I:Eea.606445895.Lower-Harbor-BrDocsDWGDWFFINAL … · 2016-09-24 · transformer (t-1) 75 kva, 480v...

Transcript of I:Eea.606445895.Lower-Harbor-BrDocsDWGDWFFINAL … · 2016-09-24 · transformer (t-1) 75 kva, 480v...

FM

FM

CR

M

TR

1

S

OXOO

S

XOOO

F

A

O

OOOX

XOO

OOX

H AO

T

M

M

M

FACP

MCPSA

TDR

*

START

STOP

G

MMS

(CIR. NO.)L6-30R

NP

MSSOR

ORS

*

LIGHTING FIXTURE TYPE, TYP.

WALL MOUNTED FIXTURE

POLE MOUNTED AREA/STREET FIXTURE

EXIT SIGN FIXTURE

FLUORESCENT FIXTURE

FLUORESCENT FIXTURE

STANCHION MOUNTED FIXTURE

W/ INTEGRAL BATTERY PACK

(D INDICATES TWO JACKS, RJ11 &RJ45, ON SINGLE WALLPLATE)

FIRE ALARM CONTROL PANEL

TELEPHONE AUXILIARY RINGER

EXPLOSION POOF EXIT SIGN FIXTURE

GROUND

MOTOR OPERATED DAMPER

LOUVER

CALARM HORN/AMBER BEACONHAZARDOUS GAS DETECTION

INTRUSION SYSTEMDOOR CONTACT

STOP/LOCKOUT PB STATION

GROUND GRID

DRIVEN GROUND ROD

SINGLE POLE SWITCH (P) PILOTLIGHTTHREE-WAYSWITCHFOUR-WAYSWITCHMOTOR STARTING SWITCH WITH OVERLOADPROTECTION

MANUAL MOTOR STARTER

DUPLEXRECEPTACLEQUADRECEPTACLE

SINGLE RECEPTACLE

SPECIAL RECEPTACLE WITHDESIGNATION

THERMOSTAT

CONTINUOUS RATING

MOTOR CIRCUITPROTECTOR-TRIP RANGE SETTINGBASED ON ACTUAL MOTOR FULLLOAD AMPSCONTACTOR TYPE AND NEMA SIZEAS REQUIRED FOR MOTOR FULLLOAD AND CHARACTERISTICS

OVERLOAD HEATERS OR RELAY

MOMENTARY OPEN PUSHBUTTON(NORMALLY OPEN)

MOMENTARY CLOSED PUSHBUTTON(NORMALLY CLOSED)

MAINTAINED CONTACT PUSHBUTTONWITH MECHANICAL INTERLOCK

THREE POSITION MAINTAINEDCONTACT SELECTOR SWITCH

FOUR POSITIONMAINTAINED CONTACTSELECTOR SWITCH

NORMALLY OPEN

NORMALLY CLOSED

TIME DELAY AFTERCOIL ENERGIZED

TIME DELAY AFTERCOILDE-ENERGIZED

NORMALLY OPEN CONTACT

NORMALLY CLOSED

NORMALLY OPEN

NORMALLY CLOSED CONTACT

TEMPERATURESWITCHLIMIT SWITCH

FLOAT SWITCH

PRESSURESWITCH

SOLENOID VALVE COIL

MOTOR OPERATEDVALVEINDICATING LIGHT*=COLORR - RED W - WHITEG - GREEN A - AMBER

PUSH-TO-TEST INDICATINGLIGHT

NAME PLATE

RED MUSHROOM HEAD PUSHBUTTON(MAINTAINED)

MOUNTING STAND

CONTROL RELAY

TIMER

TIME DELAY RELAY

MOTOR STARTER CONTACTOR COIL OTHER COILDESIGNATIONS:SL- SLOW O - OPENFS- FAST C - CLOSEDF - FORWARD L - LOWR - REVERSE H - HIGH

LIMITSWITCH

FLOW SWITCH

PRESSURE SWITCH

VIBRATION SENSOR

MOTOR OPERATEDDAMPER

CONTROLSTATION

UTILITY POLE

UTILITY POLE W/STREETLIGHT

ELAPSED TIME METER

FLEXIBLE CONDUIT

WIRES CONNECTED

WIRES NOT CONNECTED

CURRENT LIMITINGFUSESWITCH WITH CURRENT LIMITINGFUSE

MOLDED CASE CIRCUIT BREAKER

DISCONNECT SWITCH

SQUIRREL CAGE INDUCTIONMOTOR AND HP HP, VARIES

RESISTANCE LOAD

DRAW OUT FEATURE

TRANSFORMER

PHONE JACK (MOUNT AT 12" AFF,FOR FUTURE DESK PHONE BYOWNER)

PHONE JACK (MOUNT AT 54" AFF, FORFUTURE WALL-MOUNTED PHONE BYOWNER)

TYPE RJ-31X JACK FOR FIRE ALARMDACT SIGNALS

DRILLED GROUND ROD

AIR TERMINAL

EARTH TERMINAL

CABLE TURNING DOWN

SMOKE DETECTOR

HORN/STROBE COMBINATION ALARM

HEAT DETECTOR

PULLSTATION

HORN ALARM

STROBE

P

S

CR= CORROSION RESISTANTXP= EXPLOSION PROOF

CR= CORROSION RESISTANTXP= EXPLOSION PROOF

CR= CORROSION RESISTANTXP= EXPLOSION PROOF

F FLAME DETECTOR

D= DUCTSMOKE DETECTOR

LIGHTING SYMBOLS

D

T

TELEPHONE SYSTEM SYMBOLS

LS

FS

PS

LIGHTNING SYSTEM SYMBOLS

VS

SYMBOLS

FIRE ALARM SYSTEM SYMBOLS

W

X

ETM

EX

X

X

10

5

DS

EX-XP

CS

M

MOD

LUV

SLO

ABBREVIATIONS

F

G

W

T

U

V

N

O

D

E

C

B

A

R

S

L

M

Q

I

J

K

PH

MOTOR CONTROL CENTERMCC

EWC

EUH

FLOW

FEET

FAST-SLOW

EWF

F

FT

F-S

FOS FAST-OFF-SLOW

FRAME

GREEN

FR

F-R

G

GPM

GROUNDGRD

GFI

ELECTRIC WALL FIN

ELECTRIC WATER COOLER

ELECTRIC UNIT HEATER

GALLONS PER MINUTE

FORWARD-REVERSE

GROUND FAULT INTERRUPTER

( )OL

No.

N.O.

N.C.

NP

MTR

NF

NFDS

MX

TIME-OPEN CONTACT

TIME-CLOSE CONTACT

TEMPERATURE SWITCH

TELEPHONE CONDUIT-( )

SHIELDED TRIPLE CABLE

TWISTED SHIELDED PAIR

VOLTS ALTERNATING CURRENT

VARIABLE FREQUENCY DRIVE

VOLTS DIRECT CURRENT

VOLTAGE TRANSFORMER

VA VOLT - AMPERE

WATT

WEATHERPROOF

VS

VDC

W

WP

VT

VOLTMETER SWITCH

THERMOSTAT

TIMING RELAY

TEMPERATURE

TYPICAL

UNIT HEATER

NORMALLY CLOSED

NAMEPLATE

NON FUSED

NON FUSIBLEDISCONNECT SWITCH

MOTORIZED TIMING RELAY

MOTOR AUXILIARY RELAYS

NUMBER

NORMALLY OPEN

OVERLOAD ( ) NUMBER OF

TEMP

TR

TOC

TCC

TS

T-( )

TRI

TSP

TYP

UH

VAC

VFD

T or T'STAT

MF-( )

MCM or kcmil

LP( )-( )

L

M

LC

LS

CONDUITCDT

CPT

CC-( )

I/P

I/I

CR-( )

CT

DS

DC

DP

DIRECT CURRENT

TRANSDUCER

TRANSDUCER

C-( )

EMT

DPDT

ETM

DISCONNECT SWITCH

DIFFERENTIAL PRESSURE

CURRENT TRANSFORMER

CURRENT TO PNEUMATIC

CURRENT TO CURRENT

CONTROL RELAY-( ) ID

CONTROL POWER TRANSFORMER

CONTROL CONDUIT-( ) ID

CONTRACT-( ) ID

ELAPSED TIME METER

ELECTRIC METALLIC TUBING

DOUBLE POLE, DOUBLE THROW

LM

LP( )

KW

mA

MCP

MGD

MTD

JB

IT

IC

IF

ID

AFF

ANN

AS

AC

MX

AA

AUXILIARY RELAY

ANNUNCIATOR

AMMETER SWITCH

BREAKER

CHLORINE

CENTERLINE

BKR

2

LC

CL

CF(P OR L)

CH

COMPT

CR(P OR L)

COMPARTMENT

AUTOMATIC ALTERNATOR

ABOVE FINISHED FLOOR

ALTERNATING CURRENT

CONVECTION HEATER

(PRESSURE OR LEVEL)CLOSE ON RISING

(PRESSURE OR LEVEL)CLOSE ON FALLING

CONDUCTORCOND

KVA

HP

HZ

HOA

I/O

IMC

KV

KVAR

POTENTIAL TRANSFORMER

POLES ( ) NO OF POLES

PNEUMATIC TO CURRENT

PNEUMATIC TIMING RELAY

POWER AND CONTROL CIRCUIT

POLYVINYL CHLORIDE CONDUIT

POWER ROOF EXHAUSTER

POWER FEEDER ( ) ID

POWER CIRCUIT ( ) MCC

POWER WALL VENTILATOR

PROGRAMMABLE LOGIC

( ) MCC ID/ ( ) ID

ROOT MEAN SQUARE

RIGID STEEL CONDUIT

REMOTE TERMINAL UNIT

SHIELDED TWISTED PAIR

SINGLE POLE, DOUBLE THROW

START/STOP LOCKOUT

QUANTITYQTY

RED

RECEPTACLE

STOP LOCKOUT

START/STOP

SYMMETRICAL

KILOWATT

R

LOUVER CONTROLLER

LIMIT SWITCH

LEVEL

MAIN FEEDER-( ) ID

MAIN CONTACTOR

LOUVER MOTOR

MILLIAMPERES

THOUSAND CIRCULAR MILS

LIGHTING PANELBOARD

LIGHTING CIRCUIT ( )

MOUNTED

MOTOR CIRCUIT PROTECTOR

MILLION GALLONS PER DAY

RECPT

RMS

RSC

RTU

SS

SV

SPDT

SHLD TW PR

SL

S/SL

SYM

S/S

SOLENOID VALVE

SELECTOR SWITCH

PHASE

TRANSDUCER

or PH

P/I

PT

PVC

( )P

ID/ ( ) ID

PRESSURE

CONTROLLER

PF-( )

P( )-( )

P

PS

PRE

PWV

PLC

PC( )-( )

INFRARED HEATER

HORSEPOWER

HERTZ

IDENTIFICATION NUMBER

HAND-OFF-AUTOMATIC

JUNCTION BOX

KILOVOLT AMPERE

KILOVOLT

OR INSTANTANEOUS TRIPINTERCHANGEABLE TRIP

INTERRUPTING CAPACITY

INTERMEDIATE STEEL CONDUIT

INPUT/OUTPUT

KILOVOLT AMPERES REACTIVE

TR

PRESSURE SWITCH

S

3

4

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64NOT TO SCALE

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-001SYMBOLS, ABBREVIATIONS & NOTES

GENERAL ELECTRICAL DRAWING NOTES:

1. EXACT EQUIPMENT CONDUIT CONNECTIONS ARE TO BE DETERMINED BY THEELECTRICAL INSTALLER BASED ON ACTUAL FIELD LOCATION OF EQUIPMENT. INSTALLCONDUIT IN ACCORDANCE WITH SPECIFICATION SECTION 16110.

2. ALL PENETRATIONS THROUGH NON-FIRED RATED WALLS, CORE HOLE AND SEALAROUND CONDUIT WITH NON-SHRINK GROUT. ANY PENETRATIONS THROUGHEXTERIOR WALLS SHALL BE SEALED WATER TIGHT WITH SILICONE MASONRYSEALANT. ALL PENETRATIONS THROUGH FIRE RATED WALLS SHALL BE SEALED WITHFIRE STOPPING PER SPECIFICATION SECTION 16120 AND DETAILS ON SHEET E-307.

3. EVERY EFFORT HAS BEEN MADE TO IDENTIFY REMOTE ITEMS TO BE CONNECTED BYTHE ELECTRICAL CONTRACTOR, EITHER IN THE ELEMENTARIES OR ON THESCHEDULES. HOWEVER, NOT ALL OF THE REMOTE DEVICES MAY HAVE BEEN SHOWNON THE ELECTRICAL DRAWING. SEE DRAWINGS OF RESPECTIVE CONTRACTS TOLOCATE OR CONFIRM THEIR LOCATION.

4. IN GENERAL, ALL WORK SHOWN ON THE ELECTRICAL DRAWINGS IS THE WORK OFTHE ELECTRICAL TRADE UNLESS SPECIFICALLY STATED OTHERWISE. WORK FORTHIS CONTRACT IS GENERALLY USING HEAVY LINE WEIGHTS, WITH THE WORK OFOTHER CONTRACTS SHOWN WITH LIGHTER LINE WEIGHTS AND/OR CALLED OUT ONTHE PLANS.

5. ALL ELECTRICAL WORK IN CLASS I, DIVISION 1, GROUP D AREAS SHALL BE IN STRICTACCORDANCE WITH THE NATIONAL ELECTRICAL CODE ARTICLE 501 AND THECONTRACT SPECIFICATIONS. ALL MATERIALS PROVIDED IN SUCH AREAS SHALL BELISTED AS SUITABLE FOR THE ENVIRONMENT IN WHICH THEY ARE INSTALLED. REFERTO THE ROOM SCHEDULE ON SHEETS E-101 FOR AREA CLASSIFICATIONS.

6. FASTENERS ON THE UNDERSIDE OF PRECAST/PRESTRESSED CONCRETE MEMBERS(PLANKS OR DOUBLE TEES) WHICH SERVE FOR DIRECT ATTACHMENT OR FORHANGERS OF ELECTRICAL EQUIPMENT , CONDUIT, CHANNEL, ETC. MAY NOT BEDRILLED OR SHOT IN THE VICINITY OF THE PRESTRESSING TENONS. THIS MEANS THATFASTENERS AT CONCRETE PLANKS CAN ONLY BE PLACED AT THE JOINTS BETWEENUNITS. CONTRACTOR SHALL PROVIDE INTERMEDIATE SUPPORTS NEEDED TOACCOMPLISH THIS.

1. THIS IS A STANDARD SYMBOL LIST, SOME SYMBOLS MAY NOT APPEAR ON THEACCOMPANYING DRAWINGS.

2. REFER TO SPECIFICATIONS FOR DETAILED REQUIREMENTS.3. PLAN & SECTION SYMBOLS MAY ALSO BE USED ON DIAGRAMS.4. ON ONE-LINE DIAGRAMS FOR 3-PHASE SYSTEMS, DEVICE QUANTITY = 3 UNLESS

OTHERWISE NOTED.5. WIRE SIZES SHOWN ARE AWG. (AMERICAN WIRE GAUGE)6. FOR ADDITIONAL ABBREVIATIONS, REFER TO THE GENERAL DRAWINGS.7. ALL WORK PERFORMED BY THE CONTRACTOR ON THIS PROJECT SHALL BE PERFORMED

IN STRICT ACCORDANCE WITH THE CONTRACT DRAWINGS , SPECIFICATIONS, ANDAPPLICABLE CODES.

GENERAL NOTES:

THE DESIGN TO PROVIDE A POWER DISTRIBUTION AND LIGHTING SYSTEM FOR THE CSOSTORAGE FACILITY WILL BE GOVERNED BY, BUT NOT LIMITED TO THE FOLLOWINGREQUIREMENTS:

• AMERICAN NATIONAL STANDARDS INSTITUTE (ANSI)• AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM)• ILLUMINATING ENGINEERING SOCIETY OF NORTH AMERICA (IESNA)• NATIONAL ELECTRICAL MANUFACTURERS ASSOCIATES (NEMA)• NATIONAL FIRE PROTECTION ASSOCIATION (NFPA)• OCCUPATION SAFETY AND HEALTH ACT (OSHA)• UNDERWRITERS LABORATORY, INC. (UL)

GENERAL NOTES:

DESIGN CRITERIA:

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

TRANSFORMER (T-1)75 KVA, 480V PRIMARY,208/120V SECONDARY

MOTOR CONTROL CENTERMCC-N, SEE ONE-LINESHEET E-301

SCADA SYSTEMENCLOSURE

TANK DEWATERING PUMPNO.1 VFD AND HARMONICFILTER

ELECTRIC101

STAIR104

MECHANICAL105

BATH106

OFFICE107

HALL102

UTILITY METERINGENCLOSURE (TYPICAL)

LEVEL TRANSMITTERLIT-200, LIT-201, LIT-202,LIT-203 AND LIT-204

FLOW TRANSMITTERFIT-200

CENTER FLUSH HYDRAULIC CONTROLPANEL.

LIGHTING PANEL LP1,SEE PANEL SCHEDULESHEET E-305

P-11

P-1

P-1A

P-11A

ELECTRIC WATERHEATER EWH-1

10'-0"x3/4" DIAMETERCOPPER WELD GROUNDINGROD (TYPICAL)

FIRE ALARM CONTROLPANEL AND BATTERYCABINETS

P-10A

A

VENTILATION SYSTEMALARM AND HORN

EUH-2

EBH-1PTAC-1

P-9

TANK DEWATERING PUMPNO.2 VFD AND HARMONICFILTER

HEATINGCOIL EDH-1

DAMPER D-1

VESTIBULE103

ECH-1

EUH-1

SF-5

M

EUH-3

P-17

P-16

LP1-16

LP1-22,24,26

P-19

LP1-25

LP1-9,11LP1-10,12

LP1-19LP1-17

LP1-20

P-8

TELEPHONETERMINATIONBOARD

LP1-15

P-10

SEE SHEET I-201 FORCONDUIT AND WIRINGREQUIREMENTS (TYPICAL FORBOTH FIT AND AIT'S)

MF-A

LP1-21

LP1-21

LP1-21LP1-18

LP1-18

LP1-28

GAS MONITOR TRANSMITTER/INDICATOR (AIT-214) FORSTORAGE TANK STAIRWELLGAS SENSOR

C-007

P-18

SEE SHEET E-202FOR CONTINUATION

LOUVERLV-2

C-206

C-006

C-009 & P-21, STUB-UP6" AFF AND CAP

C-010

C-001

C-002

C-003

GROUND BAR MOUNTED 12" AFF,SEE GROUND BAR DETAILSHEET E-307

#4/0 GROUND CONNECTIONTO GROUND BAR

BOND INCOMING WATER LINETO BUILDING PERIMETER GROUNDLOOP WITH #4/0 BARE TIN PLATEDCOPPER GROUND CABLE

#4/0 BARE TIN PLATED COPPERGROUND CABLE, 2'-6" BELOWFINISHED GRADE (TYPICAL)

SEE SIGNAGENOTE

LIGHTING PANEL LP2SEE PANEL SCHEDULESHEET E-305

P-10B

UP TO ANTENNA MASTON ROOF, SEE SHEET E-103FOR ANTENNA LOCATION

1600A SERVICEDISCONNECT

MOBILE GENERATORCONNECTION BOX, SEEDETAIL SHEET E-309

300 AMP MANUAL TRANSFERSWITCH, SEE ONE-LINE SHEET E-301

MOTOR CONTROL CENTERMCC-E, SEE ONE-LINESHEET E-301

P-2

P-2B

P-2A

LOUVER L-1

ROOM/AREA CLASSIFICATION

ROOMNUMBER ROOM NAME CLASSIFICATION

101 ELECTRIC ROOM

102 HALL

104 STAIR

105 MECHANICAL ROOM

ODOR CONTROL

CLASS 1, DIV 2, GROUP D WITHIN 3'-0" OF ODORCONTROL SYSTEM DUCTWORK BLOWERS,

SCRUBBERS OR ANY OTHER POTENTIAL LEAKSOURCE. OUTSIDE THIS 3'-0" ENVELOPE, IS

UNCLASSIFIED

106 BATH

107 OFFICE UNCLASSIFIED

STORAGE TANK STAIRWELL

STORAGE TANK

CLASS 1, DIVISION 1, GROUP D

UNCLASSIFIED

UNCLASSIFIED

UNCLASSIFIED

UNCLASSIFIED

CLASS 1, DIVISION 1, GROUP D

103 VESTIBULE UNCLASSIFIED

CLASS 1, DIVISION 1, GROUP D

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-101UTILITIES BUILDING - POWER PLAN

SCALE: 1/4" = 1'-0"POWER

2 10864201/4"=1'-0"

1. PROVIDE SIGNAGE ON THE DOOR IN ACCORDANCE WITH SPECIFICATIONSECTION 16196. LABEL AS "BEFORE ENTERING THE AREA BELOW,PERSONNEL ARE REQUIRED TO PLACE THE VENTILATION SYSTEM INMAINTENANCE MODE THROUGH THE SYSTEM PLC"

SIGNAGE NOTE:

REQUIREMENTS FOR ELECTRICAL WORK ANDMATERIALS VARIES FOR EACH ROOM OR AREA.

REFER TO THE TABLE ON THIS SHEET FORROOM/AREA CLASSIFICATIONS

AREA CLASSIFICATION NOTE

1. IT IS THE CONTRACTORS RESPONSIBILITY TO COORDINATE AND SCHEDULEALL WORK WITH THE OWNER, ENGINEER AND OTHER CONTRACTORS.

2. CONDUIT ROUTINGS SHOWN ARE SCHEMATIC ONLY, CONTRACTOR SHALLROUTE CONDUIT BASED ON ACTUAL FIELD CONDITIONS AND INCOORDINATION WITH ALL OTHER EQUIPMENT BEING INSTALLED UNDERTHIS CONTRACT.

3. WHERE TRENCHING FOR ELECTRICAL IS REQUIRED, CONTRACTOR SHALLVERIFY EXISTENCE OF UNDERGROUND OBSTRUCTIONS PRIOR TOEXCAVATION.

4. CONTRACTOR SHALL FIELD VERIFY ALL LENGTHS AND DIMENSIONS NOTSPECIFICALLY CALLED OUT ON THE DRAWINGS OR OTHERWISE NOTED.

5. ALL SPLICES IN UNDERGROUND CONDUCTORS (I.E. JUNCTION BOXES)SHALL BE SEALED WITH 3M SCOTCHCAST.

6. WORKING CLEARANCE TO BE MAINTAINED IN FRONT OF ELECTRICALEQUIPMENT, PER NEC TABLE 110.26(A)(1).

GENERAL NOTES:

SUMP PUMPCONTROLPANEL

SEE SHEET E-202FOR CONTINUATION

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

1. THE GROUNDING SYSTEM IS SHOWN DIAGRAMMATICALLY. EXACTLOCATION OF CABLE GROUND RODS AND CONNECTIONS SHALL BEDETERMINED IN THEFIELD.

2. ALL BURIED GROUNDING CABLE CONNECTIONS SHALL BE CADWELDOR THERMOWELD. THE WELDED CONNECTIONS SHALL BE LEFTEXPOSED FOR INSPECTION BY ENGINEER PRIOR TO BACKFILLING.ALL BURIED GROUND CONDUCTOR SHALL BE TIN-PLATED COPPER.SEE SPECIFICATION SECTION 16100.

3. WHERE EXPOSED TO MECHANICAL INJURY, THE GROUNDINGCONDUCTOR SHALL BE SUITABLY PROTECTED BY PIPE OR OTHERMECHANICAL PROTECTION. EACH END OF PROTECTING CONDUIT (IFMETALLIC) SHOULD BE GROUNDED TO THE BARE CABLE AT BOTHENDS.

4. ALL EXPOSED CABLE LUGS AND CONNECTIONS SHALL BE OF THEMECHANICAL OR COMPRESSION TYPE UNLESS OTHERWISE NOTED.

5. STEEL MUST BE CLEANED THOROUGHLY AND CABLE MUST BECOMPLETELY DRY BEFORE MAKING WELD CONNECTIONS.

6. THE GROUNDING SYSTEM SHALL BE CONNECTED TO A METALLICWATERLINE WITH A MINIMUM OF 10 FEET LENGTH UNDERGROUND ANDTO THE GROUNDING ELECTRODES.

7. REMOVE PAINT FROM UNDER ALL GROUNDING LUGS, INCLUDING SHOPFABRICATED PANELS.

GROUNDING NOTES:

600

(ADDENDUM NO. 1)

3

3

3

3

LP1 -3

CC C

C C C

LP1 -5

C

C

CLP1 -6

EX

EX

EX

EX

EX

EXP2

E

E

EX

EX-XP

C

C

C

C

CCC

ELECTRIC101

MECHANICAL105

BATH106

OFFICE107

HALL102VESTIBULE

103

STAIR104

LP1-1

LP1-1

LP1-1

LP1-1

LP1-4

LP1-4

LP1-4

LP1-30LP1-30

LP1-30

LP1-30

LP1-30

LP1-2

LP1-2 LP1-2

LP1-2

LP1-30

LP1-5

LP1-6

GFI

LP1-4

LP1-4 LP1-4

LP1-4

PCLP1-7

PHOTOCELLS

S7

S7

S7

LP1-32

LP1-37

S7

SEE SIGNAGE NOTEPC

LP2-3

LP2-2

TO POLE MOUNTE LIGHT FIXTURELOCATED AT FLAP VALVE STRUCTURE.SEE SHEET E-002 FOR CONTINUATION.

xp

A

EXP2

LUMINARIES TYPES AND MOUNTING HEIGHTS

BUILDING NAME ROOMNUMBER

ROOMDESIGNATION VOLTS/PHASE TYPE OF

FIXTUREMOUNTING HEIGHT TOBOTTOM OF LUMINAIRE

UTILITIES BUILDING 101 ELECTRIC ROOM 120/1 C 10' AFF

102 HALL 120/1 10' AFFUTILITIES BUILDING

107 OFFICE 120/1 10' AFFUTILITIES BUILDING

106 BATH 120/1 10' AFFUTILITIES BUILDING

105 MECHANICALROOM 120/1 10' AFFUTILITIES BUILDING

104 STAIR 120/1 8' ABOVE UPPER& LOWER LANDINGUTILITIES BUILDING

STAIR 120/1 10' AFFSTORAGE TANK

EXTERIOR 120/1 9' ABOVE FINISHEDTANK ROOFUTILITIES BUILDING

EXTERIOR 120/1 18' POLEACCESS ROAD

C

C

EMX

C

EXP2

EXP2

S7

PM1

EXTERIOR CANOPY 120/1 UNDERSIDE OF CANOPYUTILITIES BUILDING E

103 120/1 10' AFFUTILITIES BUILDING CVESTIBULE 103

EMERGENCY BALLAST WIRING DIAGRAMNOT TO SCALE

3-WAY 3-WAY

LINE

COMMON

EMERGENCY BALLAST WIRING DIAGRAM

FLUORESCENT FIXTURE

EMERGENCYBALLAST

AC BALLAST

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-102UTILITIES BUILDING - LIGHTING PLAN

SCALE: 1/4" = 1'-0"LIGHTING PLAN

1. PROVIDE CONDUIT SLEEVE FOR EXTERIOR LIGHTING AND DEVICES.2. VERIFY CLEARANCE REQUIREMENTS FOR ANY FIXTURE DIRECTLY

ABOVE EQUIPMENT.3. REFER TO PANELBOARD SCHEDULE ON DRAWING E-305.4. WALL MOUNTED EXIT SIGNS TO BE MOUNTED 8'-0" AFF AND CIRCUITED

TO PANEL AS SCHEDULED. SEE PANEL SCHEDULE SHEET E-305.5. NIGHT LIGHT CIRCUIT IS ON THE UN-SWITCHED CIRCUIT, WIRE THIS

CIRCUIT DIRECTLY TO THE CIRCUIT BREAKER ASSIGNED.6. EMERGENCY LIGHT IS TO BE CIRCUITED TO THE HOT LEG OF THE

CIRCUIT FEEDING THE LIGHTS IN THE SAME AREA.7. LIGHT FIXTURE MOUNTING HEIGHTS ARE TO BE LISTED AS BOTTOM OF

FIXTURE.8. INSTALL FIXTURES AT HEIGHT SHOWN IN TABLE UNLESS A SPECIFIC

MOUNTING HEIGHT IS CALLED OUT ON PLAN DRAWINGS.9. INSTALL FIXTURES IN LOCATIONS AS SHOWN, AS NOTED OR AS CLOSE

AS POSSIBLE TO THESE LOCATIONS. WHEN ADJUSTMENTS TO AVOIDINTERFERENCE ARE REQUIRED, FIXTURES SHALL BE INSTALLED LEVELAND PLUMB.

10. CLEAN EACH FIXTURE AT THE TIME OF SUBSTANTIAL COMPLETION.11. REPLACE AT THE TIME OF SUBSTANTIAL COMPLETION ANY LAMPS THAT

ARE OUT, REPLACEMENT LAMPS SHALL NOT COME FROM SPARE LAMPSBEING PROVIDED.

12. OPERATE EACH FIXTURE AFTER INSTALLATION AND CONNECTION.INSPECT FOR AND REPAIR ALL IMPROPER CONNECTIONS ANDOPERATION.

13. INSTALL EXIT SIGNS IMMEDIATELY ABOVE THE EXITS SO THEY AREVISIBLE FROM THE DIRECTION OF TRAVEL TO THE EXIT.

GENERAL LIGHTING NOTES:

1. PROVIDE SIGNAGE ON THE DOOR IN ACCORDANCE WITHSPECIFICATION SECTION 16196, LABEL AS "BEFORE ENTERINGTHE AREA BELOW, PERSONNEL ARE REQUIRED TO PLACE THEVENTILATION SYSTEM IN MAINTENANCE MODE THROUGH THEPLANT PLC".

SIGNAGE NOTES:

REQUIREMENTS FOR ELECTRICAL WORK ANDMATERIALS VARIES FOR EACH ROOM OR AREA.

REFER TO THE TABLE ON SHEET E-101 FORROOM/AREA CLASSIFICATIONS

AREA CLASSIFICATION NOTE

2 10864201/4"=1'-0"

TO SITE LIGHTINGSEE SHEET E-002FOR CONTINUATION

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

PRE-1

PRE-2

PRE-3

LP1-13

LP1-14

LP1-13

DISCONNECTSWITCH(TYPICAL FOR 3)

#4 BARE COPPER GROUND CONDUCTORDOWN TO GROUND GRID, SEE SHEETE-101 FOR CONTINUATION

ROOF MOUNTEDYAGI ANTENNA

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-103UTILITIES BUILDING - ROOF PLAN

SCALE: 1/4" = 1'-0"ROOF PLAN - POWER

2 10864201/4"=1'-0"

1. IT IS THE CONTRACTORS RESPONSIBILITY TO COORDINATE AND SCHEDULEALL WORK WITH THE OWNER, ENGINEER AND OTHER CONTRACTORS.

2. CONDUIT ROUTINGS SHOWN ARE SCHEMATIC ONLY, CONTRACTOR SHALLROUTE CONDUIT BASED ON ACTUAL FIELD CONDITIONS AND INCOORDINATION WITH ALL OTHER EQUIPMENT BEING INSTALLED UNDERTHIS CONTRACT.

3. CONTRACTOR SHALL FIELD VERIFY ALL LENGTHS AND DIMENSIONS NOTSPECIFICALLY CALLED OUT ON THE DRAWINGS OR OTHERWISE NOTED.

GENERAL NOTES:

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

S

P

P

P

P

P

S

W

R DC

1

2

J

R DC

1

2

J

R DC

1

2

J

RDC1

2

J

SWP

WP

WP

WP

WP

CR

LEGENDJUNCTION BOX FOR DOORMECHANISM/BADGE READER SYSTEM.

SECURITY PANEL2

1

XP

XP

XP

XP

SECURITY SYMBOL LEGEND

JJ

CR

R

DC

MTG HTDESCRIPTIONSYMBOL

SECURITY DOOR CONTACTS

DOOR RELEASE (MOTION SENSOR LOCATED ON SECURE SIDE OF DOOR)

CARD READER

JUNCTION BOX-CEILING MTD./WALL MTD.

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-104UTILITIES BUILDING - FIRE ALARM, INTRUSIONAND TELEPHONE SYSTEM PLAN

SCALE: 1/4" = 1'-0"

FIRE ALARM, INTRUSION AND TELEPHONE SYSTEMPLAN

1. ACTUAL LOCATION OF ALL FIRE ALARM SYSTEM DEVICES SHALL BEDETERMINED IN THE FIELD. ADJUST LOCATIONS TO AVOID CONFLICTSWITH UNIT HEATERS, HOT WATER PIPING, FANS VENTILATION INTAKE ANDDISCHARGE LOUVERS AND OTHER EQUIPMENT.

2. FOR EACH DUCT SMOKE DETECTOR AND FOR ANY DETECTOR (HEAT ORSMOKE) THAT IS NOT VISIBLE OR READILY "ACCESSIBLE", PROVIDE AREMOTE TEST STATION. TEST STATION TO BE LOCATED IN A CONVENIENTAND ACCESSIBLE LOCATION AND BE SUITABLE FOR THE AREA OFINSTALLATION. PROVIDE CONDUIT AND WIRE AS REQUIRED BYMANUFACTURER.

3. PROVIDE LAMINATED PLASTIC PLACARD WITH 2" WHITE LETTERS ON REDBACKGROUND, TO READ "FIRE ALARM. IF FLASHING CALL 911 TO REPORTFIRE". MOUNT DIRECTLY BENEATH HORN/STROBE UNIT.

4. FIRE ALARM SIGNALING APPLIANCES SHALL BE MOUNTED SUCH THATTHE ENTIRE LENS IS NOT LESS THAN 80 INCHES AND NOT GREATER THAN95 INCHES ABOVE THE FINISHED FLOOR.

5. ALL FIRE ALARM DEVICES SHALL MEET ADA REQUIREMENTS.6. THE FIRE DETECTION SYSTEM SHALL BE INSTALLED IN ACCORDANCE

WITH NFPA-72.7. ALL WIRING FOR THE FIRE DETECTION SYSTEM SHALL BE INSTALLED

WITHIN A DEDICATED CONDUIT.

FIRE ALARM SYSTEM NOTES:

FIRE ALARM CONTROL PANEL(FACP) AND BATTERY CABINETS

COMBUSTIBLE GAS DETECTIONALARM HORN AND LIGHT

WEATHERPROOF HORN/STROBEFIRE NOTIFICATION DEVICE. SEENOTE 3. PROVIDE PLACARD PERSPECIFICATION SECTION 16721.

2 101/4" = 1'-0"

240 2 6 8

MAIN TELEPHONE EQUIPMENTMOUNTING PANEL

TWO RJ-21X JACKS MOUNTED IN THE MAIN FACPOR IMMEDIATELY ADJACENT TO THE PANEL

COMBUSTIBLE GAS DETECTIONALARM HORN AND LIGHT

REQUIREMENTS FOR ELECTRICAL WORK ANDMATERIALS VARIES FOR EACH ROOM OR AREA.

REFER TO THE TABLE ON SHEET E-101 FORROOM/AREA CLASSIFICATIONS

AREA CLASSIFICATION NOTE

1. PROVIDE COMPLETE FULLY FUNCTIONAL SECURITY SYSTEM INACCORDANCE WITH THE CONTRACT DRAWINGS AND SPECIFICATIONS.

2. PROVIDE FLUSH DOOR CONTACTS WHERE SHOWN.3. CARD READERS, CARD READER CONTROLLER, DOOR CONTACTS, AND

INTERIOR DOOR MOTION DETECTOR WILL BE PROVIDED AND INSTALLEDUNDER THIS CONTRACT. CONTRACTOR SHALL PROVIDE AND INSTALLALL CONDUIT AND CONDUCTOR , DEVICE BOXES AS REQUIRED FORINSTALLATION AND TERMINATION. DOORS WILL BE "PREPARED" TORECEIVE ELECTRIC STRIKES AND DOOR CONTACTS.

4. ALL DOORS WILL BE OPENED ON FIRE FROM SECURE SIDE USINGPANIC HARDWARE ON DOORS.

SECURITY SYSTEM NOTES:

T-1 TO INCOMING PRIMARYSERVICE POLE. SEE SHEETE-002 FOR CONTINUATION.

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

1

D

C

B

A

2

4

5

3

TANK DEWATERINGPUMP NO.1 (M-200A)

TANK DEWATERINGPUMP NO.2 (M-200B)

WET WELLCHOPPERPUMP (M-201)

AE-213C (H2S)AE-213B (LEL)

AE-213A (O2)

LE-200

SUBMERSIBLE PRESSURETRANSMITTER/TRANSDUCER.SEE MOUNTING DETAILSHEET I-201

SEE SHEET I-201 FORCONDUIT AND WIRINGREQUIREMENTS (TYPICAL)

LS-205B LE-202

MOUNT INSTRUMENTSADJACENT TO ROOFHATCH. SEE MOUNTINGDETAIL SHEET I-201

SUMP PUMPDISCONNECT SWITCHES

UP TO SUMP PUMP CONTROLPANEL LOCATED IN MECHANICALROOM

P-18A

P-18B

CIRCULAR TANK FLUSHINGSYSTEM CONTROL PANEL

SUMP PUMP CONTROLPANEL

FLEX CONNECTION TOPUMP (TYPICAL)

CIRCULAR TANKFLUSHING SYSTEM

LE-205

LS-205A

AE-212C (H2S)

AE-212B (LEL)

AE-212A (O2)

AE-211C (H2S)AE-211B (LEL)AE-211A (O2)

P-1B

P-11B

P-7

DISCONNECT SWITCH (TYPICAL)SEE NON-METALLIC MOUNTINGPANELS DETAIL SHEET E-307

AE-210C (H2S)AE-210B (LEL)

AE-210A (O2)

AE-214C (H2S)

AE-214B (LEL)

AE-214A (O2)

GAS MONITOR TRANSMITTERS/INDICATORS(AIT-210, AIT-211, AIT-212 & AIT-213) MOUNTEDADJACENT TO DOOR. (FOR GAS MONITORSLOCATED IN STORAGE TANK AREA)

START/STOP PUSHBUTTONCONTROL STATION FOR THECIRCULAR TANK FLUSHINGSYSTEM

SEE SHEET I-201 FORMOUNTING DETAIL

C-205A

C-205C

HS-003 (EMERGENCY CALL)LOCATED ADJACENT TO WATERTIGHT DOORAT ELEV. 327'-0". SEE I-201 FOR ADDITIONALDETAIL.C-008

SEE SHEET I-201 FORCONDUIT AND WIRINGREQUIREMENTS

SEE SHEET I-201 FORCONDUIT AND WIRINGREQUIREMENTS

C-205B

C-205

LSL-200

C-200

LP1-36

LSL-201

DC

C-207

THE EQUIPMENT FOR THE CHOPPER PUMPAND DEWATERING PUMPS SHALL BE FREESTANDING, SEE NON-METALLIC MOUNTUINGPANELS DETAIL SHEET E-307

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-201STORAGE TANK - POWER PLAN

SCALE: 3/32" = 1'-0"STORAGE TANK POWER PLAN

8 2416803/32"=1'-0"

PUMP CABLE PROVIDED BYPUMP MANUFACTURER

REQUIREMENTS FOR ELECTRICAL WORK ANDMATERIALS VARIES FOR EACH ROOM OR AREA.

REFER TO THE TABLE ON SHEET E-101 FORROOM/AREA CLASSIFICATIONS

AREA CLASSIFICATION NOTE

1. IT IS THE CONTRACTORS RESPONSIBILITY TO COORDINATE ANDSCHEDULE ALL WORK WITH THE OWNER, ENGINEER AND OTHERCONTRACTORS.

2. CONDUIT ROUTINGS SHOWN ARE SCHEMATIC ONLY, CONTRACTORSHALL ROUTE CONDUIT BASED ON ACTUAL FIELD CONDITIONS AND INCOORDINATION WITH ALL OTHER EQUIPMENT BEING INSTALLEDUNDER THIS CONTRACT.

3. WHERE TRENCHING FOR ELECTRICAL IS REQUIRED, CONTRACTORSHALL VERIFY EXISTENCE OF UNDERGROUND OBSTRUCTIONS PRIORTO EXCAVATION.

4. CONTRACTOR SHALL FIELD VERIFY ALL LENGTHS AND DIMENSIONSNOT SPECIFICALLY CALLED OUT ON THE DRAWINGS OR OTHERWISENOTED.

5. ALL SPLICES IN UNDERGROUND CONDUCTORS (I.E. JUNCTION BOXES)SHALL BE SEALED WITH 3M SCOTCHCAST.

GENERAL NOTES:

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

?

1

D

C

B

A

2

4

5

3

ODOR CONTROLVESSEL OCV-2

ODOR CONTROLVESSEL OCV-1

SUPPLY FANSF-3

EXHAUST FANEF-1

SUPPLY FANSF-2

SUPPLY FANSF-1

SUPPLY FANSF-4

EXHAUST FANEF-2

P-12

P-3

P-14

P-13

P-4

P-15

P-5

P-6

DISCONNECT SWITCH MOUNTEDON NON-METALLIC MOUNTING PANEL(TYPICAL). SEE DETAIL SHEET E-307

BLOWERBL-1

BLOWERBL-2

DC

DC

DC

DCDC

DC

ROOF ACCESS HATCH(TYPICAL FOR 8)

DOOR CONTACT (TYPICAL)SEE SHEET I-201 FOR TYPICALINTRUSION ALARM DOOR SWITCHESELEMENTARY DIAGRAM AND INTRUSIONALARM SCHEDULE.

DAMPERD-1

DAMPERD-2

PRE-4

LP1-14

GFIWP

LP2-7

GFIWP

LP2-7

C-004

C-005

BLOWER CONTROL PANEL(TYPICAL FOR 2)

P-12AP-12B

P-3A

P-3B

8'-0"x5/8" DIAMETERCOPPER WELD GROUNDINGROD (TYPICAL)

#4/0 BARE COPPER GROUND CABLECONNECT TO BUILDING STEEL (TYPICAL FOR 5 PLACES)

GROUND GRID CONNECTION TOBLOWER MOTOR FRAME (TYPICALFOR BLOWER BL-1 AND BL-2)

FOR CONTINUATIONSEE SHEET E-101

FOR CONTINUATIONSEE SHEET E-101

J

C-011

#4/0 BARE COPPER GROUNDCABLE, 2'-6" BELOW FINISHEDGRADE (TYPICAL)

DAVITCRANE

LP2-1

DC

DC

GRAVITY ROOFVENTILATOR GRV-1

LP2-9

LP2-9

HEAT TRACE POWER CONNECTION BOX,SEE HEAT TRACE DETAILS ON SHEET E-310 (TYPICAL FOR ODOR CONTROLVESSEL OCV-1). SEE SHEETS H-202 ANDH-203 FOR PIPE SIZE, LENGTH ANDLOCATION.

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-202STORAGE TANK - ROOF POWER PLAN

SCALE: 3/32" = 1'-0"STORAGE TANK ROOF POWER PLAN

1. IT IS THE CONTRACTORS RESPONSIBILITY TO COORDINATE ANDSCHEDULE ALL WORK WITH THE OWNER, ENGINEER AND OTHERCONTRACTORS.

2. CONDUIT ROUTINGS SHOWN ARE SCHEMATIC ONLY, CONTRACTORSHALL ROUTE CONDUIT BASED ON ACTUAL FIELD CONDITIONS AND INCOORDINATION WITH ALL OTHER EQUIPMENT BEING INSTALLEDUNDER THIS CONTRACT.

3. WHERE TRENCHING FOR ELECTRICAL IS REQUIRED, CONTRACTORSHALL VERIFY EXISTENCE OF UNDERGROUND OBSTRUCTIONS PRIORTO EXCAVATION.

4. CONTRACTOR SHALL FIELD VERIFY ALL LENGTHS AND DIMENSIONSNOT SPECIFICALLY CALLED OUT ON THE DRAWINGS OR OTHERWISENOTED.

5. ALL SPLICES IN UNDERGROUND CONDUCTORS (I.E. JUNCTION BOXES)SHALL BE SEALED WITH 3M SCOTCHCAST.

GENERAL NOTES:

8 2416803/32"=1'-0"

REQUIREMENTS FOR ELECTRICAL WORK ANDMATERIALS VARIES FOR EACH ROOM OR AREA.

REFER TO THE TABLE ON SHEET E-101 FORROOM/AREA CLASSIFICATIONS

AREA CLASSIFICATION NOTE

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

FACP

P

S

F

FACP

P

S

F

FACP

P

S

F

E-203

2

1

D

C

B

A

2

4

5

3

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2

XP2B

XP2B

XP2B

XP2B

XP2B

XP2B

XP2B

XP2B

XP2B

XP1

XP1

XP1

XP1

XP1

EX-XP

LP1-27

LP1-29

TO XP1 TASKLIGHTINGFIXTURES

LP1-27

LP1-27

LP1-27LP1-27

LP1-27

LP1-37

DOWN TO STAIRWELLLIGHTING SEESECTION 2 THIS SHEET

EX-XP

DC

C-208

FINISHED FLOOREL.

378' - 0"

WALKWAY EL.370' - 0"

T/ TANK ROOF EL.382' - 0"

FIRST FLOOR PLAN378' - 0"

WALKWAY EL.370' - 0"

T/ TANK ROOF EL.381' - 0"

HIGH PT. STRUCT. SLAB EL.327' - 0"

T/ WALKWAY EL.370' - 0"

B/ ROOF EL.381' - 0"

T/ RAINWATER WALL EL.350' - 0"

Lower Tank Plan330' - 0"

T/ STAIR LANDING-1 EL.358' - 11"

T/ STAIR LANDING-2 EL.347' - 10"

T/ STAIR LANDING-3 EL.336' - 9"

T/ DIAPHRAGM WALL EL.363' - 0"

B/ OUTFALL368' - 6"

T/ CULVERT OPNG378' - 6"

T/ CULVERT SLAB373' - 6"

T/ DROP MAT366' - 0"

T/ FIN. FLR.378' - 0"

T/ STAIR LANDING-A358' - 4"

T/ STAIR LANDING-B346' - 8"

T/ STAIR LANDING-C335' - 7"

T/ COLLAR BEAM367' - 0"

T/ RAINWATER STORAGE SLAB347' - 0"

TOPPING HIGH PT382' - 8"

T/ UPPER CONC. STRUT360' - 0"

T/ LOWER CONC. STRUT337' - 3"

T/ STORAGE SLAB325' - 10"

T/ WALKWAY EL.370' - 0"

FIRST FLOOR PLAN378' - 0"

SECOND FLOOR PLAN382' - 0"

WALKWAY EL.370' - 0"

T/ FIN. FLR.378' - 0"

UP TO LIGHT FIXTURE ATLANDING, SEE PLAN VIEWTHIS SHEET

XP2B

XP2B

XP2B

XP2B

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-203STORAGE TANK - LIGHTING PLAN AND SECTION

SCALE: 3/32" = 1'-0"STORAGE TANK LIGHTING PLAN

8 2416803/32"=1'-0"

2 10864201/4"=1'-0"

1. PROVIDE CONDUIT SLEEVE FOR EXTERIOR LIGHTING AND DEVICES.2. VERIFY CLEARANCE REQUIREMENTS FOR ANY FIXTURE DIRECTLY

ABOVE EQUIPMENT.3. REFER TO PANELBOARD SCHEDULE ON DRAWING E-305.4. WALL MOUNTED EXIT SIGNS TO BE MOUNTED 8'-0" AFF AND CIRCUITED

TO PANEL AS SCHEDULED. SEE PANEL SCHEDULE SHEET E-305.5. NIGHT LIGHT CIRCUIT IS ON THE UN-SWITCHED CIRCUIT, WIRE THIS

CIRCUIT DIRECTLY TO THE CIRCUIT BREAKER ASSIGNED.6. EMERGENCY LIGHT IS TO BE CIRCUITED TO THE HOT LEG OF THE

CIRCUIT FEEDING THE LIGHTS IN THE SAME AREA.7. LIGHT FIXTURE MOUNTING HEIGHTS ARE TO BE LISTED AS BOTTOM OF

FIXTURE.8. INSTALL FIXTURES AT HEIGHT SHOWN ON TABLE, SHEET E-102 UNLESS

A SPECIFIC MOUNTING HEIGHT IS CALLED OUT ON PLAN DRAWINGS.9. INSTALL FIXTURES IN LOCATIONS AS SHOWN, AS NOTED OR AS CLOSE

AS POSSIBLE TO THESE LOCATIONS. WHEN ADJUSTMENTS TO AVOIDINTERFERENCE ARE REQUIRED, FIXTURES SHALL BE INSTALLED LEVELAND PLUMB.

10. CLEAN EACH FIXTURE AT THE TIME OF SUBSTANTIAL COMPLETION.11. REPLACE AT THE TIME OF SUBSTANTIAL COMPLETION ANY LAMPS THAT

ARE OUT, REPLACEMENT LAMPS SHALL NOT COME FROM SPARE LAMPSBEING PROVIDED.

12. OPERATE EACH FIXTURE AFTER INSTALLATION AND CONNECTION.INSPECT FOR AND REPAIR ALL IMPROPER CONNECTIONS ANDOPERATION.

13. INSTALL EXIT SIGNS IN THE LOCATIONS AS INDICATED ON THEDRAWINGS.

14. INSTALL EXIT SIGNS IMMEDIATELY ABOVE THE EXITS SO THEY AREVISIBLE FROM THE DIRECTION OF TRAVEL TO THE EXIT.

GENERAL LIGHTING NOTES:

1/4" = 1'-0" E-2032SECTION 1

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

FACPFACPFACP

1

D

C

B

A

2

4

5

3

XP

XP

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-204STORAGE TANK - FIRE ALARM AND INTRUSIONPLAN

SCALE: 3/32" = 1'-0"STORAGE TANK FIRE ALARM PLAN

HEAT DETECTOR(TYPICAL)

XP

XP

XP

XP

XP

XP

XP

XP

XP

XP

XP

XP

XP

XP

XP

XP

REQUIREMENTS FOR ELECTRICAL WORK ANDMATERIALS VARIES FOR EACH ROOM OR AREA.

REFER TO THE TABLE ON SHEET E-101 FORROOM/AREA CLASSIFICATIONS

AREA CLASSIFICATION NOTE

1. ACTUAL LOCATION OF ALL FIRE ALARM SYSTEM DEVICES SHALL BEDETERMINED IN THE FIELD. ADJUST LOCATIONS TO AVOID CONFLICTSWITH UNIT HEATERS, HOT WATER PIPING, FANS VENTILATION INTAKE ANDDISCHARGE LOUVERS AND OTHER EQUIPMENT.

2. FOR EACH DUCT SMOKE DETECTOR AND FOR ANY DETECTOR (HEAT ORSMOKE) THAT IS NOT VISIBLE OR READILY "ACCESSIBLE", PROVIDE AREMOTE TEST STATION. TEST STATION TO BE LOCATED IN A CONVENIENTAND ACCESSIBLE LOCATION AND BE SUITABLE FOR THE AREA OFINSTALLATION. PROVIDE CONDUIT AND WIRE AS REQUIRED BYMANUFACTURER.

3. PROVIDE LAMINATED PLASTIC PLACARD WITH 2" WHITE LETTERS ON REDBACKGROUND, TO READ "FIRE ALARM. IF FLASHING CALL 911 TO REPORTFIRE". MOUNT DIRECTLY BENEATH HORN/STROBE UNIT.

4. FIRE ALARM SIGNALING APPLIANCES SHALL BE MOUNTED SUCH THATTHE ENTIRE LENS IS NOT LESS THAN 80 INCHES AND NOT GREATER THAN95 INCHES ABOVE THE FINISHED FLOOR.

5. ALL FIRE ALARM DEVICES SHALL MEET ADA REQUIREMENTS.6. THE FIRE DETECTION SYSTEM SHALL BE INSTALLED IN ACCORDANCE

WITH NFPA-72.7. ALL WIRING FOR THE FIRE DETECTION SYSTEM SHALL BE INSTALLED

WITHIN A DEDICATED CONDUIT.

FIRE ALARM SYSTEM NOTES:

8 2416803/32"=1'-0"

XP

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

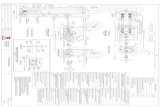

POWERMETER

TVSS

1600AT3000AF

MCC-N

ODORCONTROLBLOWER

BL-1

EXHAUSTFANEF-1

SUPPLYAIR FAN

SF-1

SUPPLYAIR FAN

SF-2

ODORCONTROLBLOWER(FUTURE)

CHOPPERPUMP

ODORCONTROLBLOWER

BL-2

ODORCONTROLBLOWER(FUTURE)

EXHAUSTFANEF-2

SUPPLYAIR FAN

SF-3

SUPPLYAIR FAN

SF-4

125 15 15 15125

25

125 125 15 25 25

SERVICETRANSFORMER

1250 KVA 480/277VTRANSFORMER AND PADBY UTILITY

PRIMARY CABLE BY UTILITY, CONDUITPROVIDED AND INSTALLED UNDER THISCONTRACT, CONDUCTORS BY UTILITY, SEESHEET E-002 FOR UTILITY POLE LOCATION

TRANSFORMER SECONDARYCONDUIT AND WIRE UNDERTHIS CONTRACT

TRANSFORMER (T-A)1000 KVA13.2 KV PRIMARY480/277V SECONDARY

1600 AMP BUS

225250

60150

225250

40150

40150

40150

225250

225250

70150

70150

40150

70150

MF-A

P-3 P-4 P-5 P-6 P-12P-13 P-14 P-15

P-7

SUMPPUMPS

20150

P-18

1 1SUMP PUMPCONTROLPANEL

BLOWER CONTROLPANEL

BLOWER CONTROLPANEL

P-18A

P-18B

20150

P-20TVSS

500AT600AF

MCC-E

(T-1) TRANSFORMER75 KVA 480V

PRIMARY 120/208SECONDARY

VFD

TANKDEWATERING

PUMPNO.2

VFD

HARMONICFILTER

TANKDEWATERING

PUMPNO.1

EUH-15KWUNIT

HEATER

EUH-25KWUNIT

HEATER

PANEL-BOARD

LP1

6464

600 AMP BUS

60150

125150

20150

125150

125150

20150

P-10

P-10A

P-16

P-1

P-1A

P-1B

P-11

P-11A

P-11B

P-8

HARMONICFILTER

ECH-1ELECTRICCABINETHEATER3.3 KW

20150

P-9

EUH-35KWUNIT

HEATER

20150

P-17

HEATINGCOIL

EDH-17.5 KW

20150

P-19

ONE-LINE DIAGRAMNOT TO SCALE

PANEL-BOARD

LP2

P-10B

500600

GENERATOR

GENERATORDISCONNECT

(NOT PART OF CONTRACT)

MOBILEGENERATORCONNECTIONBOX MANUAL TRANSFER

SWITCH MTS-1600 AMP, 3 POLE 480/277V OPENTRANSITION

20150

GATEOPERATOR

SPARE(TYP. FOR 3)

SIZE 1SIZE 2

SIZE 2 SIZE 2 SIZE 2 SIZE 2 SIZE 2 SIZE 2

20250

P-22

SLUICEGATE

SUG-102

20250

P-23

SLUICEGATE

SUG-101

20250

P-24

SLUICEGATE

SUG-103

P-2

P-2A

P-2B

1600A SERVICEDISCONNECT

UTILITY METERING,COORDINATE WITHUTILITY

PORTABLE GENERATOR

3

3

3

MOTOR CONTROL CENTER MCC-N ELEVATIONNOT TO SCALE

MOTOR CONTROL CENTER MCC-E ELEVATIONNOT TO SCALE

E1A

SPACE

E1M

E1K

E2A

E2E

E2I

E2M

E2Q

E2U

E3A

E3E

E3I

E3M

E3Q

E3U

N5A

N5E

N5I

N5M

N5Q

N5U

N4M

N4Q

N4U

N3A

N3E

N3I

N4G

N4A

N3M

N2A

N2E

N2G

N2M

N2S

N2W

N1A

N3V

N6A

N6E

N6I

N6M

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64NOT TO SCALE

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-301MOTOR CONTROL CENTER ONE-LINE DIAGRAMNO. DATE REVISION INT.

1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW3 9/19/11 ADDENDUM NO. 1 MRW

-

+

OOX

M

L1

L2

L3

G

T1

T3

T2

480V PRIMARY50 VA EXTRACAPACITY120V SECONDARY

480V,3ɸ60HZ

SUPPLY

HAND AUTOOFF

XOO

OOXCR1

RUN/FAULTSTATUS TOSCADA I/OMODULE

RUN

FAULT

CR1RUNNING

ELAPSED TIME METER

RESET

400

800

(10 SEC)

GF

CR5

GROUND FAULTRELAY

TO GROUND FAULTRELAY RESET CONTACTS

HARMONICFILTER

CR2

L1

L2

L3

U

V

W

CR1

CR2

53

55

12

18

01

01

W

W

02

03

G

ETM

SPEEDCONTROL

SPEEDFEEDBACK

PLCOUTPUT

DISCONNECTINTERLOCK

H-O-A IN "AUTO" TO SCADAI/O MODULE

LEAKAGE

WINDINGOVER-TEMPERATURE

LEAKAGE

PUMP MOTORPROTECTION RELAY

RESET LIQUID LEVELSWITCH

SUBMERSIBLE PUMP MOTOR

WINDING TEMP. SW.'S

CR4

CR3

R

R

CR5

A GROUND FAULT

WALL MOUNTED NEXTTO VFD ENCLOSURE

TANK DEWATERING PUMP NO.1 CONTROL ELEMENTARYNOT TO SCALE

3 PHASE INVERTERDUTY MOTOR

(TYPICAL FOR TANK DEWATERING PUMP NO.2)

LEAKAGESHUTDOWNRELAY

WINDING OVER-TEMPERATUREWINDING OVER-TEMPERATURESHUTDOWNRELAY

GROUND FAULTRELAY POWER

CR3LEAKAGE &OVERTEMPSTATUS TOSCADA I/OMODULE

CR4

CR3 CR4

-

+

GF

CR3

RESET

400

800

(10 SEC)

M

OL

OL

OL

M

ETM

L1

L2

L3

HAND AUTO

G

T1

T3

T2

480/120 PRIMARY50 VA EXTRACAPACITY 120VSECONDARY

OFF

X00 M MOTOR STARTERCONTACTOR

ELAPSED TIME METER

RUNNING

480V,3ɸ60HZ

SUPPLY

00X

OLCR2CR1

CHOPPERPUMP

M

RUN STATUS TOSCADA I/O MODULE

REMOTEAUTO START

WINDING OVER-TEMPERATURESHUTDOWN RELAY

WINDING OVER-TEMPERATURE

LEAKAGESHUTDOWN RELAY

LEAKAGE

WINDINGOVER-TEMPERATURE

LEAKAGE

PUMP MOTORPROTECTION RELAY

RESET

M

LIQUID LEVELSWITCH

SUBMERSIBLE PUMP MOTOR

WINDING TEMP. SW.'S

CR2

CR1

DISCONNECTINTERLOCK

G

R

R

TO GROUND FAULTRELAY RESET CONTACTS

CR3

GROUND FAULTRELAY

CR3

A

GROUND FAULTRELAY POWER

GROUND FAULT

CONTROL STATION"CS" AT MCC

TERMINAL IN STARTER(TYPICAL)

CONTACT FROM SCADACLOSES TO RUN MOTOR

CHOPPER PUMP CONTROL ELEMENTARYNOT TO SCALE

SEENOTE1

VARIABLEFREQUENCYDRIVE(VFD)

MCC-1

TO SCADA SYSTEMMAIN CONTROL PANEL

{

XP

HOA

MPMR

JB

XP

XP

NOT TO SCALE(TYPICAL FOR PUMP NO. 2)

SCHEMATIC

TANK DEWATERING PUMP NO.1 DIAGRAM

64

STORAGE TANKCLASS I, DIVISION 1, GROUP D

HAZARDOUS AREA

ELECTRICROOM(101)

UNCLASSIFIED

CS

DS

3/4"C w/2-#16 TSP, SPEED CONTROLAND SPEED FEEDBACK

3/4"C w/14-#14, IN-AUTO MODE,START/STOP, RUN STATUS, FAULT STATUS,MOISTURE ALARM, TEMPERATURE ALARM

1-1/2"C w/3-#2, 1-#6GRD(PUMP POWER)

SEAL OFFFITTING(TYPICAL)

3/4"C w/16-#14 (MOISTURE/TEMPERATURE,DISC AUX, HOA, IN LOCAL TO PLC,5 SPARES)

3/4"C w/2-#14 (DISC. AUX)

JUNCTION BOX, PROVIDEWITH TERMINAL BLOCKS3/4"C w/5-#14

STRAIN RELIEFBUSHING

PUMP MANUFACTURER/SUPPLIERPROVIDED CABLE ASSEMBLY, WITHCONDUCTORS FOR PUMP POWER, ANDMOISTURE/TEMPERATURE SENSOR

SUBMERSIBLE PUMP MOTOR WITHINTEGRAL MOTOR WINDING THERMALPROTECTORS AND MOISTURE SENSOR.

1. MONITORING RELAY FOR TEMPERATURE/MOISTURE SENSOR SHALL BEPROVIDED BY PUMP MANUFACTURER/SUPPLIER. THE RELAY SHALL BEPROVIDED TO THE VFD MANUFACTURER FOR INSTALLATION AT THEFACTORY. THE ELECTRICAL CONTRACTOR SHALL COORDINATE THETRANSFER OF THE RELAY WITH THE GENERAL CONTRACTOR.

NOTE:

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64NOT TO SCALE

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-302ELEMENTARY DIAGRAMSNO. DATE REVISION INT.

1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

M

OLL1

L2

L3

G

T1

T3

T2

480V PRIMARY50 VA EXTRA CAPACITY120V SECONDARY

M

ELAPSEDTIME METER

RUNNING

480V,3ɸ60HZ

SUPPLY

H-O-A IN "AUTO"TO SCADA I/O MODULE

OL

REMOTEAUTO START

MOTOR

M

ETM

HAND AUTOOFF

X00

00X

00X

M

M

RUN/FAULT STATUSTO SCADA I/O MODULEFAULT

DISCONNECTINTERLOCK

MOTORSTARTER COIL

M

OFF

ANTI CONDENSATION HEATER

R

G

TERMINAL IN STARTER(TYPICAL)

CONTACT FROM SCADA I/OMODULE CLOSES TO RUNMOTOR

SUPPLY FAN SF-1 CONTROL ELEMENTARYNOT TO SCALETYPICAL FOR SUPPLY FAN SF-2

FIRE ALARMDISABLEFROM FACP

PRE-1 CONTROL ELEMENTARYNOT TO SCALE

COOLINGT'STAT

NL

AUTOHAND

X

OFF

LP1-13

(120 VAC)

X

CR

MANUAL MOTORSTARTING SWITCH CR

1/25

PRE-1MOTOR

CR

LOUVER L-2ACTUATOR

PRE-2 CONTROL ELEMENTARYNOT TO SCALE

NL

LP1-14

(120 VAC)

MANUAL MOTORSTARTING SWITCH

1/20

PRE-2MOTOR

TYPICAL FOR PRE-3 (LP1-13) AND PRE-4 (LP1-14)

M

OLL1

L2

L3

G

T1

T3

T2

480V PRIMARY50 VA EXTRA CAPACITY120V SECONDARY

M

ELAPSEDTIME METER

RUNNING

480V,3ɸ60HZ

SUPPLY

OL

MOTOR

M

ETM

M

M

RUN/FAULT STATUSTO SCADA I/O MODULEFAULT

DISCONNECTINTERLOCK

MOTORSTARTER COIL

M

OFF

ANTI CONDENSATION HEATER

R

G

TERMINAL IN STARTER(TYPICAL)

SUPPLY FAN SF-3 CONTROL ELEMENTARYNOT TO SCALETYPICAL FOR SUPPLY FAN SF-4, EF-1 AND EF-2

START STOP

FIRE ALARMDISABLEFROM FACP

M

OLL1

L2

L3

G

T1

T3

T2

480V PRIMARY50 VA EXTRA CAPACITY120V SECONDARY

M

ELAPSEDTIME METER

RUNNING

480V,3ɸ60HZ

SUPPLY

OL

MOTOR

M

ETM

M

FAULT STATUSTO SCADA SYSTEMFAULT

DISCONNECTINTERLOCK

MOTORSTARTER COIL

M

OFF

ANTI CONDENSATION HEATER

R

G

TERMINAL IN STARTER(TYPICAL)

ODOR CONTROL BLOWER BL-1 CONTROL ELEMENTARYNOT TO SCALETYPICAL FOR ODOR CONTROL BLOWER BL-2

FAULT

OL

R

START/STOP

FIRE ALARMDISABLEFROM FACP

M

SYSTEM STARTFROM SCADASYSTEM

IN MCC-N IN BLOWER CONTROLPANEL

ODOR CONTROL BLOWERS BL-1, AND BL-2 SCHEMATICNOT TO SCALE

125

SEAL OFF

125

SEAL OFF

ODOR CONTROLBLOWER

PANEL NO.1

ODOR CONTROLBLOWER

PANEL NO.2

JB

LP2-5(120V, 1 PHASE)

ODORCONTROLBLOWER

BL-1STARTER

IN BLOWER

FACP

3/4"C w/4-#14(FIRE ALARMDISABLE)

3/4"C w/10-#14(BL-1 FAULT STATUS,SYSTEM START)

3/4"C w/2-#14(START/STOP)

3/4"C w/4-#14,(RUN IND, FAIL IND)

3/4"C w/2-#12,1-#12 GRD

3/4"C w/2-#12,1-#12 GRD

3/4"C w/2-#14(START/STOP)

3/4"C w/4-#14,(RUN IND, FAIL IND)

2"C w/3-#4/0,1-#2GRD

2"C w/3-#4/0,1-#2GRD

125

DS DS

ODOR CONTROLBLOWER BL-1

ODOR CONTROLBLOWER BL-2

3/4"C w/10-#14(BL-2 FAULT STATUS,SYSTEM START)

2"C w/3-#4/0,1-#2GRD

2"C w/3-#4/0,1-#2GRD

2"C w/3-#4/0,1-#2 GRD TOMCC-N

2"C w3-#4/01-#2 GRD TOMCC-N

PANEL NO.1

ODORCONTROLBLOWER

BL-1STARTER

IN BLOWERPANEL NO.2

LP2-4(120V, 1 PHASE)

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64NOT TO SCALE

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-303ELEMENTARY DIAGRAMSNO. DATE REVISION INT.

1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

NOT TO SCALE

FIRE ALARM SYSTEM RISER DIAGRAM

203

RJ-31X RJ-31X

P P P

WP

S

SS

P

1. REFER TO SPECIFICATION SECTION 16721 FOR ADDITIONAL SUBMITTAL,DEVICE, CONDUIT, WIRING AND INSTALLATION REQUIREMENTS.

2. ALL SYSTEMS SHALL BE A "CLASS A" TYPE SYSTEM.3. DESIGN RATING OF HEAT DETECTORS IS 40'-0" BEFORE DERATING IS

REQUIRED.4. ALL STROBES SHALL BE RATED A MINIMUM OF 15 CANDELAS UNLESS

OTHERWISE NOTED.5. ENCLOSURE AND BOXES SHALL BE COLORED RED.6. CONDUIT SHALL BE IDENTIFIED BY A LABEL READING "FIRE" EVERY 10 FEET

AND ON EACH SIDE OF WALLS OR FLOORS.

FIRE ALARM SYSTEM NOTES:

P

TELEPHONE RISER DIAGRAM

X

X

NOT TO SCALE

ELECTRICAL ROOMWALLDATA

DATAOFFICE

VESTIBULE

STORAGEXXXX

WALL

PBx

XXXX

XXXX

XXXX

1

12

2

1

3

2

3/4"C w/1-2 PR TELEPHONE CABLE

3/4"C w/2-2 PR TELEPHONE CABLE

3/4"C w/4-2 PR TELEPHONE CABLE

1

2

3

CHOPPER PUMPMOTOR

STARTER INMCC-E

TO SCADA SYSTEMMAIN CONTROL PANEL

XP

HOA

MPMR

JB

XP

XP

NOT TO SCALE

SCHEMATIC

CHOPPER PUMP DIAGRAM

25

STORAGE TANKCLASS I, DIVISION 1, GROUP D

HAZARDOUS AREA

ELECTRICROOM(101)

UNCLASSIFIED

CS

DS

3/4"C w/14-#14, IN-AUTO MODE,START/STOP, RUN STATUS, FAULT STATUS,MOISTURE ALARM, TEMPERATURE ALARM

3/4"C w/3-#8, 1-#10GRD(PUMP POWER)

SEAL OFFFITTING(TYPICAL)

3/4"C w/16-#14 (MOISTURE/TEMPERATURE,DISC AUX, HOA, IN LOCAL TO PLC,5 SPARES)

3/4"C w/2-#14 (DISC. AUX)

JUNCTION BOX, PROVIDEWITH TERMINAL BLOCKS3/4"C w/5-#14

STRAIN RELIEFBUSHING

PUMP MANUFACTURER/SUPPLIERPROVIDED CABLE ASSEMBLY, WITHCONDUCTORS FOR PUMP POWER, ANDMOISTURE/TEMPERATURE SENSOR

SUBMERSIBLE PUMP MOTOR WITHINTEGRAL MOTOR WINDING THERMALPROTECTORS AND MOISTURE SENSOR.

1. MONITORING RELAY FOR TEMPERATURE/MOISTURE SENSOR SHALL BE PROVIDED BYPUMP MANUFACTURER/SUPPLIER. THE RELAY SHALL BE PROVIDED TO THE MCCMANUFACTURER FOR INSTALLATION AT THE FACTORY. THE ELECTRICALCONTRACTOR SHALL COORDINATE THE TRANSFER OF THE RELAY WITH THEGENERAL CONTRACTOR.

NOTE:

STAIRWELL SUMP PUMP SCHEMATICNOT TO SCALE

SUMPPUMP

MOTOR

HIGH LEVEL FLOATLAG PUMP START FLOAT

SUMP PUMPCONTROLPANEL IN

MECHANICALROOM

460/3 PHASESCADA

SYSTEM

LEAD PUMP START FLOATPUMP STOP FLOAT

STRAIN RELIEF BUSHING

FLOOD LEVEL FLOAT

JB

3/4"C w/3-#12,1-#12 GRD 3/4"C w/12-#14 (RUN INDICATION,

HIGH WATER LEVEL, FLOODALARM, COMMON FAIL)

2"C w/MANUFACTURERSCABLE

MANUFACTURERSCABLE

MPMR

1

SUMPPUMP

MOTOR

MPMR

1

XPDS

XPDS 3/4"C w/10-#14

MECHANICAL ROOMUNCLASSIFIED

STORAGE AREA STAIRWELLCLASS I, DIVISION 1, GROUP D

HAZARDOUS AREA

CCTV RISER DIAGRAM

NOTES:

BILL OF MATERIALS

NOT TO SCALE

MONITORDIGITAL VIDEORECORDER

120V

120V

COAX CABLE

C-303C-302

LP2-6(120V)

C-301

CAMERA @ENTRANCE

CAMERA @JUNCTIONCHAMBER

CAMERA @FLAP GATE

STRUCTURE

GE SECURITY 19 INCH TRU-VISION LCD MONITOR(1) #GEL-19DVGE SECURITY TRU-VISION DVR 10 4-CHANNEL DIGITAL VIDEO RECORDER(1) #TVR-1004-500GE SECURITY TRU-VISION 540 TVL CAMERAS(3) #TVP-12C-E w/TVP-ESB

1. COORDINATE THE EXACT LOCATION OF THE EQUIPMENTWITH THE OWNER.

2. PROVIDE A MINIMUM OF FOUR HOURS TRAINING FOROWNERS PERSONNEL.

3. EQUIPMENT SPECIFIED IS GE SECURITY OR ASAPPROVED BY OWNER.

LP2-6(120V)

LP2-6(120V)

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64NOT TO SCALE

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-304FIRE, SECURITY & TELEPHONE SCHEMATICS

INCOMING TELEPHONE SERVICE FROM THE UTILITY POLETO TELEPHONE MOUNTING PANEL FURNISHED AND INSTALLEDBY THE TELEPHONE UTILITY. THE DUCTBANK CONDUITS ANDSERVICE RISER PROVIDED AND INSTALLED UNDER THISCONTRACT.

NOTE:

FIRE ALARMCONTROL PANEL

LOCATED INHALLWAY

SMOKE DETECTORMOUNTED ABOVE FACPIN HALLWAY

SEALOFFS ONLY REQUIREDCONDUITS EXIT AND ENTERHAZARDOUS AREAS (TYPICAL)

3/4"C w/2-#16 (TYPICAL FORALL SIGNALING LINE CIRCUITS)

3/4"C w/2-#14 (TYPICAL FOR ALL NOTIFICATIONAPPLIANCE CIRCUITS)

3/4"C w/#10 GRD

CABLE FURNISHEDBY FACP SUPPLIER

3/4"C w/1-4 PRTELEPHONE CABLE TO TELEPHONE

TERMINATION BOARD(TWO SEPARATE TELEPHONE LINES)

TO NEC DEDICATEDEARTH GROUND

3/4"C w2-#12,1-#12 GRD

3/4"C w/4-#14 (FACPIN ALARM MODE,TROUBLE MODE)

UTILITIES BUILDING

STORAGE TANK AREACLASS 1, DIVISION 1, GROUP D AREA

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

EQUIPMENT IN MOTOR CONTROL CENTER MCC-N

COMP.NO.

EQUIPNO.

EQUIPMENTDESCRIPTION

LOADCIRCUIT BREAKER

TRIP FRAME

STARTER

SIZE TYPEDOOR MOUNTED

ACCESSORIES

FIELD MOUNTED DEVICES

BY ELECTRICAL BY OTHERS

SEE ELEMENTARYOR SCHEMATIC

DIAGRAM ON SHEETN1A MCB-N MAIN CIRCUIT BREAKER FOR

MAIN FEEDER MF-A-- 1600AT 3000AF -- -- CBDH, NP -- -- 100%

RATED CB

N2A PM POWER METER- (FEEDER MF-A) -- -- -- -- -- NP --

-- --

N2G BL-1 ODOR CONTROL BLOWER 225 250 - -- --

N2S EF-1 EXHAUST FAN EF-1 40 150AF 2 -- --

N3A SF-1 SUPPLY AIR FAN 15 HP 250AF 2 -- DS, CS -- E-303

N3E -- E-303

CBDH, NP,RUN IND, FAIL IND

N2M -- ODOR CONTROL BLOWER (FUTURE) -- 225 250 -- -- -- -- ----

CBDH, NP,RUN IND, FAIL IND

DS

DS

15 HP

125 HP

CBDH, NP,RUN IND, FAIL IND

E-302

E-303

SF-2 SUPPLY AIR FAN 15 HP 250AF 2 -- CBDH, NP,RUN IND, FAIL IND

40

40

N2E TVSS TRANSIENT VOLTAGE SURGE SUPPRESSOR -- 150 -- -- CBDH, NP -- -- --60

N4G -- ODOR CONTROL BLOWER (FUTURE) -- 225 250 -- -- -- -- ----

N4M EF-2 EXHAUST FAN EF-2 40 150AF 2 -- --

N4Q SF-3 SUPPLY AIR FAN 25 HP 150AF 2 -- DS -- E-303

CBDH, NP,RUN IND, FAIL IND

DS15 HP

CBDH, NP,RUN IND, FAIL IND

E-303

70

N5A SF-4 SUPPLY AIR FAN 25 HP 150AF 2 -- DS -- E-303CBDH, NP,RUN IND, FAIL IND

70

E3E EUH-2 ELECTRIC UNIT HEATER 5 KW 150AF -- -- CBDH, NP DS -- --20

E2I EUH-1 UNIT HEATER 5 KW 150AF -- -- DS -- --CBDH, NP20

E2E -- CHOPPER PUMP 25 HP 70 150 2 FVNR DS, CS -- --

E2A -- TANK DEWATERING PUMPNO.1

125 150 VFD -- --CBDH, NP,RUN IND, FAIL IND

DS, CS64 HP E-302

E2M ECH-1 ELECTRIC CABINET HEATER 3.3 KW 150AF -- -- DS -- --CBDH, NP20

E2Q EDH-1 HEATING COIL 7.5 KW 150AF -- -- DS -- --CBDH, NP20

E3A -- 125 150 VFD -- --DS, CS64 HP E-302TANK DEWATERINGPUMP NO.2

E3I EUH-3 ELECTRIC UNIT HEATER 5 KW 150AF -- -- CBDH, NP DS -- --20

N5E -- SUMP PUMP CONTROL PANEL 2-1HPPUMPS

150AF -- -- CBDH, NPRUN IND

DS -- --20

DS, CS

E3M -- ENTRANCE GATE OPERATOR 1HP 150AF -- -- - - -- --20

N3I - SPARE - - 2 -- CBDH, NP-

N3M MTS-1 MANUAL TRANSFER SWITCH -- 400AF -- -- NP -- -- --300

N4A BL-2 ODOR CONTROL BLOWER 225 250 -- -- --DS125 HP E-302

N4U - SPARE - - 2 -- CBDH, NP,RUN IND, FAIL IND

-

EQUIPMENT IN MOTOR CONTROL CENTER MCC-E

N5I-N5U

- SPARE - - 1 -- CBDH, NP-

E1A - SPACE - - -- -- - -- ----

E1K TVSS TRANSIENT VOLTAGE SURGE SUPPRESSOR - 150AF -- -- - -- --CBDH, NP60

E1M MCB-E MAIN CIRCUIT BREAKER - 400AF -- -- - -- --CBDH, NP300

E2U - SPARE - 150AF 1 FVNR - -- --CBDH, NP20

CBDH, NP,RUN IND, FAIL IND

CBDH, NP,RUN IND, FAIL IND

E3Q -E3U

- SPARE - - 1 -- CBDH, NP- - -- --

N6A SUG-1 JUNCTION CHAMBER SLUICE GATE 5 HP 150AF - -- DS ---

CBDH, NP,RUN IND, FAIL IND

20

N6E SUG-2 JUNCTION CHAMBER SLUICE GATE 5 HP 150AF - -- DS -- -CBDH, NP,RUN IND, FAIL IND

20

N6I SUG-3 JUNCTION CHAMBER SLUICE GATE 5 HP 150AF - -- DS -- -CBDH, NP,RUN IND, FAIL IND

20

N6M - SPACE

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64NOT TO SCALE

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-305SCHEDULES

Total Amps: 49 A 48 A 49 ATotal Load: 5939 VA 5752 VA 5914 VA

41 Spare 20 A 1 0 VA 0 VA 1 20 A Spare 4239 Spare 20 A 1 0 VA 0 VA 1 20 A Spare 4037 STAIR 104 & STORAGE TANK STAIRWELL 20 A 1 64 VA 0 VA 1 20 A Spare 3835 SPARE 20 A 1 0 VA 80 VA 1 20 A EMERGENCY CALL PUSHBUTTON 3633 MOBILE GENERATOR CONNECTION BOX 20 A 1 200 VA 0 VA 1 20 A SPARE 3431 STORAGE TANK TASK LIGHTING 20 A 1 875 VA 700 VA 1 20 A STORAGE TANK ROOF TASK LIGHTING 3229 STORAGE TANK LIGHTS 20 A 1 896 VA 490 VA 1 20 A EXIT LIGHTS 3027 STORAGE TANK LIGHTS 20 A 1 960 VA 80 VA 1 15 A FLOW TRANSMITTER FIT-200 2825 DAMPER D-1 20 A 1 120 VA 2000 -- -- -- 2623 GFI RECEPTACLE @ JUNCTION CHAMBER 20 A 1 180 VA 2000 -- -- -- 2421 LEVEL TRANS. LIT-200, LIT-201, LIT-202 15 A 1 180 VA 2000 3 25 A ELECTRIC WATER HEATER 2219 BATTERY CABINET 20 A 1 200 VA 360 VA 1 20 A SCADA SYSTEM ENCLOSURE 2017 FIRE ALARM CONTROL PANEL 20 A 1 600 VA 120 VA 1 15 A LEVEL TRANSMITTER LIT-203, LIT-204 1815 SUPPLY FAN SF-5 20 A 1 300 VA 420 VA 1 20 A CENTER FLUSH CONTROL PANEL 1613 PRE-1 AND PRE-3 20 A 1 120 VA 600 VA 1 20 A PRE-2 AND PRE-4 1411 -- -- -- 500 VA 600 VA -- -- -- 129 EBH-1 20 A 2 500 VA 600 VA 2 20 A PTAC-1 107 EXTERIOR LIGHTS 20 A 1 0 VA 0 VA 1 20 A MECHANICAL ROOM RECEPTACLES 85 MECH. RM 105, HALL 102, VEST. 103 LIGHTING 20 A 1 256 VA 192 VA 1 20 A OFFICE 107, BATH 106 LIGHTING 63 ELECTRIC ROOM 101 LIGHTING 20 A 1 384 VA 128 VA 1 20 A HALL 102, BATH 106 RECEPTACLES 41 ELECTRIC ROOM 101 RECEPTACLES 20 A 1 360 VA 540 VA 1 20 A OFFICE 107 RECEPTACLES 2

CKT Circuit Description Trip Poles A B C Poles Trip Circuit Description CKT

Enclosure: Type 1 MCB Rating: 225 AMounting: Surface Wires: 4 Mains Rating: 225 A

Supply From: T-1 Phases: 3 Mains Type:Location: ELECTRIC 101 Volts: 120/208 Wye A.I.C. Rating:

Branch Panel: LP1

1. FOR THREE PHASE CIRCUITS - PROVIDE 3/4"C w/3-#12, 1-#12G FOR 20 AMPCIRCUITS SERVING EQUIPMENT WITHIN 60' OF PANELBOARD, UNLESSOTHERWISE NOTED. INCREASE WIRE AND CONDUIT SIZES IN ACCORDANCEWITH SPECIFICATION SECTIONS 16110, 16120, AND THE NEC FOR LONGERCIRCUITS OR CIRCUITS MORE THAN 20 AMPS.

2. FOR SINGLE PHASE CIRCUITS - PROVIDE 3/4"C w2-#12, 1-#12 GRD FOR 20AMP CIRCUITS SERVING EQUIPMENT WITHIN 60' OF PANELBOARD, UNLESSOTHERWISE NOTED. INCREASE WIRE AND CONDUIT SIZE IN ACCORDANCEWITH SPECIFICATION SECTIONS 16120, 16110, AND NEC FOR LONGERCIRCUITS OR CIRCUITS MORE THAN 20 AMPS.

3. ALL RECEPTACLE CIRCUITS SHALL BE POWERED THROUGH A GFCI CIRCUITBREAKER , EXCEPT AS FOLLOWS:

A. WHEN THE DISTANCE TO THE FIRST RECEPTACLE IS OVER 50' INLENGTH, USE A STANDARD CIRCUIT BREAKER AND PROVIDE AFEED THROUGH GFCI TYPE RECEPTACLE.

B. ALL RECEPTACLES MOUNTED IN LIGHT POLES OR ON HANDRAILSHALL BE GFCI TYPE.

C. PROVIDE GFCI RECEPTACLES AT ALL LOCATIONS WHERERECEPTACLES ARE MORE THAN 50' APART.

D. PROVIDE GFCI RECEPTACLES FOR ALL SINGLE PHASE CORDCONNECTED, SUBMERSIBLE PUMP, MIXERS, ETC.

PANELBOARD GENERAL NOTES:

Total Amps: 8 A 11 A 8 ATotal Load: 970 VA 1265 VA 945 VA

41 4239 4037 3835 3633 3431 3229 3027 2825 2623 2421 2219 2017 1815 1613 1411 129 OCV-1 & OCV-2 2" DRAIN PIPING HEAT TRACE 20 A 1 200 VA 107 STORAGE TANK RECEPTACLES 20 A 1 360 VA 135 VA 1 20 A SECURITY GATE CARD READER 85 ODOR CONTROL BLOWER PANEL NO.1 20 A 1 540 VA 405 VA 1 20 A SITE SECURITY CAMERAS 63 SITE LIGHTING 20 A 1 525 VA 540 VA 1 20 A ODOR CONTROL BLOWER PANEL NO.2 41 DAVIT CRANE 20 A 1 300 VA 175 VA 1 20 A FLAP VALVE STRUCTURE LIGHTING 2

CKT Circuit Description Trip Poles A B C Poles Trip Circuit Description CKT

Enclosure: Type 1 MCB Rating: 100 AMounting: Surface Wires: 4 Mains Rating: 100 A

Supply From: Phases: 3 Mains Type:Location: ELECTRIC 101 Volts: 120/208 Wye A.I.C. Rating:

Branch Panel: LP2

CBDHCSDSFAIL INDNPRUN IND

- CIRCUIT BREAKER DISCONNECT HANDLE- CONTROL STATION- DISCONNECT SWITCH- FAIL INDICATING LIGHT- NAMEPLATE- RUN INDICATING LIGHT

LEGEND

NO. DATE REVISION INT.1 04/11 ISSUED FOR APPROVAL MRW2 08/11 AS BID MRW

4. FOR HEAT TRACE CIRCUITS PROVIDE GFCI, 30mA CIRCUIT BREAKERS

500 600AF

(ADDENDUM NO. 1)

POWER CONDUCTOR AND CONDUIT SCHEDULE

FROM

MF-A

DESIGNATION

INCOMINGUTILITY TRANSFORMER "A"

REMARKSCONDUIT

MAIN CIRCUIT BREAKERMOTOR CONTROL CENTER

TO CONDUCTORS

5(4") 5-#4/0 GRD5-500 MCM PER PHASE

SIZE QTY/SIZE

-

-P-1 -

-

-

P-3 CONTROL PANELODOR CONTROL BLOWER BL-1 2" #2 GRD

3-#4/0 -

P-4 EF-1EXHAUST FAN 3/4" 1-#10 GRD, 2-#14

3-#8 -

P-5 -

P-6 -

P-1A

P-1B

MOTOR CONTROL CENTERMCC-N

MOTOR CONTROL CENTERMCC-N

P-7

75 KVATRANSFORMER T-1

1-#6 GRD3-#1

-

P-8

-

P-10 -

P-10B -

P-11A

-

P-11B

3.3 KWECH-1 ELECTRIC CABINET HEATER 3/4" 1-#12 GRD

3-#12

-

P-13

LINE REACTORTANK DEWATERING PUMP NO.1

-

TANK DEWATERING PUMP NO.1LINE REACTOR VFD

TANK DEWATERING PUMP NO.1

-

TANK DEWATERING PUMP NO.1VFD PUMP NO.1

TANK DEWATERING

-

SF-1SUPPLY AIR FAN 3/4" 1-#10 GRD, 2-#14

3-#8MOTOR CONTROL CENTERMCC-N

SF-2SUPPLY AIR FAN 3/4" 1-#10 GRD, 2-#14

3-#8MOTOR CONTROL CENTERMCC-N

MOTOR CONTROL CENTERMCC-E

MOTOR CONTROL CENTERMCC-N

MOTOR CONTROL CENTERMCC-N

MOTOR CONTROL CENTERMCC-N

MOTOR CONTROL CENTERMCC-E

LP2PANELBOARD 1 1/4" 1-#8 GRD

4-#2

-

PANELBOARDLP1

EF-2EXHAUST FAN 3/4" 1-#10 GRD,2-#14

3-#8

SF-3SUPPLY AIR FAN 1" 1-#8 GRD, 2-#14

3-#4

SF-4SUPPLY AIR FAN 1" 1-#8 GRD, 2-#14

3-#4 -

-

-

MOTOR CONTROL CENTERMCC-E PUMP

CHOPPER 1" 1-#8 GRD, 2-#143-#4

-

-

-

-

MOTOR CONTROL CENTERMCC-E 1 1/2" #6 GRD

3-#2

P-14

LINE REACTORTANK DEWATERING PUMP NO.2

TANK DEWATERING PUMP NO.2LINE REACTOR VFD

TANK DEWATERING PUMP NO.2

P-15

TANK DEWATERING PUMP NO.2VFD PUMP NO.2

TANK DEWATERING

MOTOR CONTROL CENTERMCC-E

-

1 1/2" #6 GRD3-#2

1 1/2" #6 GRD, 2-#143-#2

1 1/2" #6 GRD3-#2

1 1/2" #6 GRD3-#2

1 1/2" #6 GRD, 2-#143-#2

P-9

5 KWEUH-1 UNIT HEATER 3/4" 1-#12 GRD

3-#12

MOTOR CONTROL CENTERMCC-E

P-11

P-16 MOTOR CONTROL CENTERMCC-E 5 KW

EUH-2 UNIT HEATER 3/4" 1-#12 GRD3-#12

P-17 MOTOR CONTROL CENTERMCC-E 5 KW

EUH-3 UNIT HEATER 3/4" 1-#12 GRD3-#12

P-18 MOTOR CONTROL CENTERMCC-N CONTROL PANEL

SUMP PUMP 3/4" 1-#12 GRD3-#12

P-18A SUMP PUMPCONTROL PANEL NO.1

SUMP PUMP 3/4" 1-#12 GRD3-#12

P-18B SUMP PUMPCONTROL PANEL NO.2

SUMP PUMP 3/4" 1-#12 GRD3-#12

P-19 MOTOR CONTROL CENTERMCC-E 7.5 KW

HEATING COIL EDH-1 3/4" 1-#12 GRD3-#12

P-12 CONTROL PANELODOR CONTROL BLOWER BL-2 2" #2 GRD

3-#4/0MOTOR CONTROL CENTERMCC-N

P-3A MOTOR BL-1ODOR CONTROL BLOWER 2" #2 GRD, 2-#14

3-#4/0 -ODOR CONTROL BLOWER BL-1CONTROL PANEL

ODOR CONTROL BLOWER BL-1CONTROL PANEL D-1

DAMPER 3/4" 1-#12 GRD2-#12P-3B

P-12A MOTOR BL-2ODOR CONTROL BLOWER 2" #2 GRD, 2-#14

3-#4/0 -ODOR CONTROL BLOWER BL-2CONTROL PANEL

ODOR CONTROL BLOWER BL-2CONTROL PANEL D-2

DAMPER 3/4" 1-#12 GRD2-#12P-12B

--P-20 MOTOR CONTROL CENTERMCC-N OPERATOR

ENTRANCE GATE 3/4" 1-#12 GRD3-#12

STUB-UP 6" AFF AND CAPP-21 ELECTRIC ROOM(NORTH WALL) OPERATOR

ENTRANCE GATE 1" PULLWIRE

1 1/2"

P-10A -LP1PANELBOARD 2 1/2" 1-#4 GRD

4-#4/0TRANSFORMER T-175 KVA

-P-22 SUG-102 1" PULLWIREMOTOR CONTROL CENTERMCC-N

SLUICE GATE

-P-23 1" PULLWIREMOTOR CONTROL CENTERMCC-N

-P-24 1" PULLWIREMOTOR CONTROL CENTERMCC-N

SUG-101SLUICE GATE

SUG-103SLUICE GATE

-P-2 MTS-1MANUAL TRANSFER SWITCH 2(3") 2-#2 GRD

2-#250 MCM PER PHASE

-P-2A CONNECTION BOXMOBILE GENERATOR

-P-2B

MOTOR CONTROL CENTERMCC-N

MANUAL TRANSFER SWITCHMTS-1

MCC-EMOTOR CONTROL CENTERMANUAL TRANSFER SWITCH

MTS-1

2(3")

2(3")

-T-1 2" PULLWIREINCOMING PRIMARYSERVICE POLE MOUNTING PANEL

MAIN TELEPHONE EQUIPMENT

PF-1 PRIMARYSERVICE POLE TRANSFORMER

PAD MOUNTED 3(4")1 SPARE PULLWIRE PRIMARY CONDUCTORS BY UTILITY

2-#2 GRD2-#250 MCM PER PHASE

2-#2 GRD2-#250 MCM PER PHASE

3

CONTROL CONDUCTOR AND CONDUIT SCHEDULE

FROM

C-001

DESIGNATION

MOTOR CONTROL CENTERMCC-1

REMARKSCONDUIT

PANELSCADA SYSTEM MAIN CONTROL

TO CONDUCTORS

2"

SIZE QTY/SIZE

INCLUDES SPARES

C-002 INCLUDES SPARES

C-003 SCADA SYSTEM MAIN CONTROLPANEL SCADA SYSTEM OFFICE

ETHERNET HUB 3/4" 1-CAT 6 CABLE -

-

-

-

-

2"

C-004

SEE P&ID SHEET I-101

MOTOR CONTROL CENTERMCC-1 PANEL

SCADA SYSTEM MAIN CONTROL

SCADA SYSTEM MAIN CONTROLPANEL BLOWER BL-1

ODOR CONTROL PANEL 3/4" 1-CAT 6 CABLE

C-005 SCADA SYSTEM MAIN CONTROLPANEL BLOWER BL-2

ODOR CONTROL PANEL 3/4" 1-CAT 6 CABLE

C-205B LS-205BRAINWATER STORAGE TANK CONTROL PANEL

CIRCULAR TANK FLUSHING SYSTEM 3/4" 2-#14

C-006 SCADA SYSTEM MAIN CONTROLPANEL CONTROL PANEL

CIRCULAR TANK FLUSHING SYSTEM 3/4" 1-CAT 6 CABLE

C-205A HIGH AND LOW LEVEL SWITCHESLS-205A 3/4" 4-#14CONTROL PANEL

CIRCULAR TANK FLUSHING SYSTEM

C-205C STATION @ CATWALK DOORSTART/STOP CONTROL 3/4" 2-#14CONTROL PANEL

CIRCULAR TANK FLUSHING SYSTEM

C-300 FLAP VALVE STRUCTURELIMIT SWITCHES AT 3/4" 8-#14SCADA SYSTEM MAIN CONTROL

PANEL

C-104 AT JUNCTION CHAMBERLSH-100 LEVEL SWITCH HIGH 3/4" 2-#14

SCADA SYSTEM MAIN CONTROLPANEL

C-105 AT JUNCTION CHAMBERLSH-101 LEVEL SWITCH HIGH 3/4" 2-#14

SCADA SYSTEM MAIN CONTROLPANEL

-C-007 SCADA SYSTEM MAIN CONTROLPANEL INDICATOR (AIT-214) VESTIBULE 103

GAS MONITOR TRANSMITTER/ 3/4" 1-CAT 6 CABLE

C-008 SCADA SYSTEM MAIN CONTROLPANEL STATION

EMERGENCY CALL 3/4" 2-#14

C-205 LE-205SUBMERSIBLE LEVEL TRANSDUCER 3/4" MANUFACTURERS CABLECONTROL PANEL

CIRCULAR TANK FLUSHING SYSTEM

SEE P&ID SHEET I-101

SEE P&ID SHEET I-101

SEE P&ID SHEET I-101

SEE P&ID SHEET I-101

C-206 CONTROL PANELSUMP PUMP 3/4" 12-#14 INCLUDES SPARES,

SEE P&ID SHEET I-101SCADA SYSTEM MAIN CONTROL

PANEL

C-009 ELECTRIC ROOM(NORTH WALL) OPERATOR

ENTRANCE GATE 1" PULLWIRE STUB-UP 6" AFF AND CAP

90-#14

10-#16 TSP

C-200 LOW LSL-200, LSL-201WET WELL LEVEL SWITCH 3/4" 4-#14PANEL

SCADA SYSTEM MAIN CONTROL SEE P&ID SHEET I-101

C-010 FIRE ALARMCONTROL PANEL MCC-1

MOTOR CONTROL CENTER 3/4" 2-#14 FIRE ALARM DISABLE ALARM

C-011 FIRE ALARMCONTROL PANEL BLOWER BL-1 & BL-2

ODOR CONTROL PANELS 3/4" 4-#14 FIRE ALARM DISABLE ALARM2 CONDUCTORS TO EACH BLOWER PANEL

C-103 SUG-103SLUICE GATE ACTUATOR 3/4" 10-#14SCADA SYSTEM MAIN CONTROL

PANEL

C-102 SUG-102SLUICE GATE ACTUATOR 3/4" 10-#14

SCADA SYSTEM MAIN CONTROLPANEL

C-101 SUG-101SLUICE GATE ACTUATOR 3/4" 10-#14

SCADA SYSTEM MAIN CONTROLPANEL

SEE SHEETS E-304 & E-309C-301 ENTRANCE GATESECURITY CAMERA AT 3/4" COAX CABLE

SECURITY SYSTEMMULTIPLEXER

SEE SHEETS E-304 & E-309C-302 JUNCTION CHAMBERSECURITY CAMERA AT 3/4" COAX CABLE

SECURITY SYSTEMMULTIPLEXER

SEE SHEETS E-304 & E-309C-303 FLAP GATE STRUCTURESECURITY CAMERA AT 3/4" COAX CABLESECURITY SYSTEM

MULTIPLEXER

C-207 LIMIT SWITCH AT CATWALKUPPER LEVEL TANK DOOR 3/4" 6-#14 INCLUDES SPARESSCADA SYSTEM MAIN CONTROL

PANEL

C-208 LIMIT SWITCHLOWER LEVEL TANK DOOR 3/4" 6-#14 INCLUDES SPARESSCADA SYSTEM MAIN CONTROL

PANEL

SYRACUSE, NEW YORK

SCALE:

THIS DRAWING WAS PREPARED AT THE SCALE INDICATED IN THETITLE BLOCK. INACCURACIES IN THE STATED SCALE MAY BEINTRODUCED WHEN DRAWINGS ARE REPRODUCED BY ANY

MEANS. USE THE GRAPHIC SCALE BAR IN THE TITLE BLOCK TODETERMINE THE ACTUAL SCALE OF THIS DRAWING.

NO ALTERATIONS PERMITTED HEREON EXCEPT AS PROVIDED UNDER SECTION 7209SUBDIVISION 2 OF THE NEW YORK STATE EDUCATION LAW

In charge of

Designed by

Drawn by

Checked by

Date

File NumberONONDAGA COUNTY DEPARTMENT OF WATER ENVIRONMENT PROTECTION

LOWER HARBOR BROOK CSO STORAGE FACILITY 006.64NOT TO SCALE

ELECTRICAL

MRW

JEC

JEC

MRW

08/11 E-306CONDUIT SCHEDULES