Improved Acetabular Cementing Techniques

Transcript of Improved Acetabular Cementing Techniques

Improved Acetabular

Cementing Techniques

Masters of Applied Science (Orthopaedics)

Queensland University of Technology

Faculty of Built Environment and Engineering

BN71

Author: Dr Bjorn N Smith BAppSc (PHTY), MBBS.

Principal Supervisor: Prof Ross Crawford.

Associate Supervisors: Dr Clive Lee (External),

Mr John Timperley (External).

1

Abstract: The most common cause for revision total hip replacement surgey is aseptic loosening of

the acetabular component. This thesis explores the effect of three techniques to improve

the depth and quality of cemented acetabular component fixation in primary total hip

replacement. This may have beneficial effects on the longevity of cemented acetabular

components and reduce the rate of revision surgery for aseptic loosening.

Aims: 1. Determine the effect of the rim cutter on cement pressure during cup insertion.

2. Examine the effect of the rim cutter on cement penetration distance. 3. Evaluate the

effect of bone grafting of the acetabular notch. 4. Determine the effect of iliac suction

during cement pressurisation. 5. Compare the behaviour of bone cement with Play

Dough®.

Materials and Methods: 1. Sawbones hemi pelvis models were fitted with pressure

transducers at the rim and apex of the acetabulum. Peak pressure was measured upon

insertion of cups with different flange sizes and when the acetabulum was prepared with

the rim cutter. 2. Foam cavities were used to measure the depth of cement penetration

when the same cups and rim cutter were used. 3. Hemi pelvis models were modified to

simulate bone grafting of the acetabular notch. Again, pressure sensors were mounted at

the apex and rim of the acetabulum. Intra-acetabular cement pressure was compared with

native acetabulae. 4. A back bleeding model of the acetabulum was fitted with a suction

catheter. The effect on cement penetration into cancellous bone was measured compared

with no suction. 5. Play Dough® pressurisation and penetration into hemi pelvises and

foam was compared to bone cement.

Results: 1. Significant increase in peak apex and rim pressures when flanged cup inserted

into an acetabulum prepared with the rim cutter compared with both flanged and

unflanged cups alone. 2. Significant increase in cement penetration at the rim of the

acetabulum when rim cutter used and flanged cup inserted when compared with flanged

and unflanged cups alone. 3. Significant increase in intra-acetabular pressure when

cement pressurised in presence of simulated acetabular notch bone grafting compared

with normal acetabulae. 4. Significant increase in cement penetration distance when

2

suction used compared with no suction. 5. Significant differences in the flow

characteristics between bone cement and Play Dough®.

Conclusion: The authors recommend preparation of the acetabular rim with the rim cutter

and bone grafting of the acetabular notch to improve the depth and uniformity of the

cement mantle in cemented primary THA. Play Dough® at room temperature is not a

suitable substitute for bone cement in in-vitro cementing studies.

Key words: hip, acetabulum, cement, flanged, cup, rim cutter, suction, pressurisation,

bone graft, acetabular notch, arthroplasty, penetration, Play Dough®.

3

Contents:

Abstract………………………………………………………………..Page 1-2.

List of Diagrams and Photographs…………………………………….Page 4-5.

Statement of Authorship……………………………………………….Page 6.

Acknowledgements…………………………………………………....Page 7.

Prologue……………………………………………………………….Page 8.

Chapter One: Background……………………………………………..Page 9-19.

Chapter Two: Materials and Methods…………………………………Page 20-33.

Chapter Three: Results…………………………………………………Page 34-60.

Chapter Four: Discussion………………………………………………Page 61-83.

Chapter Five: Conclusion……………………………………………...Page 84-85.

Disclosure……………………………………………………………...Page 86.

Appendix 1……………………………………………………………..Page 87-88.

Bibliography……………………………………………………………Page 89-93.

4

List of Diagrams and Photographs:

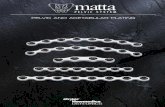

Photo 2.1: Sawbones hemipelvis model. Photo 2.2: Reamed hemipelvis model mounted in vice. Photo 2.3: Holes drilled in apex and rim of acetabulum. Photo 2.4: Holes drilled at apex and rim of acetabulum. Photo 2.5: Pressure transducers screwed into drill holes at apex and rim of acetabulum. Photo 2.6: Pressure transducers screwed into drill holes at apex and rim of acetabulum. Photo 2.7: Pressure transducers screwed into drill holes at apex and rim of acetabulum. Photo 2.8: Vinyl glove placed in acetabulum prior to cement insertion. Photo 2.9: Simplex bone cement. Photo 2.10: Load sensor mounted in shaft of acetabular pressuriser. Photo 2.11: Laptop computer and data acquisition unit. Photo 2.12: Patch of foam adhered to acetabular notch. Photo 2.13: Exeter Contemporary Cup prior to trimming. Photo 2.14: Exeter Contemporary Cup prior to trimming. Photo 2.15: Unflanged Exeter contemporary cup used. Photo 2.16: Flanged Exeter contemporary cup used. Photo 2.17: The Rim Cutter. Photo 2.18: The Rim Cutter assembled. Photo 2.19: Hemipelvis model reamed and prepared by using the rim cutter. Photo 2.20: Closer view of the acetabulum prepared with the rim cutter. Photo 2.21: Exeter contemporary cup with the flange trimmed to the second groove. Photo 2.22: Acetabular foam cavity used for cement penetration testing. Photo 2.23: Computer generated image of foam cavities. Photo 2.24: Schematic drawing of the foam cavities used to simulate acetabulae. Photo 2.25: Foam cavity mounted in jig. Photo 2.26: Pressurisation of the foam acetabulum. Photo 2.27: Pressurisation of the cup in the foam cavity. Photo 2.28: Closer view of cup pressurisation. Photo 2.29: Cavity prepared by rim cutter. Photo 2.30: Side view of cavity prepared by rim cutter. Photo 2.31: ‘Open cell’ foam used in the third part of the study. Photo 2.32: Closer view of ‘open cell’ foam. Photo 2.33: Foam pieces placed in metal box. Photo 2.34: Side view of foam in metal box. Photo 2.35: Pressurised cement in foam, with the various points labelled A to D. Photo 2.36: Side view of foam piece after cement pressurisation. Photo 2.37: Cement penetration measured by drawing a line between opposite corners of

the foam. Photo 2.38: The Eschmann TJ 240H portable suction machine. Photo 2.39: Motor oil fills the inverted 60mL syringe, suspended 77 cm above the metal

box.

5

Photo 2.40: Motor oil fills the metal box and the suction catheter can be seen at point C. Photo 2.41: Pressurisation of the cement whilst the foam bleeds oil and suction catheter

aspirates fluid from the metal box. Photo 2.42: Manual pressurisation of the cement in the metal box. Photo 3.1: Pressurisation of cement in the native acetabulum. Photo 3.2: Unflanged cup has been inserted into the hemipelvis model. Photo 3.3: Holes seen in extracted cement mantle. Photo 3.4: No holes seen in extracted cement mantle of Rim Cutter group. Photo 3.5: Anterior view of Rim Cutter cement mantle after cup removed. Photo 3.6: Cementing of the unflanged cup into the acetabular foam cavity. Photo 3.7: Cement extrudes out of the base of the cavity in the rim cutter tests. Photo 3.8: Closer view of cement extruding from holes. Table 3.1: Pressures recorded in the normal acetabulum. Table 3.2: Pressures recorded using Play Dough® in normal acetabulum. Table 3.3: Pressures recorded using cement in a ‘grafted’ acetabulum. Table 3.4: Pressure recordings in unflanged cup group. Table 3.5: Pressures recorded in the flanged cup group. Table 3.6: Pressures recorded in Rim Cutter group. Table 3.7: Penetration of pressurised bone cement (in millimetres). Table 3.8: Measurements of Play Dough penetration in each trial (millimetres). Table 3.9: Mean force exerted on pressuriser (N). Table 3.10: Penetration of bone cement with insertion of unflanged cup (millimetres). Table 3.11: Penetration of bone cement into cavities with a flanged cup inserted (mm). Table 3.12: Penetration of bone cement in cavities prepared by rim cutter (millimetres). Table 3.13: Force exerted on pressuriser in different phases of penetration testing. Table 3.14: Maximal force required to seat each cup type. Table 3.15: Cement penetration distance at rim of dry foam (millimetres). Table 3.16: Cement penetration distance in dry foam with suction at point ‘C’

(millimetres). Table 3.17: Cement penetration distance into wet foam with no suction (millimetres). Table 3.18: Cement penetration distance with back bleeding and suction at point ‘C’

(millimetres). Table 3.19: Forces exerted on cement in foam under various experimental conditions. Table 3.20: Mean cement penetration at various points (in mm).

6

Statement of Authorship:

The work contained in this thesis has not been previously submitted to meet requirements

for an award at this or any other higher education institution. To the best of my

knowledge and belief, the thesis contains no material previously published or written by

another person except where due reference is made.

Signature

Date

7

Acknowledgements: The author would like to acknowledge the principal supervisors of this project: Mr John

Timperley, Professor Ross Crawford and Dr Clive Lee for their invaluable assistance,

guidance and support in this project. Without their input this study would not have been

possible. Thanks are also extended to the Engineering Department of the University of

Exeter whose generous assistance with the design and loan of custom built testing

equipment is much appreciated. Gratitude is also expressed to the management of the

Princess Elizabeth Orthopaedic Centre for the use of their laboratory facilities. Assistance

with statistical methods was generously provided by Ms Sarah Whitehouse from the

Queensland University of Technology to whom I am most grateful. The suction testing in

part three required an assistant to manage the flow of oil and this role was carried out by

Ms Fiona Graham. The author thanks her for her assistance and support throughout the

whole study. A special mention must go to Emeritus Professor Robin Ling who is a

fantastic role model and an inspiration to the author. Finally thanks must go to the Stryker

Corporation without whose financial contribution towards the testing equipment and

materials this study would not have been possible.

8

“If a certain cup can, at the time of cup insertion, produce higher cement intrusion

pressure and depth than other cups, and if a cup, when completely inserted, is positioned

concentrically within the reamed acetabulum with a uniform cement thickness without

‘bottoming out’, then this feature would be highly desirable for lasting fixation of the

acetabular component.”

Oh, Sander and Trahearne (1985)

9

Chapter One: Background: The aims of the studies in this thesis are fivefold: (1) To determine the effect of the rim

cutter on cement pressure during cup insertion, (2) to examine the effect of the rim cutter

on cement penetration distance, (3) to evaluate the effect of bone grafting of the

acetabular notch, (4) To determine the effect of iliac suction during cement

pressurisation, (5) To compare the behaviour of bone cement with Play Dough®. The

hypotheses being tested is that each technique will increase the cement pressure or

penetration distance in vitro. Play Dough® is hypothesized to behave similarly to bone

cement. A graphical representation of the thesis plan is shown on page 19.

The history of cemented acetabular components is an interesting one. This chapter will

endeavour to explain the history of cemented total hip replacement, the advances that

have been made in cementing technique, the current problems with acetabular

pressurisation and discuss the various experimental techniques, which aim to improve the

long term outcome of cemented sockets.

History:

The first total hip replacement was performed in 1961 by Sir John Charnley in

Wrightington, UK. A number of different materials for the cup were trialled by Sir

Charnley including Teflon®. After much consideration and experimentation the

components he used consisted of a stainless steel femoral stem, and femoral head, which

articulated with a high molecular weight polyethylene cup (Charnley, 1995). Sir Charnley

used both press-fit and cemented cups in his initial series of 582 patients. The cemented

components were held in place with polymethylmethacrylate bone cement, otherwise

known as PMMA. The techniques for cementing of the components used by Sir Charnley

became known as first generation cementing techniques. On the femoral side this

involved broaching of the femoral canal, bowl mixing of the cement, finger packing of

the cement into the femur and inserting of one of a limited selection of different sized and

shaped components. On the acetabular side the subchondral bone was reamed, cement

finger packed into the cavity and the cup inserted. Since that time, the technique of

inserting and fixing the femoral and acetabular components have advanced significantly.

10

These changes have evolved to combat a variety of problems, which inevitably arise

when a completely new procedure is devised. Initially the results were very good, with a

high proportion of patients (>90%) experiencing relief of their debilitating arthritic

symptoms (Charnley, 1995). As the practice of cemented total hip replacement spread

over the years however, a number of the components appeared on radiographic review to

be loosening, and a (smaller) proportion of patients who developed symptoms related to

this required revision surgery. As the period of time since implantation of total hip

replacements increased, the problem of loosening of either of the components became

more pronounced. While the incidence of cemented femoral component loosening has

reduced significantly over the last twenty years, the rate of acetabular component

loosening has not shown such encouraging progress (Mulroy and Harris 1990). In fact,

countless authors over the last twenty years have stated that the most common reason for

revision total hip replacement is loosening of the acetabular component (Chandler et. al.

1981, Ranawat et. al. 1984, Wroblewski 1986, Kavanagh et. al. 1989, Schulte et. al.

1993, Ranawat et. al. 1995, Mulroy et. al. 1995, Sochart and Porter 1997, Wroblewski et.

al. 1999 and Callaghan et. al. 2000).

Each year there are more than one million hip replacement operations performed across

the globe (Flivik, 2005). According to the Australian Orthopaedic Association National

Joint Replacement Registry Annual Report of 2006, there were 20,683 total hip

replacements for the financial year 2004 – 2005, a number that is increasing each year.

Of these, only 9.5% (1965) used cemented acetabular fixation, a number that is gradually

decreasing each year. This indicates a trend in Australia away from cemented acetabular

fixation in favour of newer technologies such as cementless and hybrid fixation systems

and hip resurfacing. In other countries such as Sweden greater than 90% of the 10,000

plus hip replacements performed each year utilise cemented acetabular fixation (Flivik,

2005). Furthermore, because of its excellent long term results, cemented fixation systems

provide a level of reliability that at least matches if not exceeds that of cementless and

hybrid fixation. The Australian Joint Replacement Registry reports that in the 75 years

plus age group cemented total hip replacement has the lowest rate of revision at three

11

years of all fixation systems (1.52%). Of the 1965 cemented cups implanted in 2004-05

in Australia, just under half (46%) were Exeter Contemporary cups.

Comparing the last five years of data from the Australian Joint Replacement Registry

shows that revision surgery accounts for 12% of all total hip replacement operations. In

total 9194 cases out of 19257 revision operations (47.7%) were performed because of

loosening of a prosthesis. Of all major hip revision operations performed acetabular

revisions far outnumber femoral revisions (37.2% vs. 21.2%). This further highlights the

need for improved acetabular fixation methods. Countless authors agree that the key

determinant in ensuring adequate, long lasting cup fixation in cemented total hip

arthroplasty is the quality of the cementing technique (Flivik et. al. 2004).

Strength of the Bone-Cement Interface:

The work of Krause et. al. in 1982 showed that bone cement fixation is dependent on the

penetration of bone cement into the cancellous interstices of the bone. They also

demonstrated that cleaning of the bone with high-intensity lavage allows improved

cement penetration, which thereby increased tensile and shear strength of the bone-

cement interface. These effects of improved cement penetration have been supported by a

number of other authors (Halawa et. al. 1978, Panjabi et. al. 1986, Macdonald et. al.

1993, Juliusson et. al. 1994). However, Majkowski et. al. in 1994 suggested that

penetration beyond three millimetres does not enhance the strength of the bone-cement

interface. A later study of the effects of bone-porosity and cement penetration on the

bone-cement interface was conducted by Graham et. al. in 2003. That study concluded

that the strength of the bone cement interface is increased significantly by increased bone

porosity and consequently by increased cement penetration. Kuivila et. al. (1989) also

showed that increased cement penetration leads to increased tensile strength at the bone-

cement interface, a finding that was also reported by Eftekhar and Nercessian (1988).

Causes of Prosthesis Loosening:

Anderson et. al. postulated in 1972 that the causes of prosthesis loosening in hip

replacements could be due to a combination of factors including micro motion at the

12

bone-cement interface, thermal bone damage at the time of cement polymerisation or

chemical factors. In 1978 and 1979 a number of studies (Beckenbaugh and Ilstrup 1978,

MacBeath and Foltz 1979 and Gruen et. al. 1979) quoted the rates of prosthesis loosening

seen on radiological examination to be from 15 to 21 per cent after between one and

seven years of followup. Later, Mjoberg (1991 and 1994) suggested that loosening

resulted from early prosthetic instability and that the ‘late’ loosening being reported was

perhaps really just late detection of previously loose components. It has also been

suggested by DeLee and Charnley in 1976 that part of the loosening process may stem

from a layer of blood forming at the bone-cement interface, which could later go on to

form a fibrous tissue membrane. This concept has been supported by a number of other

authors (Lee and Ling 1981, Eftekhar and Narcessian 1988 and Bannister et. al. 1990).

Charnley suggested in 1975 that the accumulation of blood at the bone-cement interface

may be the cause of the radiolucent lines seen on post operative radiographs. Later,

DeLee and Charnley (1976) first classified the radiological appearance of those lucent

lines at the bone cement interface in their famous paper. Freeman et. al. 1982 first

suggested that radiolucency at the bone-cement interface may not be caused by micro-

motion but in fact be related to a biological cause. Later, Schmalzreid et al (1992)

claimed that the cause of aseptic loosening of the cemented acetabular component was in

fact different to that causing the femoral component to loosen. While the femoral

component is thought to loosen secondary to mechanical forces, they proposed that

acetabular loosening was indeed secondary to biologic phenomena. New et. al. (1999)

suggested that perhaps the better results seen recently are secondary to reduced fibrous

tissue between cement mantle and bone, which leads to reduced wear debris behind the

prosthesis.

Advances in Cementing Technique:

PMMA is by nature viscoelastic, which is important when considering the topic of

pressurisation of the acetabulum. The aim of pressurisation is to achieve an adequate

cement mantle with extensive cement interlock in cancellous bone interstices (Ranawat

et. al. 1997). This manifests stability at the bone-cement interface and prevents micro-

motion and subsequent loosening of the prosthesis. Pressurisation will therefore ideally

13

force PMMA far enough into cancellous bone to achieve a strong interlock and then

prevent movement of the cement until it has polymerised. Pressurisation must be capable

of overcoming all additional forces that act either on or within the cement. The work of

Markolf and Amstutz in 1976 investigating the penetration and flow of bone cement was

able to highlight a number of important factors. Firstly, they showed that the penetration

of bone cement into cancellous bone is proportional to the pressure applied to the cement

bolus. They also demonstrated that the majority of the depth of cement penetration

occurred in the first two seconds of pressurisation (76%) and that the depth of penetration

was three times greater when cement was pressurised at four minutes from mixing rather

than the standard six and a half minutes. Another of their findings was that vigorous

finger packing of cement produced very high pressures for a short period of time and

caused greater cement penetration than low pressure sustained for a longer period of time.

Bayne et. al. (1975) showed that higher pressures applied to the cement mantle during

polymerisation may lead to a reduction in cement porosity. The relationship between the

pressure and penetration of bone cement was also studied by Panjabi et. al. in 1983 and

1986. Their research suggested a positive logarithmic relationship between the pressure

applied to the cement and the depth of cement penetration. They also showed that there

was a linear relationship between cement intrusion penetration and bending and axial

stiffness of the bone-cement interface. A similar link between pressure and penetration

has been reported by a number of authors (Convery and Malcolm 1980, Bannister et. al.

1988, Graham et. al. 2003, Flivik et. al. 2004). Oh and Harris in 1982 proposed a cement

fixation system by pressurising cement in the acetabulum for five to ten seconds. This

was followed up by Oh et. al. in 1983 in their study of the effect of pressurising keying

holes in a dry cadaveric acetabulum with multiple short bursts of high pressure, which

yielded a cement penetration depth of 19.2 to 25.5 millimetres. A landmark study was

performed by Benjamin et. al. in 1987 who studied the effects of bleeding on cement

penetration. Their findings showed that water was able to displace low viscosity PMMA

at a pressure of ten centimetres of water. They also found that water was able to displace

PMMA up to seven minutes after mixing of cement. This research suggested a change in

practice to apply pressure onto the cement mantle until such time as its viscosity would

be sufficient to resist the back bleeding pressure of blood. Otherwise, the cement mantle

14

would be displaced both in the time between removing the pressuriser and inserting the

prosthesis and after insertion of the prosthesis if it was not itself pressurised, resulting in

a less adequate bone cement interlock. Majkowski et. al. in 1994 published results

suggesting that pressurisation for thirty seconds is adequate and that additional

pressurisation of cement in the dough stage after that is of no additional value at

physiological bleeding pressures. The simulated bleeding flow rates used in their study

however, were somewhat lower than those used in previous studies. These proposed

techniques were developed further by New et. al. (1999) who suggested that short

duration, high intensity pulses of pressure would be more effective when combined with

a sustained background pressure to resist back bleeding pressure and elastic recoil of the

cement.

Other aspects of cementing technique have been added and refined over the last thirty

years. In 1978, Oh et. al. found that when cementing femoral components, distal plugging

of the femoral canal with PMMA caused increased cement intrusion pressure, deeper

cement penetration and consequently increased tensile strength of the bone-cement

interface. Similar findings were also reported later by Macdonald et. al. (1993). In current

practice plastic or bioabsorbable femoral canal plugs are used. Cleaning of the cancellous

bone bed is known to remove debris and facilitate flow of cement and hence increased

cement penetration. This notion was supported by Krause et. al. (1982). Majkowski et. al.

(1993) examined cement penetration into bovine bone and reported no difference

between continuous lavage and pressurised pulsed lavage. However, jet lavage was

shown to be more effective at facilitating cement penetration than syringe lavage by

Breusch et. al. (2000) in their study of cadaveric femora, and also in the tibia by Dorr et.

al. (1984). Microcrystalline collagen was used as a topical haemostatic agent, but it was

later shown to significantly reduce the shear strength of the cement-bone interface by

Lange in 1979. Later, hydrogen peroxide was shown to reduce bleeding from cancellous

bone by Hankin et. al. (1984). This practice has since become common in cementing

techniques for all components. Halawa et. al. (1978) showed that in fact the greatest shear

strength at the cement-bone interface in the femur was achieved with pressurised low

viscosity cement. Noble and Swarts (1983) suggested that low viscosity cement would

15

allow increased cement penetration into cancellous bone. These findings were confirmed

by Macdonald et. al. (1993) who showed that the use of low viscosity cement did indeed

improve cement penetration. However, a study by Mjoberg et. al. (1987) found no

difference in cup loosening rates between low viscosity and high viscosity cement use.

Current practice reflects a compromise between cement of sufficiently low viscosity to

allow adequate cement penetration and cement that is of such a viscosity that it is too

difficult for the surgeon to handle (Dorr et. al. 1984). Hypotensive epidural anaesthesia

has been frequently applied in cases of cemented total hip arthroplasty for over ten years.

Ranawat et. al. (1991) demonstrated that hypotensive epidural anaesthesia allowed deeper

penetration of cement into cancellous bone of the acetabulum on radiographic evidence.

Problems with Pressurisation:

Much attention has been focussed on improving the acetabular cement mantle. The

majority of authors claim that the optimal depth of cement penetration is three to five

millimetres (Huiskes and Sloof 1981, Walker et. al. 1984, Askew et. al. 1984, Eyerer and

Jin 1986, Miller 1990). A greater depth of cement penetration imparts minimal increased

interfacial strength and avoids some of the major problems with a thicker cement mantle

(Dorr et. al. 1984). Cement mantles thicker than ten millimetres may cause increased heat

generation when the cement is polymerising, which can cause bone necrosis, bone loss

and reduction in the strength of the bone cement (Homsy et. al. 1972, Huiskes and Sloof

1981, Sew Hoy et. al. 1983). This concept is contested by Jefferiss et. al. in their 1975

paper in which they claim that bone necrosis is not a consequence of thermal damage

caused by polymerisation of PMMA. The problem with adequate generation of pressure

in the acetabulum stems from two main features. The acetabulum itself is an open

hemisphere, which compared with the relatively closed, cylindrical shape of the femoral

canal makes containment of cement more difficult. This makes it more difficult to

generate the pressures required for adequate cement penetration in the acetabulum. The

second feature is the acetabular notch under the transverse ligament. This results in

inconsistency in the rim of the acetabulum, and hence makes achieving a closed cavity

for pressurisation much more difficult (Flivik et. al. 2004). A number of different shaped

and styled pressurisers have been designed to combat this problem and to date, there is no

16

accepted gold standard design. The main drawback with current techniques in acetabular

cement pressurisation is extrusion of cement underneath the transverse ligament out

through the acetabular notch (Bernoski et. al. 1998). Martin et. al. (2003) support the

notion that the majority of cement extrusion occurs in this region with their report of a

series of post operative radiographs in which the main location of cement extrusion was

anteroinferiorly. Some authors (Oh et. al. 1983, Flivik et. al. 2004) have recommended

sequential pressurisation of keying holes in the acetabulum in order to overcome the high

pressures needed for adequate cement pressurisation. However, Gruen et. al. (1976) and

Saha and Pal (1984) have reported the formation of laminations in the cement mantle

with such pressurisation, which may cause weakening of the tensile and shear strength of

the cement mantle. Flivik et. al. (2004) claim that if the laminations form before 3.5

minutes from mixing of cement, that the polymerisation process is able to bridge the

laminations and hence prevent any reduction in the strength of the cement mantle.

Flanged and unflanged cups:

The problem of containing bone cement in the region of the acetabular notch has been

addressed since 1976 when the flanged socket was first introduced (Shelley and

Wroblewski 1988). The use of this socket was however, complicated by a tendency for it

to be placed in anteversion. Sir Charnley designed the Ogee flanged cup in the early

eighties when cross-linked polyethylene became available, which could be effectively

cast into an asymmetrical shape (Shelley and Wroblewski 1988). Oh et. al. (1985)

showed that cement pressures during cup intrusion are significantly elevated by the

employment of a cup with a continuous flange. This was supported by Shelley and

Wroblewski (1988) who showed that Ogee flanged cups generate three times more

pressure than standard unflanged cups. They also claimed that it is difficult to insert an

unflanged cup concentrically without it ‘bottoming out’. Bernoski et. al. (1998) also

agreed with this notion, by claiming that the use of a cup to generate pressure in the

acetabulum is not possible unless the cup is fitted with a suitably designed flange.

Beverland et. al. (1993) showed that inadequately sized and prepared flanges can actually

impair the pressurisation of cement in the acetabulum. In 2004, Parsch et. al. reported

that the inserting of Ogee flanged cups produced a higher intra-acetabular pressure than

17

unflanged cups, but did not result in significantly increased cement penetration. Similar

findings were also reported by Flivik et. al. (2004).

Bone grafting of the acetabular notch:

Bone grafting has had a role in cemented total hip arthroplasty for many years

(McCollum et. al. 1980). It has been utilised in patients suffering from developmental

dysplasia of the hip, where grafting allows a deeper and more stable socket to be formed

into which the cup can be cemented. Bone grafting in the acetabulum has also been used

in revision hip arthroplasty in cases of extensive bone loss in the form of impaction

grafting and primary hip arthroplasty in the presence of acetabular protrusio, where it is

essential to stabilise the medial wall of the acetabular cavity. McCollum et. al. reported in

1980 that in the case of acetabular protrusio bone grafts placed in the medial wall of the

acetabulum under cemented sockets had incorporated into the bone within three months

on radiographic evidence. Similar work into medial wall bone grafting by Heywood

(1980) and Mendes et. al. (1982), (1983) and (1984) suggested that the graft had united

within six to ten months. It has also been demonstrated by Xenakis et. al. in 1997 that

bone graft used with uncemented cups in the acetabulum will reliably consolidate and

incorporate in patients with developmental dysplasia of the hip. To the authors’

knowledge there have been no published studies specifically examining the effect of bone

grafting the acetabular notch in primary cemented total hip arthroplasty. However, an

unpublished study conducted in Exeter examining the effects of bone grafting of the

acetabular notch showed a reduction in cement extrusion clinically and an increase in

cement penetration radiographically.

Use of Iliac Sucker:

The use of a suction catheter or retractor has been proposed by Berend and Ritter (2002)

to maintain a dry acetabular cavity prior to and during cementing of sockets. Their

anecdotal evidence suggests that intra-pelvic suction may improve the cement mantle and

reduce the incidence of early radiolucent lines. This could be applied particularly to

DeLee-Charnley zone 1, where the presence of early radiolucency is currently the best

predictor of long-term stability of the acetabular component. Use of a suction catheter to

18

improve cancellous bone drying and cement penetration has also been reported as being

effective in total knee arthroplasty by Banwart et. al. (2000). Their study used cadaveric

tibiae and although it did not show an increase in cement penetration, it did show better

bone-cement interlock, with fewer voids.

Play Dough

Experimental studies of acetabular cementing techniques tend to place a very high

demand on materials. For each experiment, all components need to be brand new and

once cemented cannot obviously be re-used. This means that unless non-stick coatings

are used on the various components, they are all single use. It is not known what effect

coating components has on their physical and mechanical characteristics. The authors

have postulated that Play Dough® used at a particular temperature would be a reasonable

substitute for bone cement in terms of physical and mechanical behaviour. This would

allow re-use of all materials in further studies involving bone cement.

Proposed rationale behind the study:

A new device has been designed to combat the problem of cement leakage, the rim cutter.

The rim cutter is designed to attach to conventional acetabular reamers. It allows a

standardised, uniform rim to be cut in the acetabulum. A flanged cup that has been

trimmed to fit the rim precisely can then be inserted into the acetabulum, which will

hopefully reduce the volume of cement extrusion, thereby increasing the cement pressure

and increasing the depth of cement penetration. It is hoped that the improvement in

cement penetration will lead to less radiolucency in zone 1 and reduce the incidence of

cup loosening. The purpose of this study is also to compare the pressure generated by two

different acetabular conditions: a native acetabulum and one in which the acetabular

notch has been bone grafted. The study will also investigate the pressures generated when

inserting flanged and unflanged cups using conventional reaming techniques and when

using the rim cutter. The depth of penetration of the cement mantle in each case will also

be compared. The study will also compare the effect of the iliac aspirator on cement

penetration in the presence and absence of back bleeding and the physical properties of

play dough compared with PMMA.

19

20

Chapter Two: Materials and Methods: The study was broken into three trials. The first trial was designed to measure the cement

pressure generated in the acetabulum under various conditions. The second trial aimed to

measure the depth of penetration of cement into simulated acetabulae under a variety of

conditions. The third trial attempted to assess the effectiveness of the iliac suction

retractor used in cemented total hip arthroplasty.

Part One

The first part of the trial was divided into six experiments, each of which was performed

six times. For each experiment the same basic set up was used. The variation lay in the

preparation of the acetabulum. For the testing of pressure sawbones (Sawbones Inc.,

Sweden) hemi pelvis foam models were used (Item #1307), shown in photo 2.1. Each

model hemi pelvis was mounted in a standard vice (City 60mm swivel table vice stock

no. 3335), such that the acetabular concavity was directed upwards. Next, the hemi pelvis

model was reamed in the conventional manner using Stryker acetabular reamers (Stryker,

Howmedica) up to a 56mm diameter as shown in photo 2.2.

Two drill holes were made using a 9mm diameter drill at the apex (90°) of the

acetabulum and at the rim (10° angle to the plane of the acetabular lip) (see photo 2.3 and

2.4). Next, the drill holes were manually tapped with a T-handled tap. A finely calibrated

pressure transducer [RDP Group model A105, 0 to 200 psi (0 to 13.5 bar), (Grove Street,

Heath Town, Wolverhampton WV10 0PY, UK)] was then screwed into each of the two

drill holes such that their upper edges were flush with the wall of the acetabular cavity as

shown in photos 2.5, 2.6 and 2.7. The pressure transducers were then coated with silicone

grease to prevent the cement from adhering to them. These pressure sensors were then

connected up to a laptop computer [Toshiba Tecra A2 CE] via an analog to digital

converter. Finally the acetabular cavity was lined with a vinyl glove, which had been cut

open so that a layer of vinyl separated the cement from the pressure transducers as shown

in photo 2.8. This also prevented cement from adhering to the model, allowing the

cement to be removed after each test and the same model to be used for all testing.

21

The control group consisted of a model prepared in exactly the way described above. One

mix of PMMA (Simplex, Stryker Howmedica, photo 2.9) was hand mixed at 2-3Hz and

the bone cement introduced to the acetabular cavity at exactly six minutes from the

commencement of mixing, when the cement was at dough stage. The ambient

temperature in the laboratory at the time of testing ranged from 11.2°C to 13.5°C. For

this reason, the cement took longer to reach dough phase. The cement was then

pressurised at 275N using a Stryker pressuriser (Stryker, Howmedica) for one and a half

to two minutes, depending on the quality of the seal around the lip of the acetabulum. A

constant force was manually applied to the pressuriser by an examiner for the duration of

the test. The force being applied to the pressuriser was measured by a load sensor (RDP

model MLC, 0 to 500 N), which was mounted in the middle of the pressuriser (see photo

2.10). The measured force was then displayed graphically and simultaneously on the

display screen of the laptop computer. This provided the examiner real time feedback

about their force on the pressuriser and ensured that a known, constant force was applied

to the cement. During pressurisation, continuous measurements were made of the

pressure generated in the cement mantle at the apex and the rim using a custom designed

computer program on a laptop computer mentioned earlier as shown in photo 2.11. The

cement mantle was then removed from the hemi pelvis model using the glove lining the

socket and the pressure and force trace saved on the computer. The whole process was

then repeated five more times.

The next step was to compare the pressures generated in a standard acetabulum with

those in which the acetabular notch had been bone grafted. Special hemi pelvis models

(Sawbones, Sweden, item #1307-4) were requested of and constructed by Sawbones Ltd.

in which a piece of foam had been adhered to the model, which covered the acetabular

notch so that the rim of the acetabulum took the form of a continuous circle (see photo

2.12). The model was prepared in exactly the same manner as previously i.e. reamed to

56 mm diameter, two holes drilled at apex and rim and pressure transducers screwed into

the holes. Hand mixed PMMA was again introduced to the acetabular cavity at exactly

22

six minutes after mixing began (again due to the low temperature in the laboratory), when

the cement had reached dough phase. The cement was then pressurised using the same

apparatus, by the same examiner using the same force (275N). Again pressure

measurements were recorded on the computer for the duration of the test. The cement

mantle was then removed and the process was again repeated five more times.

To determine whether the physical properties of Play Dough® matched those of bone

cement, another round of pressurisation tests were conducted. In these tests, the standard

hemi pelvis models were used. There was no simulated grafting of the acetabular notch in

these models. The hemi pelvis that was used in the initial cement pressurisation test was

re used in these tests. Instead of introducing low viscosity PMMA, the same volume of

Play Dough® was placed in the acetabular cavity and pressurised in the same manner as

the previous twelve times. The duration of pressurisation was chosen to be ninety seconds

as this was the approximate length of time of all of the pressure testing in the previous

experiments. The temperature of the play dough was maintained in the same range as the

bone cement 11.3° to 13.5° Celsius. At that temperature the play dough was quite

viscous, it was not warmed because the degree of warming and rate of cooling could not

be adequately controlled. There were also no previous reports of comparisons between

bone cement and play dough at the same temperature, which would be the obvious

starting point for experimentation. The pressure generated in the acetabulum was again

measured continuously and recorded on the computer. The process was repeated five

times, with the play dough being removed from the acetabulum and re-moulded into a

bolus prior to each test. Once the apparatus had been dismantled at the end of testing, the

hemi pelvis was labelled.

These three different experiments allowed comparison of pressure generated in normal

versus grafted acetabulae and also the pressure generated in normal acetabulae using

PMMA and using Play Dough®. The results are described in chapter 3.

It was also necessary to measure the pressure generated in normal acetabulae when either

flanged or unflanged cups are inserted, and also when the acetabular rim is prepared for a

23

flanged cup using the rim cutter. For this part of the study only two standard Sawbones

hemi pelvis models (Sawbones, Sweden, item #1307) were used. None of the hemi pelvis

models used had simulated acetabular notch grafting. For the first two trials the

acetabulum was prepared in exactly the same manner as in the previous trials. The model

hemi pelvis was mounted, reamed, drilled and two pressure transducers fitted. The

temperature in the testing room was controlled such that it ranged from 20.0°C to 21.1°C.

Simplex bone cement was again hand mixed at 2-3 Hz for the first one and a half minutes

and introduced into the acetabular cavity at exactly six minutes (i.e. the total standard

time before cement insertion into the acetabulum [4 minutes] and pressurisation [2

minutes] in vitro). It was not necessary to pressurise the cement for these tests as the

foam models used featured closed pores, which would not allow interdigitation of

cement. At this point an Exeter contemporary cup (Stryker, Howmedica) seen in photo

2.13 and 2.14 with either the flange completely removed flush with the edge of the cup

itself (i.e. unflanged, see photo 2.15) or the flange trimmed at the first groove (i.e. flange

intact, see photo 2.16) was inserted into the acetabular cavity using the modified Stryker

acetabular pressuriser (Stryker, Howmedica). At the six minute mark, the cup was

manually inserted into the acetabulum. The duration of cup insertion lasted twenty to

thirty seconds in an attempt to reflect in vivo practice. This aspect of the experiment was

tightly controlled as pressure measurements of this nature rely on reproducible insertion

forces on the cups. The force applied to each cup was defined as the force required to seat

the cup in twenty to thirty seconds. That force varied depending on the type of cup as a

greater force was required to seat a cup with a larger flange. The cup pusher being used in

these experiments was the Stryker pressuriser mentioned earlier, but with the silicone cap

removed from the head. The load sensor mounted in the centre allowed the same

measurements of force on the cup as in the earlier pressurisation tests. The forces applied

to the cups were recorded and displayed in real time on the computer screen. The

pressure generated in the acetabulum at the rim and the apex was again constantly

measured and recorded on the computer. After the cup had been seated, a constant force

of 100N was applied to the cup via the pressuriser for the duration of the recording trace,

which, in the case of our computer program was three and a half minutes (ten minutes

total trace on computer). The experiment was repeated six times for the flanged cup and

24

six times for the unflanged cup. The same model and cups were used for all of the

experiments.

In the final experiment in Part One, the acetabulum underwent extra preparation. Again a

hemi pelvis model was mounted and the two holes were drilled for the pressure

transducers. The acetabulum was reamed to 56 mm as it had been in all of the prior

experiments, however the rim of the acetabulum was also modified in this case. The rim

cutter attachment to the standard Stryker reamer was used (see photo 2.17 and 2.18). The

acetabular cavity was still reamed to 56 mm, but an additional 3 mm wide ledge was cut

into the acetabular rim, 3 mm deep (see photo 2.19 and 2.20). It is then easily to calculate

that the diameter of the rim of the acetabular cavity is exactly 56 + 6 mm. The flange of

the Exeter contemporary cup was then trimmed along the second groove, to fit the

acetabular cavity precisely as shown in photo 2.21. After the two pressure transducers

were fitted and one mix of hand mixed PMMA was inserted into the acetabular cavity,

the specifically flanged cup was inserted. It was pressurised in the same manner as in the

two previous experiments, with the load sensor in the middle of the pressuriser providing

continuous feedback to the examiner as to how much force they were applying to the cup.

Both the force being applied and the pressure generated in the acetabulum were recorded

and displayed on the computer.

25

A flow chart showing the timing of each part of the experiment is shown below:

These data allowed comparison of cup intrusion pressures between a flanged cup versus

an unflanged cup and a flanged cup versus a flanged cup with the rim of the acetabulum

cut. The results are again described in chapter three.

Mixing Starts Trace Begins

Mixing ceases

Cement In Hand

Cement In Cavity

Cement Not Pressurised

Cup Inserted

Cup Is Seated Pressurisation at 100N

Cup pressurisation Ceases

Time: 0 secs 1min30 3min30 4min 6 min 6 min30 10 min 3min50

26

Part Two

Part Two of the study was aimed at investigating cement penetration under various

conditions. Firstly a comparison was made between bone cement and Play Dough®, then

tests were conducted to compare the cement penetration when using flanged and

unflanged cups and also a flanged cup with the acetabular rim cut. A simulated

acetabular cavity was used for all experiments. These cavities were made from Sawbones

closed cell foam blocks (Sawbones Ltd., Sweden). Each rectangular block was machined

into a hemispherical cavity with an outer diameter of 75 millimetres and an inner

diameter of 60 millimetres1 (see photo 2.22). This was specially designed to fit a 56

millimetre cup with a 4 millimetre cement mantle. Each cavity was further prepared by

drilling 1 millimetre diameter holes through it at predetermined angles. Holes were

drilled at 5° from the vertical axis of the cavity, 45° and 85°. At each angle, four holes

were drilled in each quadrant of the cavity at each of the three aforementioned angles (as

shown in figure 2.23 and 2.24). Therefore, each cavity had a total of twelve x 1

millimetre holes drilled in it. This allowed calculation of an average cement penetration

at each of the three angles: 5°, 45° and 85°. The cavities were manufactured by Stryker

Europe at their plant in Northern France.

These cavities were then mounted in a specially designed jig, which consisted of a metal

box attached to the vice mentioned earlier. The metal box was fitted with a concave

rubber base on the inside and a screw down clear plastic face plate (see photo 2.25). The

cavity was placed in the metal box and the face plate screwed onto the top to hold the

cavity steadily in the box. Conveniently, the metal box was mounted such that the

concavity of the simulated acetabulum faced up obliquely towards the examiner at an

angle of 45°. All experiments were carried out in the same room, which was air

conditioned to a temperature range between 20.0°C and 21.1°C.

1 As the thickness of the blocks was a maximum of 40 mm, the cavity had only a thickness of 12.1 mm at the apex.

27

The first experiment involved setting up the apparatus as described above. PMMA was

hand mixed at 2-3 Hz and inserted into the cavity at exactly four minutes from the

commencement of mixing. The cement was then manually pressurised at a constant force

of 200 N using the same modified Stryker® pressuriser with a load sensor mounted in it

as had been used previously in Part One. The examiner was again able to watch the

computer screen to monitor the force of pressurisation to maintain a constant

predetermined level.

After two minutes, the pressurisation was reduced to 100N to simulate the forces on a cup

after it was inserted. Pressurisation of the foam acetabular cavity is shown in photo 2.26.

This force was maintained for a further one and a half minutes and removed at the eight

minute mark. When the cement had polymerised, the cavity was removed from the jig

and the depth of cement penetration was measured. This was done by using a fine one

millimetre gauge, which was inserted into each of the twelve holes drilled in the cavity.

The thickness of the cavity was pre measured and therefore known at each of the three

angles. By measuring the remaining space left in the hole, it is possible to determine the

depth of cement penetration. Using the four holes an average depth was then calculated

for each angle. This process was then repeated five more times.

In order to compare bone cement with Play Dough®, the bone cement in the previous

experiment was substituted for Play Dough®. The foam cavities were prepared and set

up in exactly the same manner as described above. However, instead of inserting bone

cement, an equal volume of Play Dough® was inserted into the cavity. It was pressurised

using the same modified pressuriser at a constant force for the same time as in the

previous experiment. The foam cavity was then removed from the jig and the holes

measured. The average depth of cement penetration was again calculated. This process

was repeated a further five times using the Play Dough®. The results of the experiments

are discussed in chapter three.

Cement penetration measurements were also required for assessment of the flanged and

unflanged cups and the rim cutter. In these experiments, the flanged and unflanged cups

28

were prepared in the same way as in part one. An Exeter Contemporary cup (Stryker,

Howmedica) was trimmed at either the first groove or flush with the edge of the cup to

create a flanged or unflanged cup respectively. The same foam cavities were used to

simulate the acetabulum. All apparatus was set up in exactly the same manner as

previously. Hand mixed PMMA bone cement at between 20.0°C and 21.1°C was

introduced at exactly four minutes after mixing commenced. The cement was then

pressurised for two minutes at the same known force (200N) and confirmed graphically

by the computer. After pressurisation, either a flanged or an unflanged cup was inserted

into the cavity. The cup was pushed in by the modified pressuriser with the load cell

fitted in it (as used in previous experiments in part one). Once again as in the pressure

tests of part one, the cup was aimed to be seated in 25 to 30 seconds to mimic in vivo

practice. Once seated, the cup was placed under a constant force of 100N by the

pressuriser for another one and a half minutes as shown in photo 2.27 and 2.28. This

again is identical to the technique used in part one. At the ten minute mark, the pressure

trace automatically stopped and the foam cavity with the cup cemented into it was

removed from the jig. The depth of the cement penetration into each of the twelve 1mm

holes was then measured and recorded. The cavity was then labelled and stored. The

process was repeated five times for each of the flanged and unflanged cups.

The final experiment in part two once again utilised the rim cutter. The rim cutter was

attached to the standard Stryker acetabular reamer and as was done in part one and a

ledge of foam three millimetres deep and three millimetres wide was cut in the rim of the

foam cavity as shown in photo 2.29 and 2.30. Again the flange of the Exeter

contemporary cup was trimmed to perfectly fit the rim, by cutting along the second

groove of the cup. This modified cavity was then mounted in the jig as had been done for

the previous twelve tests. Hand mixed bone cement was inserted and pressurised in the

same manner as before. The flanged cup was then inserted, again over a thirty second

period, and pressurised at 100N for one and a half minutes. Finally the foam cavity was

removed from the jig and the depth of cement penetration measured at each angle and

recorded. For each of the thirty experiments in part two, a new foam cavity and a new

cup was used. None of the materials were recycled. These data allowed comparison of

29

cement penetration depth using a variety of acetabular conditions and the results are

discussed in chapter three.

Above is a flow chart showing the timing of each part of the experiment.

Mixing Starts Trace Begins

Mixing ceases

Cement In Hand

Cement In Cavity

Pressurisation Begins 200N

Pressurisation Ceases Cup Inserted

Cup Is Seated Pressurisation at 100N

Cup pressurisation Ceases

Time: 0 secs 1min30 3min30 4min 6 min 6 min30 8min 3min50

30

Part Three

The final part of the study was to examine the effect of the suction retractor (a.k.a. iliac

aspirator) on the depth of cement penetration. Four different experiments were

performed, which examined cement penetration with pressurised PMMA in dry foam,

with and without the use of a suction retractor and pressurised bone cement in ‘bleeding’

foam with and without the use of a suction retractor. To simulate cancellous bone, an

open cell foam block (Sawbones, Sweden, item number 1521–59) was used (shown in

photo 2.31 and 2.32). A metal box of dimensions 7cm x 7cm x 6cm was constructed by

staff at the University of Exeter Engineering Department into which the foam would be

placed. It consisted of five closed sides and one open frame, facing upwards, which was

screwed onto the top (see photo 2.33 and 2.34). A corner of the box was engraved with

the letter ‘A’ so that all other corners could be labelled. This allowed the foam placed in

the box to be labelled after cementing to correspond with its position in the box. A clear

piece of plastic was used to cover the exposed foam in the centre of the metallic frame,

which formed the roof of the box. A hole 47 millimetres in diameter was cut in the

middle of the plastic so that the foam below could be reamed and cemented. Finally,

silicone was used to seal all joins on the inside of the box so that it was both water and

airtight on all sides. This set up was constructed in an attempt to mimic, on a small scale,

a pelvis with the circular hole in the plastic representing the acetabular rim. The box also

had a fluid inlet port installed on one side near the base, and a small four millimetre

diameter hole drilled in one corner of the metallic roof of the box, through which air or

fluid could be aspirated. The foam pieces, originally 15cm x 7.5cm x 2cm were manually

cut into 7cm x 7cm x 2cm squares by a bandsaw. Three such pieces needed to be placed

on top of one another in order to fill the metal box. The clear plastic and the metal frame

were then screwed onto the top of the box. Play dough was used around all joins in the

roof of the box to ensure that it was both air and watertight. This step was required for

practicality reasons as the continual removing and reinserting of the foam pieces from the

box displaced the original silicone (which took 24 hours to cure once reapplied). The

foam was then reamed to a diameter of 47 mm through the hole in the plastic. Once this

31

standard preparation of the foam had been carried out, a variety of experiments were

carried out.

Firstly, one mix of Simplex PMMA bone cement (Stryker, Howmedica) was hand mixed

at 2-3 Hz as in all previous experiments. The ambient temperature in the testing room

remained controlled such that it ranged between 20.0°C and 21.5°C. The pressure trace

on the computer began at the commencement of cement mixing (T=0 mins). The cement

was then manually pressurised at a constant force of 200N by the aforementioned

modified Stryker acetabular pressuriser in the same manner as described in parts one and

two. Visual feedback was provided to the examiner via the display on the computer

screen. Pressurisation at 200N lasted for two minutes as in previous tests, at which point

the force on the pressuriser was reduced to 100N for the final four minutes of the pressure

trace. After pressurisation each region of the cement mantle was labelled A to D

according to the position of each quadrant in relation to the labelled corners of the metal

box. When the cement had polymerised, the foam with its embedded cement mantle was

removed from the jig. The uppermost two pieces of foam became solidly bound together

by the cement interdigitation and had effectively become one piece (shown in photos 2.35

and 2.36). Lines were drawn on the piece of foam from corner to corner, which

highlighted the thickness of the cement mantle at each corner of the foam block as shown

in photo 2.37. The depth of cement penetration from the edge of the simulated acetabular

cavity to the outer limit of the cement in the line marked was measured and recorded.

Finally, the foam and attached cement mantle from each test was placed in a labelled

clear plastic bag and stored. This process was repeated another five times.

The next step was to determine whether the depth of the cement penetration was different

when a suction catheter was used. A small hole of four millimetres in diameter was

drilled in a corner of the frame plate of the box. Into this hole was placed a (spinal)

suction catheter to a depth of twenty millimetres. The same process as earlier was

repeated, with hand mixed bone cement introduced at four minutes and pressurised with

the modified pressuriser at 200N for two minutes, then pressurised at 100N for a further

four minutes. In these tests however, the suction catheter was switched on for the

32

duration of the cementing. The suction used in these experiments was provided by a

portable suction machine (Eschmann TJ 240H, shown in photo 2.38) as used in some

operating rooms. It provides a variable suction pressure depending on the resistance to

flow of material. It was set to provide 200mmHg of suction when the three millimetre

calibre spinal sucker is fitted (in air). This pressure increased automatically as the

viscosity of the material being aspirated increased, or the resistance to aspiration

increased. The maximum suction possible with this machine was 700mmHg, although

this suction pressure was far greater than any achieved during testing. The quadrants of

the foam block were then labelled A to D and then the foam block was removed from the

box. The cement mantle thickness was again measured in the same way as previously in

each of the four lines drawn in the four quadrants of the foam.

The third part of the trial aimed to simulate back bleeding of the cancellous bone. The

foam used in all of the experiments in part three is open cell. This means that fluid and air

is able to move easily throughout the foam. Unfortunately this foam, even though it is the

most dense foam that is possible to manufacture, is more similar to osteoporotic bone

than healthy cancellous bone. Due to this increased porosity of the cancellous bone foam,

a liquid more viscous than saline was required in order to closer mimic the flow

characteristics of blood in native acetabular cancellous bone. Motor oil (Havoline®

10w30) was chosen as a suitable fluid as it was shown on preliminary testing to flow

through the pores of the foam block in a similar pattern and at approximately the same

rate at which blood flows through the cancellous interstices of the acetabulum at

operation. The cancellous bone foam was cut to size as it had been done previously and

placed in the metal box with its plastic cover and metal frame. It was then reamed to a

diameter of 47 millimetres as had been done in all previous tests. Play dough was used as

mentioned earlier to seal all edges of the roof of the box from the inside, and a piece of

play dough was used to plug the hole in the metal face plate since the four millimetre

hole for the spinal sucker would not be used in this part of the testing. The metal box was

filled with motor oil up to a level at the apex of the reamed hemispherical cavity. A

reservoir for the oil in the form of an inverted 60mL syringe was set up, the top of which

was suspended at a point 77 centimetres above the box as shown in photo 2.39. This was

33

shown on preliminary tests to provide a (back bleeding) pressure of forty centimetres of

water (which is roughly equal to 30mmHg). The cement bolus at dough stage was

inserted at three minutes and fifty seconds from mixing and the oil clamp was released,

allowing the remainder of the box to fill with oil around the cement bolus. As in previous

tests at four minutes from mixing the cement was pressurised at 200N for two minutes

and then at 100N for a further four minutes. The oil was seen to have completely filled

the box just prior to the commencement of pressurisation. After the cement had

polymerised, the foam was dried, labelled A to D based on its position in the box and

then each quadrant marked and measured. The piece of foam was then labelled wet foam

without suction and stored in a plastic bag. This process was repeated five more times in

an identical fashion.

The final step in the experiments of part three was to examine the effect of suction on the

simulated ‘bleeding’ acetabulum. An identical set up to the previous three steps was used.

The foam pieces were placed in the metal box, the lid sealed with Play Dough® and

screwed down. The spinal suction catheter was again inserted and set to the same suction

pressure as previously used (200mmHg). The metal box was filled with motor oil, again

just to the apex of the reamed foam cavity (see photo 2.40) and filled completely at three

minutes and fifty seconds after the cement bolus had been placed in the ‘bleeding’

acetabular cavity. The cement was pressurised in the same manner as had been done for

all of the study with the load cell positioned in the middle of the pressuriser, providing

real time graphical feedback to the examiner on the force applied. Pressurisation is shown

in photo 2.41 and 2.42. When the cement had polymerised, the foam was dried, the four

quadrants labelled A to D and removed from the metal box. The depth of the cement

mantle thickness in each quadrant was recorded. The same process was then repeated five

more times. These data allowed comparison of the cement penetration in dry bone with

and without a suction catheter and bleeding bone with and without a suction catheter with

respect to its position relative to the suction catheter. The results are discussed in chapter

three.

34

Chapter 3: Results: All measurements taken in these experiments were converted from analog to digital by

the data acquisition unit and then recorded and displayed on the computer. The data was

recorded in channels such that channel one represented the pressure in the acetabulum at

the apex, channel two represented the pressure in the acetabulum at the rim and channel

seven represented the force being applied to the cement mantle via the pressuriser. The

data was displayed on the computer screen as a graph with time on the X axis and both

pressure in Bar and force in Newton on the Y axis. However, the data acquisition unit

was not capable of simultaneously converting two different units of measurement (Bar

and Newton) on two different scales. As a result, all data was recorded as a value on an

arbitrary scale and needed to be converted manually to the appropriate units after all data

had been recorded. In this study, pressure was expressed as millimetres of mercury

(mmHg) and force was expressed as Newton (N). In the following report of the results of

the experiments, in all tables and graphs, measurements will be expressed in terms of the

absolute value assigned by the computer and then converted to the appropriate units at the

end of each section. To convert the units of pressure measured to mmHg, each value was

multiplied by 2.34. Similarly for values of force each value was multiplied by 0.64. Data

was acquired and recorded in all three channels every 0.5 seconds whilst the pressure

recording computer program was running. The pressure recording program was able to

run for a maximum of nine minutes and fifty five seconds. It could be stopped earlier, but

once it had been stopped it could not be restarted again. This ensured that the pressure

recording program ran continuously for the complete duration of all experiments reported

in this paper. The only exception to this was in the Play Dough® tests (which did not

require mixing) and in the initial pressure tests, where the laboratory temperature was

very low. In these tests, the cement needed to be inserted into the acetabulum at dough

stage at six minutes from the commencement of mixing (rather than four). The pressure

recording trace was only started twenty to thirty seconds prior to the commencement of

pressurisation as it was initially uncertain how long the cement would take to reach

dough stage.

35

Statistical analyses in this paper were carried out using Microsoft® Excel for

Macintosh® using paired and unpaired t-tests and ANOVA. The t-score could then be

used to generate the p-value for each comparison between groups. This is based on 10

degrees of freedom (dF) for each comparison as each group consisted of six trials [dF =

(n1 + n2) – 2].

36

Part One: Pressure Testing.

Pressurisation of Native Acetabulum:

As mentioned earlier in chapter two, cement was pressurised in a model of a human

acetabulum, which had undergone no modification of any kind. The cement was

pressurised at 275N at a time six minutes from mixing of cement for one and a half

minutes. The pressure was recorded at the apex and rim of the acetabulum and also the

force placed on the acetabular pressuriser. The process was repeated five more times. The

pressure trace recorded for each of these six tests are shown in Appendix 1. The peak

pressure generated in the acetabulum at the rim and apex was recorded for each trial as

was the total pressure generated at the apex and rim (represented by units [in mmHg] x

seconds). The mean force applied manually to the pressuriser by the examiner was also

calculated. These results are shown in table 3.1 below. A photograph of the cement

pressurisation is shown in photo 3.1, note the extrusion of cement from around the

pressuriser.

Normal Acetabulum

Trial Peak apex pressure

Peak rim pressure

Total pressure generated at apex

Total pressure generated at rim

Mean force applied to pressuriser

1 214 194 23762 25977 405 2 156 151 24712 26171 410 3 177 165 28267 29554 413 4 153 148 16067 16738 411 5 149 142 22875 23187 419 6 150 146 24936 26207 418

Mean values

167 units = 390mmHg

158 units= 370mmHg

23437 units= 54843mmHg

24639 units = 57655mmHg

413 units= 264 N

Table 3.1: Pressures recorded in the normal acetabulum.

Pressurisation of Play Dough in Native Acetabulum:

In exactly the same way, play dough was pressurised in a model pelvis with no structural

modifications to it. The same force was applied to the pressuriser and the same

measurements of apex and rim pressure and force on the pressuriser were recorded. The

pressure trace from each of the six tests are shown in Appendix 1. The peak pressure

generated in the acetabulum at the rim and apex was recorded for each trial as was the

total pressure generated at the apex and rim (represented by the area under the curve).

37

The mean force applied to the pressuriser was also calculated. These results are shown in

table 3.2 below.

Play Dough

Trial Peak pressure at apex

Peak pressure at rim

Total pressure generated at apex

Total pressure generated at rim

Mean force applied to pressuriser

1 384 388 53428 52254 417 2 402 381 50808 51714 417 3 347 349 50681 53104 427 4 339 348 56768 58023 405 5 291 302 50016 53764 417 6 297 326 54979 55732 394

Mean values

345 units = 807 mmHg

349 units= 817 mmHg

52780 units= 123505mmHg

54099 units = 126592mmHg

413 units= 264 N

Table 3.2: Pressures recorded using Play Dough® in normal acetabulum.

Pressurisation of Cement in ‘Grafted’ Acetabulum:

The third series of tests were conducted using bone cement in a model hemi pelvis.

However, this model hemi pelvis had undergone modification in the form of simulated

bone grafting of the acetabular notch. The bone cement was introduced into the

acetabular cavity at the same time as in the initial tests (i.e. six minutes from the

commencement of mixing of the cement), and pressurised at the same force, for the same

duration. Again there were measurements taken at the rim and apex of the acetabulum as

well as the force applied to the pressuriser. Six tests were conducted and the results of the

pressure trace recorded on the computer are shown in Appendix 1. The results are

summarised in table 3.3, which shows the measured peak pressure generated at the apex

and at the rim as well as the calculated total pressure generated at both the apex and the

rim. It also shows the mean force applied to the pressuriser for each test and for all six

tests.

38

Grafted Acetabulum

Trial Peak pressure at apex

Peak pressure at rim

Total pressure generated at apex

Total pressure generated at rim

Mean force applied to pressuriser

1 307 291 46944 48529 406 2 303 296 41253 41966 371 3 261 255 44565 46408 411 4 320 303 52438 54982 440 5 355 315 51948 53669 416 6 302 302 48689 49477 421

Mean values

308 units = 721 mmHg

295 units= 690 mmHg

47640 units= 111478mmHg

49172 units = 115062mmHg

411 units= 263 N

Table 3.3: Pressures recorded using cement in a ‘grafted’ acetabulum.

Comparisons:

The initial tests in part one were designed to allow comparison between the cement

pressure generated in the normal human acetabulum and an acetabulum in which the

acetabular notch had been bone grafted. It was also designed to allow comparison

between the behaviour of bone cement and Play Dough® in the normal human

acetabulum. Firstly, the peak pressure in the normal acetabulum will be compared with

the acetabulum with the simulated bone grafting of the acetabular notch. The mean peak

pressure at the apex of the acetabulum was 390mmHg for the native acetabulum

compared with 721mmHg for the ‘grafted’ acetabulum. When the peak pressure at the

rim of the normal acetabulum is compared with the ‘grafted’ acetabulum a similar trend

is seen. The mean peak pressure at the rim is 370mmHg in the normal acetabulum and

690mmHg in the ‘grafted’ acetabulum. This represents a significant increase in mean

peak pressure in the acetabulum at the apex (p-value < 0.001) and at the rim (p-value <

0.001) when the acetabular notch is bone grafted. Chart 3.1 in the appendix shows the

differences in peak pressure at the apex and rim of the acetabulum under the three

different conditions.

Next it is necessary to compare the total pressure generated at the apex and rim of the

normal acetabulum with the ‘grafted acetabulum’. As mentioned earlier in this chapter,

the total pressure generated at each point was calculated by measuring the total area

under the curve in each trial. The mean total pressure generated at the apex of the normal

39

acetabulum was 54.8 x 103 mmHg compared with 11.1 x 104 mmHg in the ‘grafted’

acetabulum. At the rim of the acetabulum, the mean total pressure generated was 57.7 x

103 mmHg in the normal acetabulum compared with 11.5 x 104 mmHg in the ‘grafted’

acetabulum. This again represents a significant increase in the mean total pressure

generated in the acetabulum at the apex (p-value < 0.001) and at the rim (p-value <

0.001) when the acetabular notch is ‘grafted’. The mean force applied to the cement

mantle via the pressuriser was 264N for the normal acetabulum and 263N for the

‘grafted’ acetabulum. There was no significant difference between these two groups in

terms of the forces applied to the cement (p value = 0.88).

The other important comparison in this section is between bone cement and Play

Dough®. The mean peak pressure generated by cement at the apex of the normal

acetabulum is 390mmHg compared with the mean peak pressure of 807mmHg generated

by Play Dough® in the same acetabulum. At the rim of the same acetabulum a mean

peak pressure of 370mmHg is generated by cement compared with 817mmHg when Play

Dough® is used. This represents a statistically significant increase in the peak pressures

of Play dough over bone cement at the apex (p-value < 0.001) and rim (p-value < 0.001)

of the acetabulum. When the total pressures generated at the apex and the rim are

compared, a similar association is seen. The mean total pressure at the apex of the

acetabulum is 54.8 x 103 mmHg when cement is pressurised compared with 12.4 x 104

mmHg when Play Dough® is pressurised. A similarly large difference exists at the rim

with the mean total pressure generated in the cemented acetabulum being 57.7 x 103

mmHg compared with 12.7 x 104 mmHg in the Play Dough filled acetabulum. This again

represents a statistically significant difference between the two groups at both the apex

(p-value < 0.001) and at the rim (p-value < 0.001). The mean force exerted on the

pressuriser in the cement group was 265N, which is exactly the same as the Play Dough®

group. There was no statistically significant difference between the force exerted on the

pressuriser between the groups (p-value = 0.99).

Insertion of Unflanged Cup:

40