cp + Co + Cd formulation. In this way, the costs breakdown structure helps to see the highest cost drivers.

Basic Process of LCC Analysis

There are a lot of different processes and ways to analyze the LCC. In Kawauchis’33 article, he describes the main processes of LCC analysis. These are:

• Process 1: Problem definition: This first step of LCC analysis is very important part of the analysis. In this phase whole assumptions should be defined very thoroughly. Clarity of problems may affect the other steps.

• Process 2: Cost elements definition: In this step all cost elements should be defined by using cost breakdown structures (CBS). According to an international standard of LCC, developing a cost breakdown structure is mainly about creating a basis definition of cost items.

• Process 3: System modeling: Relations between input parameters and the cost elements should be appropriate chosen in order to have a good model. Models can be useful to estimate the cost items. A system model can be developed considering many viewpoints like availability, maintainability and logistics.

• Process 4: Data collection: Certainty of the LCC can improve input data. Requirements of input data sources about LCC analysis should be identified.

• Process 5: Cost profile development: Affordability analysis is an important part of the success of LCC analysis, it should be considered long term vise of a financial planning

32 (Kloepffe, 1996) 33 (Kawauchi & Rausand , 1999)

15 (33)

system. During the process of making a financial planning, all the alternative cases should be compared on a common basis.

• Process 6: Evaluation: The last step is choosing the best alternative and evaluate it. Sensitivity analysis is a method in comparing current situations and other alternatives. If the current situation does not meet the criteria needs, it should be modified.

2.3 LOGISTICS

Logistics, according to Taylor34 has some key features:

• Movement and storage of materials. • Managing the information flows that underpin the flow of materials • Achieving customer-service standards and doing so in a cost-effective manner.

This, in turn, can be explained as: Logistics can be defined as the management of the flow of goods and the service, including planning, implementing, controlling, effective and efficient flow of goods and services between the point of origin and the point of consumption in order to meet the requirements of customers.35

Logistic management and supply chain management has many similarities, as it in the end reaches for the same goals; approach to managing the flow of materials and information across the whole supply chain, from raw materials sources to end-user consumption. This is mainly based on customer service and logistic costs. Customer service, which has been highly developed over the last fifty years, made companies realize that improvements in logistics can improve service and reduce costs, and thereby give the firm a significant competitive advantage. Logistic costs are, quite obviously, about minimizing the actual available costs.36

Logistics is a very widespread area, which includes several steps within a factory. Some of them are:

- Equipment’s, as in various tools that help increase efficiency. - Material, as in movement and storage of materials. - Transportation, which ranges across the whole supply chain; from raw materials to

final consumption of finished products, which even includes food- and personnel-logistics.

Logistics can also mean an abstract field, like information and communication, which has a fundamental role in the logistic systems.

Logistic management and supply chain management are essentially synonymous terms37. The supply chain includes not limited to the manufacturer and suppliers, but also transporters, warehouses, retailers, and even customers themselves. Within each organization, such as a

34 (Taylor, 1997) 35 (Aron, 2011 ) 36 (Taylor, 1997) 37 (Taylor, 1997)

16 (33)

manufacturer, the supply chain includes all functions involved in receiving and filling a customer request38.

2.4 ERP

To guide its activities, management can take the help of a management system. Nilsson39 explains that the management system is to provide a holistic approach that gives the ability to monitor the company's processes and its activities and outcomes. The systems are used to establish policies and link measurable goals to them. Furthermore, he explains that companies can choose to have one or more management systems. Although, for todays businesses it is vital and a prerequisite for an efficient material flow to have an information system. The information system contains invaluable information about the existing and future demands; based on sales data, forecast information and customer order information. Essential information is developed into specific purchasing, merchandising and manufacturing actions. This information initiates a value-added inventory flow. The information is generated both internally in the company by sales forecasts, but also from customers in the form of customer orders, sales, delivery schedules, setup times, production times, lead times and throughput times, capacity, forecasts and more. Other information that is usually recorded in the computer system are input and output from warehouses, bar codes, identification of goods unloaded from a truck, etc. Information on suppliers' delivery performance is also recorded in the information system. The information may consist of stock availability information, order confirmations, shipment notifications, etc. The quality of information has a major impact on the business performance. It is vital that the information is two-way communication, from SAFT to suppliers/customers/intermediaries/non-linear suppliers and secondary customers and back again, in order to get a value-added exchange of information. Information expedites coordination of planning and control of day-to-day operations, as well as, informs about changes in deliveries if delays occur. If the information is not accurate, the efforts might be misdirected.40

Swedish Standards Institute41 explains that management systems for environment, quality and work environment are advantageously integrated into a single management system. The benefit of this is that the company will have a complete picture of the organization, orderliness, and efficiency gains in order to make better decisions. However, explains Nilsson42 some of the risks of an integrated management system is that it increases the complexity and it is a large development project, which contributes to increased documentation and bureaucracy.

2.5 MAINTENANCE

Maintenance is mostly about finding different causes and prevent that those doesn’t lead to any failures, shutdowns or any deficiencies in the quality. This results in more resilient 38 (Chopra & Meindl, 2007) 39 (Nilsson, Att integrera ledningssystem, 2000) 40 (Jonsson & Mattsson, 2011) 41 (Bäckman & Nilsson, 2005:11--4) 42 (Nilsson, Att integrera ledningssystem, 2000)

17 (33)

products regarding errors, and makes it easier to find the consequences of faulty products, and if possible reduce or eliminate these.43

The two different ways of maintenance is therefore that you can try to reduce the causes of the failures, or try to reduce the consequences of failures that have already happened. These usually go hand in hand as parts of the products or machines that they must be maintained differently. For example, one machine has parts that are possible to repair, while some parts have to be bought new and replace the old and broken part, which means that they are non-repairable. The purpose of maintenance is to retain or restore units so those can be used as they are meant to do. The propensity for mistakes of a device or machine often varies with time. At the beginning of each product manufacturing, or in the up-start running time of a machine, there are often quite many errors due to material variations or measurement errors. Once these problems have been improved fewer errors occurs and the different parts of the machine or product last longer due to proper usage. Finally, after a period with little faults and small effort in maintenance, due to wear and aging the propensity for mistakes increases again.

This can easily be plotted in a graph and because of its particular appearance is called bathtub curve.

Picture 5: Bathtub curve44

The meaning of maintenance is usually to reduce costs, and maintenance is important when a production is being planned and managed. Maintenance is usually divided in two different types:

• Preventive maintenance • Corrective maintenance (failure based maintenance)

Preventive maintenance is used to reduce the probability of failures of units. These are often regular or scheduled, and may involve very simple improvements and maintenance, like daily

43 (Bergman & Klefsjö, 2001:147) 44 (Bergman & Klefsjö, 2001:153--4)

18 (33)

cleaning or protection methods like oiling. This is easily done by a scheme, which includes different checkpoints. Corrective or failure based maintenance means, which the word indicates, focuses on maintenance on the equipment when an error already has occurred.

Both methods have their pros and cons, mostly because the preventive maintenance can be quite expensive and time demanding, but time and cost-saving if it is important equipment that breaks. If not done in time this may cause shutdowns or even worse, increased risk of the employers, which may result in serious injuries. Failure based maintenance is preferable when you can tolerate an error during the repair period and the cost of this will be less than the preventive maintenance.

19 (33)

3 EMPIRICAL

3.1 QUALITY

3.1.1 BACKGROUND

• What does quality within SAFT stand for? A: In general SAFT have defined quality as a level of tolerances and standards for each step in the production. But nothing is really defined about quality, because it depends on different costumers and their requirements, demands and specifications.

• What quality systems are you working with? A: SAFT WORLD CLASS is a standard quality tool that is available at the company from the head office in France. It contains a lot of different tools such as 5 S.

3.1.2 QUALITY WORK TODAY

• Can you describe SAFTs' quality and how it works today? A: SAFT delivers batteries that exceed the customers’ expectations every time.

• What does SAFT do to ensure the quality of products? A: They deliver more powerful batteries as a safety-management, but the customers doesn´t know, and often they don´t notice.

• How and when did you update the system? A: The system of quality tools is updated on a regular basis; it is impossible to say exactly when and where. We try to be leaders in the market as much as possible.

• How is it used from a "practical" point of view? o Does project work occur?

A: The projects in SAFT WORLD CLASS TEAM are managed by different people on every project. If the company in Oskarshamn starts a new quality-project, they have to give feed-back to the head quarter in France.

o Is there anyone who takes the initiative to develop the system? A: Most of the initiative to new projects and tests are done in France and then delegated to the different factories for testing.

o What support is available when you are starting a new assignment/project? A: Since the management in France initiates the projects and tests there is always sufficient support and if not one asks for more resources or time to finish the tests.

o Where does one turn for support? A: Depending on delegation but usually it goes through the chain of command all the way up to management in France.

o How do you ensure that your suppliers are working/using the same quality-standards as you do? A:We are keeping our suppliers for a long time, and after a while they are too involved in SAFT and our business. It is very rare that our suppliers deliver faulty products, and if they do we will have a high level of feed-back so they will now about the problem. Our suppliers are working due to the same

20 (33)

standards as we do, and since our co-operation lasts for a long time, these methods will be well entrenched in their approach.

• How is results and quality control communicated to the rest of the organization? A: Depends on which result one asks for but daily, weekly, monthly etc. For example the results of production quota are published on weekly basis in the factory.

3.1.3 LEADERSHIP

• What is the managements’ role in quality control? A: Nowadays they run the show, before each factory was able to perform their own tests and projects, but that is much more limited today.

3.1.4 EDUCATION

• Is training provided to employees in the quality control work? o For whom? What kind of training?

A: New employers get a kind of training to be aware of the quality-rules. When new rules/tools are implemented they require different training steps for each new tool.

3.1.5 RESULTS

• What are the critical success factors to consider? A: Centralized initiative of projects but decentralized system of carrying out the projects.

• What has been the biggest challenge? A: The greatest challenge in Oskarshamn is that it is an old factory with a lot of history, meaning that it is more difficult to integrate new ways of working when the employers has their own, old habits.

• What has been the biggest benefit of quality work? A: Awareness of quality

• What outcomes/results of working with quality work had you expected? A: Different quality goals that have been reached and other information regarding quality are spread to their employers by tablets, both regarding the French main company and the one in Oskarshamn.

3.1.6 THE FUTURE

• How do you see the future development of quality work? o What can be improved?

A: The processes of handling quality, as well as give even more empowerment to the workers. And we need to pay less time checking the quality ALL the time and trust the system.

3.2 LCC

• What is SAFTs’ market and their mainly cost type?

21 (33)

A: SAFT are mainly focusing on two different markets where they are selling their batteries. These markets are “specialty battery group” and “industrial battery group”. “Specialty battery group” require batteries with high performance primary and rechargeable lithium batteries for the electronics, defense and space industries. Batteries that are produced with high performance may have higher life cycle costs because they have to produce the batteries with higher quality. Producing high quality batteries requires more research and development costs and more material costs. On the other hand, these high quality batteries demand less maintenance costs, which, in the long turn, may have a lower cost in total than other industrial batteries thanks to their quality. “Industrial battery group”-batteries are rechargeable nickel and lithium based batteries for demanding industrial applications. These batteries are used in different works such as metering and professional electronics, emergency lighting, rail and mass transit, aviation and clean energy storage. Industrial batteries have a higher maintenance cost than the specialty battery groups batteries.

• What are SAFTs’ batteries characteristics costs? A: SAFTs’ batteries have good quality and a reliable operation. SAFTs’ batteries have a long useful lifetime and survive between +60C - 40OC, which is quite extreme temperatures. When the batteries are used, SAFT guarantees that there are no sudden failures, which results in a low maintenance and LCC-cost, since there is low fixing and repairing-costs. SAFT are selling their batteries to a lot of countries and have to transport their batteries with none, or as few as possible, damaged batteries. Their batteries survive long storage and transport periods, where the conditions can be pretty rough. Thus SAFT enables their batteries to avoid costs of damage during the storage and transportation.

3.3 LOGISTICS

• Which logistics activities are you using? A: SAFT are using all types of different transportation systems, and they are out-sourcing their logistics to other companies that then transport the goods by boats, lorries, railroad and airplanes. They started to build a logistics chain to transport the cadmium back to SAFT as early as -88, but back then it wasn’t for the environment, but rather a question of cost as they were such a major consumers of Cadmium.

• Which sort of logistics are you using within the company? A: Line production is mainly used within the company. The products follow the flow and are transported between the machines by truck. It is the production and not the transportation between the machines that is time demanding.

3.4 ERP

• What kind of computer systems (ERP) does SAFT use in the organization? A: Today we have one main system called Movex but this one is old and will be replaced next year with a new system from Movex. Movex is complemented with other systems such as Operator, Minitab, AAP, Quickview, Excel and some other

22 (33)

systems. The new upgrade will integrate most of the “extra” systems into one, Movex. • How and when did you update the system?

A: The old system is from 1986, the reasons why we have not updated it before is money and the amount of time it takes to implement a new system. It is often preferable to use one system but it is so complex and expensive to switch systems that you usually have some more systems, which are able to handle the areas where Movex is limited. Changing the ERP-system is like a complex heart-chirurgery, you are changing the basics, the heart within the company. Even if we are changing into a new system, it is rare that the new, modern systems will be able to handle all different tasks within a company.

• Do you use any type of track and trace system? A: All pallets are equipped with an RFID-chip and some transports are equipped with other sensors in order to monitor vital data.

3.5 Maintenance

• What is maintenance to SAFT? A: SAFT has 15 mechanicals and 10 electricians who all work with different kinds of maintenance in the company. SAFT (in Oskarshamn) has 6000 machines, where 200-300 is so-called “key machines”, which they are focusing on regarding maintenance. SAFT has in total four persons who are available around the clock, whom can fix all the emergency maintenance, two physically in the factory and two on jour.

• How are you using preventive and failure-based maintenance? A: We try to use prevented maintenance. 5 years ago was 70 % of the maintenance emergency-based, and 30% prevented, nowadays is 53% prevented, which is a remarkable advance. Much of it is easy maintenance, like cleaning the machine after you have used it. Some of the machines are not necessary to use prevented maintenance on, mainly for the reason that they are very easy to fix. Some machines are much worse, where you have to find spare parts from Germany. Other machines demand much more maintenance and more continuously, mostly because they are literally too small. For example SAFT are using a 60 ton press, but would have needed an 80 ton press, but there is no actual room in the company for such a big machine.

• How do you keep track on all the 6000 machines? A: All the machines have a number, which makes it a lot easier to keep track on every particular machine – like how often it breaks and how much money we have to spend on each machine.

• What kind of maintenance is required on the batteries once they are delivered? A: The maintenance that is required on the batteries when they are installed on different places around the world is outsourced. The mainly part of maintenance on the batteries is to change the water. SAFT is nowadays working on a, kind of, maintenance-free battery regarding the water changing. The batteries require other maintenance in order to have as long life cycle as possible.

• Maintenance is much about retaining and restoring your equipment and machines. Do you have any kind of security processes and standards to prevent injuries?

23 (33)

A: All the employers have a meeting in the morning where they go through if something unusual has happened. They also have a safety expert who can stop the production if she thinks it is too risky or dangerous. All the employers have to leave a blood sample where they measure the cadmium level. There is a EU standard how high the cadmium level is allowed to be, and when the employers reach half of that level they are transferred to a different department, where the handling of cadmium is lower. Smokers have the highest cadmium level in their blood, and therefore are SAFT planning to use a “quit smoking parliament” in becoming a smoke free plant.

3.5.1 SUPPLIERS

• Which department chooses the suppliers who are responsible for the maintenance? A: It is the purchasing department who does the decisions about which company they should choose – not necessary the cheapest.

• Are you changing your suppliers often? A: SAFT are keeping the same suppliers for a long time; they have for example been using the same inspection-company for about 10 years.

• Are the suppliers working due to the same standards as SAFT does? A: SAFT are sending their standards to their suppliers, so they have the ability, or rather the necessary tools they will need to follow, with the same standards as SAFT are using. This is an easy “check-list”.

24 (33)

4 ANALYSIS

This chapter examines the empirical material we have gathered around the company SAFT against the previously presented theory.

4.1 QUALITY

Quality has evolved and expanded as a concept both theoretically and within the company SAFT, nowadays their quality models/work consists of several books. The implementation of quality work is done earlier in the production process than before and there is more projects focusing on quality and the importance of it than before. The main reason for this is that the organization wants to streamline its organization and shorten lead times and thereby become more flexible so as to provide customers with better service. The better quality generated by an organization primarily generates competitive advantages for the company and the competitive advantages in turn leads to increased profitability. This is achieved by removing the activities that are non-value adding in the organization, improve flows using various tools and establish standards when it comes to practices when working. Theorists such as Womack and Jones and Lakhal confirm these practices and policies.45, 46

SAFT also stresses the importance of a "top-down" control of quality with a clear strategic direction that knows where you are going with the implementation of different projects. It is the management that has taken the decision to implement quality into the organization, and it is from the management that the change starts. Moreover, a critical success factor in the implementation is that management brings along employees by demonstrating that it produces results both regarding efficiency and financially. In a process of change, it is essential with participation and involvement from employees for a project to be successful. When it comes to quality, it is the employees who are the key players and those who manage and develop the business. Since there is also a lot of support and understanding for quality work from management, this further contributes to increase the willingness of change of all employees in the organization. The continuous work to get better quality is done mainly through the concept of lean production and its different tools, in this essay mainly focused on 5S.

4.2 LCC

SAFT LCC assessment mainly deals with the product’s full life span from raw material to disposal. SAFTs’ batteries have a long useful lifetime, which is about twenty-five years. NiCd batteries that are produced at SAFT are completely recyclable. SAFT recycles more than 1000 tons every year. In the Nordic region 100% of SAFTs’ batteries are recycled and they are reusing the old cadmium for new manufacturing cells. About 1/3 of the cadmium used in manufacturing comes from recycled batteries. This means that SAFT more or less fulfills their environmental responsibility by recycling cadmium and are also decreasing their raw material costs by using recycled cadmium.

45 (Womack & Jones, 2003) 46 (Lakhal, 2009)

25 (33)

LCC can be useful in decision making by comparing different alternatives. For example, SAFT has a 60-ton press that demand much more continuously maintenance because of it is of a small size. The alternative is, in this case, buying an 80-ton press, which would be needed. But the problem is that there is no room for such a big machine in the company. Buying an 80-ton press would be suitable in the long term, especially if you compare the total LCC-cost of a new machine and the maintenance cost of the current machine. However only considering the costs of a new machine and the maintenance is not enough to make an accurate decisions’. Production availability, machines efficiency, capacity and the environmental effect should be other criteria’s in making these decisions.

4.3 LOGISTICS

Logistics is a costly and time-consuming part of the production of the products. It is constantly being looked at and made more efficient. By outsourcing the transportation between production site and customers to other companies specialist in transportation SAFT adheres to an efficient flow of goods.

Logistics is a wide and complicated concept, since it involves a lot of different norms, laws and rules, both national and international. Since SAFT exports a fair amount of their batteries abroad, this implies some extra logistical difficulties. Different areas in the world have different packaging-standards, and SAFT are solving this problem by outsourcing to a specialized transport-company. Other difficulties that may occur is problems regarding communication, different languages, technology and time-zones.

Since the batteries mainly are used as back-ups after power failures, some of the batteries are transported to very remote areas. This is one of SAFTs’ key selling points that they can make and deliver these specialist batteries to remote areas. It is therefore important to have a specialist transport company that can deliver the products on time and in pristine condition. The batteries have to endure rough transportations, storage and extreme weather conditions and therefore it is crucial that the transport is made with the utmost quality and care.

4.4 ERP

The information flow that goes with the flow of goods is designed to provide all parties with operational information needed on site to carry out handling, transport and storage activities. This information includes proper handling of special goods such as hazardous products within the batteries or packages. SAFT utilizes a track and trace system that monitors the flow of goods and provides the information system with valuable data. By equipping the goods with an RFID chip the information flows with the material flow and is there by up to date. Or a special sensor can monitor and document the temperature of the shipment throughout the transport. The measured data are available at each monitoring point, a feature that enables the shipper, recipient and controller to continually check the condition of the product. This is especially important when dealing with hazardous products such as toxins created at the factory. The effectiveness of containing the hazardous products can be harmed by temperature fluctuations outside the recommended range.

26 (33)

4.5 MAINTENANCE

Maintenance at SAFT is mostly about reducing costs and preventing shutdowns. They have had a remarkable progress in preventive maintenance, and are still focusing on further progresses. Since they started numbered the different machines, they have a more over-all control of their maintenance, and may, in this case, calculate and evaluate which machines they should focus on. This is also an aid so they can calculate which machines require prevented maintenance, and which machines that are more profitable if they only perform emergency-based maintenance.

Since the plant is rather old, they have had their challenges to accommodate the machines needed to get a smooth and efficient production. Therefore maintenance is even more important since they do not have the space to expand to the required production quantity they would like to.

27 (33)

5 CONCLUSIONS

The reason why organizations’ choose to change their structure can be several. We have for our study observed that the implementation of various concepts/models/tools not only have had a strategic intent, but that it depends in many cases on the desire to illustrate to its environment that they conducted a job that is future-oriented. The conclusion is thus that one chooses to introduce various concepts/models/tools such as Lean and 5S mainly because it is expected of one to do so! If you want to belong to the elite and implement cutting edge concepts/models/tools, then it is expected of you to keep up with the styles and trends. The introduction of concepts/models/tools is often because organizations want to solve problems that the business has, but sometimes the choice of concepts/models/tools cannot be directly linked to the business problem. But for a change process to be successful demands several success factors and one of the most important is motivation among employees. Well-motivated employees who feel that there is an incentive to work with change management. Another success factor is leadership - committed projects managers is not the same thing as successful leadership - especially not in an industry leading company where leaders are expected to inspire confidence, be inspiring and futuristic.

SAFT batteries have generally a low life cycle cost as they are produced with high quality, which costs more than for example lead based batteries, and require a lower, in fact close to nothing, maintenance cost as they are produced to withstand extreme surroundings such as high and low temperature, deserts and the arctic wastelands of Alaska. The somewhat higher production cost and the low maintenance cost leads to an acceptable life cycle cost, which is what most companies’ desire.

Another parameter to bring the total life cycle cost down is the recycling of the batteries. The recycling of the batteries that remain in Scandinavia is in fact 100%. Even thought that it is a fantastic number only the cadmium is reused in new batteries, the other parts like the plastic and nickel is sold to other companies. You can almost say that they reuse what the gain on reusing.

Since it is rather difficult to specialize on all different tasks in a company, outsourcing may be an alternative. One positive effect by outsourcing is that you hire a specialized company regarding that task. SAFT hires companies regarding both maintenance and logistics. During the transportations is the supplier responsible for the quality and different warranties, laws and standards. This entails in a lower cost for SAFT, and is also time-saving.

Since SAFT hires electricians and other maintenance-educated workers, they ensure that their maintenance is done by someone who is legally certified. It is logical that they are focusing on preventive maintenance, as the theory says is preferred, and even better that they are calculating on every machine in order to see if it is profitable with preventive maintenance. This ensures that they are focusing on the most important machines, keeping track on which parts of the machines that is most likely to break, and maybe even order spare-parts in advance.

Nowadays information is mainly transferred electronically all through the organization

28 (33)

including suppliers and to and from end-users. Information can be sent by mail, telephone, fax or other electronic data interchange (EDI:s)47.

Because today there is an overflow of information and a lot of it is not relevant, the effort to provide correct information is complicated. Therefore it is only logical that SAFT chooses to have an ERP system because they are in need of an integrated information system that communicates through all though the organization, including suppliers, intermediaries and others not directly linked to the organization. For example once a customer has placed an order, he receives an order confirmation from the manufacturer or retailer specifying the scheduled delivery time. At the same time the system forwards the information about the scheduled delivery to all other parties involved in the flow of goods. Consequently, these parties have been granted the time to plan and schedule, which provides optimally settings for accomplishing the flow of goods in terms of costs and services. The information that is available only after the flow of goods has been completed is for example an invoice that the recipient receives a few days after delivery. Information also flows in the opposite direction as the flow of goods, for example a status report on the execution of an order. The status report can include information from dispatching points about the time when the flow of goods passed critical stations in the transport chain. These stations can include borders in international shipments.

47 Electronic Data Interchange (EDI) is the electronic transfer of information. EDI makes it possible to ensure that the right information reaches the receiver (Parfett, 1992)

29 (33)

6 WORKS CITED

Aron. (2011 , 02 17). differencebetween.com. Retrieved 11 09, 2012, from Difference Between Logistics and Supply Chain Management: http://www.differencebetween.com/difference-‐between-‐logistics-‐and-‐vs-‐supply-‐chain-‐management/

Aronsson, H., Abrahamsson, M., & Spens, K. (2011). Developing lean and agile health care supply chains. Supply Chain Management: An International Journal , 16 (3), pp. 176-‐-‐83.

Bäckman, B., & Nilsson, U. (2005, 04). Ledarskap för tillväxt -‐ Så skapar chefer framgång. Retrieved 11 10, 2012, from Swedish Standards Institute: http://www.sis.se/upload/632489161069573286.pdf

Barringer, P. H., & Weber, D. P. (1996). Life Cycle Cost Tutorial. Fifth International Conference on Process Plant Reliability. 5, p. 58. Houston: Gulf Publishing Company and Hydrocarbon Processing .

Bergman, B., & Klefsjö, B. (2001). Kvalitet från behov till användning (Vol. Tredje upplagan). Lund, Sverige: Bergman, Studentlitteratur.

Chopra, S., & Meindl, P. (2007). Supply Chain Management: Strategy, Planning & Operations (Vol. 3). New Jersey, USA: Pearson Education, Inc.

Engström, H., & Toftrup, M. (2012). Affärsdrivet kvalitetsunderhåll. Välkommen till SAFT i Oskarshamn. Oskarshamn: SAFT.

H&M. (2012, 10 14). About H&M: Business concept & growth. Retrieved 10 14, 2012, from Our business concept: http://about.hm.com/content/hm/AboutSection/en/About/Facts-‐About-‐HM/About-‐HM/Business-‐Concept-‐and-‐Growth.html#cm-‐menu

Iaquinto, A. L. (1999). Can winners be losers? The case of the Deming Prize for quality and performance among large Japanese manufacturing firms. Managerial Auditing Journal , 14 (1/2), pp. 28-‐35.

IDG.se. (2009, 12 18). Retrieved 10 07, 2012, from H&M köper it för miljarder: http://www.idg.se/2.1085/1.280358/hm-‐koper-‐it-‐for-‐miljarder

Johansson, C., Lindgren, M., & Lissgärde, P. (1993). Att lyckas med ISO 9000-‐ en ingående studie av 23 certifierade företag. Uppsala. Uppsala, Sweden: Förlags AB Industrilitteratur.

Jones, D., & Mitchell, A. (2006). Lean thinking for the NHS. London, UK: Lean Enterprise Academy.

Jonsson, P., & Mattsson, S. (2011). Logistik – läran om effektiva materialflöden. Lund, Sverige: Studentlitteratur.

Karlsson, C., Flensburg, P., & Hörte, S.-‐Å. (2004). Knowledge spillovers and knowledge management. Cheltenham: Edward Elgar.

Kawauchi, Y., & Rausand , M. (1999, 06). Life Cycle Cost (LCC) analysis in oil and chemical process industries . Retrieved 11 06, 2012, from Life Cycle Cost (LCC) analysis in oil and chemical process industries : http://www.ntnu.no/ross/reports/lcc.pdf

Kloepffe, W. (1996). Life cycle sustainability assessment of products. International Journal of LCA .

30 (33)

Lakhal, L. (2009, 05 14). Impact of quality on competitive advantage and organizational performance. Journal of the Operational Research Society , 60 (5), pp. 637-‐-‐45.

Liker, J.-‐K. (2009). The Toyota Way,. Malmö, Sweden: Liber AB. Meland, G., & Meland, Å. (2006). Kaizen -‐ sakta ner och gör mer. Malmö, Sweden: Liber AB.

Nilsson, U. (2000). Att integrera ledningssystem (Vol. 1). Stockholm, Sweden: SIS Forum. Nilsson, U. (1994). Utveckla kvalite. Stockholm, Sweden: SIS kvalitetsforum. Olve, N., & Samuelsson, L. (2008). Controllerhandboken. Malmö, Sverige: Liber AB. Oxford University Press. (2012). Logistics. Retrieved 11 09, 2012, from Oxford dictionaries: http://oxforddictionaries.com/definition/english/logistics

Pålsson, H. (2009). Logistics value of using tracking data from uniquely labelled goods. Lund: Media-‐Tryck AB.

Parfett, M. (1992). What is EDI? A guide to Electronic Data Interchange. Oxford: NCC Blackwell Limited.

Saftbatteries. (2009, 01 09). Quality manual. Retrieved 11 11, 2012, from Saftbatteries: http://www.saftbatteries.com/SAFT/UploadedFiles/international-‐presence/quality_manual/osk_qm_en.pdf

Sashkin, M., & Kiser, K. J. (1993). Putting Total Quality Management to Work: What TQM Means, How to Use It & How to Sustain It Over the Long Run. San Fransisco, USA: Berrett-‐Koehler Publishers.

Taylor, D. (1997). Global Cases in Logistics and Supply Chain Management (Vol. 1). Oxford, UK: Alden Press Ltd.

The American Heritage® Dictionary of the English Language. (2009). Maintenance. (Houghton Mifflin Company) Retrieved 11 10, 2012, from The Free Dictionary by Farlex: http://www.thefreedictionary.com/maintenance

Toftrup, M. (2012, 09 30). SAFT Interview with quality engineer. (M. Skogmalm, C. Håkansson, & P. Ek, Interviewers)

Westwood, N., Moore, J., & Cooke, M. (2007). Going Lean in the NHS – How Lean thinking will enable the NHS to get more out of the same resources. London, UK: NHS Institute for Innovation and Improvement.

Womack, J., & Jones, D. (2003). Lean Thinking: Banish Waste and Create Wealth in Your Corporation. London, GB: Simon & Schuster.

31 (33)

APPENDICES

Questions Quality

• What is quality to you? What does quality within SAFT stand for? • What quality systems are you working with

o When were they introduced? o By whom? o How?

History

• How did the quality system look back then? o Models, tools, standards and so on?

Quality work today

• Can you describe SAFT's quality and how it works today? • What does SAFT do to ensure the quality of products? • What processes are included? • How and when did you update the system?

o Control? • How is it used from a "practical" point of view?

o Does project work occur? o Is there anyone who takes the initiative to develop the system? o What support is available when starting new assignments / projects? o Where does one turn for support?

• Quality tools / models • Who uses them? • How is results and quality control communicated to the rest of the organization?

Leadership

• What is the managements role in quality control?

Education

• Is training provided to employees in the quality control work?

o For whom? o What kind of training?

Results

• What are the critical success factors to consider? • What has been the biggest challenge? • What has been the biggest benefit of quality work? • What outcomes / results of working with quality work had you expected?

32 (33)

The Future

• How do you see the future development of quality work? o What can be improved?

ERP

• What kind of computer systems (ERP) does SAFT use in the organization?

Logistics

• Partners - how many companies are involved in the shipment to a specific customer? o Users / are all included in the ERP?

• How does SAFT manage the material flow? • What is your delivery pattern? • How do you evaluate your suppliers? • How has SAFT organized production resources? • What kind of material planning method does SAFT have?

Maintenance

• How does SAFT work with maintenance? o Do you do in-house or outsource repairs?

• How do you choose the 3rd party? o Lead-time? o Price? o Quality?

§ What is most important? • What methods are used for maintenance planning?

LCC

• Co-operation on the purchase of plastic + nickel? • Graphic map? • The manufacturing process of the battery - see blackboard Ca - Ni - Plastic sleeve – mm • The time from decision to implementation? • How does SAFT handle the LCC assessment? • How many critical using for making decision about LCC?

o Costs, o Useful life o Income