In-situ Oxygen analysis for concentrations as low as 1 x 10 ... Inputs • One or two zirconia...

Transcript of In-situ Oxygen analysis for concentrations as low as 1 x 10 ... Inputs • One or two zirconia...

Model 1231 1232 Oxygen

Probes

The Novatech 1231 and 1232 Oxygen probesincorporate the world’s most rugged zirconiasensors. They are ideal for:• Flue gas analysis• Oxygen levels in boilers, kilns and furnaces• Combustibles analysis• Carbon potential measurement• Water vapour concentration and dew

point measurement• Inert and sterile packaging• General industrial use• Annealing furnaces

The Novatech 1231 and 1232 Oxygen probes areAustralian-made and embody the research anddevelopment of one of Australia’s premier researchorganisations, the CSIRO.

The Novatech 1231 and 1232 probes are highlyaccurate, and have minimal drift (±1%).

The Novatech in-situ probes are highly durable;choose the Novatech 1231 for analysing gaseswith temperatures below 900ºC and the Novatech1232 for temperatures 700°C to 1400°C.

The Novatech 1231 and 1232 probes have a veryrapid response to changes in Oxygen levels A response time of between 1 and 4 seconds to oxygenlevel concentration changes means that potentiallyhazardous situations such as those caused through thebuild-up of dangerous, fuel-rich conditions can be avoided.

The Novatech 1231 and 1232 probes are easy to installThe probes are inserted into the flue, or other measuringpoint, and the threaded nipple (1231 has 1.5 “ BSP/NPT;1232 has 0.75” BSP/NPT) is screwed on to a mating socketwelded to the process. Connect the probe cable to thetransmitter, and you are ready to measure and/or control thecombustion process.

Novatech offers you safety of operationUse the Novatech 1632 which has a main burner safetyinterlock. This is the ONLY reliable way of preventingpotentially explosive situations; SHOULD THE MAINBURNER FAIL OR SHUT DOWN THEN THE SENSOR’SHEATER IS DE-ENERGISED SO THAT DANGEROUSFLUE GASES CANNOT BE IGNITED BY THE PROBE!

In-situ Oxygen analysis for concentrations as low as 1 x 10-30 to 100%

E Instruments

www.eigroup.biz

Optimum combustion reduces your fuel bill and helps the whole world and future generations by reducing harmful greenhouse gas emissions. The current high cost of fuel has helped to reduce the payback period for the cost of installing oxygen monitoring and air / fuel ratio control. It makes sense to consider the benefits of installing an oxygen system on your combustion process.

The 1732 oxygen transmitter is suitable for gaseous oxygen measurements in a variety of processes. These are some of those processes that the 1732 is designed for:

Optimum combustion reduces your fuel bill

Model 1732 Oxygen

Transmitter

Boilers • Power Generation

• Package

• Black Liquor Recovery

Iron & Steel • Heating Furnaces

• Coke Ovens

• Soaking Pits

Aluminium • Potlines

• Holding Furnaces

Incinerators • PVC

• Medical Waste

• Toxic Waste

Kilns & Furnaces • Rotary Lime

• Cement

• Glass

• Ceramic

• Brick

Nitrogen Purity • Generator

O2 Enrichment • Generator

Food Packaging • Continuous Monitoring

If your particular process is not listed above then we would love to hear from you. There is a good chance that Novatech Controls has an appropriate product for your process.

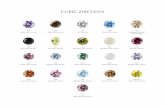

This is the sixth generation of zirconia oxygen transmitters designed and manufactured by Novatech Controls since 1980. This oxygen measurement is based on the world’s strongest zirconia sensor that was developed by the CSIRO’s Department of Materials Science. Novatech Controls holds the exclusive rights to manufacture this unique sensor.

This sensor, combined with the state-of-the-art 1732 transmitter, provides the perfect solution for your gaseous oxygen measurement.

Call your nearest Novatech distributor, or Novatech, to obtain expert advice for your particular application. We have been dedicated to designing and manufacturing the most reliable zirconia oxygen measuring instruments for more than 25 years.

E Instruments

www.eigroup.biz

Specifications

Inputs• One or two zirconia oxygen probes or sensors• One zirconia sensor & auxiliary thermocouple type J,

K, R or S• Burner “On” signal (dry contact)• Purge air flow switch

Outputs• Four programmable alarm relays• Two isolated 4-20mA or 0-20mA• SSR outputs to purge & calibration check gas

solenoid valves

Range of Outputs• Linear oxygen sensor 1• Linear oxygen sensor 2• Average oxygen• Very low oxygen• Logarithmic oxygen• Reducing oxygen• Oxygen deficiency• Carbon dioxide• Probe EMF• Auxiliary temperature• Combustibles• Burner Efficiency• No Output

Alarms• Common alarm relay with 20 user selectable

instrument alarm functions.• Three programmable process alarm relays for very low

oxygen, low oxygen, high oxygen, oxygen deviation, probe temperature low, cal check in progress, purge in progress, plus any alarms that were not selected for the common alarm. Multiple selections can be made for all relays.

Alarm Contacts• Normally open failsafe (open for alarm state)• 2A / 240VAC, 2A / 30VDC

Range of Local Indication• 1.0 x 10-30% to 100% O2

• 0.01ppm to 10,000ppm – automatically defaults to exponential format below 0.01ppm and percent format above 10,000ppm (1%)

Serial / Network Interface• RS232• RS485 MODBUSTM

Secondary Parameter DisplayAny or all of the following can be selected for display on the lower line:• Probe #1 temperature• Probe #2 temperature• Probe #1 EMF• Probe #2 EMF• Probe #1 impedance• Probe #2 impedance• Oxygen % probe #2• Average oxygen %• Auxiliary temperature• Ambient temperature• Ambient RH %• Carbon dioxide• Combustibles• Oxygen deficiency• Burner efficiency

Accuracy• ± 1% of the actual oxygen reading with a repeatability of 0.5%. For example, at 2% oxygen the accuracy would be ±0.02% oxygen.

Operating Temperature• -25°C to 55°C• 5% to 95% RH (non-condensing)

Power Requirements• 85VAC to 265VAC 50 / 60 Hz• 5W

Degree of Protection• IP65• IP54 with internal reference air pump

Dimensions• 260mm W x 160mm H x 90mm D

Weight• 3kg

Data Sheet 1732

Distributed by:

www.eigroup.biz

E Instruments

Specifications

Data Sheet 1231 & 1232 Probes

Model 1231 1232

Applications: Combustion flue Combustion flue gases

gases below above 700°C with

900°C (Note 1) no contaminants

eg natural gas, light oils

Temperature Range: 0-900°C 700-1400°C

Length: 250-2000 mm 500-1000 mm

Process Connection: 11/2" BSP or NPT 3/4" BSP or NPT

Sheath OD: 34 mm 19 mm

Electrical Connection: Weather-proof plug-in connector or optional screw terminals.

Cable: 1231 Cable can be supplied with a separate polyurethane

reference airline. 1232 Cable has an integral airline.

Heater: Yes No

Internal Thermocouple: Type “K” Type “R”

Response Time: Typically < 4 seconds Typically < 1 sec

Head Temperature: 100°C Max 150°C Max

Reference Gas: Air 50 cc/minute approx. Pump can be supplied within transmitter

Calib’n Check Gas Flow: Approx. 2 litres / minute Approx. 2 litres / minute

Ref. Air Connection: 1/4" tube Integral air line through

connector or 1/4” tube

Particulate Filter (optional): Removable titanium Not required

30 µm stand'd, 15 µm opt'n

Calib’n Check Gas Connection: 1/8" NPT female 1/8" NPT female

Weight: 1.8 kg plus 0.16 kg/100 mm 0.1 kg / 100 mm length

Notes

1. Care must be taken to avoid contact with explosive or

inflammable gases with 1231 heated Oxygen probes

when hot. Novatech Oxygen transmitters have built-in

safety protection which disconnects the heater when

the main flame is off.

2. A separate flue gas thermocouple is required with a

1231 probe if a flue gas temperature display on the

transmitter is required. A 1231 Oxygen probe has an

integral type K thermocouple which is used to

control the sensor temperature.

Ordering Information

• Probe insertion length (from process end of mounting

thread to probe sensing tip). Standard lengths below

• Weather-proof plug or screw terminal connections

• No filter or standard 30 µm filter or 15 µm option

(1231 only)

• Process connection thread type, BSP or NPT

• Cable with plug connector or no connector

Standard Probe ‘U’ Lengths

1231 1232

250 mm 500 mm

350 mm 750 mm

500 mm 1000 mm

750 mm

1000 mm

1500 mm

2000 mm

Distributed by:

E Instruments

www.eigroup.biz