Improving the knowledge of carbon storage and coal bed methane production

-

Upload

lamar-james -

Category

Documents

-

view

14 -

download

0

description

Transcript of Improving the knowledge of carbon storage and coal bed methane production

Improving the knowledge of carbon storageand coal bed methane production

by in situ underground tests

HUNOSA: N. CANTO ([email protected]), A. GONZÁLEZ, G. GONZÁLEZ, L. M. LARA, E. G. ONGALLOAITEMIN: J. L. FUENTES-CANTILLANA ([email protected]), H. L. ABÓS, J. L. GARCÍA-SIÑERIZBRGM: A. LEYNET ([email protected]), B. BOURGEOIS, P. DÉFOSSEZ, É. C. GAUCHER, V. NAUDET, É. PROUST, J. ROHMERINERIS: S. LAFORTUNE ([email protected]), C. DIDIER, F. LAHAIE, Z. POKRYSZKAGIG: J. SKIBA ([email protected]), B. JURA, P. KRZYSTOLIKTOTAL: S. VIDAL-GILBERT ([email protected])

6/ Long term safety

2/ Test area preparation

3/ Laboratory tests

4/ Injection & monitoring

5/ Modelling

S2

S1

66 cm

The Carbolab is located in the Montsacro mine, Asturias, Spain

1/ Site characterization

CARBOLAB

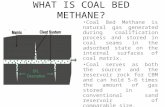

In the prospect of climate change mitigation, greenhouse gas emissions could be reduced by the geological storage of CO2.One of the promising variants of this technique is the injection of CO2 in deep unmineable coal seams.There, anthropogenic CO2 can be stored mostly by adsorption, this releasing CH4 that can be used for energy production.This method is been tested worldwide, but European coal deposits have received few interest (excepted the RECOPOL project).The processes generated during and after CO2 injection are still not well understood, nor are the opportunities in Europe.

The Carbolab project is supported by the European Fund for Coal and Steel, and involves 6 partners from three European countries, research centers as well as private companies.Its aim is to inject a significant (though not pilot-related) quantity of CO2 into a coal seam that will be pre-equipped for continuous monitoring.Putting devices in the near vicinity of the CO2 plume, only a few metres away, will allow data of much higher quality and density to be collected than in the case of injection from the surface, and to adapt the injected flow and the monitoring protocol to the evolution of the CO2 plume.

Analysis of the long-term safety of the CO2 storage in coal seams:•Simulation of behaviour, sizing of parameters for monitoring norms, risk assessment•Criteria and standards for ECBM site certification; recommendations for monitoring.

Characterization of the initial state of the site:•Synthesis of existing geological, sorption-desorption processes, and geomechanical data•Acquisition of complementary data from geology, geophysics, geochemistry, coal and gas characterization, hydrodynamics

The project started 1st July 2009 for 4 years

www.carbolab.eu

↓ in-situ permeability test Sampling for laboratory analyses ↓

↑ borehole drilling

Preparation of mine gallery to receive the future Carbolab underground laboratory test site.•Design & preparation of the test area•Injection tests•Installation of the scientific equipment•Safety matters

Measurement of intrinsic parameters on coal core samples:•In-situ coal and gas sampling•Characterization of coal and gas•Characterisation of relation between phases•Hydro-thermomechanic-chemistry experiment

Implementation of underground injection tests & monitoring:•Physical gas measurements•Seismic tests•Microseismicity•Cross-hole electrical imaging•Chemical and isotopic measurements•Atmospheric measurements & outgoing gas assessments

Modelling of the phenomena induced by the injection of the CO2:•Hydro-thermo-mechanics, core scale•Transport-chemistry, core scale•Hydro-thermo-mechanical coupling at the site scale

Reception

Transmission

Gallery

T3

T2

T1

50m

Gallery

R3

R2

R1

July 2009

Jan.2010

Nov.2010

April2011

July2011

P1

P2

Injection well ( 30 m)≃

Fan of closer wells ( 50 m)≃

Couple of farther wells ( 50 m)≃×2

north

east

20 m

5 m

coal seam

×2

×1

×3

×3

2 m

Geochemical wells ( 40 m)≃

galle

ry

↙ Proposition for injection & monitoring wells

↖ Electric monitoring

Characterization boreholes:1) permeability2) Characterization of coal and rock3) Test in-situ stress

July2013