High-resolution photoaligned liquid-crystal micropolarizer array for polarization imaging in visible...

-

Upload

vladimir-g -

Category

Documents

-

view

212 -

download

0

Transcript of High-resolution photoaligned liquid-crystal micropolarizer array for polarization imaging in visible...

December 1, 2009 / Vol. 34, No. 23 / OPTICS LETTERS 3619

High-resolution photoaligned liquid-crystalmicropolarizer array for polarization imaging

in visible spectrum

Xiaojin Zhao,1,2,* Amine Bermak,1 Farid Boussaid,2 Tao Du,1 and Vladimir G. Chigrinov1

1Department of Electronic and Computer Engineering, Hong Kong University of Science & Technology,Clear Water Bay, Kowloon, Hong Kong SAR, China

2School of Electrical, Electronic and Computer Engineering, University of Western Australia, 35 Stirling Highway,Crawley WA6009, Perth, Australia

*Corresponding author: [email protected]

Received July 23, 2009; revised October 21, 2009; accepted October 23, 2009;posted November 2, 2009 (Doc. ID 114225); published November 18, 2009

We report a superior high-resolution micropolarizer array fabrication technology that combines a linear po-larizer with a micropatterned liquid-crystal (LC) cell. A 2 �m pitch is achieved by using UV light to definethe orientation of the micropolarizer elements. Reported experimental results validate the concept of high-performance photoaligned LC micropolarizer arrays with major principal transmittance of �80% and ex-tinction ratio as high as �3200 �35 dB�. © 2009 Optical Society of America

OCIS codes: 230.5440, 230.3720, 160.5335.

Capturing the polarization state of light reflected oremitted by objects in a scene can reveal valuable in-formation about their geometrical, physical, chemi-cal, physiological, and/or metabolic properties [1,2].Examples of demonstrated applications of polariza-tion imaging include machine vision, classificationand analysis of materials and biological tissues, andindustrial quality monitoring [3–5], to name a few.Commercially available complementary metal-oxide-semiconductor (CMOS) cameras can be madepolarization-sensitive by coating individual pixelswith micrometer-scale polarizer elements. A micropo-larizer (MP) array is thus formed on top of the pho-tosensitive pixel array [6]. The main challenge is tomake the MP elements small enough to match thepixel pitch. Previously reported MP implementationsall rely on selective etching to pattern MP elementsat the pixel pitch [6–10]. Although high-resolutionpatterning can be achieved [8,10], selective etching isrelatively complex and difficult to control at themicrometer-scale pixel pitch, resulting in poor yield.

To address these limitations, we demonstrated in[11] a simple well-controlled MP technology that usesUV light to define MP orientation patterns on a spin-coated azo-dye-1 (AD-1) dichroic film. The patternedAD-1 film MP array features a 10 �m�10 �m pitchwith an extinction ratio of �100 [11]. These perfor-mance parameters are set by the spin-coated dichroicAD-1 film that is used as the MP material. As a re-sult, process optimization leads to marginal improve-ments of the extinction ratio and spatial resolution.In this Letter, we propose a superior photopatternedMP array fabrication technology that exhibits higherresolution and enables one to control the values ofthe extinction ratio and transmittance by simply se-lecting a suitable commercially available linear po-larizer for the targeted application. Our approach in-volves combining this linear polarizer and amicropatterned liquid-crystal (LC) cell, which is es-sentially an LC layer placed between two treatedglass substrates (see Fig. 2 below). The inner sur-

0146-9592/09/233619-3/$15.00 ©

faces of the LC cell consist of two layers of spin-coated sulfonic-dye-1 (SD1) film. The chemical for-mula and measured absorption spectrum of thesynthesized SD1 are given in Fig. 1. After sufficientexposure to linearly polarized UV light, this materialexhibits a molecular photo-orientation mechanismcharacterized by the SD1 having an absorption oscil-lator perpendicular to the projected polarized UVlight. This UV-induced molecule reorientation re-mains stable against subsequent UV, moisture, andthermal exposure [12,13]. Note that the photopat-terned SD1 film does not form by itself a MP array,because SD1 does not exhibit polarization dichroism.Instead, SD1 is used here to define the molecular ori-entation of individual patterns on the inner surfacesof the LC cell. By selectively photopatterning theseinner surfaces, we can make the LC cell act as a re-tarder or rotator (Fig. 3). The latter occurs whereverthe orientation pattern of the bottom inner layer isnot identical to the top inner layer, in which case thehelical structure formed by the LC molecules acrossthe liquid crystal twists/rotates the orientation of in-coming linearly polarized light. In other words, in-

Fig. 1. Sulfonic-dye-1 SD1.

2009 Optical Society of America

icro

3620 OPTICS LETTERS / Vol. 34, No. 23 / December 1, 2009

coming linearly polarized light follows the rotation ofthe molecules. In the other case, the LC cell acts as aretarder whose phase can be controlled by simplymodulating the thickness of the LC layer. We demon-strate this technology through the fabrication of a2 �m pitch MP array comprising 0° and 90° linearMP elements. The fabrication steps required to formthe micropolarizer array are summarized in Fig. 2.

Two transparent thin glass slides are used as theLC first substrate and second substrate. In the fol-lowing, we will refer to the inner surface and theouter surface of each of these substrates that will en-capsulate the LC layer. The fabrication process of theMP array can be summarized as follows. The innersurfaces of the two glass substrates are first placed inan ultraviolet–ozone (UVO) cleaner for 20 min to re-move organic contaminants. A solution of SD1 in dim-ethylformamide (DMF) with a concentration of 1% byweight is then spin-coated (800 rpm for 10 s then3000 rpm for 40 s) on the inner surfaces of both sub-strates. Both substrates are subsequently baked at140°C for 20 min to remove remaining solvents andstrengthen the adhesion of SD1 to the substrates.The SD1-coated inner surfaces of both substrates areexposed to 90° linearly polarized UV light for 15 minwithout photolithography mask applied. This resultsin a 0° photo-orientation of the SD1 molecules, sincethe latter adopt a stable molecular orientation per-

Fig. 2. (Color online) Photoaligned LC m

Fig. 3. (Color online) LC molecules: (A) 90° twisted, (B)

untwisted.pendicular to the projected linearly polarized UVlight. The inner surface of the second substratecoated with SD1 is then exposed to 0° linearly polar-ized UV light for 15 min, with a photolithographymask exposing the regions of 90° twisted LC cells, re-sulting in a 90° photoreorientation of the SD1 mol-ecules in the exposed regions. Spacers with 5 �m di-ameter are sprayed on the inner surface of the firstsubstrate. The two substrates are then assembled to-gether with their inner surfaces facing each other,leaving a 5 �m cell gap between the inner surfaces.Thermal epoxy is used for this assembly. The at-tached substrates are then baked at 120°C for 1 h tocure the epoxy. LC E7 (from Merck) is then insertedbetween the two treated glass substrates. The result-ing LC cell is immediately end-sealed with thermalepoxy and baked at 120°C for 1 h. A thin linear po-larizing film is laminated on the outer surface of thesecond substrate with its polarizing axis along 0°. Itis this linear polarizer that mainly determines theextinction ratio and transmittance of the fabricatedphotopatterned MP array, since the LC merely actsas a rotator provided that the Mauguin condition isfulfilled:

d�n � �, �1�

where d, �n, and � stand for the LC cell gap, the bi-refringence, and the wavelength of incident light, re-spectively. To satisfy the latter condition, we havechosen LC E7 ��n=0.225� and d=5 �m for the cellgap. In the final fabrication step, a UV blocking filteris laminated on the outer surface of the first sub-

polarizer array fabrication process flow.

Fig. 4. Microphotographs of the micropolarizer array

when applying (A) 0° analyzer, (B) 90° analyzer.December 1, 2009 / Vol. 34, No. 23 / OPTICS LETTERS 3621

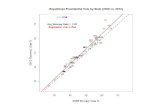

strate to protect the device from lifetime environmen-tal UV exposure. Using the above fabrication process,we have been able to attain a 2 �m�2 �m pitch (Fig.4), which is, to the best of our knowledge, the mostcompact pixel pitch ever reported for any MP array.The only other reported LC-based MP technology wasproposed by Harnett and Craighead [14]. It usesevaporated gold films to align LC molecules and se-lective etching for patterning with a minimum pitchof only 100 �m�100 �m. Using linearly polarizedlight at different wavelengths, we have evaluated theperformance of the fabricated micropolarizer array.Figure 5 indicates that Malus’s law is well satisfied.Figure 6 shows a transmittance as high as �80%.The maximum extinction ratio for twisted and un-twisted LC modes is �3200 �35 dB� (Table 1). Thetwisted arrangement of LC molecules (Fig. 3) is seento result in relatively lower major principal transmit-tance and extinction ratio. Since the performance ofthe photoaligned LC-MP array is determined mainlyby the linear polarizer, one could choose from anycommercially available thin polarizer films so as toachieve the desired values for the extinction ratio

Fig. 5. (Color online) Transmittances of 0° and 90° mi-cropolarizers following Malus’s law at differentwavelengths.

Fig. 6. Spectral measurements of the major principal

transmittance for 0° and 90° micropolarizer elements.and transmittance. When considering the actual in-tegration of the MP array on top of the image sensor,the thickness of the micropolarizer array needs to beminimized so as to reduce optical crosstalk betweenadjacent pixels. This can be achieved by (a) replacingthe laminated linear polarizing film (Fig. 2) with acommercially available ultrathin ��150 nm� metal-wire-grid polarizer (MWGP), (b) placing the MWGPon top of the image sensor before spin-coating it withSD1, and (c) further reducing the thickness of the LCcell. The fabrication process is thus identical to thatoutlined in Fig. 2, except for the fact that the 0° po-larizer is now placed internally, that is, on top of theimage sensor. In these conditions, the minimumachievable MP thickness will correspond to the thick-ness of the LC cell �� �5 �m�. Besides minimizingthe thickness, the effect of optical crosstalk could alsobe mitigated through the use of microlenses aboveeach pixel to redirect and focus oblique incident light.

The authors acknowledge the support of the Re-search Grant Council of Hong Kong SAR, China(grants GRF610608 and CERG612208).

References

1. J. S. Tyo, D. L. Goldstein, D. B. Chenault, and J. A.Shaw, Appl. Opt. 45, 5453 (2006).

2. G. C. Giakos, IEEE Trans. Instrum. Meas. 55, 1628(2006).

3. M. P. Rowe, E. N. Pugh, Jr., J. S. Tyo, and N. Engheta,Opt. Lett. 20, 608 (1995).

4. F. Goudail, P. Terrier, Y. Takakura, L. Bigue, F.Galland, and V. DeVlaminck, Appl. Opt. 43, 274 (2004).

5. S. Lin, K. M. Yemelyanov, E. N. Pugh, Jr., and N.Engheta, J. Opt. Soc. Am. A 23, 2137 (2006).

6. Z. K. Kalayjian, A. G. Andreou, and L. B. Wolff,Electron. Lett. 33, 38 (1997).

7. A. G. Andreou and Z. K. Kalayjian, IEEE Sens. J. 2,566 (2002).

8. J. Guo and D. Brady, Opt. Eng. 36, 2268 (1997).9. J. Guo and D. Brady, Appl. Opt. 39, 1486 (2000).

10. V. Gruev, A. Ortu, N. Lazarus, J. Van de Spiegel, andN. Engheta, Opt. Express 15, 4994 (2007).

11. X. Zhao, F. Boussaid, A. Bermak, and V. G. Chigrinov,IEEE Photonics Technol. Lett. 21, 805 (2009).

12. V. G. Chigrinov, H. S. Kwok, H. Takada, and H.Takatsu, in Proceedings of SID InternationalSymposium Digest of Technical Papers (SID, 2006), p.1253.

13. P. J. Shannon, W. M. Gibbons, and S. T. Sun, Nature368, 532 (1994).

14. C. K. Harnett and H. G. Craighead, Appl. Opt. 41,

Table 1. Extinction Ratios at Different Wavelengths

Wavelength(nm) 0° MP 90° MP

450 33.2 dB 28.6 dB500 29.7 dB 25.9 dB550 30.4 dB 26.1 dB600 35.3 dB 34.9 dB650 32.3 dB 27.9 dB

1291 (2002).

![[Array, Array, Array, Array, Array, Array, Array, Array, Array, Array, Array, Array]](https://static.fdocuments.us/doc/165x107/56816460550346895dd63b8b/array-array-array-array-array-array-array-array-array-array-array.jpg)