High Pressure Pump - lofisneon.lofis.net/SsangYong/Service_Manuals/Kyron/Kyron_1_Engine_0… · IMV...

Transcript of High Pressure Pump - lofisneon.lofis.net/SsangYong/Service_Manuals/Kyron/Kyron_1_Engine_0… · IMV...

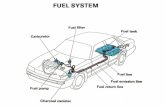

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

16 07

HIGH FUEL PRESSURE LINE

High Pressure Pump

Description

This pump generates high fuel pressure and is driven by timing chain (radial plunger principle). This pump pressur-izes the fuel to approx. 1600 bar and sends this high pressurized fuel to high pressure accumulator (common rail) viahigh pressure line.

It is possible to extend the pumping phase in order to considerably reduce drive torque, vibration and noise since thepump no longer determines the injection period. The differences from conventional rotary pumps lies in the fact thatit is no longer the hydraulic head rotor which turns inside the cam, but the cam which turns around the hydraulichead. Thus, any problems of dynamic pressure tightness are eliminated because the high pressure is generated inthe fixed part of the pump.

Specifications

1. Maximum operating pressure: 1600 ± 150 bar

2. Operating pressure limit: 2100 bar

3. Maximum sealing pressure: when using a plug instead of PRV, no leaks around pump outlet port (whenapplying 2500 bar of constant pressure)

4. Fuel pressure at inlet (pressure regulating valve): 6 bar

5. Operating temperature: Continuously operating within temperature range of -30°C ~ 120°C in engine compartment

6. Inflowing fuel temperature: The maximum inflowing fuel temperature is 85°C (continuously able to operate)

7. Pump inlet pressure: Relative pressure Max. 048 bar (to end of filter’s lifetime)

8. Driving torque: 15 Nm / 1600 bar

9. Gear ratio (engine: pump): 0.625

10. Lubrication: - Inside lubrication (rear bearing): Fuel

- Outside lubrication (front bearing): Engine oil

1. IMV (Inlet Metering Valve)

2. Hydraulic Head

3. Plunger

4. Drive shaft and cam ring

5. Housing

6. Roller and shoe

7. Transfer pump

8. Fuel temperature sensor

9. Vent

10. High fuel pressure - OUT

11. Pressure regulator

Fuel supply

Fueldischarge

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

1707

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

<Pressurize>

Principle of operation

1. During the filling phase, the rollers are kept in contact with the cam by means of coil springs mounted on eitherside of each shoe. The transfer pressure is sufficient to open the inlet valve and to move the pumping plungersapart. Thus, the dead volume between the two plungers fills with fuel.

2. When the diametrically opposite rollers simultaneously encounter the leading edge of the cam, the plungers arepushed towards each other.

3. As soon as the pressure becomes higher than the transfer pressure, the inlet valve closes. When the pressurebecomes higher than the pressure inside the rail, the delivery valve opens. Consequently, the fuel is pumpedunder pressure into the rail.

4. During the input phase, transfer pressure pushes back the inlet valve. Fuel enters the body of the pumpingelement. The valve closes as soon as the pressure in the pumping element becomes higher than the transferpressure.

5. During the input phase, the ball of the delivery valve is subject to the rail pressure on its outer face and to thetransfer pressure on its inner face. Thus the ball rests on its seat, ensuring the pressure tightness of the body ofthe pumping element. When the pressure in the element becomes higher than the pressure in the rail, the ball isunbalanced and it opens. Fuel is then pumped into the rail at high pressure.

This high pressure pump generates the driving torque with low peak torque to maintain the stress to driving components.This torque is smaller than that of conventional injection pump, thus, only a small load will be applied to pump. Therequired power to drive pump is determined by set pressure for rail and pump speed (delivery flow). Note that the fuelleakage or defective pressure control valve may affect the engine output.

<Fuel Input>

Roller

Plunger

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

18 07

Inlet valve and delivery valve

During the input phase, transfer pressure pushes back the inlet valve. Fuel enters the body of the pumping element.Under the effect of the transfer pressure, the two plungers are forced apart. When the rollers simultaneously encoun-ter the leading edge of the cam, pressure suddenly rises in the body. Of the pumping element. The valve closes assoon as the pressure in the pumping element becomes higher than the transfer pressure. During the input phase,the ball of the delivery valve is subject to the rail pressure on its outer face and to the transfer pressure on its innerface. Thus the ball rests on its seat, ensuring the pressure tightness of the body of the pumping element. When thetwo diametrically opposite rollers encounter the leading edges of the cam, the plungers are forced together andpressure quickly rises in the body of the pumping element. When the pressure in the element becomes higher thanthe pressure in the rail, the ball is unbalanced and it opens. The spring calibration is negligible compared with thepressure forces. Fuel is then pumped into the rail at high pressure.

Lubrication and cooling of the HP pump

Lubrication and cooling of the pump are provided by the fuel circulation. The minimum flow required to ensureadequate operation of the pump is 50 /h.

Phasing of the HP pump

Conventional fuel injection pumps ensure pressurizing and distribution of the fuel to the different injectors. It isessential to set the pump in such a way that the injection occurs at the required place during the cycle. The HPpump of the common rail system is no longer used for the fuel distribution, it is therefore not necessary to set thepump in relation to the engine.

Nevertheless, the setting or phasing of the pump offers two advantages:

1. It allows the torque variations of the camshaft and the pump to be synchronized in order to reduce the stresseson the timing belt.

2. It allows pressure control to be improved by synchronizing peak pressures produced by the pump with pressure-drops caused by each injection.

This phasing allows pressure stability to be improved, which helps to reduce the difference in flow between thecylinders.

<Inlet Valve> <Delivery Valve>

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

1907

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

Transfer pump High pressure pump

IMV open

Venturi

to commonrail

to fuel tankBackleak

Fuel supply

HP Pump Fuel RouteThe fuel passed through the fuel filter is sent to the transfer pump via the HP inlet pump. this fuel passes through thetransfer pump by the transferring pressure and maintains the predefined value by the regulating valve in HP pump.

Also, this fuel gets into the IMV that controls only the fuel to the high pressure pump.

The below figure describes the pump operations when acceleration and deceleration.

When need high fuel pressure (acceleration)

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

20 07

IMV close

Venturi

to commonrail

to fuel tankBackleak

Fuel supply

Transfer pump High pressure pump

<Pressure Curve of HP Pump>

When do not need high fuel pressure (deceleration)

The fuel is sent to the high pressure side (hydraulic head) and compressed by the plunger. And, goes into thecommon rail through the high pressure pipe.

The IMV installed in the high pressure side (hydraulic head) of HP pump precisely controls the fuel amount anddelivers the rail pressure feedback same as required amount.

The IMV is controlled by ECU.

Performance curve of HP pump

The time required to obtain a sufficient pressure in the rail to enable the engine to start depends on the volume of thesystem (definition of the rail, length of the pipes, etc.). The aim is to reach a pressure of 200 bars in 1.5 revolutions(3rd compression).

• Maximum operating pressure: 1600 ± 150 bar

Ra

il p

ress

ure

(b

ar)

Engine speed (rpm)

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

2107

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

<Transfer Pump>

<IMV Valve and High Pressure Pump (Drive Shaft)>

Sectional View of HP Pump

IMV valve

High pressurepump

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

22 07

<Inlet Valve, Outlet Valve, Shoe and Roller, Temperature Sensor>

<Hydraulic Head>

Inlet valve

Temperaturesensor

Supply valveShoe and roller

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

2307

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

Removal and Installation (D20DT Engine)

Preceding Works:

1. Disconnect the negative battery cable.

2. Apply the parking brake and place the chocksunder the tires. (transmission "N" position)

1. Turn the auto tensioner counterclockwise and re-move the fan belt.

2. Remove the engine belt pulleys.

1) Cooling fan pulley

2) Coolant pump pulley

3) Idle pulley

Removal

• Slacken the pulley bolt.

NOTICE

3. Unscrew lower bolt (13 mm) and upper bolt (24 mm)and remove the auto tensioner.

• To prevent oil leaks, store the removed autotensioner in upright position.

• Pump the suto tensioner several times before in-stalling it.

NOTICE

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

24 07

6. Remove the high pressure pump housing.

Preceding Work: Remove the No.2 EGR pipe.

7. Align the OT mark by rotating the crankshaft.

1) Open the oil filler cap and check if the OT markon crankshaft is aligned to the notch on thecamshaft.

8. Unscrew the bolts and remove the vacuum modu-lator bracket.

1) Disconnect the high pressure pump and vacuummodulator connector.

2) Disconnect the fuel lines to high pressure pump.

3) Plug the openings of pipes and ports with pro-tective caps to keep the cleanness of the fuelsystem.

4) Remove the high pressure fuel pipe betweenHP pump and common rail.

9. Rotate the crankshaft clockwise so that the HPpump sprocket holes are aligned to the bolt holes.

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

2507

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

8. Hold the HP pump sprocket and slacken thecenter bolt.

9. Slacken three HP pump mounting bolts until theyrest on the sprocket.

10. Loose the HP pump center nut by tapping it witha hammer.

11. Remove the remaining bolts with the same mannerand remove the high pressure pump.

• Tap the center bolt with a hammer after tightening.

• Make sure that the center bolt is securely tightened.

NOTICE

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

26 07

1. Replace the HP pump gasket with new one (cannotbe reused).

2. Tighten the HP pump bolts.

3. Hold the HP pump sprocket and tighten the centernut.

Tightening torque 25 Nm

Tightening torque 65 Nm

Installation

• The center nut should be replaced once removed(cannot be reused).

• Tighten the center nut with the specified tighten-ing torque.

NOTICE

• Replace the fuel lines to HP pump with new ones(cannot be reused).

• Make sure that the connectors are installed to thecorrect locations. (The wiring end with white tape

NOTICE

4. Install the vacuum modulator bracket.

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

2707

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

5. Apply the sealant to the HP pump housing andtighten the bolts.

6. Install the auto tensioner and belt pulleys.

7. Rotate the crankshaft pulley two revolutions and en-sure that the OT mark on the crankshaft pulley andthe OT mark on the camshaft pulley are aligned.

• Sealant (DB2210): 661 989 56 A0

NOTICE

• Open the oil filler cap and check if the OT mark oncrankshaft is aligned to the notch on the camshaft.

NOTICE

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

28 07

Removal

Preceding Works

1. Disconnection of negative battery cable

2. Removal of engine cover

1. Remove the bolts on the fan shroud. Disconnect theair intake duct from intake manifold and the coolantoutlet port connecting hose.

2. Remove the fan belt while pressing down the autotensioner adjusting bolt.

3. Unscrew the center bolt and remove the cooling fanclutch while holding the pulley with counter holder(special tool).

4. Remove the fan shroud and fan clutch simultaneously.

The trouble diagnosis should be performed before re-moving the HP pump. Refer to “Diagnosis” section.

Engine Removal & Installation (D27DT Engine)

• Plug the coolant port not to get the coolant into theengine. Add the coolant as required when installing.

NOTICE

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

2907

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T8. Unscrew the bolts and remove the cooling fan bracket

(timing chain cover side).

7. Unscrew the bolts and remove the idle pulley.

5. Unscrew the bolts and remove the belt pulley whileholding the belt pulley with a special tool.

6. Unscrew the upper and lower bolts and remove theauto tensioner.

• To prevent oil leaks, store the removed autotensioner in upright position.

NOTICE

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

30 07

10. Align the TDC mark on the crankshaft pulley tothe guide pin and rotate the pulley 720°counterclockwise. Check the mark on the camshaftagain.

9. Remove the engine oil filler cap and adjust themark on camshaft to TDC position.

11. Disconnect the vacuum line of EGR vacuummodulator (1), the vacuum line of turbo chargervacuum modulator (2) vacuum line and connectors.

12. Unscrew the bolts and remove the intake manifoldmounting bracket.

• Be careful not to be mixed the lines when installing.

NOTICE

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

3107

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

13. Disconnect the connector behind HP pump, fuelpipes and hose lines.

1) Fuel temperature sensor connector (green)

2) IMV connector

3) Fuel return hose (be careful not to break theHP pump connecting port)

4) Venturi hose

14. Remove the coolant temperature sensor and theknock sensor.

15. Unscrew the bolts and remove the high fuelpressure pipes at HP pump and common rail. Plugthe openings with sealing caps.

16. Remove the HP pump mounting bracket at engine.

• Especially, the knock sensor should be tightened bythe specified tightening torque. Otherwise, it maycause the poor engine output. For reference, the in-ternal resistance of the sensor is approx. 4.7 kΩΩΩΩΩ.

NOTICE

• Replace the fuel pipes with new ones.

NOTICE

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

32 07

Replace the O-ring with new one.

22. Remove the oil dipstick mounting bracket and oildipstick tube with O-ring.

21. Remove the exhaust EGR pipe and gasket. Removethe center EGR pipe.

• Replace the removed gasket with new one.

• Replace the removed #1 and #3 pipes with newones.

NOTICE

• Replace the O-ring with new one.

NOTICE

17. Remove the intake EGR pipe and gasket.

18. Disconnect the HFM sensor connector.

19. Loosen the clamp and separate the hose from aircleaner.

20. Separate the connection lines from turbo chargerand PCV separator.

• Replace the removed gasket with new one.

• Replace the removed #1 and #3 pipes with newones.

NOTICE

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

3307

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

24. Mark on the HP pump sprocket and timing chain.

23. Remove the chain tensioner.

25. Remove the guide rail pins (lower and upper) with aspecial tool.

26. Install the special tool (1) for holding HP pumpsprocket, unscrew the mounting bolts and removethe sprocket. At this time, rotate the crankshaft 30°to 45° counterclockwise to remove the sprocket.

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

34 07

30. Remove the mounting bracket behind the HP pump.

31. Slide the HP pump out rearward while holding it.

29. Remove the HP pump bearing bracket.

• Plug the openings of connecting hoses and pipeswith sealing caps.

NOTICE

28. Pull out the HP pump bearing with a special tool.

27. Remove the center nut for HP pump shaft.

• Be careful not to damage the bearing.

NOTICE

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

3507

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

1. HP pump sprocket

2. 12-sided bolt (20 Nm ± 90°)

3. HP pump bearing housing

4. HP pump (High pressure pump)

5. HP pump shaft

6. HP pump center nut (65 ± 5 Nm)

7. HP pump external bolt (24 ± 2.4 Nm)

8. HP pump bearing shaft

9. Oil gallery

10. Bearing bushing

11. Gasket

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

36 07

1. Install the gasket and HP pump.

Installation

2. Install the HP pump bearing bracket and HP pump tothe cylinder block.

6. Install the timing chain on the sprocket and lock thesprocket with a special tool.

4. Temporarily install the upper and lower guide rails toseat the chain.

5. Temporarily tighten the center nut for HP pump shaft.

3. Install the bearing into the bracket.

Tightening torque 24 ± 2.4 Nm

• Replace the removed gasket with new one.

NOTICE

• Align the oil galleries in cylinder block and bear-ing bracket.

NOTICE

• Be careful not to rotate the shaft.

NOTICE

• Do not apply excessive force to the timing chain.Otherwise, the TDC point deviates from correctposition.

NOTICE

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

3707

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

7. Tighten the center nut for HP pump.

9. Align the marks on the HP pump sprocket and thetiming chain and tighten the bolts.

8. Press the upper and lower guide pins into the guide.

10. Remove the special tool.

11. Install the mounting bracket behind HP pump.

12. Install the chain tensioner.

Tightening torque 20 Nm ± 90°

Tightening torque 65 ± 5.0 Nm

Tightening torque 25 ± 2.5 Nm

Tightening torque 80 ± 8 Nm

• Replace the center nut with new one.

NOTICE

• Check the timing chain and guide pin for contact.

NOTICE

• Replace the chain tensioner washer with new one.

• Be careful not to drop the washer into the hole.

NOTICE

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

38 07

15. Install the timing chain cover.

16. Install the auto tensioner assembly.

1) Upper bolt (24M):

Tightening torque 10 ± 1.0 Nm

Tightening torque 82 ± 6.0 Nm

2) Lower bolt (13M):

Tightening torque 32 ± 3.0 Nm

14. Clean the timing chain cover parting surface andapply the sealant on it.

13. Check if the mark on the intake camshaft is at thecorrect position through oil filler opening.

• Rotate the bolt on crankshaft damper pulley tworevolutions and check if the mark on the intakecamshaft is at the correct position.

NOTICE

• Align the cover and the guide pin.

NOTICE

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

3907

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

17. Install the coolant pump pulley.

18. Install the fan clutch with a special tool.

19. Install the oil dipstick tube and bracket.

20. Install the exhaust EGR pipe and bracket.

21. Engage the turbo charger and PCV separatorconnecting lines.

22. Engage the air cleaner hose and tighten the clamp.

23. Connect the HFM sensor connector.

24. Install the EGR center pipe.

Tightening torque 10 ± 1.0 Nm

Tightening torque 10 ± 1.0 Nm

Tightening torque 10 ± 1.0 Nm

Tightening torque 10 ± 1.0 Nm

Tightening torque 25 ± 2.5 Nm

25. Connect the HP pump connectors and engage thehose lines.

1) Fuel temperature sensor connectors and IMVconnector

2) Venturi hose and fuel return hose

Gasket Installingdirection

• Make sure that the con-vex surface of new steelgasket is facing the direc-tion as shown in thefigure.

NOTICE

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

40 07

32. Place the fan shroud in its location and install thecooling fan by using an open end wrench.

Tightening torque 10 ± 1.0 Nm

33. Install the fan shroud.

34. Add the coolant.

35. Check all the connections for tightness and pumpthe priming pump to deliver the fuel to the transferline of HP pump.

36. Start the engine and check if abnormality ispresent.

29. Connect the hose to coolant outlet port and tightenthe clamp.

30. Install the air intake duct.

31. Install the fan belt while pressing the auto tensioneradjusting bolt.

27. Install the vacuum modulator to the intake manifoldbracket.

28. Connect the vacuum modulator connecting linesand connector.

1) Vacuum modulator for turbo charger control

2) Vacuum modulator for EGR valve control

26. Install the coolant temperature sensor and the knocksensor.

27. When replaced the HP pump, initialize the fuelpressure by using Scan-100. Refer to “TroubleDiagnosis” section in this manual.

• If the initialization of fuel pressure has not beenperformed, the engine ECU controls new HP pumpwith the stored offset value. This may cause thepoor engine output.

NOTICE

• Ensure that the vacuum hoses are connected tocorrect positions.

NOTICE

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

4107

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

Fuel Filter

Function

Foreign materials in fuel can damage the pump components, transfer valve and injectors. Therefore, the highpressure direct injection engine must use fuel filter. Otherwise, the operation performance will drop dramatically.And, diesel fuel may contain water due to condensation by temperature changes and this condensation watercan damage the system by corroding the injection system. Thus, the common rail engine should have functionthat can drain water periodically.

Fuel filterFuel level in filter: 500 ± 25 cm3

Filtering effective• Particles larger than 3μm > 98 %• Particles larger than 5μm > 99.8 %• Particles larger than 15μm > 100 %

Drain plug

Water Sensor

Effective water storing rolame: 120cc

Warning light ON level: 39 cc

to HPpump

from HP pump to fuel tank

from fuel tank

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

42 07

Change Interval: 30,000 km

Water separation and storage function

1. Function: It separates the condensation water from diesel fuel to prevent the water from getting into FIE system,and results in protection of FIE system. (manual drain)

2. Water reserve capacity: 124 cc

3. Water warning light turning on level: 39 cc

4. Water drain interval: When changing engine oil or every 20,000 km

Water sensor

It is integrated in the filter and sends signal to ECU when water level reaches at a specified value (over 75 cc) inthe filter to let the driver drain the water.

Fuel De-Waxing – Improving starting performance in cold weather

Due to characteristics of diesel fuel, some of fuel components solidify during cold winter under below a specifictemperature (-15°C). When those symptoms happen, engine may stall; however, some of the fuel (temperaturerises due to high compression) in the HP pump in D27DT engine return to the filter to warm up fuel whentemperature is below 50°C by improving cold start performance during cold winter.

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

4307

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

2. Loosen the bracket bolts and disconnect the hose fromthe drain plug.

3. Remove the fuel filter.

4. Install in the reverse order of removal.

5. Press the priming pump until it becomes rigid to de-liver the fuel to the transfer line of HP pump.

1. Disconnect the fuel supply and return hoses.

Removal and Installation

• Plug the openings of hoses and fuel filter with seal-ing caps.

• Ensure that the hoses are connected to correctpositions.

NOTICE

D27DT

D20DT

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

44 07

Priming PumpIf fuel runs out during driving or air gets into fuel line afterfuel filter replacement, it may cause poor engine startingor damage to each component. Therefore, the hand prim-ing pump is installed to bleed air from transfer line.

When the vehicle is under the conditions as below, pressthe priming pump until it becomes rigid before startingthe engine.

Conditions for using Priming Pump

1. After run out of fuel

2. After draining the water from fuel separator

3. After replacing the fuel filter

Relations Between Pressure and Temperature in Fuel Transfer Line

1. The fuel transfer line is the line between fuel tank and HP pump inlet port. The pressure on this line affects thelifetime of fuel filter.

2. Temperature of fuel transfer line

1) Pump inlet temperature is less than 80°C.2) Above figure shows the temperature changes in each section caused by temperature changes in pump inlet

section; the temperature of fuel pump inlet is up to 80°C.And, diesel fuel has lubrication effects due to its viscosity. Thus, the fuel is also used for pump lubrication.However, this lubrication performance drops as the temperature rises. Accordingly, when the fuel temperatureis over 50°C, 100% of fuel is returned to fuel tank to cool down the temperature and then increase thelubrication effects of fuel and prevent heat damage on each section of high fuel pressure line.

to fuelfilter

from fueltank

Pump inlet pressure

Fuel transferline

Pump

Ventury

Pump outletpressure

Injector No.1 returnpressure

Injector

Injector No.5 returnpressure

High pressure common rail

• When the fuel filter is replaced, the fuel in the fuel tank should be transferred to the filter by using primingpump. So never transfer the fuel in the fuel tank to the filter by driving HP pump with cranking the engine.

NOTICE

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

4507

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

High Pressure Accumulator (Common Rail)

Description

The high pressure accumulator reserves the high pressure fuel. Simultaneously, the pressure changes due tothe delivery from HP pump and the fuel injection is diminished by rail volume. This high pressure accumulator iscommonly used in all cylinders. Even when a large amount of fuel leaks, the common rail maintains its internalpressure. This ensures that the injection pressure can be maintained from when the injector opens.

Function

1. Relieve the pressure pulsation

2. Provide pressure information to ECU (fuel pressure sensor)

Specifications

1. Material: Forged Steel

2. Dimension: • Volume: 19.5 ± 1cc (D20DT), 22 ± 1cc (D27DT)

• Length: Max. 345.11 mm (D20DT), Max. 397.7 mm (D27DT)

• Outer diameter: 27 mm (D20DT), 25.3 mm (D27DT)

3. Fuel pressure sensor Integrated type

1) Sensor input voltage: 5 ± 0.1V

2) Sensor output signal voltage: • 4.055 ± 0.125 V ≅ 1600 ± 15 bar

• 0.5 ± 0.04 V ≅ 0 bar

4. Operating pressure range

1) Normal condition: 0 ~ 1800 bar

2) Exceptional condition: available within 1800 ~ 2100 bar

3) Bursting pressure: over 2500 bar

5. Ambient temperature:

1) available within -40°C ~ 125°C

2) Spontaneous max. temperature after engine stops: 140°C (acceptable against total 15 hours)

6. Fluid temperature: -40 ~ 100°C under normal operating conditions

7. Removal and installation: 10 times without any damage

D27DTD20DT

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

46 07

<High Pressure Accumulator>

High Fuel Pressure Pipe1. Function: Resistant to pressure changes, tightness against surroundings, supplying fuel through pump, rail

and injector with high pressure

2. Material: Steel (Zn Plated)

3. Common: Cylinder 1, 2, 3, 4 (D20DT), Cylinder 1 & 3, 2 & 4, 5 (D27DT)

4. Internal pressure

1) Internal operating pressure: 0 ~ 1600 bar during its lifetime

2) Spontaneous max. pressure when restoring: 2100 bar (max. total period: 20 hours)

3) Bursting pressure: over 2500 bar

5. To keep cleanness and tightness, the high pressure pipe assembly should be used only once.

HP pipe

Injector

HP pump

HP pipe

D20DT No. 1

D27DT No. 1

No. 3

No. 2 No. 3No. 4

No. 4

No. 2

No. 5

High fuel pressurepipe

• Make sure to replace the removed high fuel pressure pipes.

• Tighten the fasteners with the specified tightening torque.

NOTICE

Fuel pressuresensor

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

4707

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

Preceding Work: Removal of engine cover

1. Disconnect the fuel pressure sensor connector.

Removal and Installation

Tightening torque 40 ± 1.0 Nm

Tightening torque 40 ± 1.0 Nm

2. Unscrew the nuts and remove the fuel supply mainpipe from the fuel line.

Installation Notice

3. Unscrew the high fuel pressure line nuts and removethe fuel pipes.

Installation Notice

• Replace the fuel pipes with new ones.

• Plug the openings of hole in the common rail withsealing caps.

NOTICE

• Replace the fuel pipes with new ones.

• Plug the openings of hole in the common rail withsealing caps.

NOTICE

• Replace the fuel pipes with new ones.

• Plug the openings of hole in the common rail withsealing caps.

NOTICE

D27DT

D20DT

D27DT

D20DT

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

48 07

4. Unscrew the bolts and remove the common railasssembly.

Installation Notice

Tightening torque 25 ± 2.5 Nm

5. Install in the reverse order of removal.

• Replace the fuel pipes with new ones.

• Plug the openings of hole in the common railwith sealing caps.

NOTICE

D27DT

D20DT

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

4907

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

Fuel Pressure Sensor

Fuel pressure sensor on the center of common rail detects instant fuel pressure changes and then sends to ECU.When received these signals, ECU uses them to control fuel volume and injection time.

The fuel in the rail reaches to sensor diaphragm via blind hole in the pressure sensor and the pressure signalconverts to electrical signal. The signal measured by sensor will be amplified to input to ECU.

This piezo element type sensor changes pressure into electrical signal. Accordingly, when the shape of dia-phragm changes, electrical resistance in the layers on the diaphragm changes then can measure 0.5 ~ 5 V.

1. Sensor input voltage: 5 ± 0.1 V

2. Output signal voltage of sensor

1) 4.055 ± 0.125 V: 1600 ± 15 bar

2) 0.5 ± 0.04 V: 0 bar

D20DT D27DT

FUEL SYSTEMKYRON SM - 2005.09

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

50 07

<Sensor Voltage>

<Circuit Diagram of Fuel Pressuer Sensor>

<Operation Principle of Fuel Pressure Sensor>

Pres-sure

Physicalchanges

Sensing area

Converts toelectric signal

Electricallyamplyfying

signal

Ampl i f ier

Outputvoltage

Pressure (P)

Upper area

Lower area

Ground

Piezo resistance

Pressure sensor

SIG

REF 5V

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

FUEL SYSTEMKYRON SM - 2005.09

5107

GE

NE

RA

LS

EN

SO

RA

SS

YH

OU

SIN

GIN

TA

KE

LU

BC

OO

LIN

GF

UE

LC

ON

TR

OL

EX

HA

US

T

Fuel Temperature Sensor

<Fuel Temperature Sensor> <Output Characteristics of Fuel Temperature Sensor>

Fuel temperature sensor is a NTC resistor that sends fuel temperature to ECU.

In case of NTC resistor, the resistance lowers if engine temperature rises so the ECU detects lowering signalvoltages.

Fuel temperature sensor is installed on the fuel return line to correct pressure after measuring fuel temperature.5V is supplied to the sensor and voltage drop by temperature is delivered to ECU to measure the fuel tempera-ture through analog-digital converter (ADC).

<Circuit Diagram of Fuel Temperature Sensor>

HFM SensorRefer to “Intake System”

Crankshaft Position SensorRefer to “Engine Assembly”

Knock SensorRefer to “Engine Assembly”

Camshaft Position SensorRefer to “Engine Assembly”

Tem

pe

ratu

re

Resistance

Signal

Ground

Fuel TempSensor