H.J.Tiziani, University of Stuttgart · 2010. 11. 9. · Advanced Optics by Aspherical Elements...

Transcript of H.J.Tiziani, University of Stuttgart · 2010. 11. 9. · Advanced Optics by Aspherical Elements...

-

Advanced Optics by Aspherical Elements

Processing and Metrology of aspheric SurfacesH.J.Tiziani, University of Stuttgart

Content

Introduction, Historical Background

Processing of aspheric surfaces

Metrology of aspheric surfaces

Summary and Future trends

1

-

Advanced Optics by Aspherical Elements Processing

Considerable progress has been made the last 30 years

Timeline 1638 Decartes; Shape copying machine principle

1920Mackensen Realisation of Shape copying

1976 Jones, Aspen, Bajuk; Computer Controlled Polishing

1976 Computer controlled grinding

1850 Manual polishing of aspheres

1980s Fluid Jet, MRF, IBF; Correction

1

Progress in generating and polishing processes (Historical)H.J.Tiziani

2

-

Principle of generating orpolishing spherical surfaces

Principle of a copy machine for aspheres

Grinding and Polishing of aspherical mirrors

Advanced Optics by aspherical Elements Processing

Grinding and Polishing of Aspheric Surfaces3 H.J.Tiziani

-

Generating Polishing/ smoothing Local correction

MetalIR material

Diamond turning

GrindingMilling

CCP

Fluid jet

Pitch polishing

Speed polishing

MRF

IBF

Fabrication

Classical Hybrid Moulding

Different fabrication processes

4 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Processing

Diamond turning Precision grinding Zonal polishing Precision optics moulding

Some manufacturing technologies5 H.J.Tiziani

-

Advanced Optics by aspherical Elements Grinding

Disc wheel grinding

The disc-shaped grinding tool is moved with precise contour-controlled axes (2 linear) to generate the aspherical surface.

6 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Grinding

Cup wheel grinding

The cup-shaped grinding tool is tilted with a constant angle to the surface normal. With this angle a point contact between tool and lens is achieved and the aspherical surfaceis generated with precise contour-controlled axes (1 swivel and 2 linear).

7 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Grinding

Roughness control by Grinding8 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Computer controlled processing

Principle and set-up of one of the first computer controlled grinding machinesbuilt by Zeiss (courtesy Carl Zeiss)

9 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Computer controlled polishing

dtds

ALCp

dtdz

⋅⋅=

where

Thickness change over time or removal rate [m/s];

Cp: Preston coefficientL: Load = Total normal force [N]; A: Surface area, where the removal takes place [m²]

: Relative velocity of work piece to tool [m/s]dtds

Polishing:The removal of material by polishing is a function of tool pressure,therelative velocity between tool and optical element and the polishing time.

Removal by polishing :Preston equation(1927)

10 H.J.Tiziani

-

≈ few µm

work pieceFilled with slurry

grain

Polishing pad

≈ few µm

work pieceFilled with slurry

grain

Polishing pad

cracks

brittle mode

surface

plastic zone

diamond

cracks

brittle mode

surface

plastic zone

diamondbrittle mode

surface

plastic zone

diamond

R

c(x): tool function

x

nominal shape

real shape

R(x)

0 x

Corrective Polishing(CCP) SmoothingGenerating

( ) ( ) ( )∫ −= ''' dxxsxxcxRTool function Real form measured

Desired removal

Computer controlled Form polishing11 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Corrective pol.

Final Form Polishing Process12 H.J.Tiziani

-

Advanced Optics by Aspherical Elements

Zonal polishing

13 H.J.Tiziani

-

Advanced Optics by Aspherical Elements CCP

tool

optical element

Computer controlled polishing process of the NTT ESO 3.5m mirror (left). Principle of the CCP process (right).

14 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Corrective polishing

Principle structure of ALPS Courtesy Schwarzhans Swiss Optic

15 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Corrective polishing

Form Corrective Polishing

Computer suported ultraprecision finishing of aspheric surfaces with Zonal Polishing is iterative because of variations of the tool function but can be economical by appropriate metrology.

Fluid jet, Magneto Reological Finishing or Ion beam correction polishing show no tool wear. The patented method of Magneto Rheological Finishing (MRF) has beeninvented in the late 80s in Minsk/Belarus. It has been further developed by a team around W. Kordonski and the Center for Optics Manufacturing (COM) in Rochester/USA for a deterministic fabrication of optical surfaces in particular aspheres). In 1998, QED Technologies introduced the first commercial product using MRF. The complete process chain with MRF for a production of aspherical surfaces was first presented in 2000 at Optatec in conjunction with Schneider Optic machines.

16 H.J.Tiziani

-

Principle of the MRF Process. The material is removed by the sheared MR fluid (W. Kordonsky, QED Technologies)

Advanced Optics by Aspherical Elements MRF Process

17 H.J.Tiziani

-

Advanced Optics by Aspherical Elements IBF

Principle of Ion Beam Figuring (IBF)(left). Outside view of an IBF System (right).

18 H.J.Tiziani

-

Guiding cylinder

spacer

Precision gob

MasterInjection molding

Hot embossing

Injection embossing

Different kinds of plastic moulding (left), the blank press method for glass (right)

Moulding temperature

Moulding method

Mould material

Advanced Optics by Aspherical Elements Moulding

19 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Micro lens fabrication

Wafer-based microlens manufacturing technology

Reactive ion etching (RIE) transfer process of resist micro lenses in fused silica. A correction of the lens slope is obtained by changing the etch rate between the resist and fused silica during the etching process.

20 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Metrology for optical systems

Metrology

Measuring principles for optical system performance

•Optical Transfer Function (OTF), The Modulation Transfer Function, MTF, as well as the a phase transfer function PTF•Interferometry•Wavefront Sensor such as the Shack-Hartmann wavefront sensor.•Foucault Test •The star test is used in astronomy and microscopy; the image of a pinhole is analysed.•Polarization properties are useful for stress analysis in the material for instance or stress induced by cementing or mounting of lenses or crystalline optical materials used for very short wavelengths •Transmission and stray light measurement.

21 H.J.Tiziani

-

Punktbild Hubble-Weltraumteleskop

Reason for limited resolution:Enlarged spread function (point image)

Hubble-Telescope

With sphericalAberration

WithoutSph. Ab.

Advanced Optics by Aspherical Elements Spread function/OTF

22 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Surface classification

Form ( shape), lateral dimension

Waviness, Defects,

Roughness,

mm1≥Λ

mmm 120 ≤Λ≤µ

mµ20≤Λ

Surface Classification and Surface Measurement

23 H.J.Tiziani

-

Metrology for optical surfaces

Surface form and roughness measurement of grinded and lapped surfaces •Stylus instrument

•Confocal instrument

•White light interferometry

Surface form measurement of polished optical surfaces•Interferometry is the best known and the most precise measuring technique for measuring the surface form.•The Shack-Hartmann wavefront sensor is an alternative•A stylus instrument is an another technique for measuring individual surface forms•Confocal instrument (scanning)•White light interferometry (scanning) •Deflectometry •Polarization optical methods

Roughness and waviness measurement of polished surfaces

•Stylus instrument ,White light interferometry, Confocal.

•Atomic force instrument

•Scattering: ARS, TIS24 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Taktile measurement

Diamond tip in tactile measurements

25 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Point measurement, Foc. Det.

White light Interferometer

Mirau-Objective 50 x

Measuring field 0,384 x 0,286 mm²

NA (Objective) 0,55

Working distance ca. 0,5 mm

Lateral Resolution ca. 1 µm

z-Resolution 10 nm

0 1 2 3 4 5

Z [µm]

100

150

I

Lightsource

Referencemirror

Object

Tubuslens

Partly reflectingmirror

Mirau-objective

Camera

Lightsource:•White light•LED•Superlum. diode•Laserdiode (antireflex)

26 H.J.Tiziani

-

PinholeBeamsplitter

f

I

z

z

Object

z=f

αλ

cos.FWHM

−⋅

=1450

α

FWHM

Advanced Optics by Aspherical Elements Point measurement, Foc. Det.

Pointdetector

Principle of Confocale Measurement27 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Surface characterization by Power Spectral Density, PDS

Micromap 2,5-fach

Micromap 20-fach

AFM

Micromap 2,5-fach

Micromap 20-fach

AFM

Power spectral density plot and related surface topography for a diamond turned master.The characteristic structures from diamond turning are clearly visible in the PSD plot

28 H.J.Tiziani

-

Topography, 5µm*5µm500 * 500 pixeltip radius < 5nm :

Roughness:0.34nm RMS

2D-Fourier Transforme :Spatial Frequency Spectrum

Spatial Frequency Filtered,Low-Pass : |kgr| = 1/λ | λ=500nm

kx /µm-1

k y/µ

m-1

Fourier-filteredTopography :

Roughness0.18nm RMS

0

0

25

-25 25

Influence of the low pass filter on the roughness measurement

29 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Surface characterization , Roughness measurement, ARS

Schematic of operation for microstructure testing(Duparre)30 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Surface measurement methods

50 mm – 2m4 - 80,01 mm – 1 mmMacroscopic Fringe Projection

o.1mm-100mm0.1nm-10nmScattering

scanningpointwise0.05nm-0.1nmAtomic force microscope

1mm-100mmscanning speed0.1mm/sec0.5nm-400nmStylus instrument

1mm - 30 mm4 - 80,1 µm - 10 µmMicroscopic Fringe Projection

50 µm - 5 mm100 - 10001 nm -10 nmWhite Light Interferometry

1 µm – 30 mmparallel proc50 - 20010nm - 10 µm

Confocale Principle (Microscope)

Diameter of Measuring field

Camera Images inpixels(typical)

Height Resolution(typical)

Measuring Principle

Comparison of 3D-microscopic surface measuring methods 31 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Interferometry for surface Form measurement

Laser

M=F‘

KS Obj.

PS

Camera

TPL3

L2

L1

Twyman Green interferometer for system or surface testing with typical fringe patterns

32 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Interferometry for Form measurement (asph.surface)

Element under Test

Beamsplitter

Beamsplitter

Mirror

Mirror

ΣRef+ ΣObj

ΣObj

Adaptive Optics

ΣRef

Master

Comparison Measurement using Mach Zehnder- Interferometer

33 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Aspheric surface Form measuring

Problem:

• Wavefront departure from a best fit sphere leads to high local fringe density in the interferogram

Reason:

• slope of aspheric wavefront

Effect:

• Interferogram cannot be unwrapped• (Violation of Nyquist-theorem)• Vignetting and caustic of the wavefront

Moiré 1.Order

Interferogram

Problems by Testing Aspherical Surfaces

34 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Form measurement of AS

Methods for Testing Aspheric Surfaces

Wavefront shaping systems + null test + partial compensation

staticdiffractive

refractive

adaptivemembrane mirror

LCD

dynamic subapertures

dynamic microlens array

static microlens array

Multiple wavelength interferometry

(Moiré techniques)

Shack-Hartmann sensor

Alternative methods

Other methods: Stilus instruments(pointwise), Stitching(lateral, along opt.axis),Deflectometry

35 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Interferometry for Form measurement of AS

Reference

Asphereunder test

CGH

CCD

Objective

Spatial filter

Reference

Aspheric system under test

CGH

CCD

Spatial filter

Testing aspherical surfaces, AS, and systems with Null lens(CGH)

Test of refractive Null lens with CGH in reflection

Testing an aspherical surface in reflection; CGH in transmission

36 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Null lens testing

PV = 133,1 nm / RMS = 21,5 nm

-100 -50 0 50 100

x [mm]

-100

-50

0

50

100

y [m

m]

-20020406080

[nm

]

PV = 53,9 nm RMS = 16,5 nm

-100 -50 0 50 100

x [mm]

-100

-50

0

50

100

y [m

m]

010203040

[nm

]

PV = 126,9 nm RMS = 13,6 nm

-100 -50 0 50 100

x [mm]

-100

-50

0

50

100

y [m

m]

-60-40-200204060

[nm

]

Refraktives K-System

CGHRefractivecompensationsystem

CGH: νmax = 500 Lp/mmpmin = 2 µmd = 220 mm

CGH as Aspheric Master (Null Mirror)

37 H.J.Tiziani

-

Advanced Optics by Aspherical Elements CGH as Null lens

Parameters to be considered in CGH-Null Testing– Interferometer type and CGH Position – Chrome on glass vs. Phase type CGH

(Diffraction efficiency, Setup: application in single/double reflection/pass?)

– Inline vs. Off axis CGH (Separation of diffraction orders)

– CGH Specification and Feasibility(Wavefront aberration caused by a patterndistortion error depends on spatial frequencyin the CGH)

CGH Design

38 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Interferometry with CGH

Procedure for testing aspheric surfaces

39 H.J.Tiziani

-

CGH-null: νmax = 35 Lp/mmpmin = 29 µmd = 86 mm

PV = 450,5 nmRMS = 79,7 nm

Alignment-CGH: νmax = 500 Lp/mmpmin = 2 µm

Testing of an asphere

Advanced Optics by Aspherical Elements Inerferometry with CGH

CGH as Null-Lens

40 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Interferometry with CGHAberrations caused by

pattern distortion

-20 -10 0 10 20

x [mm]

-20

-10

0

10

20

y [m

m]

-100

-50

0

50

100

[nm

]

1. Distortion of the hologrampattern

→ Writing errors

2. Surface figure errors of theCGH-substrate:

→ Surface figure errors, flexure

Surface figure errorsof a chrome blank

-40 -20 0 20 40

x [mm]

-40

-20

0

20

40

y [m

m]

-150-100-50050

[nm

]

CGH-Aberrations

41 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Interferometry with CGH

Cross –Comparison with different CGH‘s

42 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Interferometry with CGH

Calibration

43 H.J.Tiziani

-

Advanced Optics by Aspherical Elements CGH generation

Technical data wavelength of exposition 488 nm intensity of exposition < 20 M W /cm 2 diam eter of substrate < 290 m m thickness of substrate < 24 m m spot size 0.8 µm resolution (radia l) 80 nm resolution (azim utal) 0.1"

CGH generation with a Photoplotter for testing aspheric surfaces

44 H.J.Tiziani

-

Advanced Optics by Aspherical Elements CGH Typ

Amplitude CGH

Phase CGH

Copying Technique and Etching process45 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Form measurement

Alternative Methods

• Wavefront adaption with membrane mirrors

• Wavefront adaptation with adaptive optics(liquid crystal displays)

• Multiple Wavelengths Interf.

• Shack Hartmann (adaptive)

• Stitching lateral and axial (Verifire Zygo)

• Reflectometry

• Pointwise measurement (scanning)

46 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Deform. mirror

Wavefront adaptation in Astronomy by deformable Mirror47 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Wavefront adaptation

• continuous shape• high reflectivity, dielectric

coatings possible(even used in laser resonators)

• fast (switching times below 1 ms)

Examples for electrode layouts

Hexagonal Structur Ringshaped Structur

Membrane Mirror48 H.J.Tiziani

-

λ/4pol. BS HVamp.

.Transmission sphere-

Aspheric surfaceunder test

CCD

Reference

HeNe

telescope

TGI Setup

Membranemirror

Asphärische WellenfrontdeformationenMembranspiegel #1

-1,0 -0,5 0 0,5 1,0rel. Apertur

-40

-20

0

z [µ

m]

Asphärische WellenfrontdeformationenMembranspiegel #1

-1,0 -0,5 0 0,5 1,0rel. Apertur

-40

-20

0

z [µ

m]

Asphärische WellenfrontdeformationenMembranspiegel #1

-1,0 -0,5 0 0,5 1,0rel. Apertur

-40

-20

0

z [µ

m]

Advanced Optics by Aspherical Elements Wavefront adaptation

Wavefront Adaptation by a Membrane Mirror49 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Multi wave lengths Interferometry for Form measurement

Two wave lengths Interferometry

λ 1 λ 2

λ λ λλ λ

µsyn m= −=1 2

2 1

66 7| |

,

822 nm

0 200 400 600 800X

0

200

400

600

800

Y

0

1E-5

2E-5

3E-5

4E-5

5E-5

6E-5

812 nm precompensation

asphere

LD2 812 nm

LD1 822 nm

monomode-fiber

piezo-translator

membranemirror asreference

digital camera

50 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Adaptive optics for Shack Hartman Sensor

Shack Hartmann Sensor

Shack Hartmann Sensor measures the slopeof the wave front

Some limitations- are due to :

•Ambiguity, when the spot depasses the corresponding pixel

•Deformation or defocusing of the spot due to curvatures of the wavefront across the microlens used (large aberrations)

A solution is the use of adaptive microlenses

51 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Shack Hartmann Sensor

principle:

Local wavefront slope:

f

dy dx

dy1δ/δx W(x,y) =fδ/δy

Accuracy scales with f

Wavefront reconstruction by

• direct integration of wavefront slopes

• least square methods for error minimization

Principle of Shack Hartmann Sensors

52 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Shack Hartmann sensor for AS

extreme slopes:

spots leave target areas,ambiguity occurs

extreme curvatures:

aberrated spots not suitablefor accurate determinationof positions

Problems with extreme wavefront shapes

53 H.J.Tiziani

-

programmablehigh resolution

LCD

replacedby

Advanced Optics by Aspherical Elements Active Adaptive optics

static, diffractivemicrolens array

Dynamic microlenses generated by LCDs

54 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Shack Hartmann with adaptive optics

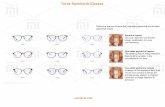

accuratedeterminationof spotpositionsImpossiblewithout localab.correction

Measurement with consideration of local wavefront aberrations:Object under test:progressive lens with an addition of 3dpt.55 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Adaptive optics for tilted wavefronts

Detail for generating the tilted reference wave and the phase shifting

Principles of dynamic reference or object beam

56 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Interfermetry with tilted wavefronts

Single phase measurements of a defocused reference surface with5x5 tilts(left), the result after unwrapping of 5x5 interferograms (right)

57 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Deflectometry

Fringe-Projector

Groundglass

Aspheric Surface(Progressive Eyeglass)

DeformedFringe pattern

CCD-Camera

Deflectometry used for testing Progressive Eyeglasses

58 H.J.Tiziani

-

Advanced Optics by Aspherical Elements Processing and Metrology

Summary and Conclusion•A lot has been invested in machines and processing lately for high precision and economic production of spherical and aspherical surfaces.

•Computer supported processing together with process simulation and

Correction has been and will be further improved

•Precision manufacturing is only possible if the quality can be measured. In particular, metrology for Form measurement of aspheric surfaces needs to be further improved. Today, metrology is a cost driver.

•Aspheric surfaces will be used more frequently when the cost of an aspheric surface is not much higher than twice the cost of a spherical surface.

•In process metrology is required. New techniques are or will be developed. Some possibilities were discussed at least in principle.

•In future system performance may be improved by an aspheric corrector surface.

•Care needs to be taken in the mounting because aspherical surfaces and systems are usualymore sensitive to centring (tilt)59

H.J.Tiziani

Punktbild Hubble-WeltraumteleskopWhite light InterferometerProcedure for testing aspheric surfacesCross –Comparison with different CGH‘sCalibrationMembrane MirrorWavefront Adaptation by a Membrane MirrorTwo wave lengths InterferometryShack Hartmann Sensor

![4 Wall thickness measurement - WTECwtec.pt/demo/sauter/wall_thickness_measurement.pdf · 44 04 [Max] mm [d] mm KERN TD GOLD 40. 22,5 0,01 450,- 961-113 120,-Wall thickness measurement](https://static.fdocuments.us/doc/165x107/5abe83a67f8b9ad8278d40e6/4-wall-thickness-measurement-04-max-mm-d-mm-kern-td-gold-40-225-001-450-.jpg)