Ignition and combustion studies on metallized UDMH-RFNA...

Transcript of Ignition and combustion studies on metallized UDMH-RFNA...

,Indian Journal of Engineering & Materials Sciences Vol. 6, Febmary 1999, pp. 13-21

Ignition and combustion studies on metallized UDMH-RFNA bipropellant system

B L Gupta & Mohan Varma

Department of Space Engineering and Rocketry, Birla Institute of Technology, Mesra 835 215, Ranchi, India

Received 1 December 1997; accepted 5 June 1998

The ignition delay studies on unsymmetrical dimethyl hydrazine gelled with methyl cellulose (4.48 wt%) containing varying amounts of metal powder (AI and Mg) with red fuming nitric acid oxidant have been carried out at and around oxidizerfuel (Off) ratios corresponding to maximum specific impulse. The minimum ignition delay is registered at a critical Off ratio which is always less than the respective stoichiometric mixture ratios. Further, the ignition delay is related with theoretical specific impulse and are both found to be inversely related with each other. The minimum ignition delay and critical Off ratio have been found to vary linearly with metal content of fuel gel. The data on 'heat of combustion' show that it increases linearly with the degree of metallization of gelled fuel and experimental value of 'heat of combustion' is found to be less than its theoretical value. The analysis of data show that the oxide formation in case of aluminium occurs mainly by water vapour-metal interaction and marginally due to direct oxidizer-metal reaction whereas for the oxidation of magnesium only the former mechanism seems to be operative.

The spontaneous ignition of propellants is highly desirable for satisfactory performance of a liquid rocket motor. Minimum ignition delay (10) coupled with smooth burning is one of the major considerations which governs the choice of a propellant system. An operational bipropellant should ideally have an ill value of the order of few milliseconds. Several studies have been conducted to understand the effect of various parameters on ignition delay of a series of liquid l

-4 and hybrid5-8

propellant systems_ However, a relatively new class of propellant, i.e., metallized liquid propellant remains unexplored as far as its ignition and combustion characteristics are concerned. Such heterogeneous fuel systems have a marked difference in -their physico-chemical characteristics in comparison to the conventional liquid propellants which may lead to significant changes in their ignition and combustion b\!haviour. In recent years, many research workers9

-12 have studied the slurry

droplet combustion with a view to understand the initial gassification process and the resultant burning of agglomerate of a coal-water/oil slurry, however, little efforts I 3-1

5 have been made to study the hett:<rogeneous combustion of metallized liquid propellants.

The gelation and subsequent metallization of the

liquid fuel would largely affect the energetics of the propellant system which can be ascertained easily by measuring heat of combustion, a means of relative assessment of the adiabatic flame temperature and performance parameters of propellants. Therefore, an attempt has been made to study the ignition behaviour of gelled and metallized fuels with red fuming nitric acid (RFNA) oxidant at ratios corresponding to maximum and near maximum specific impulse values, as obtained from theoreticai computations I6

•17

.

Efforts have also been made to correlate the ignition delay data with those of specific impulse as a function of OIF ratio. The energetics of gelled propellants has also been assessed with varying degree of metallization (AI and Mg) and a plausible mechanism for metal oxidation during combustion process has been proposed.

Experimental Procedure Ignition delay measurement

The ignition delay measurements of gelled and metallized unsymmetrical dimethylhydrazine-methyl cellulose (UDMH-MC) fuel have been carried out using RFNA (13.4% N02, 84.6% HN03, and 2% H20 by wt.) as oxidant with the help of modified Pino' s ignition delay tester l8

. The details of preparation of virgin and metallized gels are reported elsewhere l9

.

14 INDIAN J ENG. MATER. SCI., FEBRUARY 1999

The unit calibration was carried out to maintain exact oxidizer-fuel ratio as the entire amount of oxidizer contained in the outer cylinder is not found to be transferred to the fuel cylinder. The requisite amount of RFNA is taken in the oxidizer cylinder and a known amount of gel is kept in the fuel cylinder (which was cut intt)two halves with male and female threaded joints to ensure that the gel reaches the base of the fuel cylihder cone) with the help of a graduated glass syringe in which the gel was prepared. The trigger block is then pulled and the fuel cylinder descends rapidly. As soon as the cones of the cylinders fit, the oxidizer sweeps over through the peripherial holes, simultaneously giving the first signal by the electrode placed near the base of outer cylinder. This starts a time sequential counter (ECIL, India). The second signal to stop the timer is obtained from the appearance of the flame which is sensed by a strategically positioned photocell. The interval between the two signals gives the ignition delay value. All the experiments under present study have been conducted at 20 ± 2°C and an average value of ignition delay from five close readings has been obtained in each case.

Heat of combustion studies

An isothermal bomb calorimeter (Toshniwal, India) has been used to measure the heat of combustion of UDMH and its metallized compositions. A known quantity of the sample was used in the determination of heat of combustion (at constant volume) of the various compositions of metallized gels in oxygen gas at 300 psi chamber pressure. The values thus obtained have been converted to the constant pressure condition. The necessary corrections have also been taken into account.

Results and Discussion

Ignition delay studies

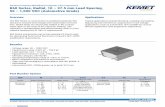

The results on the variation of ignition delay with OfF ratio (by wt.) for UDMH and UDMH-MC gels containing 0-40 wt% alum inium (average particle size: 20 ~m) and 0-20 wt% magnesium (average particle size: 200 ~m) using RFN A as oxidant have been plotted in Figs 1-4. It is seen that with the increase in OfF ra tio, ID fi rst decreases and then increases to give its minimum value at a critical OfF ratio in all the cases and is in agreement with the results reported in literature2.J. The crit ical OfF ratio

values are found to be significantly different from the point of stoichiometry (Table I).

The process of ignition of a bipropellant system is directly dependent on the rate of chemical reaction and consequent heat liberation. The rate of heat liberation is expected to go on increasing atleast up to the stoichiometric point at which minimum ID should

35

31

. E 27 ~i ...J

'''' o

z g 23 Z Q

19

r~lDl4H-RFNA Gl---e] I .Ot '-(UOMt+o-I4C)-AFNA .--.. ISPE

"fr-- ""e."

I' ........ -.-..... , " I / ,

, I \

----.'--- , , , I

~, , . I •

I I , , , I , I

, I

'/ " " "

~,' I ,

I ,

\

\ ~ '- \

\ \ \ \

, \

240

235

\ \

230

yv , , 15 225

1~.5-~2~0-~2~. 5--3~. O--3~5---~40

olF RATIO (by wt.)

~ -. '"' ~ ... .,j IL

.!!'

Fig. I-Variat ion of ID and ISPE with OIF ratio for UDM H and UDMI-I-MC gel with RFNA

55

50

~.

~ 40 o z o ~

~ 35

30

r(}--{:) AlIa WT%o ·-01 10 L- AI20WTOf."-"J 1SPE

---./ .... ,

~~-" \, I \ '

P ,', , , \ ' ,

245

242

239 ~ ~

233

. '"' ~ ...

25'--_-'-__ '---_-'--_ _ "--_ ........... 230 1·0 1·5 2,0 2·5 3·0 3-S

olF RATIO (by wi.)

Fig. 2-Dependence of ID and ISPE onO/F rati o fo r li gh tly al umin ium loaded (UDMH-MC)-RFNA system

GUPTA & V ARMA: METALLIZED UDMH-RFNA BIPROPELLANT SYSTEM 15

10 to. _ .. 40Wl%"-" ISI"I \::::: .. JOW1%"-"J 241

'0 241

• 244 .. I . ~ '10 • » I 242 l i

so 240

4O 2,. g.!I HI t·s 2'() H

O/F RATIO (by ",t.)

Fig. 3--Effect of OIF ratio on ID and ISPE of highly aluminium loaded (UDMH-MC}-RFNA system

~"'IOWT'IIo&--.] J.O. _ ... 2OWT% .. --. ISfIE

4O 24O , ..... ,

/' ) .. ~ , , ' - \', I \ I \

1.11 23S • .! ~

! • z i" 2 Ie i .!' 2

30 2JO

25 '--_.....L __ '--_....I...._-..J'--_....1...I225 1'() 1·5 2·0 2-5 3·0 H

olF RATIO (by ",t. )

Fig. 4--Variation of ID and Ispf. with OIF ratio for magnesiumized (UDMH-MC}-RFNA system

be obtained. Beyond this ratio, ID should increase as a part of thermal energy out of the maximum heat liberated would be taken away by the excess of oxidizer for its vaporization and decomposition. However, the results on ignition delay of UDMHRFNA system reveal that minimum ID is obtained at a critical OIF ratio equal to 2.73 whereas the

Table I-Ignition delay variation of liquid, gelled and metallized UDMH as function ofOIF ratio using RFNA oxidant

System Stoichiometric 'OIF ratio Average mixture ratio bywt igtlition

delay, ms

UDMH 3.38 1.84 28 .. 23±0.92 2.28· 27.25±1.60 2.73- 19.53±1.75 3.02 25.50±2.05 3.40 31.55±2.55

UDMH-MC 3.35 1.81 30.13±1.84 2.46 29.60±1.30 2.84- 18.56±l.42 3.81 20.48±0.92

UDMH-MC-lOOIo Al 3.15 1.83 40.27±0.76 2.13 37.93±2.18 2.43- 29.73±l.l8 3.20 32.23±1.38 3.86 37.23±1.38

UDMH-MC-2001o Al 2.96 1.34 50.75±2.05 1.71 44.30±1 .27 2.00 36.77±1.38 2.38- 36.43±2.44 2.96 40.90±1.87

UDMH-MC-30% Al 2.77 1.07 64.47±2.71 l.l8 62.57±2.49 1.36 52.20±2.00 1.87- 48.67±1.02 2.23 49.00±5.33

UDMH-MC-40% Al 2.57 0.84 76.20±2.00 0.91 65.33±3.18 1.10 59.47±1.38 1.73- 58.70±5.50

UDMH-MC-IO% Mg 3.12 1.60 34.40±1.87 2.10 29.15±0.95 2.51- 28.10±2.13 3.12 32.43±3.98

UDMH-MC-20% Mg 2.89 1.56 39.30±l.l0 2.03 34.85±3.25 2.33- 32.65±2.88 2.89 35.20±2.00

-Critical OIF ratio

stoichiometric OIF ratio is 3.38 (Table I). The significant divergence in critical OfF ratio from that of stoichiometry has also been observed earlier20.

It may also be argued that stoichiometric OfF ratio leads to give completely oxidized products like CO2, H20 etc. which are ultimately produced during combustion process to liberate maximum possible heat energy whereas only a certain minimum amount of energy may be required to initiate ignition . It is evident from the results (Table I) that minimum

16 INDIAN J. ENG . MATER. SCI., FEBRUARY 1999

ignition energy does liberate in the range of OfF ratio studied as all the compositions ignite spontaneous ly. Since the delay is varying with composition, it is obvious that the rate of liberation of minimum ignition energy is the controlling factor in detennining the 10. It may, however, be mentioned that ignition energy which is the threshold energy content of the system sufficient to initiate ignition is dependent on a number of factors such as nature of fuel, its composition, exothermic reactivity with oxidizer, nature of energetic gaseous products, additives etc. With the increase in OfF ratio from 1.84 to 2.73 (Table I) the rate of reaction and hence the rate of heat liberation would increase and ultimately may become very fast due to rise in temperature resulting in minimum 10 at latter OfF ratio. Beyond this ratio, the additional oxidizer concentration may increase the rate of reaction and heat liberation but simultaneously delay the attainment of minimum ignition energy level due to dissipation of heat to the excess of oxidizer. This is expected to lower the enthalpy of the mixture and consequently increase the ignition delay.

The results on the effect of incorporation of methylcellulose (MC) gellant in UDMH on its ignition has also been recorded in Table I. The variation of 10 of UDMH gel with OfF ratio is seen to follow the trend exhibited by the parent fuel. However, the ignition lag values are found to be higher for the gelled fuel in the pre-critical OfF ratio region but are less beyond the minimum 10 point (Fig. I) . This is expected as the gellification of UDMH would result in enormous increase in physical properties like viscosity and surface tension which would hinder the mixing process of fuel and oxidant. The oxidizer after coming into contact with the gelled fuel would react locally at the surface of the gel. This would cause the nitration followed by oxidative degradation of the gellant molecules resulting in the exposure of imbibed fuel to oxidizer. The diffusion of the oxidizer into the fuel gel may be slower initially but would increase as the viscosity comes down with rise in temperature of the system . Since the net amount of oxidizer available for reaction with imbibed UDMH would be less due to utilization of a certain proportion in degrading Me molecules, the ignition delay value at a given OfF ratio in case of gel would be higher than that of parent fuel. The explanat ion also gets strength from the fact that a slight positive shift in critical OfF ratio is observed

for gelled system with reference to UDMH (Fig. I). The fuel gel is apparently seen to inherit a little lower value of minimum 10, than that of pure UDMH at critical OfF ratio (the values are we ll within the experimental error) beyond which ignition lag becomes relahvely insensitive to OIF ratio. The results on the variation of 10 of metallized UDMH gels with OIF ratio have been presented in Table I and Figs 2-4 as a function of metal load ing. The data clearly show that ID first decreases and then increases to give a minimum at a critical OfF rat io as observed in case of parent fuel and virgin gel. It may, however, be noted that the magnesiumized gels show lower values of 10 in comparison to aluminized ones at similar metal loadings. This may be attributed to the coarse particle size and higher exothennic reactivity of magnesium metal blended in the gel. It is further seen that ID goes on increasing with extent of metallization . Since the optimum OfF ratio corresponding to maximum specific impulse varies significantly for each case, the experimentally obtained 10 values have been extrapolated to arbitrarily se lected OfF ratios in order to have a logical comparison.

Table 2 presents a comparative summary showing the dependence of 10 on gellification and degree of metallization 01' fuel at five different OfF ratios. It is clearly seen that incorporation of Me in UDMH to affect its gellation results in higher ignittion delay nearly at all OfF ratios. The addition of increasing amounts of metal in the gel further increases the ignition delay values at all OfF ratios in compari son to liquid and gelled UDMH . However, 10 shows a deviation from this trend only at and around critical OIF ratio in each case. It is worth mentioning at this

Table 2-Dependence of ignition delay on metal loading at different OfF ratios

System Ignition deial'* , ms at OfF ratios 1.0 1.5 2.0 2.5 3.0

UDMH 28.47 28 .07 25 .27 25 .00 UDMH-MC 30.80 30.20 29.40 18.49 UDM H-M C-I 0% A I 43 .60 42.40 39.44 29.80 31.66 UDMH-MC-20% AI 55 .00 48 .24 36.77 37.42 41.20 UDM H-MC-30% AI 66 .50 46.05 48 .55 51 .90 55.25 UDM H-MC-40% AI 61.63 57.30 61.50 68.78 UDMH-MC-IO% Mg 42 .76 37.10 29.92 28 .10 30.94 UDMH-MC-20% Mg 42.39 39.72 35 .3 8 32.58 36.52

*Obtained from respective ignition delay curves (Figs 1-4)

GUPTA & V ARMA: METALLIZED UDMH-RFNA BIPROPELLANT SYSTEM 17

stage that in igmtIon process the main reaction leading to initiation of combustion would be between organic part of the metallized gel and the oxidizer. The metal filler would act as a diluent for this reaction resulting in longer time delays. Moreover, on the basis of physical state of the system, it can be anticipated that metallization would adversely affect the accessibility of oxidizer to the organic fuel which, in tum, would again favour the increase in ID values. This can be substantiated in the following manner. If the assumption that initiation of ignition process is dependent on the exothermic reactions between the organic part of heterogeneous fuel and RFNA is correct, the OIF ratio (Table I) would be changed proportionately for unit weight of UDMH-MC gel as given in Table . 3. The corresponding ID values obtained from respective curves (Figs 2-4) have also been recorded therein. The data clearly shows that the new OIF ratio corresponding to organic part goes on increasing with metal content. The increase in ID may be due to the change in oxidizer-fuel ratio as well as/or increased metal addition. The contribution of

Table 3---Variation of ignition delay with OIF ratio based on the organic component of the heterogeneous fuels

System UDMH-MC

OIF ratio (by wt.) 1.0 1.5 2.0 2.5 3.0

H (30.80) (30.20) (29.40) (18.49) UDMH-MC-IO% A I 1.11 1.67 2.22 2.78 3.33

(43 .00) (41.52) (36.36) (31.00) (32.60) UDMH-MC-20%AI 1.25 1.88 2.50 3. \3 3.75

(51.94) (40.00) (37.44) (42.00) (45.96) UDMH-MC-30% A I 1.43 2.14 2.86 3.57 4.29

(48.00) (49.50) (-) (-) (-) UDMH-MC-40% AI 1.67 2.50 3.33 4.70 5.00

(58.20) (68.75) (-) (-) (-) UDMH-MC-IO% Mg 1.11 1.67 2.22 2.78 3.33

(4'0.82) (33.45) (28.60) (29.10) (35.40) UDMH-MC-20% Mg 1.25 1.88 2.50 3. \3 3.75

(41.55) (36.54) (32.60) (38.05) (-)

Quantity in the parentheses denotes ignition delay, ms

Table 4----Correlation of mixture ratio for minimum ignition delay with stoichiometric ratio

System ~s ~If

UDMH-MC 0.2985 0.2985 0.3521 0.2985 UDMH-MC-IO%AI 0.3175 0.3320 0.4115 0.3184 UDMH-MC-20% AI 0.3378 0.3735 0.4202 0.3465 UDMH-MC-30% AI 0.3610 0.4269 0.5348 0.3672 UDMH-MC-40% A I 0.3891 0.4981 0.5780 0.4109

degree of metal loading in increasing the ID can, however, be assessed when the time delay values of heterogeneous fuels are compared with that of virgin gel at same relative proportions of oxidizer and fuel. The variation in ignition delay values of (UDMHMC)-RFNA system lies in the range of 18-31 ms (Table I). It is thus evident that the increase in ignition delay with metal loading is solely due to the presence of metal particles in the fuel.

As mentioned earlier in case of parent and gelled fuels, the minimum ignition delays for metallized systems are also found to be much below the respective stoichiometric OIF ratios. The critical OIF ratio corresponding to minimum ignition delay goes on decreasing with the metal content of the fuel as shown in Table 4 (Column 4) as mixture ratro (~cr=F/6) which may be attributed to continuous reduction in organic fuel fraction of metallized gels. The stoichiometric mixture ratio (~s) obtai.ned from theoretical performance evaluation is found to be related with mixture ratio corresponding to minimum ID of metall ized gels (~cr) by the equation ~sc=1.263 [~cr-I+~c/'~ff-2r) ... (I)

where ~ff is the inverse of oxidizer requirement for complete oxidation of organic fuel fraction in heterogeneous fuels . ~sc, the stoichiometric mixture ratio calculated from Eq. (I) is found to be in excellent agreement with the theoretically computed ~s-values (Table 4).

I .-.... 55

[ e-Al--] .1 1.0. _M,-6 0, F

l!I 45

~ i 12

i II

35

25

'5~--7~-~~_~ __ -L_~ o 10 20 '30 40

METAL ,wi"!.

5

4

2

UDMH-MC-IO% Mg 0.3209 00 .. 33372305 0.3984 0.3198 Fig. 5--Dependence of minimum ID and critical OlF ratio for _U_D_M_H_-_M_C_'-_20_0f<_o_M...:g __ 0_.3_4_6_5 _____ o_. 4--:2;;:;92~_0-.~34~6..,..0::;:- metJltlized UDMH-MC gels with RFNA -. ... ~

&';~):~~~~'~ 0~ ~-r \ {; ("),/ . f ~::. . ... ,;' ~

<C _ A •• •

18 INDIAN J. ENG. MATER. SCI., FEBRUARY 1999

The data on mlmmum ignition delay and corresponding oxidant fuel ratio for aluminized gels have been plotted in Fig. 5 against metal content in the heterogeneous fuel. It is seen that minimum ignition delay increases while critical OIF ratio decreases linearly with percentage of metal content (M) in the gel according to relation

?--a.M+C . .. (2)

where P is dependent variable, i.e., minimum ignition delay/critical 61F ratio, a and C are the slopes and intercepts of the lines respectively. The constant C, the intercept at the ordinate refers to the value of the property when the gel is unmetallized (M=O). The values of the parameters ofEq. (2) are given in Fig. 5. It is fUrther noticed that the data points of critical OIF ratio and minimum ID for magnesiumized gels also fall on the lines obtained for aluminized fuels.

It may be mentioned that the fuel and oxidizer both in gelled state, when brought together, do not ignite though copious amount of gases are liberated showing the occurrence of exothermic reaction at the surface of contact. It is also noticed that the liquified gelled propellants show hypergolicity. No quantitative measurement of 10 has been carried out but it is apprehended that ignition lag would be slightly larger in comparison to gelled fuel-RFNA system at all OIF ratios due to poorer interdiffusional mixing.

Correlation of ignition delay with specific impulse The performance parameters like specific impulse

and characteristic velocity are known to be sensitive functions of equivalence ratio or mixture ratio2l. Isp

has been correlated with ignition delal2 as

... (3)

i.e., Isp is inversely related with ignition delay and becomes maximum at minimum ID. Thus, a plot of Isp

and. ID against OIF ratio should give curves of opposite nature.

An attempt has been made to see the validity of such a correlation for gelled and metallized propellant combinations as it has been reported to be applicable for liquid bipropellant systems22

. Accordingly, the recently reported data l7 on equilibrium specific impulse (ISPE) has been plotted alongwith ignition delay against OIF ratio for UDMH, virgin and metallized fuel gels-RFNA systems (Figs 1-4). As stated above, specific impulse and ignition delay curves show an inverse trend. The minimum ignition

delay points for UDMH, vlrgm gel and the gels containing up to 30 wfOlo of Al and 10 wt% of Mg nearly correspond to maximum specific impulse whereas the minima of ID and maxima of I SPE curve show a slight shift in OIF ratio when metal content of gel exceeds the above levels. These heterogeneous systems yietd the minimum ignition delay at progressively higher OIF ratios than that corresponding to maximum I SPE possibly due to complex mixing behaviour of the propellants.

Thermochemical studies The results on the heat of combustion of UDMH,

its virgin gel and heterogeneous fuels with varying

Table 5----Heat of combustion of gelled propellants

System

UDMH UDMH-MC UDMH-MC-IO%AI UDMH-MC-20o/oAl UDMH-MC-30%A I UDMH-MC-40% Al UDMH-MC-IO% Mg UDMH-MC-20% Mg UDMH-MC-30% Mg UDMH-MC-40% Mg

Heat of combustion, kcal/g Experimental, Mle.. Theoretical Mle.o

7.859 7.875 8.916 7.859 9.335 9.823

10.200 12.267 10.849 15.388 11.026 19.556 9.120 9.844 9.410 12.253 9.642· 15.267 9.889· 19.189

·Extrapolated from Fig. 6.

Il

11

•

It AI

IHI,

7~ __ ~ ____ ~ ____ L-__ ~ ____ ~~

o 10 20 30 40 so IoCETAL ,wt.,..

Fig. 6--EtTect of metal content in UDMH-MC gel on experimental heat of combustion

# .. p.<>.:~ ~ -:<-< -. ~"" ' :'\ ' Jj~r~

•. < /< ;\ ,J~, I " " . . ,: 9-r /~ \ I ,h'

. qfnr:T ztk (. t'",- ! /<

GUPTA & VARMA: METALLIZED UDMH-RFNA BIPROPELLANT SYSTEM \\ h :i 7, .. /<~?:.: '. ~ .;0'1 -, i . .1. <>

22 ... ] METAL OXIIATlON + ... WlJH 02.[AMe.ol

• AI, METAl. ClKIDATlON ~ Nt,! WITH H20 ... POUt.

[AHc,w] I'

16

10

'L-__ ~ ____ -L ____ ~ ____ L-__ ~~

o 10 20 30 '0 50 NETAL, wt".

Fig. 7--Plot of theoretical t!Jic versus degree of metallization showing mechanism of metal oxidation

Table 6-Values of parameters ofEq. (4)

Heat of combustion

Experimental

Theoretical (Metal+02=MetaIOxide) Theoretical (Metal+H20(g)=Metal

Oxide)

Metallic Parameters in the fo rm of ingredient

of ge l

Al Mg A l Mg A I Mg

expression

~Hc .=5. 72x 10.2 M+8 . 922 ~Hc'e=2.47x I 0·2M+8 .90 I

t!Jic.o=2.896x I 0. 1 M+ 7.187 M1c.o=2.808x JO.IM+7.266 Mfc.w=1.935x 10.1 M+7.53 I Mic.w=2.052 x I 0. 1 M+7.548

degree of metallization have been recorded in Tab le 5. The experimental value of heat of combustion of UDMH has been found to be 7.859 kcal/g which is in good agreement with the reported valueD The heat of combustion of methyl cellulose was experimentally obtained to be 5.124±0.04 kcal/g wh ich is much less than that of UDMH. Thus replacement of a known amount of UDMH by less exothermic MC should give a lower value of heat of combustion of UDMHMC gel. The experimental value for the ge l recorded in Table 5 is, however, seen to be higher than that of liquid unsymmetrical dimethylhyd razine. This is only possible when some chemical interacti on during combustion takes place between UDMH and gellant to make the system more exothermic.

/ "i~, fJ7 ; :.,- ~

Table 7-Heat of combustion of gelled syste mechanism of metal oxidation

System Mu t!Jim t!Jic,c kcal/g kcal/g

UDMH-MC- \0% A I 2.28 0.244 9.578 UDMH-MC-20% AI 9.60 2.001 11 .336 UDMH-MC-30% AI 17.35 2. 588 13.477 UDMH-MC-40% A I 26.74 5.092 16.118 UDMH-MC- IO% Mg 3.40 0.261 9.381 UDMH-MC-20% Mg 12.36 1.212 10.622 UDMH-MC-30% Mg 21.54 2.699 12.34 1 UDMH-MC-40% Mg 30.66 4.954 14.843

Mu=Metal percent unreacted

~Hc.w kcal/g

9.340 11 .053 13 .098 15.657 9.479

11.32 1 13.481 16. 11 7

~Hm=Heat contribution due to ox idat ion of un reacted metal in the gel

~Hc.w=~Hc .• +t!Jim ~Hc.c=Corrected heat of combustion

With the incorporation of increasing amounts of aluminium powder in the gel, the experimental heat of combustion, M e.e of meta llized fuels goes on increasing linearly up to 40 wt% of loading (Fig. 6), according to relation

!1H =a'M+C' e,e . .. (4)

where a ' and C' refer to slope of the line and a constant respectively . A similar behaviour is exhibited by magnesiumized gels . The va lues of parameters are given in Table 6. The results clearly show that the rate of increase in Me,e per unit weight of aluminium in the gel is more than that of magnesium, Thi s is expected as the heat of combustion24 of aluminium, 7.43 kcal/g, is higher than that of magnesium, 5,90 kcal/g.

The heat of com bustion of a ll the fuel compositions in presence of oxygen, M e,o has also been computed theoretica lly assuming the formation of completely oxidi zed products like CO2, H20 , A120 3,

MgO and N2. The heat of formation of reactants and combustion products have been taken from Ref. 17. The resu lts have been presented in Table 5 (co lumn 3) alongwith the experimental data. The f...Hc ,o values are found to follow an increas ing trend with extent of metallization supporting the experimental results. A plot of f...He.o versus metal content of ge l (Fig. 7) gives the best straight line fo ll owing Eq. (4), The values of parameters are also given in Table 6. It is observed that theoreticaHy computed f... H e.o va lues (Table 5) are

20 INDIAN 1. ENG. MATER. SCI., FEBRUARY 1999

much higher than the corresponding experimental figures. The discrepancy between results may be attributed to incomplete oxidation of metal and/or operation of different mechanism of metal oxide formation. The experimental observations reveal that a progressively increasing part of metal remains unreacted with degree of metallization, encapsulated by the solid metal oxide layer. This unreacted metal can be available to oxidation only when the temperature attained inside the chamber exceeds the boiling point of metal oxide25.26 . Accordingly, the amount of unreacted metal for different metallized fuel compositions was estimated with the help of Eq. (4) using experimental heat of combustion values (Table 5) and the parametric values given in Table 6. The unreacted metal (wt%) thus computed and shown in Table 7 was found to be in excellent agreement (±0.5%) with the chemically estimated valu'es in each case. The data show that it goes on increasing with metal content of the gel. The unreacted metal was then considered to be oxidized and the heat thus liberated Mlm, (Table 7, column 3) was added to the respective eKperimental values to get the corrected heat of combustion Mlc ,c' The values are still found to be less than the corresponding values of Mlc,o (Table 5).

As far as the metal oxide formation is concerned, only two routes are possible in propellant combustion. One way is the. oxidation of metal by oxygen and the other by its reaction with water vapour under high temperature and pressure conditions encountered in combustion chamber. It is possible that the metal oxide formation may take place partly by both the routes but it is difficult to estimate as to which one is predominant. The theoretically computed stoichiometric OfF ratios by a NASA programme27 for virgin and metallized gels containing 10, 20, 30 and 40 wt% of aluminium have been found to be 3.35, 3,15, 2.96, 2.76 and 2.57 respectively. Based on only the organic component of the metallized gels, the respective values (for 10-40 wt% of AI) come out to be 3.0 I, 2.68, 2.34 and 2.0 I. This shows that a small part of oxygen (oxidizing species provided by RFNA in rocket combustion chamber) reacts directly with th~ metal to ultimately form the oxide.

The metal oxide formation during combustion in rocket motors has been reported to be mainly due to its reaction with water vapour under conditions prevailing inside the combustion chamber28.

Accordingly, the theoretical heat of combustion values assuming metal oxide formation by AllMgwater vapour interaction, Mlc.w were computed for different fuel compositions which are present~d in Table 7. The results show that Mlc•w values for aluminized gels are close to the respective Mlc.c figures but are slightly on lower side. This suggests that the major part of metal oxide is formed by metal reaction with water vapour. Since, the Mlc•c values are marginally higher than Mlc•w it can be inferred that only a small proportion of aluminium directly reacts with oxidising species. However, the data recorded for magnesiumized gels in Table 7 show that Mlc•c values for these gels though close to respective Mlc•w figures, are always less than latter. This indicates that the formation of MgO takes place solely by the reaction of metal with water vapour.

The Mlc•w values for AI and Mg containing gels (Table 7) have also been plotted in Fig. 7 against metal loading. Both the systems show linear variation of calorific value with the metal content of gel according to Eq. (4). The values of parameters are given in Table 6. The data clearly reflect that the rate of increase of Mlc,w values per unit weight of metal incorporation in the gel is slightly more for magnesiumized compositions than aluminized ones. This is due to the fact that Al takes up 1.5 times more oxygen from water than Mg whereas the heat of

-formation of AI20 )(s) is only 1.4 times to that of MgO(s) on equal el.ement mole basis29. In other words, unreacted water in magnesiumized gels would be 1.5 times more than the fuel containing aluminium which outweighs the exothermicity of AbO)(s).

References I Gunu S V, JAm Rocket Soc, 22 ( 1952) 23. 2 Munjal N L, AIAA J, 6 (1968) 1782. _ 3 Rastogi R P, Girdhar H L & Munjal N L, Indian J Chem, 2

(1964) 301. 4 Strier M P & Rapp L R, Proc Sixth International Symposium

on Combustion, Reinhold, New York, 1956, 902. 5 Jain S R, Krishna P M M & Pai Vemeker V R, J Spacecraft

Rockets, 16 (1979) 69. 6 Rajenrlran G &. Jain S R, Fuel, 63 (1984) 709. 7 Munjal N L & Parvatiyar M G, J Spacecraft Rockets, II

(1974) 428. 8 Munjal N L & Parvatiyar M G, J Spacecraft Rockets, 13

(1976) 54. 9 Miyasaka K & Law C K, Combust Sci Technol, 24 (1980) 71 .

10 Liu G E & Law C K, Fuel, 65 (1986) 171. II Lee A & Law C K, Combust Flame, 85 ( 1991) 77. 12 Turns S R & Faeth G M, J Propulsion Power, 1(1985) 5. 13 Galecki 0 L, AIAA Paper No. 89-2883, July 1989.

GUPTA & VARMA: METALLIZED UDMH-RFNA BIPROPELLANT SYSTEM 21

14 Turns S R & Mueller D C, Final Report-Phase I, NASA Lewis Research Centre, Grant NAG3-1044, 1993.

15 Mueller D C & Turns S R, J Propulsion Power, 12 (1996) 591.

16 Munjal N L, Gupta B L & Varma M, J inst Eng (India), 71 (1991) 25.

17 Gupta B L, Varma M & Munjal N L, Indian J Technol, 30 (1992) 234.

18 Pino M A, Jet Propulsion, 25 (1955) 463 . 19 Munjal N L, Gupta B L & Varma Mohan, Propel/ants upl

Pyrotech, 10 (1985) 111-117. 20 Gupta B L & Varma Mohan, Final Tech Report, ARDB

Project, Aero/RD- I341l 0011 0174-75, 1977. 21 Barrere M A, Jaumotte A, Deveubeke B F &

Vandenkerckhove J, Rocket Propulsion, (Elsevier, New York) 1960. 1.82 & 397.

22 Kishore K & Sunitha M R, Propel/ant upl, 1977, 2, 98. 23 Kit B & Evert D S, Rocket Propel/ant Handbook, (McMillan,

New York) 1960,315. 24 Schadow K, in Space Engineering, edited by Partel G A (D.

Reidel Pub Co, Dordrecht-Holland), 1970,265.

25 Brzustowski T A & Glassman I, Prog Astronaut Aeronaut, 1964, Vol. 15, 41.

26 Glassman I, Prog Astronaut Aeronaut, 1960, Vol. 1,253.

27 Gordon S & McBride B, Computer Program NASA-SP-273 , 1971.

28 Beighley C M, Fish W R & Anderson R E, in Space Engineering, edited by Partel G A (D Reidel Pub Co, Dordrecht-Holland) 1970, 183 .

29 Stull D R & Prophet H, JANAF Thermochemical Tables, NSRDS-NBS 37, lIEd. 1971.