How different is mechanical activation from thermal activation?: A case study with PZN and PZN-based...

Transcript of How different is mechanical activation from thermal activation?: A case study with PZN and PZN-based...

Solid State Ionics 127 (2000) 169–175www.elsevier.com/ locate / ssi

How different is mechanical activation from thermal activation?A case study with PZN and PZN-based relaxors

*John Wang , Junmin Xue, Dongmei WanDepartment of Materials Science National University of Singapore, Singapore 119260, Singapore

Received 7 July 1999; received in revised form 1 September 1999; accepted 6 September 1999

Abstract

Using Pb(Zn Nb )O (PZN) and PZN-based relaxor ferroelectrics, we demonstrate that the solid state reactions1 / 3 2 / 3 3

triggered by mechanical activation of mixed oxides can proceed via a completely different route from that in theconventional solid state reactions, where the process is controlled by one or more interfacial reactions and diffusions.Nanocrystallites of perovskite Pb(Zn Nb )O are formed in a highly activated state of mixed oxides where a degree of1 / 3 2 / 3 3

amorphization has taken place, followed by a steady growth with increasing degree of mechanical activation. The absence oftransitional pyrochlores, such as the Pb Nb O -type phases which have always been observed in the conventional solid3 4 13

state reactions, and the considerably low local temperature at the collision points suggest that the perovskite phase occurs viaa process involving nucleation and subsequent diffusionless growth. 2000 Elsevier Science B.V. All rights reserved.

Keywords: Mechanical activation; Lead zinc niobate; Perovskite

1. Introduction high-rate and complex natures involved have pre-cluded the endeavour of establishing exact mecha-

Following the pioneer work of Benjamin [1], who nisms behind most of the activation-triggered re-devised mechanical alloying for synthesizing novel actions. They are, therefore, much less investigatednanocrystalline metal and alloying powders, there and understood than those in the thermally activatedhas been a surge of interest in mechanical activation solid state reactions [10]. Mechanochemical re-over the past few years. There are a number of actions at the interface in microsecond orinteresting and unique phenomena observed in as- nanosecond duration of shock, impact and collisionsociation with mechanical activation, including re- in a highly activated state [11], local temperature-finement in crystallite size [2], structure deformation facilitated solid state reactions [12], and the nuclea-[3], creation of point, surface and lattice defects [4], tion at interface and subsequent growth of crystallitesamorphization of crystalline phases [5], phase trans- [13] are among the very few suggestions. In contrast,formations [6], crystallization from an amorphous conventional solid state reactions at high tempera-state and chemical reactions [7–9]. However, the tures are well established as a process involving one

or more interfacial reactions and diffusions facili-tated by thermal activation [14,15].*Corresponding author. Fax: 1 65-77-761-26.

E-mail address: [email protected] (J. Wang) Lead zinc niobate (PZN) exhibits a partially

0167-2738/00/$ – see front matter 2000 Elsevier Science B.V. All rights reserved.PI I : S0167-2738( 99 )00275-1

170 J. Wang et al. / Solid State Ionics 127 (2000) 169 –175

disordered perovskite structure and is a relaxor type 2. Experimental procedureferroelectric [16]. It has been however impossible tosynthesize a single phase Pb(Zn Nb )O of Commercially available PbO( . 99% in purity,1 / 3 2 / 3 3

perovskite structure via conventional solid state J.T. Baker, USA), ZnO( . 99% in purity, J.T.reaction of the constituent oxides PbO, ZnO and Baker), MgO( . 99% in purity, Aldrich, USA),Nb O at high temperatures. The thermally activated TiO ( . 99% in purity, Merck, Germany) and2 5 2

solid state reaction always leads to the occurrence of Nb O ( . 99% in purity, Aldrich, USA) powders2 5

one or more pyrochlore phases, such as the were used as the starting materials in this work.Pb Nb O -type phases [17]. This is a result of the Appropriate amounts of the constituent oxides, as3 4 13

difference in reactivity among the three oxides over a required by the stoichiometric Pb(Zn Nb )O1 / 3 2 / 3 3

wide range of temperatures. There is always a much and 0.54 Pb(Zn Nb )O –0.36 Pb(Mg Nb )-1 / 3 2 / 3 3 1 / 3 2 / 3

larger interfacial area between any two of the three O –0.1 PbTiO compositions, respectively, were3 3

oxides than the common contact area where all three ball milled together in ethanol for 48 h using zirconiaoxides are present, favouring the preferred interfacial balls of 5 mm diameter as the milling media. Thereaction between PbO and Nb O to take place [18]. slurries were then dried at 808C for 4 h and the2 5

Pb(Zn Nb )O crystals of perovskite structure as-dried powders were ground using an agate mortar1 / 3 2 / 3 3

grown from molten salt of PbO have been shown to and pestle to eliminate large powder lumps beforebe thermodynamically unstable over a wide range of being passed through 40 mesh sieves. Mechanicaltemperatures [19], originated from the considerations activation of the powder mixtures was carried out insuch as tolerance factor and site potential ratio [20]. a wear-resistant cylindrical vial with 40 mm inSurprisingly however, nanocrystalline diameter and 40 mm in length containing onePb(Zn Nb )O of perovskite structure is trig- stainless steel ball of 12.7 mm diameter using a high1 / 3 2 / 3 3

gered to occur in a mechanically activated oxide energy shaker mill operated at | 900 rpm [21]. Acomposition. batch of 5 g of powder was made each time and the

Having successfully synthesized several PbO- mechanical activation time was varied from 0 to 20based relaxor ferroelectrics, piezoelectrics and fer- h. The resulting powders were then characterized forrite-based magnetic compositions [21–23], we ob- phases present using an X-ray diffractometerserved that: (i) a single step of mechanical activation (X’Pert, Philips). A high resolution transmissioncan trigger the formation of a compound that cannot electron microscope (Philips CM300 FEG) and abe formed by conventional solid state reaction, e.g. BET specific surface analyzer (Nova-2000, Quan-Pb(Zn Nb )O of perovskite structure [21]; (ii) a tachrome) were employed to study their particle1 / 3 2 / 3 3

compound that can be steadily formed by the con- characteristics. The thermal behaviour of activation-ventional solid state reaction may not be triggered to derived PZN powder was studied using DSC (Dup-form by mechanical activation, e.g. Pb(Fe W )O ont Instruments) at a heating rate of 108C/min in air2 / 3 1 / 3 3

[24]; and (iii) transitional phases that are always from room temperature to 9008C.involved in the conventional solid state reactions arenot observed in mechanical activation, e.g. pyroch-lores Pb Nb O and Pb Nb O formed among 3. Results and discussion3 4 13 2 2 7

PbO, MgO and Nb O upon calcination [18]. On the2 5

basis of a case study using Pb(Zn Nb )O and As shown in Fig. 1, the powder mixture that was1 / 3 2 / 3 3

PZN-based relaxor ferroelectrics in this work, we not subjected to any mechanical activation consistsshow that the solid state reaction triggered by of crystalline PbO, ZnO and Nb O , indicating that2 5

mechanical activation proceeds via a process involv- little or no reaction took place among the threeing nucleation in a highly activated state, followed constituent oxides in the conventional ball mill. Twoby growth in crystallinity with increasing degree of strong broadened diffraction peaks occur over the 2u

mechanical activation. This is in contrast to the angle range of 28 to 328 for the oxide mixture thatconventional solid state reactions, where the process was mechanically activated for 5 h. The one at 29.18

is controlled by one or more interfacial reactions and corresponds to PbO (111) and the one at 31.18

diffusions occurring at high temperatures. corresponds to perovskite PZN (110). The very

J. Wang et al. / Solid State Ionics 127 (2000) 169 –175 171

skite PZN phase was further established apparentlyat the expenses of PbO, although there is littlefurther increase in the specific surface area (8.97

2m /g). A single phase PZN of perovskite structure isobserved for the composition mechanically activatedfor 20 h. There is also an apparent sharpening inPZN (101), (012), (021), (202) and (122) peakswhen the mechanical activation is extended to 20 h,suggesting that there is an increase in the crys-tallinity of perovskite PZN phase. It was estimatedusing Scherrer equation [25] on the basis of halfwidth of PZN(110) peak that the PZN nanocrystal-lites in the powder mechanically activated for 20 hare in the range of 10 to 15 nm in size. These XRDphase analyses clearly demonstrate that the initialstage of mechanical activation led to a significantrefinement in particle and crystallite sizes togetherwith a degree of amorphization, followed by theoccurrence and then growth of perovskite PZNcrystallites in the highly activated oxide mixture.Transitional pyrochlore phases, such as thePb Nb O -type phases that have always been ob-3 4 13

served as interfacial reaction products in the conven-tional solid state reaction [17], are not involved priorto the perovskite PZN phase. This suggests that theoccurrence of perovskite nanocrystallites is not aresult of the interfacial reaction as stated by theRoller model [26] and suggested by Boldyrev [11].

The nanocrystallites of perovskite PZN triggeredby mechanical activation of mixed oxides are

Fig. 1. XRD traces of mixed oxides of PbO, ZnO and Nb O2 5 thermodynamically unstable at elevated tempera-subjected to 0, 5, 15 and 20 h of mechanical activation. tures. Fig. 2 is a DSC plot at a heating rate of

108C/min in air for the PZN synthesized at 20 h ofmechanical activation. Two apparent exothermic

much broadened nature of PbO (111) at 2u angle of peaks, a broadened one centred at 387.58C and a29.18 implies that the initial 5 h of mechanical strong, sharpened one at 542.28C, are clearly shown.activation resulted in a significant refinement in The relatively weak and broadened one at 387.58C isparticle and crystallite sizes, together with a degree related to the release of mechanical strains intro-of amorphization of the constituent oxides. This is duced to the nanocrystalline particles and the slightsupported by a rise in specific surface area from 3.95 rearrangement of highly disordered surface states.

2m /g for the powder that was not subjected to The strong exotherm observed at 542.28C is due to2mechanical activation to 8.56 m /g for the powder the perovskite to pyrochlore transition, although

subjected to 5 h of mechanical activation. At the there is little change in specimen weight observed insame time, considerable amount of perovskite PZN TGA study. This was confirmed by the phasenanocrystallites was formed upon the initial 5 h of analyses carried out for the powders calcined atmechanical activation of constituent oxides, as indi- temperatures below and above the exotherm. Thecated by the strong and broadened peaks at 2u angles occurrence of perovskite PZN nanocrystallites in theof 31.1, 44.6 and 55.48, respectively. When me- activated oxide composition demonstrates that thechanically activated for 15 h, the amount of perov- in-situ temperature at the collision points is below

172 J. Wang et al. / Solid State Ionics 127 (2000) 169 –175

particular, the absence of transitional pyrochloresthat have always been observed in the conventionalsolid state reactions suggest that the nanocrystallitesof perovskite structure are not a result of theinterfacial diffusions and reactions among the con-stituent oxides. It is very likely, instead, that theyoccur via a nucleation process involving all the threeoxides in a highly activated oxide matrix, where asignificant refinement in particle and crystallite sizestogether with a degree of amorphization have takenplace. In fact, there is a much smaller amount ofcommon contact areas involving all three oxides inthe powder mixture than the interfacial contact areasbetween any two of the three oxides, e.g. betweenPbO and Nb O particles. On the one hand, this,2 5Fig. 2. The DSC curve of nanocrystalline perovskitetogether with the high reactivity between PbO andPb(Zn Nb )O synthesized at 20 h of mechanical activation at1 / 3 2 / 3 3

Nb O ensure the involvement of transitionala heating rate of 108C/min in air. 2 5

pyrochlore phases in the conventional solid state5428C, above which the perovskite phase is thermo- reaction when mixed oxides PbO, ZnO and Nb O2 5

dynamically unstable. are calcined at elevated temperatures. On the otherThe steady formation of perovskite PZN hand, it is very unlikely that the formation of

nanocrystallites in the activated oxide mixture and in nanocrystallites of perovskite PZN phase triggered

Fig. 3. A high resolution TEM micrograph showing the nanocrystallites of perovskite Pb(Zn Nb )O synthesized at 20 h of mechanical1 / 3 2 / 3 3

activation of the constituent oxides.

J. Wang et al. / Solid State Ionics 127 (2000) 169 –175 173

by mechanical activation is a result of the interfacial with PbO at a second step of calcination, is the onlyreactions involving all three oxides without first viable technique for a single phasegoing through any of the transitional pyrochlore Pb(Mg Nb )O of perovskite structure. The de-1 / 3 2 / 3 3

phases. As discussed above, the local temperature at liberate choice of such a multi-component 0.54the collision points is considerably low. Therefore, Pb(Zn Nb )O –0.36 Pb(Mg Nb )O –0.101 / 3 2 / 3 3 1 / 3 2 / 3 3

the growth of perovskite crystallites cannot be due to PbTiO (PZN–PMN–PT) composition in this work,3

one or more thermally activated diffusions that occur on the one hand, creates an excellent opportunity forin the conventional solid state reactions. Rather, it is one or more of the transitional phases to occur as aa result of the equilibrium between activation-driven result of the interfacial reactions between any two ofbuild-up and destruction involving the entire masses the oxides. On the other hand, it minimizes theof a perovskite nuclei [13]. Constant collisions andrearrangement of perovskite nuclei provided bymechanical activation create opportunities for two ormore nuclei to meet at favourable positions leadingto growth in the crystallite size. At the same time,there is also a probability that the perovskitenanocrystallites are distorted and fragmented bymechanical activation. Fig. 3 is a bright field highresolution TEM micrograph showing perovskite PZNnanocrystallites of 7 to 10 nm in dimension in thepowder synthesized at 20 h of mechanical activation.These nanocrystallites occur in an amorphous oxidematrix, forming particle aggregates of 50 to 100 nmin size. An amorphous layer of 2 to 5 nm inthickness was observed at the boundaries betweenneighbouring nanocrystallites. A considerably highdegree of structural disorder is clearly visible in mostof these fine PZN crystallites.

To support the nucleation and subsequent growthof perovskite crystallites in an activated oxide com-position, mixed oxides of PbO, MgO, ZnO, TiO and2

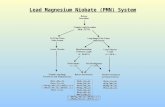

Nb O equivalent to the composition of 0.542 5

Pb(Zn Nb )O –0.36 Pb(Mg Nb )O –0.101 / 3 2 / 3 3 1 / 3 2 / 3 3

PbTiO (PZN–PMN–PT) were subjected to an3

increasing degree of mechanical activation. As hasbeen established, transitional pyrochlore phases, suchas Pb Nb O and Pb Nb O which are thermo-3 4 13 2 2 7

dynamically stable over a wide range of tempera-tures, always occur prior to the perovskite phasewhen mixed oxides of PbO, MgO and Nb O are2 5

calcined at high temperatures [18]. Thus, it has beenimpossible to form a single phasePb(Mg Nb )O of perovskite structure by an1 / 3 2 / 3 3

one-step solid state reaction of the constituent ox-ides. The Columbite method [27], whereby MgO and

Fig. 4. XRD traces of mixed oxides of PbO, MgO, ZnO, TiO2Nb O are first mixed and reacted together at2 5 and Nb O equivalent to the composition of 0.542 5temperatures of around 10008C to form a columbite Pb(Zn Nb )O –0.36 Pb(Mg Nb )O –0.1 PbTiO subject-1 / 3 2 / 3 3 1 / 3 2 / 3 3 3

MgNb O phase, prior to being mixed and reacted ed to 0, 5, 15 and 20 h of mechanical activation.2 6

174 J. Wang et al. / Solid State Ionics 127 (2000) 169 –175

chance of forming perovskite PZN–PMN–PT as a mixing homogeneity at molecular scales amongnanocrystallites via an interfacial reaction concur- the three cations was achieved prior to mechanicalrently involving all five oxides. As shown in Fig. 4, activation [28]. The activation-triggeredconsiderable amount of perovskite PZN–PMN–PT PbZr Ti O nanocrystallites underwent a steady0.52 0.48 3

phase is observed at the initial 5 h of mechanical growth from | 9 nm at 5 h of mechanical activationactivation, while there is a significant refinement in to | 20 nm at 30 h of mechanical activation. Weparticle and crystallite sizes together with a degree of have further observed that adding an appropriateamorphization. A single perovskite phase was ob- amount of Pb(Fe W )O phase as seeding in the2 / 3 1 / 3 3

tained at 20 h of mechanical activation. No inter- mixed oxides of PbO, Fe O and WO facilitates the2 3 3

mediate phases whatsoever were involved with in- formation of perovskite phase, which otherwisecreasing mechanical activation time prior to the cannot be synthesized by mechanical activation [29].perovskite phase. Fig. 5 is a bright field high This apparently supports the proposed nucleation andresolution TEM micrograph showing the subsequent growth of PZN and PZN-based relaxornanocrystallites of perovskite PZN–PMN–PT trig- ferroelectric phases of nanocrystalline structure trig-gered by 10 h of mechanical activation. They occur gered in mixed oxide compositions.in an amorphous oxide matrix, clearly indicating thatthey have been precipitated out from the amorphousmatrix as a result of the nucleation and subsequent 4. Conclusionsgrowth driven by mechanical activation.

In a separate study, nucleation and subsequent Mechanical activation of the mixed oxides of PZNgrowth of perovskite PbZr Ti O phase were and PZN-based compositions leads to a dramatic0.52 0.48 3

observed to occur at merely 5 h of mechanical refinement in particle and crystallite sizes togetheractivation in a co-precipitated amorphous precursor, with a degree of amorphization at the initial stage,where the interfacial reactions cannot possibly exist followed by nucleation and then growth of perov-

Fig. 5. A high resolution TEM micrograph showing the nanocrystallites of perovskite PZN–PMN–PT occurring in an amorphous oxidematrix triggered by 10 h of mechanical activation, indicating that they have been precipitated out from a highly activated matrix bynucleation and then growth with increasing degree of mechanical activation.

J. Wang et al. / Solid State Ionics 127 (2000) 169 –175 175

[6] G.F. Zhou, H. Bakker, Phys. Rev. B 49 (1994) 12507.skite nanocrystallites in the activated oxide matrix.[7] M.L. Trudeau, R. Schulz, Phys. Rev. Lett. 64 (1990) 99.Transitional pyrochlore phases, such as the[8] J.J. Gilman, Science 274 (1996) 65.

Pb Nb O -type phases, are therefore not involved3 4 13 [9] P. Somasundran, in: Y. Onoda Jr., L.L. Hench (Eds.),in the mechanical activation. This is very much Ceramic Processing before Firing, Wiley, New York, 1978.different from the conventional solid state reaction, [10] P.G. McCormick, F.H. Froes, JOM. Journal of the Mineral

Metals and Materials Society 50 (1998) 61.where the process is controlled by one or more[11] V.V. Boldyrev, Mater. Sci. Forum 225–227 (1996) 511.interfacial diffusions and reactions. The in-suit tem-[12] L. Takacs, Appl. Phys. Lett. 69 (1996) 436.

perature at collision points in the case of PbO, ZnO [13] N.N. Thadhani, J. Appl. Phys. 76 (1994) 2129.and Nb O is , 5428C. Therefore, it is very unlikely [14] W.D. Kingery, H.K. Bowen, D.R. Uhlmann, Introduction to2 5

that the growth of perovskite PZN nanocrystallites is Ceramics, 2nd Edition, John Wiley, New York, 1976.[15] H. Schmalzried, Chemical Kinetics of Solids, VCH, Newa result of the thermally activated diffusional pro-

York, 1995.cess. Instead, it is due to the collision and re-[16] J. Kuwata, K. Uchino, S. Nomura, Ferroelectrics 22 (1979)

arrangement of entire masses of perovskite nuclei 863.provided by consistent mechanical activation. [17] A. Halliyal, U. Kumar, R.E. Newnham, L.E. Cross, Am.

Ceram. Soc. Bull. 66 (1987) 671.[18] T.R. Shrout, A. Halliyal, Am. Ceram. Soc. Bull. 66 (1987)

704.Acknowledgements[19] H.M. Jang, S.H. Oh, J.H. Moon, J. Am. Ceram. Soc. 75

(1992) 82.The authors acknowledge the financial support of [20] N. Wakiya, K. Shinozaki, N. Mizutani, J. Am. Ceram. Soc.

the National University of Singapore (Grant no.: 80 (1997) 3217.[21] J. Wang, D.M. Wan, J.M. Xue, W.B. Ng, J. Am. Ceram. Soc.RP3979900) and the Institute of Materials Research

82 (1999) 477.and Engineering (IMRE, Grant no.: GR6611) during[22] J. Wang, J.M. Xue, D.M. Wan, W.B. Ng, J. Am. Ceram. Soc.

the course of this work. 82 (1999) 1358.[23] J.M. Xue, D.M. W an, S.E. Lee, J. Wang, J. Am. Ceram. Soc.

82 (1999) 1687.[24] S.K. Ang, J. Wang, D.M. Wan, J.M. Xue, (submitted to J.References

Am. Ceram. Soc.).[25] H.P. Klug, L.E. Alexander (Eds.), X-Ray Diffraction Pro-

[1] J.S. Benjamin, Sci. Am. 234 (1976) 40. cedures For Polycrystalline and Amorphous Material, Wiley,[2] E. Gaffet, D. Michel, L. Mazerolles, P. Berthet, Mater. Sci. New York, 1954, pp. 491–538.

Forum 235–238 (1997) 103. [26] A.N. Dremin, O.N. Breusov, Russ. Chem. Rev. 37 (1968)[3] T.G. Shen, C.C. Koch, T.L. Mccormick, R.J. Nemanich, J.H. 392.

Huang, J.G. Huang, J. Mater. Res. 10 (1995) 139. [27] S.L. Swartz, T.R. Shrout, Mater. Res. Bull 17 (1982) 1245.[4] U. Steinike, D.C. Uecker, K. Menning, B. Rosner, in: K. [28] J.M. Xue, D.M. Wan, S.E. Lee, J. Wang, J. Am. Ceram. Soc.

Tkacova (Ed.), Proceedings of the InCoMe’93, Cambridge 82 (1999) 1641.Interscience, Cambridge, 1993, pp. 121–130. [29] S.K. Ang, J. Wang, J.M. Xue, to be published (1999).

[5] G.J. Fan, F.Q. Guo, Z.Q. Hu, M.X. Quan, K. Lu, Phys. Rev.B 55 (1997) 11010.

![[email protected] online activation instructions [email protected] online activation instructions](https://static.fdocuments.us/doc/165x107/613d4690736caf36b75b678c/emailprotected-online-activation-instructions-emailprotected-online.jpg)