HVAC EQUIPMENT FLOTEL VESSEL “EDDA FIDES” · PDF fileHVAC EQUIPMENT FLOTEL VESSEL...

Transcript of HVAC EQUIPMENT FLOTEL VESSEL “EDDA FIDES” · PDF fileHVAC EQUIPMENT FLOTEL VESSEL...

Job Report

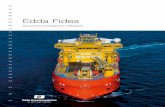

HVAC EQUIPMENT FLOTEL VESSEL “EDDA FIDES”SHIPYARD Astillero Barreras, Vigo, Spain SHIP OWNER Østensjø Rederi AS

DESCRIPTION OF THE PROJECTThe vessel was designed by ship designer Vik & Sandvik (now Wärtsilä) for ship owner Østensjø Rederi AS in Norway. “EDDA FIDES” was delivered in March 2011 as the first pur-pose-built flotel/accommodation vessel.During rebuilding and major overhauls on offshore installa-tions a lot of people are working on the rig and they need a place to live. Similar, the vessel can be used as living quarter for offshore installations on a longer basis.The contract for Novenco has included functional design and engineering, delivery of equipment and on-board testing of HVAC systems for accommodation.

VESSEL MAIN DATA:Length overall: 130 mBeam: 24 mClass: DNV, +1A1, ICE C, Passenger Ship, SPS, Fire Fight-er II, DYNPOS AUTRO, CLEAN DESIGN, DK(+), COMF-V(2), COMF-C(3), NAUT AW, HELDK-SH, PMS, EO, ISM, SFCrew/Passengers: 600 pers.The vessel is capable of moving from harsh winter conditions of -20°C to 35°C and 90% relative humidity, keeping a high comfort indoor climate at 20°C for crew and passengers.

Recreation areas such as exercise room, sauna, swimming pool and cinema accompany the high standard cabins on-board.

CHALLENGES“EDDA FIDES” is an extreme project in many ways, with pio-neer design for both accommodation and technical systems, giving extra challenges for the amount of systems to be designed and coordinated.The project’s intention is to have extreme focus on quality, functionality and comfort. Introduction of cruise standard ac-commodation to the offshore ship industry gives challenges, as it is outside normal standard.

SOLUTIONSThe success of integrating well-functioning HVAC-systems in a ship requires a good cooperation between shipyard, ship owner, ship designer, accommodation contractor and HVAC-supplier.The size of the vessel, combined with the high focus on qual-ity, functionality and comfort required Novenco to put on a large and experienced team of engineers. They have chosen high quality products, designed systems according to rules,

Job Report

HVAC EQUIPMENT TECHNICAL DESCRIPTION EQUIPMENT

regulations and the strict project requirements, and they have designed the duct systems carefully to reduce noise and pressure loss.The comprehensive class notation and the innovative design require that Novenco has top knowledge of rules and regula-tions involved.Novenco’s extensive experience with passenger vessels is securing well functioning HVAC-systems and high level of comfort for the passengers and crew. In order to deliver the required quality, Novenco is cooperating closely with long term Spanish partner Exacta to coordinate all aspects of accommodation and HVAC systems.

Environmental friendly design requires high efficiency equipment to reduce the power consumption and finally reduce the emission to air from power plant. This vessel has installed enthalpy exchangers for the main air handling units, recovering 70% of the energy. AHU fans are capacity con-trolled according to system pressure. Engine room fans are of high efficiency type, improved with automatic frequency drives to adjust the airflow according to the actual need of the engine room machinery. Novenco’s name on such envi-ronmental friendly design is e Vent.

SCOPE OF SUPPLY:

SERVICES PROVIDED:Project managementDevelopment of functional designCalculations, drawings and documentationOn-board commissioning

EQUIPMENT:• 14 air handing units for accommodation, mostly incl.

enthalpy exchangers• 24 air handling units for cooing of technical spaces• 535 MicroVent VAV re-heat Cabin units• Air handling unit for Wheelhouse/defroster system• 2 Air handling units for Galley• 14 fan coils• 14 fans

• 9 chiller units• Control panels and frequency converters• Top level HVAC automation system• External louvers• Fire dampers• Complete set of valves for chilled water system

MICROVENT:We have supplied a high pressure MicroVent single-pipe VAV system with re-heating coils in the cabin units. VAV means Variable Air Volume, and makes it possible to maintain the selected temperature in the room by automatic regulation of air temperature and air flow for optimum comfort.Stainless steel air handing units are chosen for a minimum of maintenance during the lifetime of the vessel.

mu 15199 0715

WWW.NOVENCO-MARINE.COM

Owing to continued product development Novenco Marine & Offshore reserves the right to introduce alterations without prior notice

![The Younger [Prose] Edda](https://static.fdocuments.us/doc/165x107/577ce3391a28abf1038b9bea/the-younger-prose-edda.jpg)