HYDRAULIC DD PRESS BROCHURE - Incredible Machines · 2019. 10. 5. · Powder Compacting Press...

Transcript of HYDRAULIC DD PRESS BROCHURE - Incredible Machines · 2019. 10. 5. · Powder Compacting Press...

-

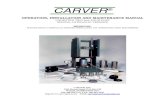

INCREDIBLEM A C H I N E S

“The Perfect Machine For Your Precious Work”

Hydraulic Deep Drawing Press

-

Hydraulic Deep Drawing Press

Design & Engineering

Geometrical Accuracies

Reliability

Precise and Safe motion control by Hydraulic Modules.

Customised design will ensure the quality and reliability of machine

Compact power pack design will helpful in easy running operation

Use of standard components to ensure reliability

Geometrical Accuracies as per JIS Grade

To achieve high level of accuracy, we have to

machined all components precisely

Each part is machined in an uninterrupted work

cycle of CNC base milling centre and boring to

optimize overall accuracy

-

Hydraulic Deep Drawing Press

8 Point GIB Guiding System

Push Button Control Panel

Die Cushion

8 Point GIB Guiding System with replaceable

phosphorus bronze Liner provides extreme

stability and accurate slide movement

These guided plates significantly enhance balance

and precision even when dealing with eccentric

forces

Also this guided system is easy to set as per other

guiding system

Standard parameters like speed, pressure, stroke

length and positioning can be precisely controlled

by the push button panel allowing for a more

diverse range of pressing applications

Also we provide movable arm type panel fixture

which is easy to operate for operator

The die cushion is additional equipped with 4 point

guiding system for small cushion and 8 point

guiding system for big cushion

Replaceable hardened blocks is provided on

cushion bed

These guided plates significantly enhance balance

and precision even when dealing with eccentric

forces caused by irregular or complex mould

shapes

-

Hydraulic Deep Drawing Press

Power Pack

Safety

Our hydraulic system allowing for reliable and

smooth control of stroke, speed and pressure

throughout the complete pressing cycle

Our power pack contains components with

high technology

There are no additional piping required,

will reduced chances of leakage

Due to logical oil circuit design press operation is

smooth and heat generation is reduced

Double Pressure relief valve system

Interlocks for filter Clogging, Oil Temperature,

Oil Leval etc.

Design of Electrical, Hydraulic & Mechanical

systems as per IEC & ISO standards

Extra Safety buttons

Control Voltage 110V AC & 24V DC for operation

safety

Safety blocks for safety of operator & maintenance

staff

Two hand push button for operator safety

Ease of Operation

Programmable Logic Controller with user friendly

operator interface through Ergonomically designed

operator screens.

HMI screens with diagnostic feature developed by

constant improvement through feedback from

press users

-

Hydraulic Deep Drawing Press

315 T Hydraulic Deep Drawing Press | Bolster Size: 1200 mm x 1000 mm

-

Hydraulic Deep Drawing Press

Accessories

HMI with Main Operator Panel

Programmable Logic Controller

Two Hand Operation Stand

Safety Block

Oil Cooling (Water Cooled Heat Exchanger)

Oil Filtering and Magnetic Particle Removal

Customized Accessories

Additional Two Hand Operation Stand

Side Locking at Top Dead Centre

Variable Pressing Speeds

Forced Air Cooling System for Oil Cooling

Hydraulic Damper for Cutting Loads

Proportional Hydraulic Controls

Programmable NC Die Cushion

Oil Cooling through Water Chiller Unit

Die Cushion and Ejector

Die Space Details as per JIS and Customer

Specification

Moving Bolster Option

Quick Die Change System

Photo Electrical Safety Guard

Other Product Range

SMC/DMC/FRP Moulding Press

Powder Compacting Press

Rubber Moulding Press

Hot and Cold Forging Press

C and H Frame Hydraulic Press

Metal Forming Press

Contact Heating Press

Auto Feeder Press

-

Our Presence

Head Office & Manufacturing Unit

Sales & Service

Scan this for more information

Page 1Page 2Page 3Page 4Page 5Page 6Page 7