Improve Landed Cost Visibility - Informktforms.gtnexus.com/rs/...improve-landedcost-msi.pdf ·...

Transcript of Improve Landed Cost Visibility - Informktforms.gtnexus.com/rs/...improve-landedcost-msi.pdf ·...

A STRATEGIC IMPERATIVE FOR MANUFACTURERS

Improve Landed Cost VisibilityHow to Automatically Collect, Assemble, Track and Measure Global Supply Chain Cost Actuals as They Occur

Global supply chains require goods to pass through

many stages before they reach the point of delivery.

While manufacturers may have found unit costs suffi-

cient in planning for profitability in the past, today’s

environment requires much more data — most of it

from outside the manufacturer’s four walls.

What’s often poorly projected

as “overhead costs” can

include fees that shipments

incur in transit, at customs, and

inland before delivery. These

costs vary greatly on the back

of demand changes and grow-

ing lead times, causing a large

discrepancy in actual vs. esti-

mates and plaguing manufac-

turers with hours of reactive,

manual data collection.

Companies need to fill in the

blank space where landed

costs can decrease a product’s

margin with real-time analytics.

Without this, they will struggle

to understand the true price of

the products they are sourcing.

Traditional approaches to determining

landed cost often uncover “surprise”

costs after the product is delivered —

too late to make corrective

adjustments.

Impact of Poor Supply Chain Cost Analytics

Without a way to calculate the costs that add up due

to unpredictable demand and long lead times, manu-

facturers end up making decisions based on very little

real-time information. Managing suppliers this way is

difficult; if the true costs of sourcing a product do

become clear, it is only long after the fact.

In this scenario, manufacturers are forced to resort to:

• Piecing together information on actual costs and

lead times

• Choosing suppliers based on unit cost alone

• Guessing at product margins based on past data

• Collecting and managing data manually

• Attempting to make leap-of-faith target delivered

unit costs

The Root of the Problem

There is a widening gap between projected landed

costs and end-of-year actual recaps. This happens

when shipments enter the information “black hole” —

the month or two in which goods travel through an

extended supply chain, often across borders, and no

data is available on their activity. During this time, they

may be picking up drayage, consolidation, deconsoli-

dation, and agent fees that were not included in the

margin calculation. When the product finally reaches

its destination, those fees are noted — however,

there’s no way of knowing how they break down at

the unit level or if the next shipment will incur the

same costs.

1. Costs from many sources in different formats

When a manufacturer has a list of supply chain

partners and cost information in many different

charges, currencies, and other data types it must

deal with several issues:

• Reconciling the different units, formats,

and currencies

• Tracking down late or incomplete information

• Attempting to compare estimates with

incongruent data

2. Difficulty assigning cost to specific product

Charges can come in on varying levels, from order

to shipment to bill of lading. Often these costs are

collected after the fact and never tracked back to

the product line. As a result, manufacturers are

forced to work with:

• Limited information on the SKU level

• Documented costs that are impossible to break

down and allocate to individual products

The Challenge

Companies can’t see all the costs associated with a landed product, so they make decisions based on unit cost alone.

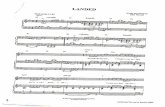

FirstCost

Freight

Duties

FirstCost

Freight

Duties

"Overhead"Drayage

ConsolidationFees

TypicalCost Recap

ActualCosts

AgentFees

DeconsolidationFees

Margin Loss

Traditional software leaves a significant information

gap in the time a shipment leaves origin to the time it’s

delivered. This missing data lowers the accuracy of

any cost or profit projections and makes it difficult to

compare suppliers.

Manufacturers can counter this effect by adopting a

cloud-based platform that allows them to pull real-time

data on their supply chain costs from their network of

logistics partners. This allows them to monitor actual

costs as they are incurred, measure them against targets,

and audit financial performance.

A cloud-based solution automates the capturing of

supply chain costs and connects data to the SKU level.

Managers can then use tactical day-to-day operational

reports for orders and shipments in motion to make

essential supply chain decisions. Landed cost data

becomes a strategic analytical tool for trending

and measurement.

On

Ord

er

At OriginIn

lan

dD

elive

red

In P

rod

uct

ion In Transit In Customs

MonitorAgainst targets/plans Financial liabilities

$

$

MeasureLanded costActual vs. target cost

AuditCharges/invoicesFinancial performance

Actual Costs $

$ $$

From order to delivery, costs must be accurately captured and

factored into expected product margins.

Measure landed cost data on a cloud-based platform.

• Track actual costs and lead times as they occur

• Automate allocation process to apply costs to the

correct level (SKU, shipment, business line)

• Use analysis engine to compare actual against

target estimates

How to use it to improve landed cost estimates:

1. Understand the total cost components of a

SKU/item

2. Compare cost estimates to actual cost per item

3. Make more informed sourcing decisions by taking

actual product margin into account

4. Make adjustments to course correct in real-time

Value Propositions

With good analytics, managers can decide to change

production strategies, bring on new suppliers, and

estimate landed costs based on high-quality data from

their supply chain network. They will have the tools to:

1. Increase profitability

• Lower COGS by accurately measuring total cost

of a part

• Improve labor efficiency and lower admin costs by

eliminating manual processes

2. Improve sourcing activity and target costing

• Accurately measure total cost and actual lead

times against estimates to plan for the future

• Collaborate with partners on reducing costs and

lead times

3. Capture end-to-end supply chain costs including

transportation costs, handling fees, brokerage fees

and document fees for better margin visibility

• Automate landed cost determination (no more

spreadsheets)

• Save time and resources by reducing re-keying of

cost data in AP/GL systems

Supply Chain Cost Analytics and the

Networked Company

To understand true landed costs and how they impact

margins, companies must transform themselves

from silo-based, inward-facing corporate operators

to interconnected, highly agile business network

orchestrators.

NetworkConnectivity

Agility

B

A

Sense more accurately

Operate more e�ciently

Respond faster

Make better decisions

The SolutionIt’s impossible to predict margins on the

SKU level without real-time data from

supply chain partners. Cloud changes

that, fi lling the information “black hole”

with actual costs as they are incurred.