ID FAN VFD

-

Upload

dhananjay-nandanpawar -

Category

Documents

-

view

1.213 -

download

68

Transcript of ID FAN VFD

VFD Proposal for ID Fan

By Santosh Mestry , Sr. Manager (OPN)

confidentia

l 2

Flow of Presentation

Company & Plant Profile Background Principle Of Hydraulic Coupling Hydraulic Coupling Losses Loss Calculation by Heat Loss method Validation by Slip Loss method Efficiency Aspect Recommendation Benefit

confidentia

l 3

Company Profile

confidentia

l 4

2 x 250 MW Thermal Plant, Supplies Electricity to Mumbai.

Amongst top performers in the world, on all operational parameters:

o lowest heat-rate. o highest capacity utilisation.o least secondary fuel consumption.o highest plant availability.

Certified for Integrated Management System (ISO9001, 14000, 18000),

SA 8000, ISMS 27000.

Energy efficiency at core.

DTPS

Plant Profile

confidentia

l 5

Dahanu Thermal Power Plant (DTPS)

confidentia

l

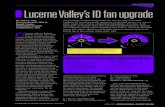

Background : Function of ID Fan Thermal power plant has several fans such as Induced draft (ID)

fans, Forced draft (FD) Fans, Primary air fans (PA fans). These fans contribute to significant auxiliary power consumption. ID fans alone contribute to about 12% of total auxiliary power consumption

The function of Induced Draft fan is to suck the gases out of furnaces and push them into the stack. Boiler is provided with two nos. of Induced Draft Fans.

Each ID fan is provided with regulating damper control and scoop control for controlling the loading on fans, Inlet/Outlet gates for isolation to facilitate startup/maintenance of fan.

confidentia

l

GD-15

GD-16

TE 3no

s

STACK

TE 3nos

TE 3nos

FROM ECO

O2 ANA.

AUXAIR

MAIN

APH-A

MAIN

AUXAIR

APH-B

PTTE

3nos

GD-14

EP-B

EP-A

PT PT

GD-13

GD-9

GD-10GD-6

GD-5

GD-7 GD-11

GD-12

GD-8

GD-4

GD-2

GD-1 GD-3

PT TE

PT

O2 ANA.

O2 ANA.

GD-20

GD-19

ID FAN-B

ID FAN-A

PT

TE

PT

TE

HYD. COUP

GD-18

HYD. COUP

GD-17

CO ANA.

FLUE GAS PATH

Background : Function of ID Fan

confidentia

l 8

Technical specification of ID Fan

General specification: Application : ID Fan No per boiler : Two Type : NDZV 33 Sidor Medium handle : Flue gas Orientation : 45 degree inclined suction horizontal delivery

Fan Design rating: Capacity : 258 cu.m /sec Total head developed : 496 mmwc Temp. of medium : 145 degree C Speed : 701 RPM (Max at 100% scoop)

Type of Regulation :Speed & damper

Drive Motor: Motor Make : BHEL- Haridwar Rating : 1850 KW Speed : 745 RPM

confidentia

l

Flow ∞ Speed Pressure ∞ (Speed)2 Power ∞ (Speed)3

1 1

2 2

Q N

Q N

21 1

2 2

SP N

SP N

3

1 1

2 2

kW N

kW N

Varying the RPM by 10% decreases or increases air delivery by 10%.

Varying the RPM by 10% decreases or increases the static pressure by 19%.

Varying the RPM by 10% decreases or increases the

power requirement by 27%.

Where Q – flow, SP – Static Pressure, kW – Power and N – speed (RPM)

ENERGY CONSERVATION OPPORTUNITIES

FAN LAWS

confidentia

l

Principle of Hydraulic Coupling The ID fans are controlled with VFC control. The variable fluid coupling works on the principle of hydrodynamics. It consists of an impeller and rotor(runner) enclosed in a Casing. The impeller

is connected to the prime mover, while the rotor is connected to the driven machine. The coupling is filled with fluid, usually mineral oil. The speed of the driven equipment is varied by varying the quantity of fluid Supplied between the impeller and the runner.

10

confidentia

l

P Pump impellerT Turbine wheelS Scoop chamber1. Main lube oil pump2. Input shaft3. Output shaft4. Gear5. Working oil pump6. Scoop tube (adjustable)7. Scoop tube control (VEHS)

Principle of Hydraulic Coupling

confidentia

l

Hydraulic Coupling Losses:-

12

Hydraulic Losses

(W.R.T. Slip)

Losses (KW)

Sp

eed

(R

PM

)

Sli

p (

%)

Mechanical Losses (W. R. T. Speed)

There are two Types of Losses of power in VFC: Hydraulic Losses Mechanical Losses

confidentia

l

Hydraulic Coupling Losses: SLIP A difference between input & output speed is essential in a fluid coupling in

order to enable it to transmit torque. Difference between input & output speed is normally expressed as percentage of the input speed & refereed to as slip.

13

(I/P speed- O/P speed)Slip % = x100 I/P speed

confidentia

l

Hyd. Loss : Heat Loss Method

Total heat loss (KW) = ECW flow in m3/h x ECW Temp. Gain in °C x 1000 860 Kcal/hr

Hydraulic loss:-

14

SR. NO. PARAMETER UNITUNIT-1 UNIT-2

AVERAGEID FAN-1A ID FAN-1B ID FAN-2A ID FAN-2B

A

Cooling Water Flow of Working Oil Cooler

M3/Hr 104 78 89 105 94

BTemp. Rise of CW Across WO Cooler

Deg. Celsius 2.2 2.6 3 2.8 2.65

C Scoop Position % 55 54 53 54 54

D = (A*B*1000) 860

Total Heat Loss in VFC KW 266.04 235.81 310.46 341.861 288.54

confidentia

l

Validation SLIP Loss Method

15

O/P Power I/P Power = x100 1 - Slip

confidentia

l 16

SR. No. PARAMETER UNIT

UNIT-1 UNIT-2

AVERAGEID FAN-

1AID FAN-

1BID FAN-

2AID FAN-

2B

A Motor I/P Power KW 1224.00 1243.00 1257.00 1289.00 1253.25

B ID fan Motor Efficiency

% 96.00 96.00 96.00 96.00 96.00

C Scoop Position % 55.00 54.00 53.00 54.00 54.00

D Motor Speed RPM 733.00 734.00 731.80 733.50 733.08

E Fan Speed RPM 574.00 576.10 568.20 573.00 572.83

F = 100 * (F-G) F

Slip % 21.69 21.51 22.36 21.88 21.86

G = A * B 100 VFC, I/L Power KW 1175.04 1193.28 1206.72 1237.44 1203.12

H=G*(1-F/100) Fan Shaft I/L Power KW 920.15 936.58 936.95 966.67 940.09

I=G-H VFC Loss KW 254.89 256.70 269.77 270.77 263.03

Validation of Hydraulic loss by slip loss calculation

confidentia

l

Efficiency Aspect Efficiency of variable fluid coupling is= 1- slip. Fan driving system efficiency can be improved

by regulating fan speed by digital Variable Frequency Drive(VFD) instead of VFC.

Fan driving system efficiency η driving= η motor* η VFC = η motor*(1-slip)

17

MOTOR FAN

ηmotor= 96% ηVFC= 1-slip I/P Power = P * ηmotor % * ηVFC %at Fan Shaft

I/P Power = P

VFC

confidentia

l

Present Efficiency Calculation

Average Slip of VFC =21.86%.

18

SR. NO. PARAMETER UNIT ηold A ηmotor % 96

B Slip % 21.86

C=(1-B/100)100 ηvfc % 78.14

D=A*C/100 ηdriving % 75.0144

confidentia

l

Recommendation Installing a Variable Frequency Drive for this variation in flow requirements

will result in substantial energy savings. The speed of the fan can be varied to attain the desired flow.

There are two options:

1. To install variable frequency drives for the ID fans with VFC in place. In this case, fan speed is varied by VFD keeping VFC scoop 100% open.Design VFC slip at scoop 100%: - 3.4%

19

SR. NO. PARAMETER UNIT ηnew A ηmotor % 96

B Slip % 3.4

C=(1-B/100)100 ηvfc % 96.6

D=A*C/100 ηdriving % 92.736

confidentia

l

2. To install variable frequency drives for the ID fans & remove VFC . In this case VFC slip loss is nil since slip =0

20

SR. NO. PARAMETER UNIT ηold A ηmotor % 96

D=A*C/100 ηdriving % 96

confidentia

l

Cost-Benefits:

21

(New Efficiency-Old efficiency) % Energy Saving = ------------------------------------------ * 100 New efficiency

SR. NO. PARAMETER UNIT Value

AAVERAGE MOTOR I/P POWER A 1253.25

B ηold % 75.01

VFD WITH VFC OPERATING AT FULL SPEED(SCOOP=100%)

VFD WITHOUT VFC

C ηnew % 92.73 96

D=100*((C-B)/C) ENERGY SAVING % 19.10 21.86

E=A*C/100 KW SAVING KW 239.48 274.02

confidentia

l

In DTPS, there are 4no. ID fans. Above energy saving calculation is for one fan. If cost of unit- 3.50 Rs/KWH & annual Operating Hrs. =8200 Hr, benefit & simple payback period is shown in the following table:

22

SR. NO. PARAMETER UNIT

Value

VFD WITH VFC\OPERATING AT FULL SPEED(SCOOP=100%)

VFD WITHOUT VFC

A ENERGY SAVING/FAN KW 239.48 274.01

B NO.OF FAN No4

C=A*BTOTAL ENERGY

SAVING KW 957.92 1096.04

D COST/UNIT Rs. 3.5 3.5

E TOTALINVESTMENT Rs.CR. 5.6 5.6

FANNUAL OPERATING

HRS Hrs. 8200 8200

G=C*D*F ANNUAL SAVING Rs CR 2.74 3.14

F=12*(E/G)SIMPLE PAYBACK

PERIOD Month 24.44 21.36

Thank you