Improving sterilization productivity with Lean Toyota...

Transcript of Improving sterilization productivity with Lean Toyota...

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Improving sterilization productivity with Lean Toyota approach

Jean-Marc Legentil Lecturer

HEC Montréal Canada President of Bell Nordic Consulting

Page 2

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Page 3

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

DEPARTMENT MEASURE IMPROVEMENT

CENTRAL PROCESSING and

SUPPLY

Instrument Tray Processing Time

54%

Floor Space Freed 740 ft2 ; 82m2

Labor Productivity 16%

Training Time for New Employee

50%

Page 4

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Akron Children’s Hospital Sterile processing � Increase in demand for surgical instruments � Expansion of $3.6 million USD � More space � More people

� OR

� Lean analysis � Employee involvement � Increased capacity from 13,000 to 16,000 procedures a year

(+23%) � No additional employee

Page 5

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

The Virginia Mason Production System

Virginia Mason Medical Center Strategic Plan

Page 6

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Toyota and healthcare

ell NoNorordicdic InI I c, , 20120100

Toyota Memorial Hospital

Translation in appendix

Page 7

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Industrialisation of healthcare ?

The industrialisation of healthcare is the only way to increase the human touch of care.

Marcus Froehling MD

Page 8

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Plan of this presentation

� Origins � Value added activities � The continuous improvement dilemma � Key methodologies

• 5S • Process review • Unit flow and U shape cells • Kanban • Poka-yoke and jidoka • SMED • TPM and check list

� Change management � Conclusion

Page 9

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Origin of the Toyota production system and introduction of the Lean/Toyota

approach in a hospital setting

Page 10

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Lean: definition

� A quality and process improvement management system

� based on the Toyota Production System � that emphasizes customer needs, � improving quality, � and reducing time delays and costs, � all through continuous improvement � and employee involvement.

Adapted from Graban, Lean Hospitals, 2009

Page 11

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Introduction to Lean Toyota Production System Or LEAN

Page 12

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Standardisation

� First step of a Continuous Improvement Program � When adressing a problem, the first question is:

do we have a standard?

Dr Gary Kaplan, CEO Virginia Mason Medical Center,

March 2009

standardize stabilize improve Innovate

Page 13

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Improving value added activitities

Page 14

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

VAA and NVAA Value added activity (VAA) � One that transforms or modifies a product or a service

into what can be sold to customers and from which they will perceive value.

Non value added activity (NVAA) � One that uses time, resources or space without adding

value to a product or a service. These activities don’t have an impact on the shape, function and utilization of the product or service.

Non value added activities (NVAA) are considered as waste and increase costs. MUDA.

In Lean-Kaizen activities, we try to eliminate all MUDAs.

Page 15

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Eliminating Seven sources of waste---- muda Reducing non value added activities

1. Overproduction 2. Lead time/delays 3. Transportation of materials 4. Stocks 5. Ineffective processes/operations 6. Defects/repairs/do-overs 7. Unnecessary movements (once step = one second, one

second = one yen) Maybe two important sources of non value added activities

are: Confusion No formal continuous improvement of Work Organisation

Page 16

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Work content analysis Only 43% Value added

activities

s

Page 17

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Examples of non added value in a hospital

Sector Process % VAA NVAA % AVA

Radio oncology

3 patients per hour exposed to source for 3 minutes each time

9 minutes 51 minutes out of 60 15%

Emergency Sprained ankle Examination/diagnostic 7 minutes X-rays 2 minutes

8 hours waiting time 2%

Haematology Blood test 1 minute blood test 50 minutes wait time 2%

Surgery Surgery on a bladder tumour

20 minutes surgery 5 hours from the time the patient leaves his room until he returns

7%

Radiology Mammogram 2 mammograms and 1 biopsy: 30 minutes

7 weeks wait time ≥ 1%

Care unit Various duties related to nursing

Direct patient care training

Making the bed, dressing the patient, seeking medical supplies, carrying meal trays

40%

Recruiting Hiring 4 hours of interviews, 30 minutes reading documents, 30 minutes fact checking

90 day delay in hiring 1%

Page 18

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Zero defect

� It is a paradigm shift: instead of accepting errors as being inevitable or to be expected, we have to find how NOT to make mistakes.

� Error free medicine is feasible, we just do not know how to make it happen yet.

Dr Gary Kaplan, CEO du Virginia Mason Medical Center, mars 2009

Page 19

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010 CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell N

« We have zero medication errors for two years. And those sorts of things� »

Dr John Toussaint

Président et CEO

ThedaCare, WI

Page 20

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

The expressions and acronyms dilemma

Page 21

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

What is Continuous Improvement (CI) ?

Continuous improvement is a structured step by step plan which enables organizations to review the ways they operate by using appropriate techniques in order to make each procedure more efficient.

Continuous improvement is a discipline,

an art form, which must be constantly in use;

it’s a way of life.

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 ©

Page 22

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Each problem has its own methodology

Problem Methodology Time wasting, frequent work accidents Five-S

Inefficient process Process review Backlog of files, patients in a waiting room, high stock level between operations

One piece flow U shape cell

Inefficient scheduling , delays, unnecessary stock and stock out at the same time

KANBAN

Too many repetitive errors Poke yoke Set up time too long between 2 operations SMED Critical errors occurs or should be avoided Check list /TPM

Page 23

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Lean: main tools

� Five-S – visual management � Process review � One piece flow and U shape

cell � Kanban � Poka-Yoke and Jidoka � SMED � TPM and verification prior to

start

Page 24

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Lean: main tools

� Five-S – visual management � Process review � One piece flow and U shape

cell � Kanban � Poka-Yoke and Jidoka � SMED � TPM and verification prior to

start

Page 25

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

� A productive � and efficient work area � which self-regulates at all times � through guidelines and visual instructions.

� Standardize practices � Reduce impact of illiteracy � Reduce confusion; improve communication

Objectives of the 5S’s

Page 26

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

5S definitions

S1 Sort (Seiri)

Remove all useless objects from the work area

S2 Situate(Seiton)

Everything at the right place A place for everything

S3 Shine (Seiso)

Keep it clean; cleaning is inspection

S4 Standardize (Seiketsu)

Make sure it is easy to understand All do it the same agreed upon way

S5 Sustain (Shitsuke)

Implement the necessary discipline for good work to be done

Page 27

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

The 6 essential key questions for events to occur:

� Where ? � What ? � When ? � Who ? � How ? � How many/much ?

• And do not forget that 30% of our population are functional illiterate (cannot write and read )

• For those who can, 30% have variable reading (and understanding) skills

• They have developed strategies to work effectively • But they do not read procedures, they learn them

Page 28

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

S1 Sort

Page 29

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

S4- Standardize

Page 30

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

S4- Standardize

Page 31

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Intraveineux

Urinaire

Respiratoire

Gastro-Intestinal

Pansements

Divers

CODE DE COULEURS

Mini systems

S4- Standardize

Page 32

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Lean: main tools

� Five-S – visual management � Process review � One piece flow and U shape

cell � Kanban � Poka-Yoke and Jidoka � SMED � TPM and verification prior to

start

Page 33

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Definitions

Process Sequence of activities, for example the process of handling an order

Sub-process Group of logical activities that are part of the process; for example, the order taking/receiving sub-process, the conception sub-process, the billing sub-process

Activity Defined by actions: to cut, walk, post, serve, write, sign

Task Related to an activity: a sequence of activities assigned to one person that become his or her tasks within the process

Procedure Detailed explanation of every sub-process, often using SIPOC.

Page 34

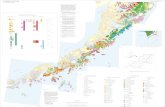

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010 Préparé par: Jean-Marc LegentilNote: Un document photo est complémentaire à cette cartographie

Infirmière

PAB

Technicien en stérilisation

Docteur

Institut de cardiologie de MontréalProcessus de Stérilisation

1Picking

Case Cart par

l'infirmière

Transport

4Utilisation

au bloc opératoire

5Transport de l'équipement

souillé

6Souillé

7Nettoyage

et brossage du matériel

souillé

8Préparation

de la solution pour le lavage

3Picking sur place des fournitures

stériles(seringues, tubulures...)

2Picking des

outils au bloc(ciseaux,

scalpel...)

9Filtration de

l'eau qui sera utilisé

pour le lavage

10Rincer et laver les tubulures

11Remplissage de

la machine à laver

12Machine à

laver en opération

13Séchage des outils propres

14Séchage

des tubulures

15Inspection

après lavage

16Inv. des Outils

Propres

Rejet

17Lire la

commande à partir du cahier d'instruction des

kits d'assemblage

18Kitting et

picking des outils requis

19Assemblage

des kits

20Emballage

des kits à

envoyer stériliser

21Stérilisation

22De la zone

stérile à l'entrepôt

23Inventaire

en Entrepôt

24Inventaire au Bloc

Page 35

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Lean: main tools

� Five-S – visual management � Process review � One piece flow and U shape

cell � Kanban � Poka-Yoke and Jidoka � SMED � TPM and verification prior to

start

Page 36

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

BEFORE

AFTER, U SHAPE CELL

BEFOREUse U Shape Cell to increase productivity

Spaghetti diagram

Page 37

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Use U Shape Cell to increase

productivity using UNIT FLOW

Page 38

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Lean: main tools

� Five-S – visual management � Process review � One piece flow and U shape

cell � Kanban � Poka-Yoke and Jidoka � SMED � TPM and verification prior to

start

Page 39

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Kanban: definition

Kan = card and Ban = signal

� Decentralized stock management method by which the activation of operations is assigned to the work stations

upstream. These then signal the procurement or the authorization to produce.

� The Kanban system was developed more than 40 years ago by Taiichi Ohno, vice-president of Toyota.

Page 40

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Kanban for sterilized items

Page 41

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Kanban for sterile supplies

Page 42

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Kanban board: Supply board

Two bin system in Canadian healthcare 9 am

Page 43

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Lean: main tools

� Five-S – visual management � Process review � One piece flow and U shape

cell � Kanban � Poka-Yoke and Jidoka � SMED � TPM and verification prior to

start

Page 44

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Poka-Yoke

� Means fool proof in Japanese � System to prevent a person from making

a mistake � Zero mistakes, error free work method � An employee can verify his work himself

� How could we not make mistakes?... Is the

challenge

Page 45

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Three POKE-YOKE levels

1. Guide

2. Picket fence

3. Brick wall

P R O G R E S S I O N

Page 46

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Poka-yoke – GUIDE LEVEL

Page 47

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Lean: main tools

� Five-S – visual management � Process review � One piece flow and U shape

cell � Kanban � Poka-Yoke and Jidoka � SMED � TPM and verification prior to

start

Page 48

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

It’s the acronym for : � Single Minute Exchange of Die � Refers to a technique for performing setup

operations in 9 minutes or less Objective:

� Each exercise aims at reducing the time needed by 30-50%.

What is SMED?

SMED

Page 49

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Lean: main tools

� Five-S – visual management � Process review � One piece flow and U shape

cell � Kanban � Poka-Yoke and Jidoka � SMED � TPM and verification prior to

start

Page 50

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Checking the plane before starting the engine

COCOCOCONCONONONNNF WF WF WF WF WF WF WFHSFHSFHSFHSFHSFHSSSSSSS TURTURTURTURTURTURQUIQUIQUIQUIQUIQUIE LE LE LE LE LE Leaneaneaneanean ttoytoytoytoytoy totaotaotaotaota hheaheaheaheaheaththcthcthcthcthcareareareareare SUSUSUSUSU SUMMAMMAMMAMMAMMAMMARYRYRYRYRYRY 7v 7v 7v 7v 7v 7 22-2-222 © C© C© C© C© C© Copyopyopyopyopy irigrigrigrigrighthtshtshtshtshts JJJJJ Jeaneaneaneanean MMa-Ma-MaMaMarcrcrcrcrc LLegLegLegLegLeg tentententententililililil,il, BBeBeBeBe Bellllllllllll NNorNorNorNorNordidicdicdicdicdic IInInInIn Incccc,c, 201201201201201201000000

Page 51

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Checklist

Page 52

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Managing changes for organizational transformations

Plan and orchestrate change

Page 53

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

� Essentially • TPS for healthcare • To reduce non value added activities • By using appropriate tools

� Essence • Work standardization and standardized

processes

� Essential • The people

The Toyota/Lean Approach Applied to Health Care

Page 54

CONF WFHSS TURQUIE Lean toyota heathcare SUMMARY v 7-2 © Copyrights Jean-Marc Legentil, Bell Nordic Inc, 2010

Thanks!

Jean-Marc Legentil Lecturer

HEC Montréal, Canada President of Bell Nordic Consulting