Hydrolysis Oleuropeinby Lactobacillusplantarum …65013 Citti S. Angelo (Pescara),2 Italy Received 3...

Transcript of Hydrolysis Oleuropeinby Lactobacillusplantarum …65013 Citti S. Angelo (Pescara),2 Italy Received 3...

Vol. 60, No. 11APPLIED AND ENVIRONMENTAL MICROBIOLOGY, Nov. 1994, P. 4142-41470099-2240/94/$04.00+0

Hydrolysis of Oleuropein by Lactobacillus plantarum StrainsAssociated with Olive Fermentation

G. CIAFARDINI,l* V. MARSILIO,2 B. LANZA,2 AND N. POZZI2Department ofAnimal, Plant, and Environmental Science, Agriculture Faculty, University of Molise,

86100 Campobasso,' and Elaiotecnic Experimental Institute,65013 Citti S. Angelo (Pescara),2 Italy

Received 3 June 1994/Accepted 27 August 1994

Oleuropein (Chemical Abstracts Service registry number 32619-42-4), a bitter-tasting secoiridoid glucosidecommonly found in leaves of the olive tree as well as in olives (Olea europaea L.), was found to be hydrolyzedby the j-glucosidase (EC 3.2.1.2.1) produced by oleuropeinolytic LactobaciUlus plantarum-type strains. Threestrains, designated B17, B20, and B21, were isolated from the brine of naturally ripe olives not treated withalkali. These strains were rod-shaped forms, grown at a pH 3.5 limit, and tolerated 1% oleuropein and 8% NaClin the growth medium. The 0-glucosidase produced hydrolyzed 5-bromo-4-chloro-3-indolyl-,-D-glucopy-ranoside as well as oleuropein. The presence of 2% glucose in the medium inhibited activity by 40 to 50%,depending on the bacterial strain. Chromatographic analysis of the trimethylsilyl derivatives of the productsobtained after 7 days of incubation at 30°C of strain B21 showed all the hydrolysis products of oleuropein, i.e.,aglycone, iridoid monoterpen, and 3,4-dihydroxyphenylethanol (hydroxytyrosol). Oleuropein and its aglyconeafter 21 days of incubation decreased to trace levels with the simultaneous increase in concentration of,-3,4-dihydroxyphenylethanol.

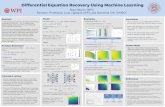

Oleuropein (Chemical Abstracts Service registry number32619-42-4) is a bitter-tasting secoiridoid glucoside commonlyfound in the leaves of the olive plant and in the olive itself(Olea europaea L.). For direct consumption, olives must first bedebittered by hydrolysis of the oleuropein to glucose plusaglycone and conversion of the latter, in turn, to more simple,nonbitter compounds like elenolic acid and P-3,4-dihydroxy-phenylethyl alcohol (Fig. 1). The transformation of table olivesrequires a brining stage during which the olives ferment.However, olives can be debittered before brining by treatmentwith NaOH according to a commonly used Spanish-systemprocess or they can be preserved directly in brine, where theyare fermented for 7 to 12 months, after which they arepackaged in new brine. The spontaneous lactic acid fermenta-tion of Spanish-system olives is due mainly to Lactobacillusplantarum (18), while those brined directly without any treat-ment are fermented by yeast, lactic bacteria, or both (10, 19).The predominance of yeast over lactic bacteria in the brines ofnaturally ripened olives brined directly after harvesting is dueto the presence of naturally occurring phenolic compoundsderived from the hydrolysis of the oleuropein (4-8, 21). In fact,for L. plantarum it has been proven that oleuropein and itshydrolysis productb induce leakage of glutamate and inorganicphosphate from the bacterial cell as well as degradation of thecell wall itself (14, 22). Lactic bacteria including L. plantarumare strongly recommended for preserving ripe olives, since theyproduce adequate acidity resulting from the metabolism of thesugar eluted from olives in brine (19). The acid pH producedby the metabolism of the microorganisms in the brine, inaddition to aiding in the preservation of the product, is held bysome authors to hydrolyze oleuropein in directly brined olives(2). In any case, even if some lactic bacteria, including L.plantarum, can use small amounts of oleuropein present in themedium as the sole carbon source (11), it is not known

* Corresponding author. Phone: 39 874 98744. Fax: 39 874 98743.

whether, aside from acid hydrolysis, oleuropein can be hydro-lyzed directly by lactic bacteria through the action of one ormore enzymes. Moreover, it is not known whether the finalproducts derived from the enzymatic reaction are the same asthose obtained chemically by Panizzi et al. (17).

Considering the important role that the lactobacilli mayhave in the biological debittering process of naturally ripenedolives, we conducted a study on the hydrolysis of oleuropein byseveral L. plantarum-type strains isolated from the brine ofolive fermentation.

MATERIALS AND METHODS

Isolation of oleuropeinolytic bacteria. The isolation of thebacteria started with brine samples of table olives transformedwith the Spanish system or naturally ripe (black) olives brineddirectly after harvesting. The samples, after dilution, wereinoculated into MRS agar medium (3) containing 1% (wt/vol)oleuropein (Extrasynthese, Genay, France). The inoculatedpetri dishes were placed inside plastic bags (100 by 150 mm),sealed, and incubated for 3 days at 30°C. The colonies ofoleuropein-tolerant microorganisms were first examined withthe light microscope, and then the bacterial colonies wereaseptically transferred onto MRS agar (Oxoid, Basingstoke,Hampshire, England) by separate collection of 40 colonies perplate and incubation under the conditions described above.The isolated bacteria were further screened to isolate thespecies producing 3-glucosidase.

P-Glucosidase activity was revealed by use of a substrate of5-bromo-4-chloro-3-indolyl-,B-D-glucopyranoside (X-Gluc) (Sig-ma Chemical Co., St. Louis, Mo.). The test was carried out byspreading 0.2 ml of a N,N-dimethylformamide solution to afinal concentration of 0.3% (wt/vol) X-Gluc on MRS agar. Theplates were left to dry for 3 h in the dark, inoculated with thebacterial colonies, and incubated under the same conditions asthose described above. After 5 days of incubation, the coloniesproducing 1-glucosidase (blue in color) were tested for oleu-

4142

on October 28, 2020 by guest

http://aem.asm

.org/D

ownloaded from

OLEUROPEIN HYDROLYSIS BY L. PLANTARUM 4143

HO - OCH 3OH C'O

CH3CHH O-C6H1105

H4H20

OHCH2

HO

HO

*OH CH300

CH3CH 'OH

HOmu ,oCH3HO CUO

+ + Glucose

CH3CH HOH

, -3, 4-Dihydroxyphenyl - Elenolic acidethyl olcohol

B -Glucosidoxe

Oleuropelon aglycone

FIG. 1. The structures of oleuropein and its hydrolysis products. From Walter et al. (23), based on the work of Panizzi et al. (17).

ropeinolytic activity by use of a modified MRS medium withthe following composition (in grams per liter): oleuropein(Extrasynthese, Genay, France), 1.0; peptone from meat (Sig-ma), 10.0; beef extract powder (Sigma), 8.0; yeast extract(Merck, Darmstadt, Germany), 4.0; dipotassium phosphate(Merck), 2.0; sodium acetate (Merck), 1.5; triammonium ci-trate (Sigma), 2.0; magnesium sulfate (Sigma), 0.2; manganesesulfate (Sigma), 0.05; and 1 ml of Tween 80 (Bio-Rad, Rich-mond, Calif.) per liter; final pH, 7.4. The tests were carried outin Microwell plates (standard 96 well; Cole Parmer, Chicago,Ill.) by inoculation of 0.2 ml of modified MRS broth with singlebacterial strains. After 7 days of incubation at 30°C, sampleswere taken from each well, centrifuged at 10,000 x g for 10min, and analyzed by thin-layer chromatography (TLC) per-

formed on precoated silica gel 60 plates, 0.26 mm thick(Merck). The spots were detected under UV light at 254 nmand revealed by spraying of Folin-Ciocalteu's reagent (Merck),which reacts with the phenolic group of compounds obtainedfrom the oleuropein hydrolysis to form brown spots. Thesolvent mixture used to develop the TLC plates was n-

propanol-benzyl alcohol-88% formic acid-water (50:72:20:20)(1). The bacteria able to hydrolyze oleuropein were isolatedand grown in MRS agar.

Identification of oleuropeinolytic bacteria. The oleuropeino-lytic bacteria were identified by the criteria reported byHammes et al. (12). The bacteria grown in MRS broth were

used for the production of gas with Durham tubes and forGram staining with the HT90-1-4 kit (Sigma). The isomers oflactic acid were determined by the enzymatic method of Noll(16). The production of catalase was demonstrated by place-ment of a drop of 3% (vol/vol) H202 on the colonies grown inMRS agar, whereas tryptophan medium (13) was used for theproduction of NH3. Carbohydrate fermentation was evaluatedby the API 50 CHL system (bioMerieux, Marcy l'Etoile,France). Lastly, growth in selective SL medium (20) was

checked as well as growth in MRS broth at 15 and 45°C (12).Physiological characteristics. Physiological studies were

conducted on three bacterial strains (designated B17, B20, andB21) chosen from 100 strains for their better oleuropeinolyticactivity as revealed by the tests; all the experiments were

performed with three repetitions.(i) Growth at various pHs. After a few preliminary trials to

confirm a stable medium pH during bacterial growth, a test wasperformed in triplicate by growing the bacterial strains into testtubes containing 10 ml of MRS broth in which the pH was

varied from 3 to 7 by use of 0.1 M potassium phosphate buffer.After 3 days of incubation at 30°C, the bacterial cultures were

centrifuged at 10,000 x g for 10 min, resuspended in the samevolume of sterile water, and analyzed spectrophotometricallyat 535 nm. Bacterial growth was estimated by comparison of

the optical density of the samples with that obtained for thesame quantity of bacteria used initially to inoculate each testtube.

(ii) NaCl tolerance. The NaCl tolerance test was carried outby use of MRS broth with added NaCl at concentrationsbetween zero (control) and 13% (wt/vol). After inoculationinto test tubes containing 10 ml of medium, the bacteria wereincubated at 30°C and, after 3 days, were analyzed with thespectrophotometer according to the above-reported proce-dure.

,-Glucosidase activity. ,B-Glucosidase activity of the oleuro-peinolytic bacteria isolated was studied by analysis of theproducts from the hydrolysis of both X-Gluc and oleuropeinused as enzyme substrates.

(i) X-Gluc hydrolysis. Hydrolysis of the X-Gluc substratewas studied by use of the modified MRS agar medium con-taining concentrations of glucose between 0 and 10% (wt/vol).After solidification of the agar medium, 0.2 ml of N,N-dimethylformamide containing X-Gluc (0.3%) was distributedon each plate. The plates were dried in the dark for 1 h at 30°C,and the bacteria to be studied were transferred with a looponto each plate. After three days of incubation at 30°C, thebacterial cultures were removed with a scalpel by cutting of thecolored substrate on which the bacteria had grown and trans-ferred into calibrated Microfuge tubes. Then, 1.5 ml of N,N-dimethylformamide was added to each tube, which was put ina water bath at 60°C for 10 min. The Microfuge tubes were

then agitated with a vortex and centrifuged at 10,000 x g for 10min. The supernatant was then analyzed with a spectropho-tometer (Carlo Erba, Milan, Italy) at 627 nm, whereas thepellets made up of bacteria were weighed. The analytic dataare for samples of 0.2 g (wet bacterial mass).

(ii) Oleuropein hydrolysis. The oleuropein hydrolyzed bythe oleuropeinolytic bacteria was analyzed by gas chromatog-raphy and mass spectrometry. The tests were carried out bygrowing the more active oleuropeinolytic bacteria in themodified MRS broth. The same substrate was used for a test inwhich the oleuropeinolytic bacteria were replaced with 0.1%(wt/vol) P-glucosidase from almonds (Fluka, Buchs, Switzer-land) and a control with neither bacteria nor enzyme. The testtubes, containing 10 ml of medium and closed with screw caps,were incubated at 30°C for 21 days with constant mechanicalstirring at 5 rpm. At the moment of test preparation (timezero) and after each week of incubation, 2 ml of sample was

withdrawn from each tube and frozen at -20°C. At the end ofeach trial period, the samples were defrosted and centrifugedat 12,000 x g for 10 min, and the supernatant was extractedwith 3 ml of chloroform-methanol (2:1). After agitation with a

vortex for 1 min, the samples were centrifuged at 3,500 x g for5 min. The organic fraction was evaporated to dryness under a

Oleuropein

VOL. 60, 1994

on October 28, 2020 by guest

http://aem.asm

.org/D

ownloaded from

4144 CLAFARDINI ET AL.

i_M1 _ r U ~~~~~~~~~~~~DoStI +

-/ti | O DoSl|~~2~ + + +| C

_ E3L C 37HN

X-_ _ \ _ I n alelve-a I ~~~~~~~~++ + I

1__ asoxA-a I I

.s1uuu__+a+u+

FIG. 2. The oleuropeinolytic activity of some lactic bacteria pro- > asoq1oS-iducing P-glycosidase, isolated from olive brines. (A) TLC analysis of _ ;DsouLjnjL-G Icmodified MRS broth after 7 days of incubation at 30°C with a Enonproducer bacterium (lane 1) or with a P-glucosidase producer a aoq!a-(lane 2). (B) The same samples as in panel A deposited on silica gel 7r aiLeoonto + + + :plates and observed under UV light (254 nm). (C) Appearance ofdark,halos in modified MRS agar due to oleuropein hydrolysis. o lop!qoV--I

_ ov!qur-u + + + CZ

IN., osoxne-uicwith a silylation reagent made up of pyridine-hexamethyldisi- XsoWOS-i Iolazane-trimethylchlorosilane (2:1:1) (Merck) at 40°C for 30 w 1°Xllxmin. The derived compounds were kept in iso-octanealyssof Xchromatography (Merck) and mass spectrometry. Capillary gas Schromatography was carried out with a Carlo Erba Mega Serieinstrument with an OV 1 column (15 m by 0.32 mm inside 0 0soiozaaJ-W + ++diameter, 0.1 to 0.15 mm film thickness) and hydrogen as theic ulnuuo l ++carrier gas (head pressure, 35 kPa). The temperature gradient

moluiiqJ- ++ +

for analysis of the oleuropein derivatives was 90 to 310°C (at8wC/min). Injection was in the on column mode, and the flame + ++ionization detector temperature was 330C. A Hewlett-Pack-4 asoq!w + +ard model 5890A gas chromatograph equipped with an HP L5970 B mass selective detector was used to identify the

3sOope + + +

0~~~~~~~~~~

compounds by comparison of their mass spectra with reference = o soxliyg + + + .data. The capillary column (DB-5 fused silica glass capillarygUas!Ls + + +column [30 m by 0.32 mm inside diameter, 0.25 mm filmthickness]; J&W Scientific) was directly introduced into the ionsource operating in the electron impact mode. Other relevant 3soiqollaD + + +conditions and parameters were as follows. The interface wasdiennqtV + + +at 320aC, and the column oven programs were as most 0 oimlOll +++ Eappropriate. Helium was the carrier gas with a head pressure S +++of 2.0 lb/in' and a flow rate of19c3min-' with 70 eV of Olue +++ionizino electron energy, 0.3 mA of electron current, and an ++I!souIion source at 200C; the vacuum was 10 torr (ca. 1.3 kPa).Approximately 0.6 ml of sample solution was injected in the on ++columnmode. Massspectraldata of compounds [mrz (rel. 3souu2Ii ++++int.)]: (i) for 3,4-dihydroxyphenylethanol, [M+] 370 (36), 267cpasolaru- + + +(100), 113 (17), 73 (28), 45 (10); (ii) for oleuropein aglycone,[M+] 596 (1), 280 (100), 193 (19), 73 (24). E

asolneleD + + +

01!UOPVRESULTS ;asoJAX-10 IIc

Isolation of oleuropeinolytic bacteria. The microorganisms asoqo,H + ++ CZ

isolated from olive brines consisted of yeast and lactic bacteria. asomu-V-- + +++The addition of oleuropein to the growth medium created a

moiutVa1.

selective activity on the bacteria only, doubling the yeast/ 2suqr-bacterial cell ratios on the same plates compared with theead prssr

control. Many bacterial forms (approximately 40%) tolerant to IoiIUUU +++ ooleuropein 1% (wt/vol) demonstratedof -glucosidase activity on othe X-Gluc substrate; however, the 1t-glucosidase they pos- . Iosessed proved active even on the oleuropein. In fact, TLC mmm

APPL. ENVIRON. MICROBIOL.

on October 28, 2020 by guest

http://aem.asm

.org/D

ownloaded from

OLEUROPEIN HYDROLYSIS BY L. PLANTARUM 4145

4.5

4

3.5E

'3

2.5

2t2L

.~1.501

0.5

3 3.5 4 5 6

pH

FIG. 3. Effect of acid pH on the growth of the B17 (0), B20 (-),B21 (A), and ATCC 8014 (0) strains of L. plantarum. The test wasperformed in MRS broth, and after 3 days of incubation at 30°C, theoptical density at 535 nm was measured with a spectrophotometer.Data are means ± standard deviations.

showed the disappearance of the oleuropein in the modifiedMRS broth medium after 7 days of bacterial growth (Fig. 2A).Furthermore, the same samples deposited on the silica gelplates and observed under UV light (254 nm) showed markedfluorescence where the oleuropein had been hydrolyzed (Fig.2B).The tests carried out in modified MRS agar medium

4

3.5

3j ?

C

2.5

2

*j 1.5 }\

01

0.5

00 1 2 3 4 5 6 7 8 9 10 11

NaCI (%, whv)FIG. 4. Effects of sodium chloride on the growth of B17 (0), B20

(-), B21 (A), and ATCC 8014 (0) strains of L. plantarum. Thetriplicate test was carried out with MRS broth containing differentconcentrations of NaCl; the optical density at 535 nm was measuredafter 3 days of incubation at 30°C. Data are means ± standard deviations.

to

E

..0*

C4404,_ .

E% cm:

0 10

E2v-_Cs

0 2 4 6 8 10

Glucose (%)

FIG. 5. 13-Glucosidase activity of B17 (0), B20 (-), and B21 (A).L. plantarum-type strains were plated on X-Gluc substrate in increas-ing glucose concentrations. After 3 days of incubation at 300C, theX-Gluc hydrolysis products were extracted and analyzed spectropho-tometrically (optical density at 627 nm); the test was carried out withthree repetitions. Data are means ± standard deviations.

showed, in the areas where oleuropein was hydrolyzed, theappearance of dark halos, which were more intense and spreadout as the bacteria were more active (Fig. 2C). Identificationtests were done only for the rod-shaped bacteria that, underdifferent conditions, demonstrated elevated oleuropeinolyticactivity. On the basis of the tests, the carbohydrate fermenta-tion patterns, and other parameters reported in Table 1, thebacteria were classed as of the L. plantarum type, and thestrains used for further experiments were designated B17, B20,and B21.

FIG. 6. TLC p3-glucosidase activity of the B21 L. plantarum-typestrain, inoculated in modified MRS broth without glucose and with 1%oleuropein (lane 1), in modified MRS broth with 2% glucose and 1%oleuropein (lane 2), in modified MRS broth without glucose and with3% oleuropein (lane 3), and in modified MRS broth with 2% glucoseand 3% oleuropein (lane 4).

VOL. 60, 1994

on October 28, 2020 by guest

http://aem.asm

.org/D

ownloaded from

4146 CIAFARDINI ET AL.

A

0 5 10 15 20 25min

FIG. 7. Gas chromatography analysis of oleuropein (A) present inmodified MRS broth immediately after inoculation (time zero) withthe B21 L. plantarum-type strain.

Physiological characteristics. The B17, B20, and B21 L.plantarum-type strains normally grow in an acidic environment.In fact bacterial growth was drasticallv reduced onlv below nH

u

F

Olemocpres

C

B A

s s 2- n0 5 10 15 20 25

FIG. 9. Gas chromatography analysis of the modified MRS brothwith oleuropein, inoculated with the B21 L. plantarum-type strain andincubated for 21 days at 30°C. (A) Oleuropein; (B) aglycone; (C),B-3,4-dihydroxyphenylethanol.

--------- El.the -... of the B20 and B21 strains, wh')e behavior was very similar to that of the ATCC 8014 strain used~,specially in the case of the B20 and B21 strains, whose

asrfene(i.3 TeNCintemduwssmlryas reference (Fig. 3). The NaCl in the medium was similarlytolerated by the three L. plantarum-type strains up to aconcentration of 7%, above which bacterial growth was dra-

B matically reduced (Fig. 4).I-Glucosidase activity. The 3-glucosidase activity of the

B17, B20, and B21 L. plantarum-type strains evaluated on theX-Gluc substrate correlated negatively with the glucose con-centration of the medium (r = 0.90). Enzyme activity wassharply reduced with an increase of the glucose concentration.In fact, inhibition varying between 40 and 50%, depending onthe bacterial strain (Fig. 5), was observed even with the lowestconcentration (2%) of glucose tested. The B21 strain, in theabsence of glucose, was able to hydrolyze the oleuropein in thegrowth medium completely, up to its maximum 1% concentra-tion (Fig. 6). Chromatographic analysis of modified MRSbroth samples with oleuropein, incubated for 180 min inpresence of f-glucosidase from almonds, showed that more

A than 90% of the glucoside was readily hydrolyzed into aglyconeand glucose (Fig. 7 and 8). The ,B-glucosidase produced by theB17, B20, and B21 L. plantarum-type strains was equally activeon oleuropein. Gas chromatography analyses of the trimethyl-silyl derivatives of the extract from the modified MRS brothmedium containing oleuropein, inoculated with the B21 strain,showed after 7 days of incubation, the hydrolysis products ofoleuropein, viz., aglycone, the iridoid monoterpen, and P-3,4-

5 10 m 15 20 25 dihydroxyphenylethanol. No elenolic acid was detected (datam i n not shown). The chromatographic patterns obtained from the

IG. 8. Oleuropein hydrolysis by f-glucosidase from almonds. (A) extracts of the same samples, analyzed after 21 days ofuropein; (B) aglycone. The test was carried out by incubation of the incubation, indicate that oleuropein and its aglycone decreaseddified MRS broth containing oleuropein for 180 min at 30°C in the to trace levels with the simultaneous increase of P-3,4-dihy-sence of 13-glucosidase from almonds. droxyphenylethanol (Fig. 9).

L

LA

APPL. ENVIRON. MICROBIOL.

4, e

IA

on October 28, 2020 by guest

http://aem.asm

.org/D

ownloaded from

OLEUROPEIN HYDROLYSIS BY L. PLANTARUM 4147

DISCUSSION

A characteristic of L. plantarum is that because of its lacticfermentation it creates an acidic environment unsuitable formany other microorganisms that are responsible for some

serious olive defects (10). The finding that the B20 and B21strains grew at pH 3.5 whereas B17 was able to grow even atpH 3 (Fig. 3) can be attributed, according to McDonald et al.(15), to the ability of L. plantarum to maintain an internal pHgradient that permits its survival even when the external pH isvery low.

Tolerance of NaCl is another important characteristic withregard to application. In general, brines with 5 to 6% NaCl are

used to process olives by the Spanish system; however, toimprove the preservability of the product, brines of up to 7%NaCl have been used (10). The NaCl tolerance we found forthe B17, B20, and B21 L. plantarum-type strains can beconsidered on average slightly higher than results reported byFermandez Gonzalez et al. (9). Our research demonstrated theability of the B21 L. plantarum-type strain to hydrolyze oleu-ropein via 3-glucosidase production to aglycone and othermore simple compounds, among which 13-3,4-dihydroxyphe-nylethanol was identified (Fig. 2 and 9). Because of the ratherunstable hemiacetal moiety present in the molecule, the agly-cone from oleuropein consisted of configurational isomers, asshown by the trimethylsilyl derivatives detected as a multiplecomponent peak (Fig. 8), and hydrolyzed nonenzymatically atacid pHs (17). The P-glucosidases include a family of enzymesthat can hydrolyze a wide range of ,-glucosides. The P-gluco-sidase produced by the oleuropeinolytic L. plantarum-typestrains B17, B20, and B21 is an end product enzyme inhibitedby glucose (Fig. 6), which regulates the activity of the enzymeitself (Fig. 5). However, our research demonstrated that thisenzyme is completely inhibited only by glucose concentrationsthat are unlikely to be reached in olive brines, given that theglucose is consumed by the bacterium itself. Therefore, espe-cially at the beginning of the fermentation process of the olivesnot treated with alkali, the hydrolysis of oleuropein can beattributed not only to the acid pH (2) but also to the3-glucosidase produced by oleuropeinolytic microorganisms.

REFERENCES

1. Blecher, M., and B. Glassman. 1962. Determination of glucoseoxidase: effect of pH on absorption spectrum of oxidized o-

dianisidine. Anal. Biochem. 3:343-352.2. Brenes, M., P. Garcia, M. C. Duran, and A. Garrido. 1992.

Concentration of phenolic compounds change in storage brine ofripe olives. J. Food Sci. 58:347-350.

3. De Man, J. C., M. Rogosa, and M. E. Sharpe. 1960. A medium forthe cultivation of lactobacilli. J. Appl. Bacteriol. 23:130-135.

4. Duran, M. C., P. Garcia, M. Brenes, and A. Garrido. 1993.Lactobacillus plantarum survival during the first days of ripe olivebrining. Syst. Appl. Microbiol. 16:153-158.

5. Etchells, J. L., A. F. Borg, I. D. Kittel, T. A. Bell, and H. P.

Fleming. 1966. Pure culture fermentation of green olives. Appl.Microbiol. 14:1027-1041.

6. Federici, F., and G. Bongi. 1983. Improved method for isolation ofbacterial inhibitors from oleuropein hydrolysis. Appl. Environ.Microbiol. 46:509-510.

7. Fleming, H. P., and J. L. Etchells. 1967. Occurrence of an inhibitorof lactic acid bacteria in green olives. Appl. Microbiol. 15:1178-1184.

8. Fleming, H. P., W. M. Walter, Jr., and J. L. Etchells. 1973.Antimicrobial properties of oleuropein and products of its hydro-lysis from green olives. Appl. Microbiol. 26:777-782.

9. Fernandez Gonzalez, M. J., P. Garcia Garcia, A. Garrido Fernan-dez, and M. C. Duran Quintana. 1993. Microflora of the aerobicpreservation of directly brined green olives from Hojiblancacultivar. J. Appl. Bacteriol. 75:226-233.

10. Garcia Garcia, P., M. del Carmen Duran Quintana, M. BrenesBalbuena, and A. Garrido Fernandez. 1992. Lactic fermentationduring the storage of "Alorena" cultivar untreated green tableolives. J. Appl. Bacteriol. 73:324-330.

11. Gamdo-Fernandez, A., and R. H. Vaughn. 1978. Utilization ofoleuropein by microorganisms associated with olive fermentation.Can. J. Microbiol. 24:680-684.

12. Hammes, W. P., N. Weiss, and W. Holzapfel. 1992. The generaLactobacillus and Camobactenum, p. 1535-1594. In A. Ballows,H. G. Truper, M. Dworkin, W. Harder, and K-H. Schleifer (ed.),The prokaryotes, vol. II. Springer-Verlag, New York.

13. Harrigan, W. F., and M. E. McCance. 1979. Culture mediacomposition, p. 46-54. In Laboratory methods in microbiology.Editorial Academic, Leon, Spain.

14. Juven, B., Y. Henis, and B. Jacoby. 1972. Mechanism of theantimicrobial action of oleuropein. J. Appl. Bacteriol. 35:559-567.

15. McDonald, L. C., H. P. Fleming, and H. M. Hassan. 1990. Acidtolerance of Leuconostoc mesenteroides and Lactobacillus planta-rum. Appl. Environ. Microbiol. 56:2120-2124.

16. Noll, F. 1974. In H. U. Bergmeyer (ed.), Methods of enzymaticanalysis, vol. 2. Verlag Chemie, Weinheim.

17. Panizzi, L. M., J. M. Scarpati, and E. G. Oriente. 1960. Constitu-zione della oleuropeina, glucoside amaro e ad azione ipotensivadell'olivo. Nota II. Gazz. Chim. Ital. 90:1449-1485.

18. Rodriguez de la Borbolla y Alcala, J. M., J. M. Fernandez-Diez,and F. Gonzalez-Cancho. 1969. Influence of pasteurization and lyetreatment on the fermentation of Spanish-style Manzanilla olives.Appl. Microbiol. 17:734-773.

19. Rodriguez de la Borbolla y Alcala, J. M., F. Gonzalez-Cancho, andF. Gonzalez Pellis6. 1971. Aceitunas verdes y de color cambianteen salmuera. Grasas Aceites. 22:455-460.

20. Rogosa, M., J. A. Mitchell, and R F. Wiseman. 1951. A selectivemedium for the isolation and enumeration of oral and fecallactobacilli. J. Bacteriol. 62:132-133.

21. Ruiz-Barba, J. L., M. Brenes-Balbuena, R. Jimenez-Diaz, P.Garcia Garcia, and A. Garrido-Fernandez. 1993. Inhibition ofLactobacillus plantarum by polyphenols extracted from two differ-ent kinds of olive brine. J. Appl. Bacteriol. 74:15-19.

22. Ruiz-Barba, J. L., R M. Rios-Sanchez, J. M. Fedriani-Jriso Olias,J. L. Rios, and R Jimenez-Diaz. 1990. Bactericidal effect ofphenolic compounds from green olives on Lactobacillus planta-rum. Syst. Appl. Microbiol. 13:199-205.

23. Walter, W. M., Jr., H. P. Fleming, and J. L. Etchells. 1973.Preparation of antimicrobial compounds by hydrolysis of oleuro-pein from green olives. Appl. Microbiol. 26:773-776.

VOL. 60, 1994

on October 28, 2020 by guest

http://aem.asm

.org/D

ownloaded from

![LUCA CAPOGNA, GIOVANNA CITTI, AND COSIMO SENNI … · arxiv:1208.6211v2 [math.ap] 19 jan 2013 sub-riemannian heat kernels and mean curvature flow of graphs. luca capogna, giovanna](https://static.fdocuments.us/doc/165x107/5fb6932741fd2b4dca6a9512/luca-capogna-giovanna-citti-and-cosimo-senni-arxiv12086211v2-mathap-19-jan.jpg)