Highlights from Faraday discussion 170: Challenges and...

Transcript of Highlights from Faraday discussion 170: Challenges and...

6248 | Chem. Commun., 2015, 51, 6248--6256 This journal is©The Royal Society of Chemistry 2015

Cite this:Chem. Commun., 2015,

51, 6248

Highlights from Faraday discussion 170:Challenges and opportunities of modernmechanochemistry, Montreal, Canada, 2014

Tomislav Friscic,*a Stuart L. James,b Elena V. Boldyreva,cd Carsten Bolm,e

William Jones,f James Mack,g Jonathan W. Steedh and Kenneth S. Suslicki

The Faraday Discussion Mechanochemistry: From Functional Solids to Single Molecules which took

place 21–23 May 2014 in Montreal, Canada, brought together a diversity of academic and industrial

researchers, experimentalists and theoreticians, students, as well as experienced researchers, to discuss

the changing face of mechanochemistry, an area with a long history and deep connections to manufac-

turing, that is currently undergoing vigorous renaissance and rapid expansion in a number of areas,

including supramolecular chemistry, smart polymers, metal–organic frameworks, pharmaceutical materi-

als, catalytic organic synthesis, as well as mineral and biomass processing and nanoparticle synthesis.

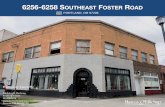

In May 2014, the New Residence Hall ofMcGill University provided a home to aunique gathering of approximately 100 exp-erts, novices and aficionados of mechano-chemistry (Fig. 1).1 Entitled Mechanochemistry:From Functional Solids to Single Molecules,the 256th Faraday Discussion was inspired bythe rising importance of mechanochemistryin making, understanding and manipul-ating molecules, and was envisioned as a firststep towards bridging the perceived gap

between researchers in different sub-areas ofmechanochemistry.

Grinding and milling of bulk materialshave traditionally been associated with

Fig. 1 Macdonald Physics Building, a hallmark of McGill University, and the site of Ernest Ruther-ford’s pioneering studies on a-, b- and g-radiation.

a Department of Chemistry and the Centre for Green

Chemistry and Catalysis, McGill University,

801 Sherbrooke St. W., H3A 0B8 Montreal, Canada.

E-mail: [email protected] School of Chemistry and Chemical Engineering,

Queen’s University, Belfast, UKc Novosibirsk State University, ul. Pirogova, 2,

Novosibirsk, Russiad Institute of Solid State Chemistry and

Mechanochemistry SB RAS, ul. Kutateladze, 18,

Novosibirsk 630128, Russiae Institut fur Organische Chemie der RWTH Aachen

University, Landoltweg 1, 52056 Aachen, Germanyf Department of Chemistry, University of Cambridge,

Lensfield Road, Cambridge, CB2 1EW, UKg Department of Chemistry, University of Cincinnati,

301 Clifton Court, Cincinnati, OH 45221-0172, USAh Department of Chemistry, Durham University, South

Road, Durham, DH1 3LE, UKi School of Chemical Sciences, University of Illinois at

Urbana-Champaign, 600 S. Mathews Av., Urbana,

IL 61801, USA

DOI: 10.1039/c5cc90113h

www.rsc.org/chemcomm

ChemComm

CONFERENCE REPORT

Publ

ishe

d on

18

Mar

ch 2

015.

Dow

nloa

ded

on 2

9/07

/201

5 20

:43:

46.

View Article OnlineView Journal | View Issue

This journal is©The Royal Society of Chemistry 2015 Chem. Commun., 2015, 51, 6248--6256 | 6249

metals,2 inorganic materials,3 specificallyminerals,4 and polymers,5 but has nowalso become the focus of chemists wishingto develop solvent-free and energy-efficientapproaches to molecules and molecularmaterials, or who are simply interested inexploring the properties and advantages ofa non-conventional reaction medium.Mechanochemistry has found followersin broad areas of chemistry and industrialdevelopment, ranging from inorganicchemistry6 to organic7 and supramolecularchemistry,8 with the most recent additionsincluding the synthesis of coordinationpolymers (including metal–organic frame-works, MOFs)9 and pharmaceutical solids(e.g. making and screening polymorphs,cocrystals, amorphous phases).10 In con-trast, ultrasonic radiation provides anotherway to expose molecules and particles tohigh shear forces suitable for materialsprocessing and fundamental studies ofchemical bonding.11 The most clear-cutapproach to mechanochemistry is mani-pulation of individual molecules andatoms by tools of high precision, such asthe tip of the atomic force microscope(AFM), allowing the determination of fun-damental properties of individual mole-cules (e.g. flexibility of protein structures),as well as precise surface patterning andmodification.12

Another, very different aspect ofmechanochemistry is understanding theprocesses which occur in different typesof mechanical devices, e.g. by in situmonitoring of reaction progress,13 ortheoretical modelling of distribution ofstress and temperature throughout thesample being milled, with the ultimatepurpose to scale-up and optimise thetype of mechanical action for a specificchemical transformation.

Therefore, it was clear from the outsetof this meeting that mechanochemistry isof exceptional, as well as growing interestfor chemists, physicists, theoreticians andindustrial researchers. This broadness wasreflected in the composition of participantswho spent three days discussing funda-mentals, applications and problems thatdistinguish or, perhaps, connect differentaspects of mechanochemistry. The parti-cipants included researchers from acrossNorth & South America (USA, Canada,Mexico, Colombia, Brazil), Europe (United

Kingdom, France, Germany, Poland,Slovakia, Croatia, Switzerland) and Asia(India, China, Russia), representatives ofchemical, mining, pharmaceutical andfood industries, as well as representativesof manufacturers of milling equipment(e.g. Retsch US, Spex).

Opening lecture

The conference was opened by WilliamJones (University of Cambridge), whoprovided a short but elaborate overviewof the history of mechanochemistry (notingthat some of the seminal experimentsin mechanochemistry were reported byMichael Faraday) and its future opportunities(DOI: 10.1039/C4FD00162A). The openinglecture highlighted the importance ofmechanical processing in the context ofindustrial and materials manufacture,and especially in pharmaceuticals materialsscience. Prof. Jones described howsophisticated mechanochemical techniques,such as liquid-assisted grinding, bring aboutimprovements in generating and controllingnew solid forms of pharmaceuticals,such as pharmaceutical cocrystals,12

while at the same time the behaviourrequired of materials and processingparameters during large-scale mechanicalprocessing remain an open problem. Thisinspiring and exciting opening lecturewas followed by the first of the fourtopical sessions, chaired by Stuart L.James (Queen’s University Belfast) andTomislav Friscic (McGill University).

Session 1:mechanochemistry oforganic molecules, softmaterials andpharmaceuticals

The session was off to a dynamicstart with the presentation by LeonardR. MacGillivray (University of Iowa) whodescribed a novel and experimentallysimple strategy for coupling photochemistrywith mechanochemical milling (DOI:10.1039/C4FD00006D). This vortex grindingstrategy14 allows mechanochemical grindingof photoactive solids under continuousexposure to ultraviolet light, leading to

completely solvent-free and quantitativesynthesis of a para-cyclophane (Fig. 2a).The discussion that ensued, and that wasfacilitated by the student hosts Patrick A.Julien and Igor Huskic (McGill University),established that this technique resolves along-standing problem of light penetrationin solid-state photochemical synthesis.†The second presentation, by GraemeM. Day (University of Southampton),described efforts in computationallyaddressing reversible covalent reactionsby mechanical milling (DOI: 10.1039/C4FD00162H), specifically the base-catalyzed equilibration of aromatic dis-ulfides.15 Outcomes of these computa-tional studies show that lattice energycalculations, combining anisotropicatom–atom potentials with moleculardensity functional theory (DFT), open away to rationalise or even predict the courseof reversible mechanochemical transforma-tions. However, successful modelling andprediction of mechanochemical reactivityunder thermodynamic equilibrium are stillat a very early stage, with the principlehurdle being the conformational flexibilityof explored molecules. The discussion†that followed was highly positive aboutthis major computational advance inmodelling mechanochemical reactions,and highlighted the modelling of reactionkinetics as the next big challenge. In thefinal presentation of this session TamaraD. Hamilton described the application ofmechanochemistry to one of the persistentlyhighly challenging problems of syntheticorganic chemistry: the synthesis of por-phyrins (DOI: 10.1039/C4FD00140G).Prof. Hamilton presented a two-stepmethodology to access a variety of meso-substituted porphyrins by mechano-chemical reaction of suitable aldehydesand pyrroles, followed by a mechano-chemical oxidation step. This protocolgave porphyrin targets with significantbenefits compared to solution-basedprotocols: reactions are much faster (lessthan an hour compared to several hours)and the use of high temperatures andcorrosive reagents is avoided (reflux inpropionic acid is the conventional syntheticalternative). A mechanochemical first step

† Transcripts of all discussions are also published inthe Faraday Discussions volume 170.

Conference Report ChemComm

Publ

ishe

d on

18

Mar

ch 2

015.

Dow

nloa

ded

on 2

9/07

/201

5 20

:43:

46.

View Article Online

6250 | Chem. Commun., 2015, 51, 6248--6256 This journal is©The Royal Society of Chemistry 2015

followed by oxidation in chloroform givesyields comparable to those obtained froman entirely solution-based process, whileeliminating a large amount of solventand reducing reaction time. The sub-sequent discussion† revealed that the‘green’ nature of this methodology canbe further improved by the using solvent-free entrainment sublimation for productpurification. The benefits and simplicity ofthis mechanochemical approach arereflected in all metrics relevant to sustain-ability and environmentally-friendly natureof chemical reactions.

The effect of different types of mechanicalaction on chemical reactivity was demon-strated in the contribution of AdamMichalchuk and co-workers (Universityof Edinburgh and Novosibirsk State Uni-versity) (DOI: 10.1039/C4FD00150D).Mixtures of a-glycine and b-malonic acidwere shown to produce two unique reac-tion products when submitted to isolatedimpact and shear treatments. This leadsto the formation of zones with distinctchemical reactivity within a single millingvessel,16 an observation of particular

importance when considering the purityand control of industrialized mechano-chemical processes. Thermal investiga-tion suggested that reactivity undershear treatment may be induced due toheating, while a tablet-induced pressuremodel was suggested as a potentialmechanism for reactions under impacttreatment. The first session was followedby a Lightning Session of 14 rapid flashpresentations selected by the organizersto highlight the most outstanding postercontributions.

Flash presentations

The flash presentations were given byKatharina Holz (University of Kiel) on‘‘A 1,2,3-triazole for mechanically induced1,3-dipolar cycloreversion’’, who describedmechanical reversal of the popular ‘clickreaction’ of an alkyne and an azide bypulling on a triazole fragment using theAFM tip. Next, Robert Schmidt (Universityof Jena) highlighted his work on assessingenergetics of the milling aldol reactionbetween barbituric acid and vanillin. FilipTopic (University of Jyvaskyla) described a

new strategy for the preparation of ternary(three-component) cocrystals held by acombination of hydrogen and halogenbonds, enabled by mechanochemicalcocrystal screening. The next presenterwas Manuel Jorres (RWTH Aachen Univer-sity) who presented the use of ball millingfor solvent-free organocatalytic Michaeladditions. Qiwen Su (Barry University) gavea highlight of a novel mechanochemicaltechnique for the preparation of por-phyrins, while Daniel Prochowicz out-lined an unprecedented technique forthe synthesis of isoreticular MOFs(IRMOFs), including the archetypal materialMOF-5, that have so far resisted synthesisby mechanochemical means.17 The nextpresentation was from Canada, given byGeorge Margoutidis (Memorial University,Newfoundland), who described ballmilling for depolymerisation of chitininto small amino-substituted molecules.Gurpaul Kochhar (Queen’s University,Kingston) gave a brief overview of his workon theoretical modelling of mechanically-induced distortions in molecular structureand ring opening of cyclobutene mechano-phore. Frederic Lamaty (Institut des Bio-molecules Max Mousseron, Montpellier)gave a summary of his poster ‘‘Mechano-chemistry in organic synthesis’’, describingstoichiometric and catalytic mechano-chemistry in the synthesis of amides,amino acids and (oligo)peptides. Next,Vladimir Stilinovic (University of Zagreb)gave details of his systematic investigationof the role of acetone vapor on forming newcrystalline phases in thin layers. AileenNielsen (Columbia University) highlightedher poster ‘‘High resolution single-moleculeforce spectroscopy probes inter-molecularinteractions’’, on using AFM to evaluate theuse of intermolecular recognition and non-covalent bonding in making two-moleculejunctions. Cristina Mottillo (McGill Uni-versity) presented a novel approach forthe synthesis of solid-state fluorescentmaterials, by entrapment of BODIPY dyesinto MOFs using either mechanochemistryor the recently developed accelerated agingtechnique. Next, Matej Balaz described thesynthesis of L-cysteine-capped core–shellluminescent quantum dot nanoparticlesCdS@ZnS by a rapid three-step millingprocedure, delineated in his poster‘‘Characterization of mechanochemically

Fig. 2 (a) The para-cyclophane prepared by the MacGillivray group using vortex grinding, combin-ing simultaneous ball grinding and photochemical [2+2] photodimerisation. Products of mechano-chemistry at different scales: (b) a cluster crystal of guanidine carbonate produced by shaking thepowder suspended in a saturated solution at 1000 rpm (presented by L. Cuccia) and (c) a compositeof lignin matrix and rhenium nanoparticles prepared by the Moores group through milling Re(CO)5Brwith Kraft lignin.

ChemComm Conference Report

Publ

ishe

d on

18

Mar

ch 2

015.

Dow

nloa

ded

on 2

9/07

/201

5 20

:43:

46.

View Article Online

This journal is©The Royal Society of Chemistry 2015 Chem. Commun., 2015, 51, 6248--6256 | 6251

synthesized CdS@ZnS quantum dots:focus on surface properties and potentialinteraction with capping agent’’. Thefinal presentation was given by LouisCuccia (Concordia University), whoseposter ‘‘Enantiomer-specific orientedattachment in conglomerate crystals ofguanidine carbonate’’ demonstrated inter-particle collisions as a mechanism of crystalgrowth and spontaneous deracemizationin Viedma ripening (Fig. 2b). The rapidlyconcluded Lightning Session was followedby a rich and social poster session,accompanied by an apparently almostinexhaustible wine reception and a freeevening that saw a large number of meetingparticipants spontaneously gathering at theMcGill University Graduate Student Club,the (in)famous Thomson House pub.

Session 2:mechanochemistry ofinorganic compoundsand coordination-basedmaterials

The excitements of the previous nightdid not hinder the timely beginning ofthe second session on Thursday morning.The session, chaired by Leonard MacGillivrayand Laszlo Takacs, was opened by DavidW. Peters (ATMI, USA), who describedthe first large-scale synthesis of an impor-tant organometallic compound bis(n-pro-pyltetramethylcyclopentadienyl)strontium(SrCp02), by mechanical agitation of SrI2

and KCp0 in diethyl ether (EtOEt) (DOI:10.1039/C4FD00157A). Development ofthis first large-scale organometallicmechanosynthetic procedure was basedon the unexpected discovery that smallscale reactions, stirred by a magnetic stir-rer, reproducibly gave the product (SrCp02�EtOEt), whereas large batch reactions stir-red by an overhead stirrer did not result inany product. This revealed that the reac-tion takes place by mechanical crushingof the reagent solids in the presence ofether. Realisation of the mechanochemicalnature of this process enabled scale-up to atleast 0.5 kg amounts using a speciallydesigned large-volume glass reactorequipped with steel milling balls. The dis-cussion focused on the importance of ether

which, although a poor solvent for thereactants, performs several roles in thisprocess: as a ‘lubricant’ for kinetic accelera-tion of the reaction, as a heat sink for thisexothermic reaction, as a dispersant forproduct removal from the reaction sites,and as a suspending agent for thereactants.† Next, Lucia Maini (Universityof Bologna) highlighted mechanochemicalsynthesis and discovery of new luminescentcopper(I) iodide (CuI) materials based onthe ligand tris(2-pyridyl)phosphine (PN)(DOI: 10.1039/C4FD00164D). Ball millingwas demonstrated as a simple means,complementary to solution synthesis, toscreen for supramolecular architectureswith attractive properties, such as phos-phorescence.18 While conventional solutionchemistry yields three different CuI archi-tectures, application of ball milling readilyexpanded this library of luminescent CuImotifs. Solution-achievable phases arebased either on a monomeric CuI motif inCuI(PN)3, a dimer in Cu2I2(PN)3 or a tetra-mer in Cu4I4(PN)2. In addition to these, ballmilling also made accessible new materialsCuI(PN)2, of still unknown structure, andCuIPN0.5 with a polymeric CuIN structure.Her presentation also tackled the problemof structurally characterising mechano-chemical products, either by crystal growthin solvothermal synthesis or by structuresolution from X-ray powder diffraction datausing direct space methods. Lisa Trobs(BAM Federal Institute for MaterialsResearch and Testing in Berlin) outlinedmechanistic studies of mechanochemicalsynthesis of bismuth(III) coordinationframeworks, conducted by rapid stepwiseanalysis using Raman spectroscopy andX-ray powder diffraction (DOI: 10.1039/C4FD00163F). The results demonstratedtime resolution in seconds, so far unpre-cedented in stepwise studies of mechano-chemical reactions. In a twist particularlyrelevant for supramolecular solid-statechemistry and pharmaceutical materials,the presentation also highlighted theuse of rapid stepwise analysis for moni-toring the cocrystallisation of two phar-maceutical ingredients, carbamazepineand indomethacin.

Next, the discussions switched toinorganic materials, such as magneticoxides and hydrides for hydrogenstorage.† The first presentation was given

by Vladimir Sepelak (Karlsruhe Institutefor Technology), whose group19 has pio-neered multi-faceted investigations ofmechanochemically prepared materials,combining Mossbauer and solid-stateNMR (SSNMR) spectroscopy with X-raydiffraction and high-resolution electronmicroscopy. The presentation gave adetailed structural explanation for themodification of magnetism in bariumhexaferrite by milling (DOI: 10.1039/C4FD00137G). Milling was found toinduce amorphization and distortion ofthe crystal structure of the material downto ca. 2 nm below the milled particlesurface. The ability to observe surfacedeformations in milled particles withnanometer resolution, and provide adetailed description of such deforma-tions by combining spectroscopy, diffrac-tion and microscopy gave an excellentillustration of the power of modern ana-lytical techniques and an inspiration forfurther investigations in inorganic,metal–organic and organic systems.Further in the spirit of mechanochemistryin the service of inorganic chemistry,Shalabh Gupta and Vitalij Pecharsky(Iowa State University) presented a new,mechanochemical methodology for thedirect generation of non-solvated alane,AlH3, a highly unstable compound ofconsiderable appeal for its high gravimetrichydrogen content (DOI: 10.1039/C4FD00161J). Although mechanochemicalsynthesis of alane has been achievedpreviously by milling LiAlH4 with AlCl3,such procedures were vexed by in situdegradation of reactive intermediatesinto metallic aluminium. The Amesgroup circumvented this obstacle byperforming AlCl3 addition in severalsmall portions, in that way ensuring acontinuous excess of hydride reagent.At the same time, the procedure wasingeniously simplified by replacing thehighly reactive and difficult to handleLiAlH4 with LiH resulting in the firstroom-temperature, solvent-free approachto generate alane from stoichiometricreagents and without the need for stabilizingorganic solvents.

The next two presentations addressedthe hot and rapidly developing area ofnanoparticle20 mechanosynthesis. AudreyMoores (McGill University) unveiled a

Conference Report ChemComm

Publ

ishe

d on

18

Mar

ch 2

015.

Dow

nloa

ded

on 2

9/07

/201

5 20

:43:

46.

View Article Online

6252 | Chem. Commun., 2015, 51, 6248--6256 This journal is©The Royal Society of Chemistry 2015

methodology for mechanochemical pro-duction of nanoparticles of copper, gold,palladium, ruthenium or rheniumembedded within a reductive organicmatrix (DOI: 10.1039/C4FD00053F). Themechanochemical synthesis of these nano-particles is exceedingly simple, achievedwithout extensive dilution normallyrequired by conventional procedures.Milling with Kraft lignin led to in situreduction of metal precursors to elemen-tary metal nanoparticles with sizes from2.8 nm (from palladium(II) acetate) to14.8 nm (from HAuCl4), that remainimmobilised in the organic lignin matrix.Besides providing a rapid, simple andinexpensive approach to metal nano-particles, this work also revealed the abilityto direct the organisation of nanoparticleseither within or onto the organic matrix byjudicious choice of precursor: inorganicprecursors led largely to nanoparticles asso-ciated with lignin surface, while morehydrophobic precursors preferred intimatenanoparticle–lignin composites (Fig. 2c).Development of a mechanochemicalbottom-up procedure21 for solvent-freeassembly of nanoparticles of binary com-pounds was presented by Peter Balaz(Institute of Geotechnics, Slovak Academyof Sciences) who outlined the synthesis ofmonodisperse PbS nanoparticles (32–34 nm diameter) by milling lead(II) acetatewith L-cystine (disulfide dimer of theaminoacid L-cysteine). High-resolutiontransmission electron microscopy revealedthat nanoparticles are highly crystalline,with clearly observable lattice fringes, andfaceted, adopting the morphology of trun-cated octahedra. Excess cystine was foundattached to particle surface, highlighting asimple methodology to obtain group II–VInanoparticles with biocompatible surfaces.

All four presentations in the inorganicmaterials session inspired active discus-sions that addressed different aspects ofparticle structure, formation and advancedtechniques for product characterisation inmechanochemical reactions. The presenta-tions formed a neat, high-impact overviewof technological and methodologicaladvances in making and understandingmechanochemically synthesised nano-particles.22 The effectiveness and simplicityof mechanochemistry in generating mono-disperse nanoparticles are particularly

impressive when considered from theperspective of extensive research investedin developing conventional approaches tosuch systems in solution, which demandcareful control of reagent choice andaddition, and depend on extensive useof solvent and additional energy input(e.g. rapid shaking or sonication).

Session 3: mechanisticunderstanding, catalysisand scaling up

After the lunch break, which gave extensiveopportunity for further interaction betweenpresenters and exhibitors, the afternoonsession, chaired by Carsten Bolm and PeterBalaz, began by addressing the latestdevelopment of a technique for quantitativereal-time monitoring of mechanochemicalreactions. Ivan Halasz (Institute Ru:erBoskovic) described the use of high energysynchrotron X-ray powder diffraction forquantitative in situ and real-time monitor-ing of mechanochemical reaction pathways(DOI: 10.1039/C4FD00013G). The presentedstudies, which focused on mechanosynth-esis of zeolitic imidazolate frameworks(ZIFs), demonstrated that kinetic behaviourof mechanochemical reactions can strongly

resemble 1st or 2nd order reaction kineticsof solution reactions (Fig. 3a and b).

This confirmed the notion that rapidlymilled reaction mixtures can behave as‘pseudo-fluid’ reaction environments.23

In addition, the ability to conduct a quan-titative Rietveld analysis of in situmechanochemical reaction data providedan unprecedented opportunity to monitorthe participation of amorphous phases inthe reactions. Next, Richard Blair (Univer-sity of Central Florida) addressed scaling-up of mechanochemical reactions, withparticular focus on differences betweendifferent types of milling equipment, suchas shaker, planetary and attrition mills,and how differences in design of millingequipment affect energy and materialstransfer in mechanochemical processes(DOI: 10.1039/C4FD00007B).† The contri-bution dealt with two industrially relevantprocesses: mechanochemical degradationof cellulose and mechanochemical edgeoxidation and delamination of graphene.A particularly eye-catching aspect of thepresentation was the simulation ofthe motion of milling media and of thedistribution of high-energy impacts,obtained by discrete element modelling.Such modelling, a novelty to a large num-ber of participants, offers a means not

Fig. 3 (a) A two-dimensional time-dependent X-ray powder diffractogram for the mechanochemicalsynthesis of a zeolitic framework and (b) changes in the composition of the milled reaction mixturecontaining the product (green), reactants (yellow, blue) and the intermediate amorphous phase (red),as reported in the paper of Halasz and Friscic. (c) Illustration of the screw design used in the scaling upof mechanochemical cocrystallisation of the drug candidate AMG-517 by twin screw extrusion (TSE),as presented by K. Nagapudi.

ChemComm Conference Report

Publ

ishe

d on

18

Mar

ch 2

015.

Dow

nloa

ded

on 2

9/07

/201

5 20

:43:

46.

View Article Online

This journal is©The Royal Society of Chemistry 2015 Chem. Commun., 2015, 51, 6248--6256 | 6253

only to understand the motion of millingmedia in different experiments, but alsoto rationalise and even predict thermaleffects in mechanochemical reactions.

Reaction scale-up was also the topic ofthe presentation by Karthik Nagapudi(Amgen Inc.), who outlined details oflarge scale mechanochemical processfor the synthesis of pharmaceuticalcocrystals (DOI: 10.1039/C4FD00153A).This team previously described the firstapplication of extrusion24 for scaling upof mechanochemical cocrystal formationand the current presentation was the firstto highlight the details of the design,focusing on the synthesis of cocrystalsof AMG-517, a potent and selectiveTRPV1 antagonist, with sorbic acid(Fig. 3c). Twin screw extrusion provides anefficient, scalable, and environmentally-friendly process for the continuous pro-duction of cocrystals. The presentation,however, also initiated a lively discussionon the importance of amorphous phasesor eutectics as either intermediates25 ornecessary activated phases in mechano-chemical reactions.†

Understanding and modelling of thermaleffects and energy transfer are among thecentral challenges of mechanochemistry.This topic was addressed by LaszloTakacs (University of Maryland, Balti-more County) who presented studies ofmechanochemically-induced self-pro-pagating reactions (MSRs) (DOI: 10.1039/C4FD00133D). The MSRs are aunique subset of mechanochemical reac-tions in which the ratio of reactionenthalpy and heat capacity (DH/C) issufficiently large to allow the reaction tobecome a self-sustained thermal process.Such behavior is found in milling thermitemixtures, as well as binary mixtures leadingto the formation of borides, carbides, orchalcogenides.26 One aspect of MSRs thatparticularly captured the attention of theaudience was the induction period, where-upon milling leads to little initial chemicalchange but is followed by a rapid onset ofthe reaction. It was noted during the vigor-ous discussion† that this delay, althoughstill poorly understood, corresponds to amechanochemical activation of startingmaterials, which can take place by differentmechanisms simultaneously, includingparticle comminution, mixing, surface

amorphisation, structure distortion andcreation of defects. Such a view ofmechanical activation is supported bydetailed investigations of milled particles,presented by the Sepelak group. Conse-quently, MSRs provide clear examples ofmechanochemical transformations inwhich mechanical agitation is primarilya means to activate, rather than sustain, achemical reaction.

In the final talk of the session AchimStolle (Friedrich-Schiller University Jena)described a systematic investigation ofthe experimental parameters (convenientlydivided into chemical, technological andprocess parameters) important for reactionoptimisation, scaling-up and process inten-sification in planetary milling.27 This studyprovided a unique overview of the richnessof experimental parameters that can bevaried for fine-tuning a mechanochemicalorganic reaction, such as the diameter ofmilling balls, rotation frequency, as well asthe filling degree of the milling vessel (withrespect to packing of milling media and/orthe amount of substrate). This work,which is of particular relevance to indus-trial researchers, is very likely to become

a central reference point in the design ofmechanochemical processes in planetarymills.

The evening after the afternoon sessionsaw all participants gather once again, thistime for the Conference Dinner held in theclassical environment of the McGill FacultyClub ballroom. An excellent and high-spirited mood extended throughout theevening, enhanced by the traditional LovingCup ceremony of the Faraday Society(Fig. 4). The dinner was also an excellentenvironment for the acting president ofthe Faraday Society, Prof. Peter Skabara(University of Strathclyde) to announce thewinner of the Best Poster Award, graduatestudent Gurpaul S. Kochhar, for his workModelling mechanical processes under con-stant force and constant extension conditions,performed under the supervision of Prof.Nicholas J. Mosey at Queen’s University,Kingston. Following an outstandingfour-course meal, the scientific discus-sions (Fig. 4) continued over music andpool at the Bar de Pins, a popular venue ofMcGill graduate students. convenientlylocated across the road from theconference site.

Fig. 4 (a) Members of the Organising Committee with the Faraday Society acting president Peter Skabara(from left to right): C. Bolm, W. Jones, T. Friscic, P. Skabara, S. L. James, K. S. Suslick and J. Mack. (b) Thegood mood at the Conference Dinner was sustained by a special four-course meal at the McGill FacultyClub, arranged by the chef Pierre Marjois. (c) The Faraday Society acting president Peter Skabara hands theaward for the best poster presentation to Gurpaul S. Kochhar (Queen’s University, Kingston, ON) and (d) theLoving Cup of the Faraday Society, brought to Canada by the RSC personnel Heather Montgomery andMichael Spencelayh. Photographs taken by Nenad Judas, University of Zagreb.

Conference Report ChemComm

Publ

ishe

d on

18

Mar

ch 2

015.

Dow

nloa

ded

on 2

9/07

/201

5 20

:43:

46.

View Article Online

6254 | Chem. Commun., 2015, 51, 6248--6256 This journal is©The Royal Society of Chemistry 2015

Session 4: sonication andmacromolecularmechanochemistry

The final session of the meeting tookplace in the morning of the third day ofthe conference and was dedicated toapproaches to mechanochemistry otherthan milling: molecular cleavage underultrasonic irradiation, and manipulationof individual chemical bonds using a tipof the atomic force microscope.

The duty of chairing this morningsession belonged to James Mack (Univer-sity of Cincinnati) and Richard Blair, andthe opening presentation was given byStephen L. Craig (Duke University), whodescribed a highly efficient design (DOI:10.1039/C4FD00001C) for incorporatingmechanophores, i.e. functional groupssensitive to mechanical tug,28 into poly-mers, leading to materials responsive tomechanical deformation. In particular, itwas discovered that the incorporation ofpolybutadiene containing mechanopho-ric gem-dibromocyclopropane groups asa central component in a triblock ABAcopolymer with polystyrene leads to atleast a 7-fold increase in mechanochemicalresponse compared to mechanophore-richpoly(butadiene) only. Next, Martin Beyer(Leopold-Franzens-Universitat Innsbruck)presented the use of atomic force micro-scope spectroscopy (AFMS) for evaluatingenergetics and mechanisms of covalentbond scission. The presentation compared

dynamic (or force-ramp) AFMS (DOI:10.1039/C4FD00119A), in which bond clea-vage is recorded while ramping the force ona molecule stretched between a surface andthe AFM tip, to force-clamp AFMS, whichmonitors bond cleavage events with themolecule under constant stress.29 Whileboth methodologies gave similar bond dis-sociation parameters for acid hydrolysis ofamylose esters, which confirmed the pre-viously proposed degradation mechanism,the force-clamp technique gave a greaterability to identify fine differences in thestructure of the reactive ester site. Thediscussions then switched to bulk beha-viour of mechanically treated polymers,with the talk of Fernando Galembeck(National Center for Energy and MaterialsResearch, Campinas, Brazil) on the tribo-electric effect, i.e. the appearance anddistribution of electrical charge onrubbed polymer surfaces (DOI: 10.1039/C4FD00118K) (Fig. 5a).

Prof. Galembeck provided a detailedanalysis of chemical composition andcharge on surfaces of rubbed polymers,pointing to the formation of highlymobile macromolecular fragments thatreadily diffuse across the surface or caneven be transferred in the form of nano-particles. Whereas this study provided anexplanation why it has so far not beenpossible to establish a triboelectrical ser-ies of polymers, a particularly exciteddiscussion developed around the demon-strated presence of nitrogen on the

surface of initially completely nitrogen-freepolymers, such as poly(tetrafluoroethylene)(PTFE) or polyethylene.† Prof. Galembeckexplained that the extensive coverage ofpolymer surface by nitrogen species is mostlikely the result of chemisorption from air,sparking speculations on possible develop-ment of processes for binding atmosphericnitrogen. The final talk of the session wasdelivered by Charles E. Diesendruck fromthe Moore group (University of Illinois atUrbana – Champaign), on the developmentof a new triphenylsulfinium-based mechan-ophore (DOI: 10.1039/C4FD00027G). Theo-retical investigation of mechanochemicalscission of this mechanophore indicatedthat heterolytic bond breaking, generatingphenyl cations, would be slightly preferredto the homolytic cleavage, which would giverise to phenyl cations (Fig. 5b). The predic-tions were confirmed by sonochemically-induced cleavage of the mechanophoreplaced between poly(methylacrylate) chains,with the formation of phenyl cationsdetected by 1H NMR and UV/Vis spectro-scopy in trapping experiments. The workclearly illustrated the ability to use theoreti-cal modelling for developing new mechan-ophores for applications in self-healingmaterials. Anatoly Politov and Olga Golyazi-mova (Novosibirsk Institute of Solid StateChemistry and Mechanochemistry, RussianAcademy of Sciences) addressed the effi-ciency of converting mechanical energy intouseful chemical energy. Focusing on theapplication of ultrasound to lignocellulosicsubstrates, with the intention to facilitatesubsequent fermentative hydrolysis, itwas shown that judicious selection ofmechanical treatment allows ten-foldincreases in reaction yield, even at smallinputs of energy. Development of such atargeted mechanochemical approachdepends on detailed studies of howmechanical action can be optimised togenerate defects and radicals central fora particular transformation.

Closing lecture

The Closing Lecture (DOI: 10.1039/C4FD00148F) was delivered by KennethSuslick (University of Illinois at Urbana-Champaign), a renowned expert and a pio-neer in the development of sonochemistry

Fig. 5 (a) Electrostatic potential maps of PTFE film (left) sheared with low-density polyethylenefoam slabs, presented by F. Galembeck (DOI: 10.1039/C4FD00118K) and (b) LUMO of the triphenyl-sulfinium mechanophore compared to the LUMO of the phenyl radical and cation, calculated inSpartan’10 at the B3LYP/6-31G* level of theory, presented by C. E. Diesendruck (DOI: 10.1039/C4FD00027G).

ChemComm Conference Report

Publ

ishe

d on

18

Mar

ch 2

015.

Dow

nloa

ded

on 2

9/07

/201

5 20

:43:

46.

View Article Online

This journal is©The Royal Society of Chemistry 2015 Chem. Commun., 2015, 51, 6248--6256 | 6255

of molecules and materials.30 The closinglecture provided an excellent and light-spirited overview of the development andrecent advances in sonochemistry, and atthe same time highlighted connections togrinding or milling. Prof. Suslick stronglystressed the analogies and connectionsbetween different areas of mechano-chemistry, such as ball milling and sonicirradiation. Although these areas mayappear unconnected on superficial inspec-tion, a careful examination of physical andchemical consequences of sonochemicaland grinding processing on inorganic mate-rials reveals exactly the same list (Fig. 6a).

Prof. Suslick also noted that modernmechanochemistry, despite a tremen-dous growth of interest, remains a highlyunderdeveloped area, poorly understoodby experimentalists and theoreticiansalike. This, to an extent, can be attributedto the complex nature of mechano-chemical processes. While these can bedivided into surface modification, crackpropagation, surface electrification,plasma-like transients, dislocations andamorphisation, appearance of meta-stable polymorphs and localised heating,it is important to remember that nosingle mechanism can explain all ofmechanochemistry. Indeed, a more realisticpicture is obtained by understandingthat all these mechanisms operate all atonce and at very different timescales, from

nanoseconds to days or weeks. Differentmechanisms will be more dominant insome reactions and for some configurationsthan others. The closing lecture also notedthe importance of developing the modelsand understanding of mechanochemistrythat will enable rational, rapid and efficientscaling up (Fig. 6b).

Conclusions

The very end of conference was dedicatedto a discussion of the current state andfuture developments of mechanochemistry.Several developments in mechanochemicalresearch were identified as particularly pro-mising for its development:

(1) exploration of the materials at verysmall length scales, such as in micro-scopy and nanoindentation studies;

(2) the increased use of concepts ofsupramolecular chemistry and inter-molecular interactions in understandingmechanochemical activation and defects;

(3) the development of new methodolo-gies for observing mechanochemical reac-tions as they take place, at different lengthscales, from bulk to molecular level.

(4) the development of theoreticalmodels and simulations addressingmass and energy transfer in mechano-chemical reactions at different scales.

(5) the development of smart mechano-chemistry, i.e. a highly selective approach tooptimise reactivity by judicious applicationof one or more types of mechanical treat-ment, based on systematic investigation ofhow different types of mechanical actionaffect chemical reactivity.

Conference attendees also attemptedto outline several questions and potentialdirections for the future development ofmechanochemistry. The first one addressedthe definition of mechanochemistry. WhileIUPAC briefly defines a mechano-chemicalreaction as a chemical reaction that isinduced by the direct absorption of mechan-ical energy,31 contributions at the 256th

Faraday Discussion illustrated thatmechanochemistry is a much broaderarea which includes, besides conven-tional modes of organic and inorganicreactivity, processes of molecular organi-sation and self-assembly in two or threedimensions. It may, therefore, be bene-ficial to include in the definition ofmechanochemistry aspects of supramo-lecular chemistry and self-assembly thatunderlie processes of mechanochemicalactivation (e.g. amorphisation) or certaintypes of reactions (e.g. cocrystallisationor polymorphic transformations).8,10,32

Such an attempt to improve the definitionof mechanochemistry should describemechanical force (including agitation) asa means to enable, either directly orthrough an intermediate activation pro-cess, the assembly or dissociation ofobjects ranging in dimensions from nan-ometers (molecules, molecular com-plexes) to millimeters (bulk materials).

Next, it was obvious that understand-ing of the mechanisms remains a centralproblem of modern mechanochemistryand it may be that future studies shouldtake into account several interactingpathways (for example, vapour phase dif-fusion simultaneous to amorphisation)rather than interpret mechanochemicalbehaviour according to one particularmechanism. The complexity of suchfuture studies will require the researchersof different backgrounds to communicateand increasingly work together.21 In thatcontext, the conference had brilliantlyserved its purpose, to bring togetherresearchers with different interests and

Fig. 6 (a) Physical and chemical consequences of sonochemical and milling processing of inor-ganic materials are identical; (b) a central problem of modern mechanochemistry is reaching thelevel of understanding and modelling that would allow rational scale-up of reactivity demonstratedon a small scale, as illustrated by K. S. Suslick.

Conference Report ChemComm

Publ

ishe

d on

18

Mar

ch 2

015.

Dow

nloa

ded

on 2

9/07

/201

5 20

:43:

46.

View Article Online

6256 | Chem. Commun., 2015, 51, 6248--6256 This journal is©The Royal Society of Chemistry 2015

background, and encourage their under-standing, exchange of ideas, collaborationand communication. In that spirit, Prof.Lamaty has kindly invited the attendeesto a future mechanochemistry meeting,planned in Montpellier, France, in thesummer of 2015.

Acknowledgements

We acknowledge Prof. L. R. MacGillivray,University of Iowa (USA), Prof. G. M. Day,Southampton University (UK), Prof. T. D.Hamilton, Barry University (USA), Dr D. W.Peters (ATMI), Dr L. Maini (University ofBologna), Prof. A. H. Moores (McGill Uni-versity), Dr L. Batzdorf (nee Trobs), Prof. R.G. Blair (University of Central Florida); Prof.V. Sepelak (Karlsruhe Institute for Technol-ogy), Dr S. Gupta (Iowa State University),Prof. V. Pecharsky (Iowa State University),A. Michalchuk (University of Edinburghand Novosibirsk State University), Prof. A.Politov (Novosibirsk Institute of SolidState Chemistry and Mechanochemistry,Russian Academy of Sciences) for helpin composing this report. Ms SandraAerssen, McGill University is acknowl-edged for professional assistance in meet-ing organisation and Prof. D. N. Harpp inhelp in organisation of the event at theMcGill University Faculty Club. Warmthanks go to the McGill University FacultyClub staff Pierre Marjois, Luigi Foschini,Nicolas Zrihen and Adrian Chu.

Notes and references1 S. L. James, C. J. Adams, C. Bolm, D. Braga,

P. Collier, T. Friscic, F. Grepioni, K. D. M.Harris, G. Hyett, W. Jones, A. Krebs, J. Mack,L. Maini, A. G. Orpen, I. P. Parkin, W. C.Shearouse, J. W. Steed and D. C. Waddell,Chem. Soc. Rev., 2012, 41, 413–447.

2 (a) C. Suryanarayana, Prog. Mater. Sci.,2001, 46, 1–184; (b) C. Suryanarayana,

E. Ivanov and V. V. Boldyrev, Mater. Sci.Eng., A, 2001, 304–306, 151–158.

3 E. Boldyreva, Chem. Soc. Rev., 2013, 42,7719–7738.

4 (a) P. Balaz, Int. J. Miner. Process., 2003,72, 341–354; (b) P. Balaz, A. Alacova,M. Achimovicova, J. Ficeriova andE. Godocikova, Hydrometallurgy, 2005, 77,9–17.

5 (a) M. M. Caruso, D. A. Davis, Q. Shen,S. A. Odom, N. R. Sottos, S. R. White andJ. S. Moore, Chem. Rev., 2009, 109, 5755–5798;(b) A. L. Black, J. M. Lenhardt and S. L. Craig,J. Mater. Chem., 2011, 21, 1655–1663.

6 P. Balaz, M. Achimovicova, M. Balaz, P. Billik,Z. Cherkezova-Zheleva, J. M. Criado, F. Delogu,E. Dutkova, E. Gaffet, F. J. Gotor, R. Kumar,I. Mitov, T. Rojac, M. Senna, A. Streletskii andK. Wieczorek-Ciurowa, Chem. Soc. Rev., 2013,42, 7571–7637.

7 (a) A. Stolle, T. Szuppa, S. E. S. Leonhardtand B. Ondruschka, Chem. Soc. Rev., 2011,40, 2317–2329; (b) L. Chen, B. E. Lemma,J. S. Rich and J. Mack, Green Chem., 2014,16, 1101–1103; (c) D. C. Waddell, T. D.Clark and J. Mack, Tetrahedron Lett.,2012, 53, 4510–4513.

8 (a) T. Friscic, Chem. Soc. Rev., 2012, 41,3493–3510; (b) A. N. Sokolov, D.-K. Bucar,J. Baltrusaitis, S. X. Gu and L. R. MacGillivray,Angew. Chem., Int. Ed., 2010, 49, 4273–4277.

9 (a) A. Lazuen-Garay, A. Pichon andS. L. James, Chem. Soc. Rev., 2007, 36,846–855; (b) D. Braga, S. L. Giaffreda,F. Grepioni, A. Pettersen, L. Maini,M. Curzi and M. Polito, Dalton Trans.,2006, 1249–1263.

10 (a) D. Braga, L. Maini and F. Grepioni,Chem. Soc. Rev., 2013, 42, 7638–7648;(b) A. Delori, T. Friscic and W. Jones,CrystEngComm, 2012, 14, 2350–2362.

11 C. R. Hickenboth, J. S. Moore, S. R. White,N. R. Sottos, J. Baudry and S. R. Wilson,Nature, 2007, 446, 423–427.

12 M. K. Beyer and H. Clausen-Schaumann,Chem. Rev., 2005, 105, 2921–2948.

13 (a) T. Friscic, I. Halasz, P. J. Beldon, A. M.Belenguer, F. Adams, S. A. J. Kimber,V. Honkimaki and R. E. Dinnebier, Nat.Chem., 2013, 5, 66–73; (b) I. Halasz,A. Puskaric, S. A. J. Kimber, P. J. Beldon,A. M. Belenguer, F. Adams, V. Honkimaki,R. E. Dinnebier, B. Patel, W. Jones,V. Strukil and T. Friscic, Angew. Chem., Int.Ed., 2013, 52, 11538–11541.

14 J. Stojakovic, B. S. Farris and L. R.MacGillivray, Chem. Commun., 2012, 48,7958–7960.

15 A. M. Belenguer, T. Friscic, G. M. Day andJ. K. M. Sanders, Chem. Sci., 2011, 2, 696–700.

16 A. A. L. Michalchuk, I. A. Tumanov andE. V. Boldyreva, CrystEngComm, 2013, 15,6403–6412.

17 D. Prochowicz, K. Sokołowski, I. Justyniak,A. Kornowicz, D. Fairen-Jimenez, T. Friscicand J. Lewinski, Chem. Commun., 2015, 51,4032–4035.

18 L. Maini, D. Braga, P. P. Mazzeo andB. Ventura, Dalton Trans., 2012, 41, 531–539.

19 V. Sepelak, S. Begin-Colin and G. Le Caer,Dalton Trans., 2012, 41, 11927–11948.

20 M. J. Rak, N. K. Saade, T. Friscic andA. Moores, Green Chem., 2014, 16, 86–89.

21 L. Takacs, Chem. Soc. Rev., 2013, 42, 7649–7659.22 (a) M. Ojeda, A. Pineda, A. A. Romero,

V. Barron and R. Luque, ChemSusChem,2014, 7, 1876–1880; (b) M. Balaz, P. Balaz,G. Tjuliev, A. Zubrık, M. J. Sayagues,A. Zorkovska and N. Kostova, J. Mater.Sci., 2013, 48, 2424–2432.

23 X. Ma, W. Yuan, S. E. J. Bell and S. L. James,Chem. Commun., 2014, 50, 1585–1587.

24 C. Medina, D. Daurio, K. Nagapudi andF. Alvarez-Nunez, J. Pharm. Sci., 2010, 99,1693–1696.

25 T. Friscic and W. Jones, Cryst. Growth Des.,2009, 9, 1621–1637.

26 L. Takacs, Prog. Mater. Sci., 2002, 47, 355–414.27 A. Stolle, R. Schmidt and K. Jacob, Chem.

Soc. Rev., 2014, 170, 267–286.28 (a) P. A. May and J. S. Moore, Chem. Soc. Rev.,

2013, 42, 7497–7506; (b) J. M. Lenhardt,A. L. Black and S. L. Craig, J. Am. Chem.Soc., 2009, 131, 10818–10819.

29 S. W. Schmidt, P. Filippov, A. Kersch,M. K. Beyer and H. Clausen-Schaumann,ACS Nano, 2012, 6, 1314–1321.

30 H. Xu, B. W. Zeiger and K. S. Suslick, Chem.Soc. Rev., 2013, 42, 2555–2567.

31 IUPAC Compendium of Chemical Terminol-ogy, 2nd edn (the ‘‘Gold Book’’), compiledby A. D. McNaught and A. Wilkinson,Blackwell Scientific Publications, Oxford(1997). XML on-line corrected version:http://goldbook.iupac.org (2006-) createdby M. Nic, J. Jirat, B. Kosata; updatescompiled by A. Jenkins, ISBN 0-9678550-9-8, DOI: 10.1351/goldbook, http://goldbook.iupac.org/MT07141.html.

32 (a) T. N. Drebuschak, A. A. Ogienko andE. V. Boldyreva, CrystEngComm, 2011, 13,4405–4410; (b) D. Braga, F. Grepioni andG. I. Lampronti, CrystEngComm, 2011, 13,3122–3124; (c) M. C. Etter, S. M. Reutzeland C. G. Choo, J. Am. Chem. Soc., 1993,115, 4411–4412.

ChemComm Conference Report

Publ

ishe

d on

18

Mar

ch 2

015.

Dow

nloa

ded

on 2

9/07

/201

5 20

:43:

46.

View Article Online

![of the American Mathematical Societyto Notices of the American Mathematical Society, P.O. Box 6248, Providence, RI 02940-6248 USA.] Publication here of the Society’s street address](https://static.fdocuments.us/doc/165x107/5f0d811a7e708231d43aafcb/of-the-american-mathematical-to-notices-of-the-american-mathematical-society-po.jpg)

![Bi-boxRegressionfor PedestrianDetection and ...openaccess.thecvf.com/content_ECCV_2018/papers/...Bi-boxRegressionfor PedestrianDetection and OcclusionEstimation Chunluan Zhou1,2[0000−0003−0284−6256]](https://static.fdocuments.us/doc/165x107/5f263d6352cce15fc459b170/bi-boxregressionfor-pedestriandetection-and-bi-boxregressionfor-pedestriandetection.jpg)