High Flow Filter for UPW Applications – A Field Case Study

description

Transcript of High Flow Filter for UPW Applications – A Field Case Study

UPW-Micro Conference November 2008 Slide 1

High Flow Filter for UPW Applications – A Field Case Study

Gary Van Schooneveld, CT Associates Inc.Peter Nadolny, W.L. Gore and Associates, Inc

November 12, 2008

UPW-Micro Conference November 2008 Slide 2

• Critical feature sizes of current and developing semiconductor devices continue to drive the need for improved filter retention of particles smaller than 50 nm.

• Improvements in the retention of small particles in ultrapure water filters have typically come at the expense of increased pressure drop across the filter.

• Recent advances in membrane materials and structure has resulted in filters with improved particle retention and reduced pressure loss.

• This paper will review the performance of a newly developed 20 nm filter from WL Gore installed in a ultrahigh purity water system.

Introduction

UPW-Micro Conference November 2008 Slide 3

Presentation Outline

• Filter description and selection

• Water system description

• Post installation rinse-up measurements

• Particle and pressure drop performance

• 6 month performance check

• Summary

UPW-Micro Conference November 2008 Slide 4

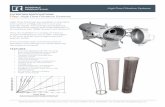

Case Study Filter Description

• 10” Cartridge

• Media – Hydrophilic expanded PTFE

• Supports and Housing – Polypropylene

• O-rings – Viton Type 2-222

UPW-Micro Conference November 2008 Slide 5

Screening Tests – Filter Rinse-up

T h o rn to n2 0 0 C R

7 7 6 1 N R M

U P W

S iev e rs5 0 0 R L

e lec tro n icflo w m ete r

U P W

U P W

1 0 lp m

U P W re tu rn o r d ra in

U P W re tu rn o r d ra in

1 0 0 - 1 5 0 m L /m in

5 0 - 8 0 m L /m in

d ra in

U P W re tu rn

v en t

filte rh o u s in g

Pd iffe ren tia l

p re ssu resen so r

P M S M 5 0

U P W re tu rn o r d ra in

1 0 0 m L /m in

1 0 lp m

UPW-Micro Conference November 2008 Slide 6

Screening Tests – Filter Retention

H ig h P u rityW ate r

F lo wC o n tro lV a lv e

P e ris ta lticP u m p

P S L S u sp en s io no r T rito n X -1 0 0

S o lu tio n

3 0 0m l/m in

P M S M 5 01 0 0

m l/m in

P 1D ra in

D ra in

V en t

S h u t-o ff V a lv e

F ilte rH o u sin g

R e tu rn

P

d iffe ren tia lp re ssu re sen so r

P 2

1 0 lp m

e lec tro n icflo w m ete r

The test is a modified version of SEMATECH Provisional Test Method for Determining Particle Contribution and Retention by UPW Distribution System Components (1992).

Technology Transfer Number 92010949B.

UPW-Micro Conference November 2008 Slide 7

Filter Performance Comparisons

Attribute GORE 20 nm High Flow Filter

Supplier A - 20 nm (Polysulfone)

Supplier B -

40 nm (PES)

Particle Rinse Volume

(1 count added 50 nm)< 30 hours < 30 hours < 30 hours

TOC Rinse Volume

(0.1 ppb added)< 40 hours < 40 hours < 40 hours

Resistivity Rinse Volume

(0.1 M-cm added)< 1 hour < 1 hour < 1 hour

Non-Volatile Residue Rinse volume (0.1 ppb added)

< 3 hours < 35 hours < 50 hours

Filtration Efficiency – PSL Challenge ( 50 nm)

> 99.9% > 99.9% > 90%

Particles Released After Flow Stoppage ( 50 nm)

3 x 106 100 x 106 300 x 106

Pressure Drop @ 10 LPM 0.7 psid 2.2 psid 2.6 psid

Filters tested at 10 liters per minute flow rate.

UPW-Micro Conference November 2008 Slide 8

High Purity Water System Schematic

C atio nR esinC ity

W ate r

M ix edB ed

C arb o nF ilte r

0 .4 5 m ic ro nfilte r

C h a rg edM em b ran e

F ilte r

F 1

P 1

F 2

P 2

P 6P 7P 8

T 2R 2

P T 1

T O CM o n ito r

C h a rg edM em b ran e

F ilte r

0 .4 5 m ic ro nfilte r

H ig hP u rityT an k

F ilte r

1 8 5 /2 5 4 n mU V L ig h t

A n io nR esin

P 3 P 4

F 3

P 5

R 1

T 1

F 5

P 1 3

F M

1 8 5 /2 5 4 n mU V L ig h t

U ltra H ig h P u rityW ate r S y stem

UPW-Micro Conference November 2008 Slide 9

High Purity Water System

Parameter Typical Performance

Particle Concentration < 1 count/mL 100 nm

Total Organic Carbon (TOC) 40 – 100 ppb

Resistivity 18.1 M - cm

UPW-Micro Conference November 2008 Slide 10

UPW System Schematic (before case study filter installation)

U ltra -H ig hP u rityT an k

1 8 5 n m U V L ig h t

M ix edB e d

0 .4 5 m ic ro nfilte r

N R MM o n ito r

T O CM o n ito r

0 .0 5 m ic ro nfilte r

F 4

P 9 P 1 0 P 1 1

P 1 2

T 3

R 3

P T 2

P a rtic leC o u n te r

H ig h P u rityW a te r S y s tem

UPW-Micro Conference November 2008 Slide 11

Ultrahigh Purity Water System

Parameter Typical PerformanceParticle Concentration (# /mL 100 nm

< 0.05

Total Organic Carbon (ppb) < 1

Resistivity (M – cm) 18.2

Non-Volatile Residue (ppb) < 1

Operating Pressure (MPa) 0.27

Flow Rate (Lpm) 20

UPW-Micro Conference November 2008 Slide 12

Case Study Details

• The average flow rate for the water system at the time of the filter installation was 20 Lpm (4.5 gpm).

• The outlet pressure after the water system final filter was 0.26 MPa (37 psi).

• The water temperature was 27oC.

• The filter was installed in the final filter position replacing the 0.05 m filter in October 2007.

UPW-Micro Conference November 2008 Slide 13

UPW System Schematic(after case study filter installation)

U ltra -H ig hP u rityT an k

1 8 5 n m U V L ig h t

C u rren t U ltra H ig h P u rity W ate r S y stemB lo ck D iag ram

M ix edB e d

0 .4 5 m ic ro nfilte r

N R MM o n ito r

T O CM o n ito r

2 0 n me P T F E filte rF 4

P 9 P 1 0 P 1 1

P 1 2

T 3

R 3

P T 2

P a rtic leC o u n te r

H ig h P u rityW a te r S y s te m

UPW-Micro Conference November 2008 Slide 14

Case Study Instrumentation

Property Location Instrument

Particle concentrationEnd of loop

Out of filterPMS UDI 50 (x2)

Particle concentration Into test filter PMS M50

TOC End of loopG.E. Sievers Model

500RL

Nonvolatile residue End of loopFluid Measurement

Technologies Model 7700 NRM

Resistivity End of loop Thornton Model 200CR

Pressure Drop Filter housing vent portsSentra 0 – 10 psi P

sensor

UPW-Micro Conference November 2008 Slide 15

Test Results

UPW-Micro Conference November 2008 Slide 16

TOC Rinse-up

Time After Installation (hours)

0.1 1 10 100

Tot

al O

rgan

ic C

arbo

n a

dded

(pp

b)

0.01

0.1

1

10

100

1000

Increase due to increased TOC in incoming water.

Time After Installation (hours)

0 20 40 60 80 100

To

tal O

rga

nic

Car

bo

n (

ppb

)

0

2

4

6

8

10

Average incoming atend of test

Time After Installation (hours)

0.1 1 10 100

Tot

al O

rgan

ic C

arbo

n (

ppb)

0.1

1

10

Average incoming atend of test

UPW-Micro Conference November 2008 Slide 17

NVR Rinse-up

Time After Installation (hours)

0.01 0.1 1 10 100

Non

-vol

atile

res

idue

add

ed (

ppb)

0.01

0.1

1

10

Time (hours)

20 40 60 80 100

Non

-vo

latil

e re

sidu

e (p

pb)

0

1

2

3

4

5

6

7

Average incomingIncoming 3 sigma confidence limits

Time (hours)

0.01 0.1 1 10 100

Non

-vol

atile

re

sidu

e (

ppb)

0.1

1

10

Average incomingIncoming 3 sigma confidence limits

UPW-Micro Conference November 2008 Slide 18

Resistivity Rinse-up

Time After Installation (hours)

0.01 0.1 1 10 100

Res

istiv

ity d

ecr

ease

(M

-cm

)

0.01

0.1

1

10

Time After Installation (hours)

0 5 10 15 20

Res

istiv

ity (

M

-cm

)

16

17

18

19

Average Incoming

Time After Installation (hours)

0.01 0.1 1 10

Res

istiv

ity (

M

-cm

)

16

17

18

19

Incoming Average

UPW-Micro Conference November 2008 Slide 19

Particle rinse-up after filter installation – first 100 hours

Time After Installation (hours)

0.01 0.1 1 10 100C

um

ula

tive

Pa

rtic

le C

on

cen

tra

tion

(#

/mL

)0.001

0.01

0.1

1

10

100

1000

> 0.05 m> 0.10 m> 0.15m> 0.20 m

Particle conconcentration measured at end of loop

Time After Installation (hours)

0.01 0.1 1 10 100

Cu

mu

lativ

e P

artic

le C

on

cen

tra

tion

(#

/mL

)

0.001

0.01

0.1

1

10

100

1000

> 0.05 m> 0.10 m> 0.15 m> 0.20 m

Particle concentration measured at filter outlet

UPW-Micro Conference November 2008 Slide 20

Particle rinse-up after filter installation(10 – 480 hours)

Time After Installation (hours)

10 100

Cu

mu

lativ

e P

art

icle

Co

nce

ntr

atio

n (

#/m

L)

0.0001

0.001

0.01

0.1

1

10

> 0.05 m> 0.10 m> 0.15m> 0.20 m

Particle conconcentration measured at end of loop

Time After Installation (hours)

10 100

Cu

mu

lativ

e P

art

icle

Co

nce

ntr

atio

n (

#/m

L)

0.0001

0.001

0.01

0.1

1

10

> 0.05 m> 0.10 m> 0.15 m> 0.20 m

Particle concentration measured at filter outlet

Average particle concentration, 430 - 480 hours:• 0.057 per mL 50 nm • 0.015 per mL 100 nm

UPW-Micro Conference November 2008 Slide 21

Filter Rinse Measurements

Time required to achieve specified concentration added (hours) Contaminant

1 ppb 0.1 ppb NVR 0.3 3 TOC 0.7 20

Time required to achieve specified resistivity decrease (hours) Instrument

1.0 M-cm 0.1 M-cm Thornton CR200 < 0.08 0.4

Time required to achieve specified concentration (hours) Particle size

10/ml 1/ml 0.1/ml 0.05 µm 0.5 2.4 17 0.10 µm 0.2 1.2 5 0.15 µm < 0.2 0.6 2 0.20 µm < 0.2 0.3 1

Flushing times required to achieve NVR and TOC cleanliness levels

Flushing times required to achieve inorganic cleanliness levels

Flushing times required to achieve particulate cleanliness levels

UPW-Micro Conference November 2008 Slide 22

Performance Improvement – Particles

Channel Size (PMS UDI 50)

> 0.05 um >0.10 um > 0.15 um

Pa

rtic

le c

on

cen

tra

tion

(#

/lite

r)

0

500

1000

1500

2000

2500

Filter inlet concentrationEnd of loop prior to filter changeEnd of loop after filter change

Channel Size (PMS UDI 50)

> 0.05 um >0.10 um > 0.15 um

Pa

rtic

le c

on

cen

tra

tion

(#

/lite

r)1

10

100

1000

10000

Filter inlet concentrationEnd of loop prior to filter changeEnd of loop after filter change

UPW-Micro Conference November 2008 Slide 23

Performance Improvement – Pressure Loss

Pre

ssu

re D

rop

Acr

oss

Fitl

er

(psi

d)

0

2

4

6

8

10

Pressure drop acrossprior filter @ 4.5 gpmPressure drop across Gore20 nm high-flow filter @ 4.5 gpm

90.2% pressure drop reduction

UPW-Micro Conference November 2008 Slide 24

Particle levels 6 months after installation(exiting the filter)

Time (hours)

0 20 40 60 80 100

Cu

mu

lativ

e C

on

cen

trat

ion

(#/

mL

)

0.001

0.01

0.1

1

> 50 nm (30 minute ave.)> 100 nm (30 minute ave.)> 50 nm (4 hour ave.)> 100 nm (4 hour ave.)

Particle concentration - 100 hour average :• 0.041 per mL 50 nm • 0.013 per mL 100 nm

UPW-Micro Conference November 2008 Slide 25

Filter Case Study Summary (1)

• A 0.05 m filter was replaced with a 20 nm expanded hydrophilic PTFE filter in this case study.

• Particle concentrations 50 nm and 100 nm at the end of the supply loop were reduced 62% and 55% respectively when measured 100 hours after filter installation.

• Pressure drop across the filter was reduced by over 90%.

• Non-volatile residue recovered to 1 ppb added within 20 minutes of rinsing.

UPW-Micro Conference November 2008 Slide 26

Filter Case Study Summary (2)

• TOC recovered to 1 ppb added within 45 minutes of rinsing.

• Resistivity recovered to 0.1 M-cm with 5 minutes of rinsing.

• Particle concentrations out of the filter 50 nm and 100 nm achieved one count/mL within 150 and 75 minutes of rinsing respectively.

• Particle concentrations out of the filter measured 6 months after filter installation were slightly lower than the concentrations measured at 480 hours.