HOW THE MOLD COMPOUND THERMAL EXPANSION OVERRULES THE SOLDER COMPOSITION...

Transcript of HOW THE MOLD COMPOUND THERMAL EXPANSION OVERRULES THE SOLDER COMPOSITION...

HOWTHEMOLDCOMPOUNDTHERMALEXPANSIONOVERRULESTHESOLDERCOMPOSITIONCHOICEINBOARDLEVELRELIABILITYPERFORMANCE

AUTHORS:B.VANDEVELDE,L.DEGRENDELE,M.CAUWE,B.ALLAERT,R.LAUWAERT,G.WILLEMS

SPEAKER:M.TSURIYA(iNEMI)

OUTLINE

¡ Introduction

¡ Experimental Setup

¡ Results ofthe Thermal Cycling Experiment

¡ Cross-sectional Analysis

¡ Conclusions

2

OUTLINE

¡ Introduction

¡ Experimental Setup

¡ Results ofthe Thermal Cycling Experiment

¡ Cross-sectional Analysis

¡ Conclusions

3

USEOFLOW-CTEMOLD COMPOUND

¡ Drivingfactors:¡ toreduce thestressonthesiliconchip(CPI:chip-package-interaction)¡ tolowerthemoistureuptake:SiO2 based fillercanreduce theamountofhygroscopicresinto

decrease theMSLanditislessexpensive thanresinfiller¡ Tousehalogen-free “green” compounds which isachieved byhighamountofSiO particles

¡ Asaconsequence¡ theamountofSiO2 particlesintheepoxymatrixincreased uptoafillercontentof85%.¡ Thisleaded toareductionoftheCTEofthemoldcompoundbelow10ppm/°C(CTEofSiO2 is

0.5ppm/⁰C).

4

DRIVING FACTORSAND CONSEQUENCES

USEOFLOW-CTEMOLD COMPOUND

¡ Formostpackages, themoldcompoundeasilytakesmorethan50%ofthetotalvolumeofthepackage

¡ So,themoldCTEhasahugeimpactontheaverageCTEofthecomponent

5

LOW-CTEMOLD COMPOUNDS

USEOFLOW-CTE“GREEN”MOLD COMPOUNDS

6

THECHANGE-OVER TOOKPLACEBETWEEN 2005-2010

0%10%20%30%40%50%60%70%80%90%

Q1 2005

Q3 2005

Q1 2006

Q3 2006

Q1 2007

Q3 2007

Q1 2008

Q3 2008

Q1 2009

Q3 2009

(datafromaleadingsemiconductorsupplier)

Use ofGreenMouldCompounds for plasticpackagesThe introduction ofthe “green” mold compoundsisan indication for the introduction ofthe uselow-CTE versions inthat period. Inrecentyears,also greenmold compoundwithhigher CTEareused through changing the resinmaterials.

USEOFLOW-CTEMOLD COMPOUND

¡ FEMSimulation,byassumingthesamepropertiesforPCB.¡ Testsample:

¡ UsePBGA27x27mm,1.27mmpitch¡ 6versionsofPBGAwithdifferentMoldCTE

¡ TestBoards:¡ Use4differentthicknessofPCBboard(incl.oneflexboard)

¡ SimulationResult:¡ At0.8mmPCBboardassembly,6versionsPBGAfailurerateareno

different.

¡ MoldCTEofthePBGAbecomesveryimportantwhenthePCBislessflexible

¡ AslocalbendingofthePCBbelowthecomponentcanlesscompensatefortheincreasedCTEmismatchbetweenPBGAandPCB.

7

INCREASED CTEMISMATCHWITH THE PCB

0

1000

2000

3000

4000

5000

6000

5 10 15 20

MTTF(cycle

s)MoldCTE(ppm/°C)

0.8mm

1.6 mm

2.4 mm

No PCB flexing

FEMSimulationResultExample:PBGA27x27areaarray1.27mmpitch

LOW-CTEMOLD COMPOUNDS

¡ Highermoldstiffnesscanlead tobrittlefracture (inparticular inshockloadings)

¡ Low-CTE moldcompounds alsohaveahigherstiffnessduetothehigherSiOfillercontent

8

OTHER NEGATIVE IMPACTS

Each datapoint onthis graph represents acommercially available mold compound

LOW-CTEMOLD COMPOUNDS

¡ Higher mold stiffness can lead to brittle fracture (inparticular inshockloadings)¡ Moreissueswith head-in-pillow due to packagewarpage

¡ ThedifferentCTEofthe mold changed the packagewarpage behaviour during solder reflow

9

OTHER NEGATIVE IMPACTS(2)

LOW-CTEMOLD COMPOUNDS

¡ Higher mold stiffness can lead to brittle fracture (inparticular inshockloadings)¡ HigherCTEmismatchbetween copperwireandmoldCTE leadtowirefatiguefractures

10

OTHER NEGATIVE IMPACTS(3)

OUTLINE

¡ Introduction

¡ Experimental Setup

¡ Results ofthe Thermal Cycling Experiment

¡ Cross-sectional Analysis

¡ Conclusions

11

EXPERIMENTAL SETUP

¡ Test component:¡ 9x9mmQFNwith64pins¡ The solderable exposedpadisabouthalfofthepackage size.¡ Die sizeisroughly4x4mm2

¡ Itmakesthatthispackagehasaratherlowdietopackageratio.¡ Threeversions aremade:

12

PACKAGEDESCRIPTION

MoldCTE LeadTipPlating WettableFlank

QFN#1 7ppm/°C CuExposed Yes

QFN#2 7ppm/°C E’less Tinplating Yes

QFN#3 12ppm/°C CuExposed No

WettableFlank

EXPERIMENTAL SETUP

¡ PCB:¡ 8-layerboardswiththe6innerlayers

completely filledwithcopper¡ tomaximizethestiffnessoftheboards¡ ToobtainaCTEasclosetothatofCuaspossible

¡ The totalthicknessis2.4mm.¡ Assembly:

¡ Twodifferent soldermaterials:SnPb andSn3%Ag0.5%Cu.

13

PCBANDBOARDASSEMBLY

2.4mmPCB

EXPERIMENTMATRIX

QFNtypeMold CTELeadTip

Wettable Flank

SolderPaste

SnPb SAC305

QFN17ppm/ ⁰CCuExposed

WettableFlank0to 100°CTC 0to 100°CTC

QFN27ppm/⁰CTinplating

WettableFlank0to 100°CTC 0to 100°CTC

QFN312ppm/⁰CCuExposed

Non -Wettable0to 100°CTC 0to 100°CTC

14

EXPERIMENTAL SETUP

15

THERMAL CYCLING TESTCONDITIONS

¡ The IPC-9701TC1test condition forsolder jointevaluation wasselected asthemostappropriate test.¡ 0to100⁰Cthermalcycling(air-to-air)¡ Totalcyclingtime=1hour

¡ rampuptime=10minutes¡ dwell-time=20minutes

¡ In-situmeasurement foropens

-20020406080100120

0 20 40 60 80 100 120 140 160 180 200

Tempe

rature

(°C)

Time(min.)

OUTLINE

¡ Introduction

¡ Experimental Setup

¡ Results ofthe Thermal Cycling Experiment

¡ Cross-sectional Analysis

¡ Conclusions

16

THERMAL CYCLING TESTRESULTS

17

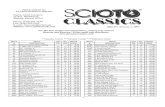

WEIBULL DISTRIBUTIONSQFN type Solder N63% β

QFN #1 SnPb 971 4.4

QFN #2 SnPb 1720 4.8

QFN #3 SnPb 5323 3.0

QFN #1 SAC305 1682 6.3

QFN #2 SAC305 1901 3.7

QFN #3 SAC305 5604 3.0

The results clearly reveal that the mostdominant parameter is the CTE of themold.• For SAC305 assemblies, the difference

between 7 ppm and 12 ppm/C QFN’s isa factor three.

• Solder material and flank wettabilityhavemuch less on the BLR.

OUTLINE

¡ Introduction

¡ Experimental Setup

¡ Results ofthe Thermal Cycling Experiment

¡ Cross-sectional Analysis

¡ Conclusions

18

CROSS-SECTIONAL ANALYSIS

¡ Forallanalyzedsamples,oneorevenallfourcorner jointsshowedfractures leading tothedaisychainresistance increase. ¡ Thisconfirmsthatthefractureisinducedbythe

CTEmismatchbetweenQFNandPCB,whichishighestinthe4corners.

¡ The fracturewasalwaysinsidethesolderjoint,andnotattheintermetallic compoundsnorthecopperpaditself.

¡ The solderfracturesareinduced throughlow-cyclefatigueduringthetemperature cycling.

19

GENERAL FINDINGSCreep strain (-)

CROSS-SECTIONAL ANALYSIS

20

QFN#1:MoldCTE:7ppm/°C; Cuexposedtip,Wettableflank

SnPb solder paste Failing after 971 cycles

• This assembly showed the earliest failures.• It is related to the non-optimal wetting resulting in almost all solder at the side,

however, not really functioning as a strong fillet.

CROSS-SECTIONAL ANALYSIS

21

QFN#2:MoldCTE:7ppm/°C;E’less Tinplatingontip,WettableFlank

SnPb solder paste Failing after 1720 cycles

¡ Thankstothefillet,thissolderjointcanresistmorecycles

¡ Cross-section showsstrongdamagewhichisduetotherepeated largeexpansion mismatchbetween QFNandboardineach cycle,after ithasalready failedmuchearlier butwhilethetestwasstillongoing.

¡ Thiscanonlybeexplained bythelow-CTEmoldcompoundusedinthisQFNpackage.

CROSS-SECTIONAL ANALYSIS

22

QFN#1:MoldCTE:7ppm/°C; Cuexposedtip,Wettableflank

SnAgCu solder paste Failing after 1682 cycles

¡ While theSnPb solderedQFNshowedverylowstand-offheightsatoneside,theSAC305solderedQFN’shasaquiteuniformstand-offheightresultinginaboutdoublelifetime

¡ The fracturesarefoundneartheinterfacewiththeleadofthecomponent, however,stillinthesolderjointitself(noIMCfailure).

¡ Alsohere, quitesomedamagewereseenwhichisrelated tothelarge expansionmismatchbetween QFNandPCB.

CROSS-SECTIONAL ANALYSIS

23

QFN#2:MoldCTE:7ppm/°C;E’less Tinplatingontip,WettableFlank

SnAgCu Solder paste Failing after 1901 cycles

¡ Similarconclusion aswithnon-wettableflankQFN

¡ Andasthesolderjointshapeisalsosimilartothenon-wettable version,weindeed canexpect aboutthesamelifetime.

CROSS-SECTIONAL ANALYSIS

24

QFN#3:MoldCTE:12ppm/°C;Cuexposed ontip,non-wettableflank

SnPb Solder paste Failing after 5323 cycles

¡ TheQFNwiththe12ppm/°Cmoldmaterialsurvivesaboutthreetimemoretemperature cycles.

¡ The fractureisvisible,butthere isnotsuchalargedamageasseenwiththepreviouscases.

CROSS-SECTIONAL ANALYSIS

25

QFN#3:MoldCTE:12ppm/°C;Cuexposed ontip,non-wettableflank

SnAgCu Solder Paste Failing after 5604 cycles

¡ Atinycrackisseenoverthewholelength.¡ BothSnPb andSAC305solderpastecan

surviveslonger than5,000cycleswhen12ppmCTEmoldcompound isusedinencapsulation.

OUTLINE

¡ Introduction

¡ Experimental Setup

¡ Results ofthe Thermal Cycling Experiment

¡ Cross-sectional Analysis

¡ Conclusions

26

CONCLUSIONS

¡ The conclusionoftheelaborated testwasthattheimpactofthesoldermaterialandflankwettability(electroless vsCuexposed) wasminimum(lessthan20%ofdifference) whilethemoldcompoundhadahugeimpact. Thecharacteristic lifetimeoftheQFN’swith12ppm/⁰Cwas3timeshigher thantheQFN’swith7ppm/⁰C.¡ Adifference insolder qualitywasseenwithnon-uniform stand-offheightsforSnPbsoldered

versusuniformstand-offheightswithSAC305solder.¡ Thisresultedinatwotimeshigher lifetimefortheSAC305solderedQFN.This wasonly

experienced with the Cuexposed QFN’s.¡ Forhighreliabilityapplicationsandelectronics operatingunder severeconditions, thismold

compound change createsamajorreliability concern andrequiresthoroughevaluation.¡ The impactonelectronics reliabilityisconsiderably greaterthanthatofachange insolderalloy

butasyetdidnotgetasimilarlevelofattention.

27

NEXTSTEPS

¡ Perform abroader experimental programto demonstrate the impactofthe mold CTE, andbenchmark its effect to other parameterssuch asD2Pratio,boardstiffness and solder composition

¡ Characterisation techniques to measure the mold CTEofcommercial components¡ Explore mitigation techniques

Inordertogetabroaderandgeneric viewontheimpactofthemoldCTEonBLR, andtocreateawarenesswithintheworld-wide industry,INEMI initiatedaprojectonthistopicwithmajorplayersintheelectronics assemblyindustry.

28

INEMINEWCOLLABORATIVE EFFORTS