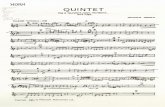

Horn

description

Transcript of Horn

Horn

A.K.Ichikawa, KEK

050310 T2K collaboration meeting

1st Horn 2nd Horn 3rd Horn

Graphite Targetbeam I=320kA

Activity around Horns

Japanese construction group

Target design : T. Nakadaira et. Al

S. Hatakeyama (stripline insulation)

Y.Hayato (3rd horn inner conductor)

S. Koike (support structure)

T.Nakadaira (3rd horn inner conductor)

H. Sato (cooling test, 1st horn outer conductor)

S. Tada (support structure)

Y. Yamada (support structure)

International collaboration

US( Colorado ) (E.Zimmerman, L.Bartoszek)

Start working on design and beam MC.

Beam MC

New plots and numbers based on the 04b flux

Notice:

Primary proton energy is 40 GeV since that value is planed for the 1st phase of the J-PARC accelerator.

The number of interaction at Super-K is decreased from the LOI number because

a) Smaller beam power at 40 GeV with same assumption on POT.

b) Smaller cross section for OAB2.5deg than OAB2.0deg.

e contamination is increased due to the longer decay volume(~130m) than the LOI assumption (~80m)

Still sensitivity plot is not updated.

OA3°

OA0°

(ref.: BNL-E889 Proposal)

TargetHornsDecay Pipe

Super-K.

Quasi Monochromatic Beam x 2~3 intense than NBB

Statistics at SK (OAB 2.5 deg,1 yr,22.5 kt)

~ 2200 tot ~ 1600 CC e ~0.4% at peak

Tuned at oscillation maximum

Neutrino energy spectrum x (Note )

OA2°

E

OA2.5°

Off Axis Beam

Flux OAB2.5deg, Ep=40GeV

e

Near/Far ratio

at 280m at 2km

Flux at SK

Flux at ND

Flux at SK

Flux at ND

Neutrino Energy Spectrum of charged current interaction

Event rate at ND280mper 1021POT

detector area(cm^2) nu mu nu_e ND2 300 x 300 1.08e+06 9.32e+03 events/ton = 0.35/spill/ton ND3 1000 x 100 8.83e+05 8.38e+03 events/ton ND4 100 x 1000 9.00e+05 8.44e+03 events/ton ND5 300 x 300 1.70e+05 3.34e+03 events/ton =0.056/spill/ton ND6 300 x 800 1.82e+05 3.31e+03 events/ton

Y. Hayato

On-axis

OAB2.5deg

Engineering issues of horns

Optimization of inner-conductor shape based on stress analysis

Stress due to Lorenz force and heat load have been examined by FEM.

• 1st horn : Optimization by static analysis and confirmation by dynamical analysis already done

• 2nd horn : First version by static analysis

• 3rd horn : Optimization by static analysis

This time, confirmation by dinamical analysis done.

=18MPa (c.f. allowable= 25MPa)

1st Horn-design and prototype production-

Big contribution to the design from US group (Colorado univ., Bartoszek Engineering)

Prototype production

Inner conductor

Prototype production

Outer conductorMade from a forged block!

Nozzle port

Service port

Fixing port

Prototype production

Current Feeder

Current Density

(A/m2)

18/23

ElectroMagnetic analysis by FEM

(A/m2) (A/m2)

20/23

Current Density

(A/m2) (A/m2)

(a)View1 (b)View2

22/23

Current Density

(A/m2) (A/m2)

(a)View1 (b)View2

23/23

Current Density

(T)

15/23

Magnetic Flux Density

Next FY plan-1st horn-

Design and production of remaining items

Current feeder shape based on the electromagnetic analysis

Cooling pipe configuration

Fixation

etc. etc….

Test operation

250kA at first

Cooling test

Field measurement

250kA endurance test

etc.etc…

3rd Horn Inner-conductor-design and prototype production-

Now being manufactured. It will arrive soon,

Next FY plan-3rd horn-

Design and production of remaining items

Outer Conductor

Insulator ring

Current feeder shape based on the electromagnetic analysis

Cooling pipe configuration

Fixation

etc. etc….

Stripline R&D

Conceptual design of support structure

Concrete

structure

Iron

Shield

(2.2m)

Concrete

shield

(1m)

Helium vessel

3rd

horn 2nd

horn

Target in

1st Horn Iron structure

Bus bar

Transformer

Iron shield

CollimatorProton beam

Pions into

Decay Volume

Service pit

Target Area

Very conceptual design

~4m

~1m

~1.5m くらいか

Supporting point

Achieve 1mm accuracy at the horn with ~300m alignment at the supporting point

Iron box

Distortion~200m

1st horn w/ Support structure

Drawn by S. Koike

3rd horn w/ support structure

Alignment

Dock of hornsDo positional alignment between a horn and support structure at the Target Station ground floor.

Baffle target and 1st horn 2nd horn 3rd horn

http://jnusrv01.kek.jp/~ichikawa/jhfnu/tgt-horn/support/TSsupport.040927.ichikawa.dwg

Remote Maintenance

Maintenance scenario (not official)

Target + 1st horn : exchange once per 2 years at most

2nd horn : exchange once per 4 years

3rd horn : exchange once per 4 years

Baffle : exchange once per 5 years

Requirement

Reproduce with 1mm accuracy

To save the waste stock room, it is desired that the equipment and support structure can be disconnected (remotely of course).

To save the waste stock room more, and to save the operation cost, it is preferred that the support structure is re-usable.

Remote disconnection/connection of horn stage, strip-line, water pipe, He pipe.

Remote stripline clamp test

How to hook and unhook horn from power stripline remotely in radiation area?Shaft toggles clamp to provide pressure for good electrical connection

Contact surfaces fine after two plug/unplug cycles 1.8 million pulses total

NuMI horn外国の研究所では、

バスバーのリモート着脱案

支持機構の着脱 –吊り下げロッド -

ホーン台支え棒

吊り下げロッド

アルミニウム?

支持機構箱に固定

ステンレス?

このような吊り下げロッドで、4箇所から吊り下げる。

1本にかかる荷重は、最大 200kg 程度。

ジャッキで引き上げる?

回転してホーン台支え棒を引っ掛ける

高さ位置決め

位置決めロッド

水平方向位置決め

ホーン台の2箇所につける。

1 番目 : 水平両方向

2番目 : 水平一方向

支持機構側

1番目 2番目

吊り下げロッド

ここら辺と反対側に位置決めロッド

R&D work for each component will be done in next FY.

There are many rooms for contribution from outside KEK.

Contact either Kobayashi-san, Yamada-san or me.

Schedule of FY2005

1st Horn

Design&Production

August

Test Operation

3rd HornDesign

Production

Stripline

Support structure

R&D