HTL Test Report - Tubelite Inc. · 2019-08-16 · HTL Test Report Tubelite, Inc. 3056 Walker Ridge...

Transcript of HTL Test Report - Tubelite Inc. · 2019-08-16 · HTL Test Report Tubelite, Inc. 3056 Walker Ridge...

HTL Test Report

Tubelite, Inc.

3056 Walker Ridge Drive N.W. Walker, MI 49544

“Forcefront Blast Curtainwall and Forcefront Blast Monumental Doors”

HTL Report #: T584-0102-11

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 1 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

Daniel Simmons

Kristin Ahders

6.27.2011 6.27.2011

Tubelite, Inc. Forcefront Blast Curtainwall and Forcefront Blast Monumental Doors

Test Report #: T584-0102-11

1.0 MANUFACTURER’S IDENTIFICATION 1.1 Name of Applicant: Tubelite, Inc. 3056 Walker Ridge Drive N.W. Walker, MI 49544 Voice: 800.866.2227 Fax: 616.301.0008 1.2 Contact Person: John Campbell

2.0 SCOPE OF WORK 2.1 Introduction

Tubelite, Inc. retained HTL, LLC to conduct a shocktube blast test on their Forcefront Blast Curtainwall and Forcefront Blast Monumental Doors per the requirements of ASTM F 1642-04 and UFC 4-010-01.

3.0 PRODUCT IDENTIFICATION 3.1 Product Type: Monumental Doors in Curtainwall Frame 3.2 Model Designation: Forcefront Blast 3.3 Performance Class: exceeds 6 psi – 42 psi-msec 3.4 Overall Size: 78-1/2" (w) x 87-5/8" (h) 3.5 Number of Operable Door Leaves: 2 3.6 Size of Operable Door Leaves: 35-13/16" (w) x 83-7/16" (h) 3.7 Location: Lynn County, Texas3.8 Specimen and Test Conditions: Table 1 gives the specimen number, test date, test time,

ambient temperature, relative humidity, and weather condition for each specimen.

Table 1: Specimen and Test Conditions

Specimen # Test Date Time

Ambient Temperature

(F)

Relative Humidity

(%) Weather Conditions

1 March 01, 2011 1:44 pm 78.4 2 Winds 5-10 mph, Partly Cloudy 2 March 03, 2011 12:56 pm 82.8 2 Winds 10-15 mph, Overcast 3 March 07, 2011 12:16 pm 85.3 2 Winds 20-30 mph, Partly Cloudy

3.9 Configuration: Please refer to Tubelite, Inc.’s drawings labeled “TUBELITE

FORCEFRONT BLAST MONUMENTAL DOOR & FORECEFRONT BLAST CURTAINWALL - DRY SET” (sheet 1 of 6) for the configuration of these specimens.

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 2 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

3.10 Drawing: This test report is incomplete if not accompanied by Tubelite, Inc.’s drawing labeled “TUBELITE FORCEFRONT BLAST MONUMENTAL DOOR & FORECEFRONT BLAST CURTAINWALL - DRY SET” (Sheets 1 thru 6) bearing the originally signed digital stamp of Hurricane Test Laboratory, LLC.

3.11 Sample Source: Tubelite, Inc. provided the test specimens. 4.0 EXPLOSIVE CHARGE 4.1 Charge Type: C-4 (Composition 4) 4.2 Charge Weight: 600 grams 4.3 Standoff Distance: 68 feet 5.0 BLAST REACTION CHAMBER

The shocktube construction consists of a 90 foot long steel tube reinforced with wide flange steel beams, steel tubes, and steel skin. HTL also placed a 4 foot long, 1.5 foot diameter steel pipe at the standoff indicated in Section 4.0. The overall dimensions of the shocktube are 7.5 feet wide, 8 feet tall and 90 feet long. An exterior platform houses the occupied space and witness panels. The sealed surfaces of the reaction buck and shocktube prevent air blast pressure from wrapping around the test specimen, so the blast pressure loads only one side of the test specimen.

6.0 PRODUCT DESCRIPTION 6.1 Frame Construction

The frame was fabricated using the aluminum extrusions defined in Table 2.

Table 2: Aluminum Extrusions Details Description Part # Overall Cross-Section Alloy

Curtainwall Tube E55TB02FB 6.625” x 2.500” x 0.125” 6063-T5 Shear Block Clip PTB60 2.250” x 1.250” x 0.125” 6063-T5 Sub Frame E4TB11 0.750” x 4.500” x 0.125” 6063-T5 Glazing Pocket Closure E3192FB 0.813” x 1.563” x 0.063” 6063-T5 1” x 1” Door Stop E6504 1.000” x 1.000” x 0.125” 6063-T5 Horizontal Door Stop E2298 3.500” x 2.688” x 0.063” 6063-T5 Pocket Filler E4011 0.375” x 1.250” x 0.063” 6063-T5 Vertical Door Stop Cover E6501 1.063” x 0.500” x 0.063” 6063-T5 Vertical Door Stop Base E6500 1.375” x 1.688” x 0.063” 6063-T5 Removable Mullion Clip E3826 2.180” x 4.000” x 0.250” 6063-T5

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 3 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

6.1.1 Typical Corner Construction The verticals ran through while the horizontals were square cut, butted, and mechanically fastened to the verticals using the Shear Block Clip (Part #PTB60). The Shear Block Clip was mechanically fastened to each vertical using three (3), 1/4-20 x 1/2” Type B Hex Head Screws (Part #S139) and mechanically fastened to each horizontal using two (2), 10-24 x 3/4” Pan Head Phil SS Screws (Part #S270) and two (2), 10-24 x 1/2” Truss Head Phil Screws (Part #S191). At the sill corners Tremco® Dymonic® FC Fast Curing, Low Modulus, Silane End-Capped, Polyurethane Hybrid Sealant was used.

6.1.2 Sub Frame Corner Construction The verticals ran through while the horizontals were square cut and butted to the verticals.

6.1.3 Head and Jambs The Glazing Pocket Closure (Part #E3192FB) was snap fit to the Curtainwall Tube (Part #E55TB02FB).

6.1.4 Door Sub Frame Jambs The Sub Frame (Part #E4TB11) and Vertical Door Stop Base (Part #E6500) were mechanically fastened to the Curtainwall Tube using a single row of 6-32 x 1” Flat Head Phil, Type F Screws (Part #S6504) at 2” from ends and 6” on center thereafter. The Vertical Door Stop Cover (Part #E6501) was snap fit to the Vertical Door Stop Base.

6.1.5 Door Sub Frame Head The Sub Frame (Part #E4TB11) was mechanically fastened to the Curtainwall Tube using a single row of 1/4-20 x 1/2” Type B Hex Head Screws (Part #S139) at 2” from ends and 6” on center thereafter. The Pocket Filler (Part #E4011) was snap fit to the Sub Frame. The 1” x 1” Door Stop (Part #E6504) was mechanically fastened to the Pocket Filler using a single row of 1/4-20 x 3/4” HHCS Type F Thread Cutting Screws (Part #S6505) at 6” from ends and 12” on center thereafter. The Horizontal Door Stop (Part #E2298) was mechanically fastened to the 1” x 1” Door Stop (Part #E6504) using a single row of 6-32 x 1” Flat Head Phil, Type F Screws (Part #S6504) at 2” from ends and 6” on center thereafter.

6.1.6 Removable Mullion At the center of door opening on the interior side a Von Duprin 111018-4954 Removable Mullion (Part #P6511) was attached using two (2), 1.5” long Removable Mullion Clips (Part #E3826). The top Removable Mullion Clip was mechanically fastened to the Sub Frame using two (2), 1/4-20 x 1-1/2” Flat Head Phil Screws (Part #S092) and mechanically fastened to the Removable Mullion using one (1), 1/4-20 x 1-1/2” Flat Head Phil Screw (Part #S092). The bottom Removable Mullion Clip was mechanically fastened to the opening using two (2), 3/8” x 2-1/2” Galvanized Lag Screws (Part #S0002) and mechanically fastened to the Removable Mullion using two (2), 1/4-20 x 1-1/2” Flat Head Phil Screws (Part #S092).

6.2 Pressure Plate and Snap Cover Assembly Table 3 provides the extrusions used in the pressure plate and snap cover assembly.

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 4 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

Table 3: Pressure Plate and Snap Cover Details Description Part # Overall Cross-Section Alloy

Pressure Plate E4TB63FB 2.375” x 0.500” x 0.125” 6063-T5 Face Cover E4TB64FB 2.500” x 0.750” x 0.063” 6063-T5

6.2.1 Pressure Plate and Snap Cover Assembly

The Pressure Plate (Part #E4TB63FB) was mechanically fastened to the Curtainwall Tube using a single row of 1/4” – 20 x 1-1/2” Hex Washer Head Type ‘F’ Zinc Plated Class 2A Pressure Plate Screw (Part #S359) with Thermal Barrier Gasket (Part #PTB94) at 2” from each end and 6” on center thereafter. The Face Cover (Part #E4TB64FB) was snap fit to the Pressure Plate.

6.3 Steel Reinforcements

Table 4 provides the steel reinforcements used in the test specimens. They were mechanically fastened to the jambs using a single row of 1/4-20 x 3” Flat Head Phil Screws (Part #S155) at 8” from each jamb end and 6” on center thereafter. Steel was 6” from each end of jamb.

Table 4: Steel Reinforcement Details Location Description

Left and Right Jambs C4 x 5.4 Steel Channel

6.4 Operable Door Leaf Construction Table 5 provides the extrusions used in the Operable Door Leaf assemblies.

Table 5: Operable Door Leaf Details Description Part # Overall Cross-Section Alloy/Temper

10” Bottom Rail E2954 10.000” x 2.000” x 0.188” 6063-T5 Wide Stile Hinge Stile E2937 6.000” x 2.000” x 0.188” 6063-T5 Wide Stile - Lock with Astragal E1155 6.000” x 2.000” x 0.188” 6063-T5 6” Top or Bottom Rail E1051 6.000” x 2.000” x 0.188” 6063-T5 RD Face Stile E2938 6.000” x 2.000” x 0.188” 6063-T5 Exterior Glazing Stop Standard E6503 0.688” x 1.125” x 0.063” 6063-T5 Interior Glass Stop E6502 1.625” x 1.313” x 0.125” 6063-T5 Astragal- For CVR, Rim & Mid Exit E1152 0.563” x 0.938” x 0.188” 6063-T5 6.4.1 Top/Bottom Corner Construction

Stiles ran through while rails were square cut, butted, and mechanically fastened using the 3/8” Threaded Tie Rod (Part #P020B), Door Rod Washer (Part #P853), and 3/8-16 x 3/8 Stud Nut (Part #S071).

6.4.2 Interior Glass Stop

The Interior Glass Stop (Part #E6502) was mechanically fastened to the door frame member using a single row of 6-32 x 1” Flat Head Phil, Type F Screws (Part #S6504) at 2” from each end and 6” on center thereafter.

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 5 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

6.4.3 Exterior Glass Stop The Exterior Glazing Stop Standard (Part #E6503) was snap fit to the Interior Glass Stop (Part #E6502) and door frame member.

6.4.4 Astragal The Astragal- For CVR, Rim & Mid Exit (Part #E1152) with Adjustable Astragal Steel Spring (Part #P1539) was mechanically fastened to the Wide Stile - Lock with Astragal (Part #E1155) using seven (7), 10-24 x 3/4” Phil Head Screws (Part #S341) with seven (7) Screw and Shoulder Screw Washers (Part #P1553).

6.5 Glazing Details 6.5.1 Glazing Materials

Glass Type GL-1 consisted of an insulated glass lite with an overall thickness of 1.035” (nominal) with the following components: - 1/4” Fully Tempered - 3/8” Airspace - 3/16” Heat Strengthened - 0.035” DuPont SentryGlas® ionoplast interlayer - 3/16” Heat Strengthened Glass Type GL-2 consisted of an insulated glass lite with an overall thickness of 1.060” (nominal) with the following components: - 1/4” Fully Tempered - 3/8” Airspace - 3/16” Heat Strengthened - 0.060” DuPont SentryGlas® ionoplast interlayer - 3/16” Heat Strengthened

6.5.2 Glazing Method

The glass lites used in the specimens were glazed using the typical procedures described in Table 6.

Table 6: Glazing Details

Location Typical Procedure

Interior Exterior

Doors Using continuous strips of EPG 60

Durometer Dense EPDM Door Glazing Gasket (Part #P0017)

Using continuous strips of EPG 60 Durometer Dense EPDM Door Glazing

Gasket (Part #P0017)

6.5.3 Daylight Opening and Glass Bite Table 7 provides the daylight opening and glass bite for each lite used in the test specimens.

Table 7: Daylight Opening and Glass Bite Details

Qty. Glazing Material Type Location Daylight Opening Glass

Bite 1 GL-1 Left Door 21-13/16” (w) x 65-7/16” (h) 5/8” 1 GL-2 Right Door 21-13/16” (w) x 65-7/16” (h) 5/8”

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 6 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

6.6 Weather Stripping Table 8 provides details of the weather stripping used in the specimens.

Table 8: Weather Stripping Details Location Description

Horizontal and Vertical Door Stops

Single rows of Amesbury Group Pile (Part #P1098A)

Threshold Single row of Bulb Gasket included with Nat’l Guard Products Threshold (Part #XB896N)

6.7 Hardware

Table 9 provides the hardware used in the specimens. For more information please refer to sheet 4 of Tubelite, Inc.’s drawing labeled “TUBELITE FORCEFRONT BLAST MONUMENTAL DOOR & FORECEFRONT BLAST CURTAINWALL - DRY SET”.

Table 9: Door Hardware Details Qty. Location Description

6

3 per Leaf at 6”, 36-1/2”, and 73” from Bottom of

Door

Mortised HD Butt Hinges (Part #P1558) mechanically fastened to door using four (4), 12-24 x 1/2” Flat Head Screw (Part #S070) and the sub

frame using four (4), 12-24 x 1/2” Flat Head Screw (Part #S070)

12 2 per Hinge Butt Hinge Reinforcement (Part #P2092) mechanically fastened to

door or sub frame using eight (8), 10-24 x 1/2” Flat Head Phil Screws (Part #S161)

1 Lock Stiles CVR with Lever Panic – First Choice 3600 x Rim Cylinder (Part #P3692C X P573)

2 Top Rails Dorma 8616 Closer, Surface Mounted (Part #P2201)

1 Threshold Nat’l Guard Products Threshold (Part #XB896N) was mechanically fastened to the wood opening using eight (8), 1/4-20 x 1-1/2” Flat

Head Phil Screw (Part #S6506) through pre-drilled holes. 1 set per

door 33-1/2” from

Bottom of Door Rockwood Pull Set 33”

1 Interior at Center of Door Opening Von Duprin 111018-4954 Removable Mullion

6.8 Weep Holes

Two (2), 7/32” diameter weep holes were used at 1/4 points of the Pressure Plate and Cover at the head.

6.9 Sealants Used Table 10 provides details of each sealant used in the specimens.

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 7 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

Table 10: Sealant Details Location Sealant Description

Perimeter Sealant Tremco® Dymonic® FC Fast Curing, Low Modulus, Silane End-Capped, Polyurethane Hybrid Sealant

Frame Joint Sealant Tremco® Dymonic® FC Fast Curing, Low Modulus, Silane End-Capped, Polyurethane Hybrid Sealant

Glazing Sealant None Used

7.0 PRODUCT INSTALLATION 7.1 Table 11 provides details of the product installation into the wood opening. The rough opening allowed

for a 1/2” shim space. Each anchor had a minimum embedment depth of 1-1/4”.

Table 11: Product Installation Details Location Qty. Fastener Schedule and Description Jambs @

Head 2 per

Specimen The F Anchor (Part #P6515) was slid into the jamb and mechanically fastened to the wood opening using three (3), 3/8 - 16 x 2” HH Screws (Part #S6501).

Jambs @ Sill 2 per Specimen

The U Anchor (Part #P6516) was slid into the jamb and mechanically fastened to the wood opening using three (3), 3/8 - 16 x 2” HH Screws (Part #S6501).

Perimeter 3 per Specimen

Each F Perimeter Anchor (Part #E3162FB) was slid in between the Curtainwall Tube and Pressure Plate and mechanically fastened to the wood opening using

a single row 3/8 - 16 x 2” HH Screws (Part #S6501) as shown on sheet 2 of Tubelite, Inc.’s drawing labeled “TUBELITE FORCEFRONT BLAST MONUMENTAL

DOOR & FORECEFRONT BLAST CURTAINWALL - DRY SET”.

8.0 INSTRUMENTATION 8.1 Data Acquisition System

HTL used a high speed data acquisition system with a system record time of one-hundred thousand (100,000) samples per second.

8.2 Reflected Pressure Transducers HTL placed three (3) reflected pressure transducers on the exterior face of the shocktube reaction buck to measure the reflected blast pressure time histories acting on the surface of the specimen. The reflected pressure transducer locations are given in Figure 1.

8.3 High Speed Cameras

HTL used one (1) digital high speed camera to record system response under air blast pressure. The camera filmed the interior of the specimen during air blast pressure loading.

8.4 Witness Panels HTL used witness panels defined in ASTM F 1642-04 Section 8.7.5. The witness panel makeup consisted of two layers of material. The outer layer consisted of one-half (1/2) inch thick rigid foam plastic thermal insulation board composed of polyisocyanurate foam bonded to a durable white-matte non-glare aluminum facer and a reflective reinforced aluminum facer with a density of two (2) pounds per cubic foot. The inside layer consisted of one (1) inch extruded polystyrene insulation with a density of 1.8 pounds per cubic foot.

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 8 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

9.0 BLAST ENVIROMENT AND DATA 9.1 Reflected Pressure Transducer Location

Figure 1 shows the locations of the reflected pressure transducers on the air blast reaction buck.

Figure 1: Reflected Pressure Transducer Locations

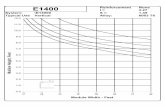

9.2 Reflected Air Blast Pressure Results

Table 12 summarizes the reflected blast pressure and positive phase impulse for each pressure transducer location. Figures 2 and 3 provide the reflected air blast pressure (blue) and impulse (red) time histories graphically for Specimen 1. Figures 4 through 6 provide the reflected air blast pressure (blue) and impulse (red) time histories graphically for Specimen 2. Figures 7 through 9 provide the reflected air blast pressure (blue) and impulse (red) time histories graphically for Specimen 3.

Table 12: Reflected Air Blast Pressure Results

Specimen # Air Blast Parameter RPT 1 RPT 2 RPT 3 Average

1 Peak Pressure, (psi)

Failed 9.694 10.89 10.29

Positive Phase Impulse, (psi-msec) 37.69 39.36 38.52 Positive Phase Duration (msec) 10.40 12.27 11.33

2 Peak Pressure, (psi) 9.937 9.327 11.60 10.29 Positive Phase Impulse, (psi-msec) 47.12 42.61 43.83 44.52 Positive Phase Duration (msec) 13.48 13.21 11.86 12.85

3 Peak Pressure, (psi) 10.33 9.066 11.61 10.34 Positive Phase Impulse, (psi-msec) 48.13 43.53 46.02 46.30 Positive Phase Duration (msec) 14.84 13.69 12.89 13.81

3'-938"

7'-8"

3'-812"

2 516"

3'-8"

7'-101516"

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 9 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

Figure 2: Reflected Air Blast Pressure (RPT #1) Figure 3: Reflected Air Blast Pressure (RPT #2)Specimen 1 Specimen 1

Figure 4: Reflected Air Blast Pressure (RPT #1) Figure 5: Reflected Air Blast Pressure (RPT #2) Specimen 2 Specimen 2

Figure 6: Reflected Air Blast Pressure (RPT #3) Specimen 2

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 10 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

Figure 7: Reflected Air Blast Pressure (RPT #1) Figure 8: Reflected Air Blast Pressure (RPT #2) Specimen 3 Specimen 3

Figure 9: Reflected Air Blast Pressure (RPT #3) Specimen 3

10.0 TEST RESULTS 10.1 Specimen 1 - Results

10.1.1 Glazing Response None of the lites fractured during air blast pressure loading. Zero (0) fragments were observed in the occupied space. Zero (0) perforations or fragment indents were observed anywhere in the vertical witness panel. Table 13 provides a summary of the glazing response under air blast pressure loading. Figures B.2 and B.3 shows the pre-blast specimen with lite labels and Figures C.1 and C.2 shows the post-blast specimen.

Table 13: Glazing Response Summary

Lite # Temp. Fracture Status

Comments ˚F Inboard Outboard

D1 94.5 No No No tears or pullout observed. D2 95.0 No No No tears or pullout observed.

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 11 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

10.1.2 Door Response 10.1.2.1 Door Frame Response

The center mullion was released from the head and fell to the interior of the occupied space under air blast pressure loading.

10.1.2.2 Hardware Response D2’s Rockwood Push/Pull attachment screws released under air blast pressure loading allowing the exterior handle to fall to the exterior.

10.1.2.3 Door Leaf Response

No visible damage occurred at the door leaves under air blast pressure loading. 10.1.2.4 Door Anchor Response

No visible damage occurred at the door anchors under air blast pressure loading.

10.2 Specimen 2 - Results 10.2.1 Glazing Response

D1’s inboard lite fractured under air blast pressure loading. Zero (0) fragments were observed in the occupied space. Zero (0) perforations or fragment indents were observed anywhere in the vertical witness panel. Table 14 provides a summary of the glazing response under air blast pressure loading. Figures B.4 and B.5 shows the pre-blast specimen with lite labels and Figures C.11 and C.12 provides the post-blast specimen.

Table 14: Glazing Response Summary

Lite # Temp. Fracture Status

Comments ˚F Inboard Outboard

D1 81.0 Yes No No tears or pullout observed. D2 82.0 No No No tears or pullout observed.

10.2.2 Door Response

10.2.2.1 Door Frame Response Deformation and separation was occurred at the frame head to jamb connections. The center mullion was released from the head and fell to the interior of the occupied space under air blast pressure loading.

10.2.2.2 Hardware Response

D2’s Rockwood Push/Pull attachment screws released on under air blast pressure loading allowing the exterior handle to fall to the exterior.

10.2.2.3 Door Leaf Response

No visible damage occurred at the door leaves under air blast pressure loading. 10.2.2.4 Door Anchor Response

No visible damage occurred at the door anchors under air blast pressure loading.

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 12 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

10.3 Specimen 3 - Results 10.3.1 Glazing Response

None of the lites fractured under air blast pressure loading. Zero (0) fragments were observed in the occupied space. Zero (0) perforations or fragment indents were observed anywhere in the vertical witness panel. Table 15 provides a summary of the glazing response under air blast pressure loading. Figures B.6 and B.7 shows the pre-blast specimen with lite labels and Figure C.19 provides the post-blast specimen.

Table 15: Glazing Response Summary

Lite # Temp. Fracture Status

Comments ˚F Inboard Outboard D1 83.0 No No No tears or pullout observed. D2 84.0 No No No tears or pullout observed.

10.3.2 Door Response

10.3.2.1 Door Frame Response Separation at the frame head to left jamb connection and sheering of one (1) fastener holding the right head horizontal door stop occurred under air blast pressure loading.

10.3.2.2 Hardware Response One (1) of the two (2) D2 Rockwood Push/Pull attachment screws released during air blast pressure loading.

10.3.2.3 Door Leaf Response

No visible damage occurred at the door leaves under air blast pressure loading. 10.3.2.4 Door Anchor Response

No visible damage occurred at the door anchors under air blast pressure loading. 11.0 STANDARD RATING SUMMARY 11.1 Table 16 gives a summary of the test outcome for the specimen.

Table 16: Standard Rating Summary

Standard Standard Rating Standard Explanation of Rating

ASTM F 1642-04

Minimal Hazard

The glazing is observed to fracture and the total length of tears in the glazing plus the total length of pullout from the edge of the frame is less than 20% of the glazing sight perimeter. Also, there are three or less perforations caused by glazing slivers and no fragment indents anywhere in a vertical witness panel located 3 m (120 in.) from the

interior face if the specimen and there are fragments with a sum total united dimension of 25 cm (10 in.) or less on the floor between 1 m (40 in.) and 3 m (120 in.) from the

interior face of the specimen. Glazing dust and slivers are not accounted for in the rating.

UFC 4-010-01 Medium

Glazing will fracture, remain in the frame and results in a minimal hazard consisting of glass dust and slivers. (Minimal hazard rating) Doors will stay in frames, but will not be

reusable.

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page 13 of 13 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

TEST DIRECTOR REPORT WRITER

6.27.2011 6.27.2011

12.0 CERTIFICATION AND DISCLAIMER STATEMENT All tests performed on these specimens were conducted in accordance with the specifications of the applicable codes, standards and test methods listed below by HTL, LLC. HTL, LLC does not have, nor does it intend to acquire or will it acquire, a financial interest in any company manufacturing or distributing products tested at HTL. HTL is not owned, operated or controlled by any company manufacturing or distributing products it tests. This report is only intended for the use of the entity named in Section 1.0 of this report. Detailed assembly drawings showing wall thickness of all members, corner construction and hardware applications are on file and have been compared to the specimens submitted. A copy of this test report along with representative sections of the specimens will be retained at HTL for a period of three (3) years. All results obtained apply only to the specimens tested and they do indicate compliance with the performance requirements of the test methods and specifications listed in the following section.

13.0 APPLICABLE CODES, STANDARDS, AND TEST METHODS

ASTM F 1642-04 - Standard Test Method for Glazing and Glazing Systems Subject to Airblast Loadings UFC 4-010-01 – DoD Minimum Antiterrorism Standards for Buildings

14.0 WITNESSES Daniel Simmons Test Director HTL, LLC Kyle Turner Assistant OM HTL, LLC Bart Master Test Technician HTL, LLC Jay Ignasinski Test Technician HTL, LLC

15.0 APPENDICES This test report is incomplete if not accompanied by the following Appendices. Appendix A: Specimen Drawings .............................................................................................. 7 Pages Appendix B: Test Setup ........................................................................................................... 3 Pages Appendix C: Photographic Record ............................................................................................. 7 Pages Revision Log ............................................................................................................................ 1 Page

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page A1 of A7 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

APPENDIX A: “TUBELITE FORCEFRONT BLAST MONUMENTAL DOOR & FORCEFRONT BLAST

CURTAINWALL - DRY SET” SHEETS 1 THRU 6

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page B1 of B3 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

APPENDIX B: TEST SETUP

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page B2 of B3 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

Figure B.1: Shocktube Setup Figure B.2: Pre-Blast Specimen 1 Setup Exterior

Figure B.3: Pre-Blast Specimen 1 Setup Figure B.4: Pre-Blast Specimen 2 Setup Interior Exterior

D1 D2

D1 D2

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page B3 of B3 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

Figure B.5: Pre-Blast Specimen 2 Setup Figure B.6: Pre-Blast Specimen 3 Setup Interior Exterior

Figure B.7: Pre-Blast Specimen 3 Setup Interior

D1 D2

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page C1 of C7 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

APPENDIX C: PHOTOGRAPHIC RECORD

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page C2 of C7 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

Figure C.1: Specimen 1 - Exterior Figure C.2: Specimen 1 - Interior Post-Blast Post-Blast

Figure C.3: Specimen 1 Removable Mullion Figure C.4: Specimen 1 Removable Mullion Hardware Post-Blast Post-Blast

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page C3 of C7 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

Figure C.5: Specimen 1 Removable Mullion Figure C.6: Specimen 1 - Interior Post-Blast Post-Blast

Figure C.7: Specimen 1 - Interior Figure C.8: Specimen 1 Closer Post-Blast Post-Blast

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page C4 of C7 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

Figure C.9: Specimen 1 Closer Figure C.10: Specimen 1 - Exterior Post-Blast Post-Blast

Figure C.11: Specimen 2 - Exterior Figure C.12: Specimen 2 - Interior Post-Blast Post-Blast

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page C5 of C7 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

Figure C.13: Specimen 2 Removable Mullion Figure C.14: Specimen 2 Removable Mullion Post-Blast Post-Blast

Figure C.15: Specimen 2 Removable Mullion Hardware Figure C.16: Specimen 2 - Interior Post-Blast Post-Blast

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page C6 of C7 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

Figure C.17: Specimen 2 - Interior Figure C.18: Specimen 2 Hardware - Exterior Post-Blast Post-Blast

Figure C.19: Specimen 3 - Exterior Figure C.20: Specimen 3 Removable Mullion Post-Blast Post-Blast

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Page C7 of C7 Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

Figure C.21: Specimen 3 Removable Mullion Figure C.22: Specimen 3 Removable Mullion Hardware Post-Blast Post-Blast

Figure C.23: Specimen 3- Exterior Figure C.24: Specimen 3 Frame Corner Post-Blast Post-Blast

BRANCH OFFICE Test Report #: T584-0102-11 525 32nd Street Revision Log Lubbock, TX 79404 P: 888.477.2454 F: 806.744.2280 HTLTEST.COM

LINKING MANUFACTURERS WITH KNOWLEDGE, EXPERIENCE & SERVICE IN ARCHITECTURAL TESTING

Revision Log

Rev. # Date Page(s) Section # Revision(s) 0 6.27.2011 N/A N/A Original report issued.