henkel chart.pdf

-

Upload

mangal-deo-pathak -

Category

Documents

-

view

323 -

download

24

Transcript of henkel chart.pdf

-

Henkel Industrial Solutions Selector GuideAdhesives, Sealants, Metal Pretreatments, Coatings, Cleaners and Metalworking Fluids

-

Introduction to Henkels

Industrial Solutions

At Henkel Corporation, we provide solutions to industrys biggest challenges. We are dedicated to understanding the markets we serve and developing partnerships that stand the test of time.

But just how well do you know Henkel? Our customers have long recognized us as the leader in surface treatment, sealant, adhesive and metalworking lubricant technologies. You should also know that we now offer:

Products that manage the stress and strain energies of an assembly, allowing it to flex, reduce fatigue and absorb shock without damage.

Products that manage noise, vibration and harshness, reducing airborne and structure-borne noises.

Products that manage the intrusion of air, water, fuel and other elements into assemblies.

Products that manage the structural vibration that travels through assemblies and is felt by occupants.

Custom-engineered parts and components specifically designed for your application.

Reliable, environmentally responsible and increasingly green products.

Fully integrated equipment systems from standard shelf items to full turnkey systems.

Not every company can accommodate the technical staff and equipment necessary to compete in todays challenging manufacturing environment. Our chemists and engineers work in partnership with customers to improve design, assembly, productivity and profitability. Whether a customer needs competent recommendations on chemical properties or a full-blown turnkey process design, Henkel provides solutions.

This selector will aid you in choosing the right solution and product for a wide range of common industrial challenges. For additional information on Henkel products, please contact us at (800) 521-1355.

-

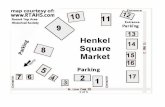

Table of Contents

Henkel Brands ....................................... 2-3

MarkeTSAgriculture/Construction ........................ 4-5Appliance .............................................. 6-7Filter ...................................................... 8-9HVAC/Insulation ................................. 10-11Medical Devices & Equipment ............ 12-13Outdoor Power Equipment ................. 14-15Pump & Compressor .......................... 16-17Recreational Vehicle ........................... 18-19Smart Cards ...................................... 20-21Solar Energy ...................................... 22-23Specialty Vehicle ................................ 24-25Wind Energy ...................................... 26-27

ProduCTSSurface Preparation, Cleaning & Conversion Coating ............................ 28-35Autodeposition Coatings .................... 36-39Chemical Specialties .......................... 40-41Metalworking Fluids .......................... 42-47Hot Melt Adhesive Bonding ................ 48-53Structural Bonding ............................. 54-59Elastomeric Bonding & Sealing .......... 60-61 Potting, Molding & Encapsulating ....... 62-65Seam Sealing .................................... 66-67Energy, NVH & Fluid Management ...... 68-69Water-Based Adhesives ..................... 70-75Integrated Equipment Solutions ......... 76-77

ProduCT LISTIng and IndexAdditional Supporting Products .......... 78-79Index ................................................. 80-81

-

2

Beginning in the 1940s, Adhesin branded adhesives have represented a full range of water-based adhesives for various market segments and applications in the packaging industry. Adhesin adhesives include homopolymers and copolymers dispersions and natural-based products: PVAC, PVOH and starch dispersion mixture, natural rubber, acrylic water-based adhesive, cellulose ester, cellulose.

Registered as a trademark in 1946 as the conversion coating for aluminum substrates, Alodine is a series of conversion coatings to improve paint adhesion and provide corrosion protection for light metal substrates that consists of metal pretreatments and post rinses for light metal pretreatments.

The autodeposition coating process is a more simple, cost-effective and environmentally responsible way of applying a functional anti-corrosive organic paint layer to metal substrates by means of a chemical, rather than an electrically driven reaction. Aquence products include Waterborne Organic Coatings and related metal pretreatment (chemical cleaners and rinses) products.

S ince the early 1930s, Bonderite was well established in the automotive and metalworking industries as the conversion coating processes and chemistries to improve paint adhesion, corrosion protection and wear resistance to ferrous-based alloys, mixed metal alloys and plastic surfaces. The products that make up the Bonderite brand include process line chemistries, cleaners, pretreatment chemistries including activators and conditioners, conversion coating chemistries, post treatment chemistries (including rinses and passivation), as well as auxiliary products including toner, additives, accelerators and neutralizer.

The brand name Dorus (an acronym of the founders grandsons name Doktor Rudolf Schieber) was registered in 1935 and includes adhesives and systems for the woodworking and furniture industry. Dorus branded adhesives include hot melts (PUR, PO, PA, EVA); 3D dispersions (PU), dispersions (PVAc, EVA) and urea resin glues; one- and two-component reactive adhesives (PU); and solvent-based adhesives.

For more than 30 years, Macromelt adhesives have been known as engineered hot melt adhesives for industrial applications in various market segments. These adhesives are thermoplastic 100% solids and include polyamide (PA) and polyolefin (PO) hot melts.

Alodine

Henkel is a leader with brands and technologies that make peoples lives easier, better and more beautiful.

With superior brands and the technologies they represent, our innovations continue to help shape the future of the industrial manufacturing market.

-

3

O riginally launched in 1967, these structural and semi-structural adhesives are used in the manufacture of industrial goods and attributes for the cable industry. Macroplast branded products include one- and two-component polyurethanes (PU), PU elastomers, PU hot melts, one- and two-component epoxy, and solvent-based contact adhesives and cleaners.

S ince the early 1970s, Multan branded products have been synonymous with metal removal and forming lubricants. From liquids to pastes, these water-miscible and non-water-miscible products are used in manual and automated application systems. Multan branded products are available in fully synthetic, semi-synthetic, soluble or straight oil formulations.

Registered in 1894, the P3 brand didnt begin to represent cleaners until the late 1920s. These cleaners are for metallic and nonmetallic surfaces, fouling prevention and corrosion protection together with disinfection of water, and use with wastewater treatments. These products are liquid/powdery products designed for use in low and high temperature applications at different pH ranges (acid, neutral and alkaline), and in high-pressure applications, depending on customer conditions.

O riginally launched in 1989, these reactive polyurethane hot melts are used in a wide range of high-end assembly bonding applications.

F irst introduced into industrial assembly applications in 1975, Technomelt branded hot melts have been used for consumer packaged goods and general industrial applications. These hot melt adhesives are thermoplastic 100% solids, non-reactive conventional technology, and have open times ranging from short to permanent pressure sensitive.

Teroson branded products have been around since the turn of the 20th century and include adhesives, sealants, coatings and parts for automotive assembly, auto aftermarket and general industrial manufacturing. Teroson branded products include cleaners; epoxy adhesives; EVA adhesives; MS sealants and adhesives; polyurethane sealants and adhesives; PVC sealants, adhesives and coatings; rubber sealants and adhesives; silicone sealants; and water-based adhesives, sealants and coatings.

-

4

agriculture/Construction equipment

OverviewFarming, mining, and construction equipment must operate reliably and efficiently under some of the worst imaginable conditions. Equipment manufacturers are always looking for ways to extend usable working life, improve overall aesthetics and increase robustness. Henkel has developed a wide range of products that simplify assembly, extend paint life, minimize part fatigue and increase operator comfort.

For cab enclosures, our seam sealing and Noise Vibration Harshness (NVH) technologies help control the elements that pass through the cab and affect the ultimate comfort of the operator from weather to noise, shock and vibration.

Featured Products

Aquence 930 extreme corrosion protective coating Page 38

Bonderite NT-1 phosphate-free conversion coating Page 31

Multan B-204 semi-synthetic metal removal fluid Pages 42, 43

Terophon 21007 injection molded expanding NVH foam Pages 68, 69

Terostat MS 930 adhesive/sealant for elastic bonding Pages 60, 61, 68, 69

Henkels Terostat adhesive technologies have been specially formulated to bond and seal

dissimilar substrates for multiple cab applications ranging from plastic to metal bonding.

MA

rk

et

SA

Gr

ICu

ltu

re

/C

on

St

ru

Ct

Ion

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

-

5

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

reinforcing

Hot Melt adhesive BondingStructural Bonding

Metalworking Fluids

air/Water & energy Management

Surface Preparation, Cleaning & Conversion Coating

Seam Sealing

Vibration damping

Water-Based adhesives

MA

rk

et

SA

Gr

ICu

ltu

re

/C

on

St

ru

Ct

Ion

autodeposition Process

-

6

appliance

OverviewHenkel offers a range of products used in appliance assembly, from low VOC stamping lubricants for dishwasher panels to UL-approved sealants that resist unsightly crazing to water-based, spray-applied adhesives for multi-substrate bonding.

Our low temp cleaners, nanotechnology coatings, and plastics cleaners help our customers reduce their carbon footprints, greenhouse gas emissions and overall energy consumption. Our bio-resistant metalworking products reduce waste, improve in-plant working conditions and lengthen expensive tool life.

Featured Products

Bonderite NT-1 phosphate-free conversion coating Page 31

P3 Polyprep 110 Cleaner low temp plastics cleaner Page 40

Adhesin 56-5545 water-based insulation adhesive Pages 72, 73

Terostat MS 930 adhesive/sealant for elastic bonding Pages 60, 61, 68, 69

Multan F 6740 a synthetic metal forming lubricant Pages 44, 45

Henkels surface treatment products prepare metal and plastic surfaces prior to paint to

create a lasting finish.

MA

rk

et

SA

PP

lIA

nC

e

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

-

7

Seam Sealing

Surface Preparation, Cleaning & Conversion Coating

Water-Based adhesives

Structural Bonding

reinforcing

Metalworking Fluids

Hot Melt adhesive Bonding

air/Water & energy Management

Vibration damping

MA

rk

et

SA

PP

lIAn

Ce

Potting & encapsulating

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

-

8

Filter

OverviewHenkel offers a range of adhesives, lubricants, and surface preparation products used to fabricate, assemble, and extend the life cycle of the worlds finest filters. Our products reduce process complexity and minimize downtime.

For filter can processing, our deep draw lubricants reduce thinning and splitting. For filter media bonding, our UL-certified, VOC-free adhesives are environmentally responsible and easy to apply. Our latest innovations include tack-free hot melts that allow high speed first-last pleat bonding, and toughened foaming assembly adhesives for fuel resistant filter designs.

Featured Products

Adhesin 56-5531 water-based assembly adhesive Pages 72, 73

Macromelt 2384 fuel/oil resistant hot melt adhesive Pages 48, 49

Multan F 985 semi-synthetic metal-forming fluid Pages 44, 45

Bonderite TecTalis phosphate-free conversion coating Page 31

From draw compounds for metal filters to hot melt adhesives for pleating and end cap potting,

Henkel has the right product from end to end.

MA

rk

et

SFI

lte

r

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

-

9

Metalworking Fluids

Surface Preparation, Cleaning & Conversion Coating

Water-Based adhesive

MA

rk

et

SFIlt

er

Structural Bonding

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

Potting & encapsulating

Hot Melt adhesive Bonding

-

10

HVaC/Insulation

OverviewHenkel provides reliable, environmentally responsible adhesive, sealant, metalworking and surface treatment technologies for HVAC/insulation manufacturers. Used for bonding, seam sealing, lubricating, and vibration control, our HVAC products include flexible duct adhesives, VOC-free insulation adhesives, structural adhesives, weather-tight sealants, NVH management systems, and surface treatment coatings for metal parts.

Our latest innovations include low-VOC fin lubricants, fast-setting assembly adhesives, green nano-based multi-metal pretreatments, and the worlds first extreme corrosion-resistant electroceramic coating for aluminum components.

Featured Products

Alodine EC2 extreme corrosion protective coating Page 34

Bonderite NT-1 phosphate-free conversion coating Page 31

Multan PL 1439 low-VOC fin stamping lubricant Pages 44, 45

Bonderite TecTalis phosphate-free conversion coating Page 31

Adhesin XA-7594 Black UL-approved laminating adhesive for flexible ducting Pages 70, 71

Adhesin XA-7597 UL-approved laminating adhesive for flexible ducting Pages 70, 71

Bondmaster 40-452A water-based insulation adhesive Pages 70, 71

Bondmaster 40-0880 water-based insulation adhesive Pages 70, 71

Henkels metalworking fluids are used with the Appli-Coater system to produce cooling

fins in the HVAC industry.

MA

rk

et

SH

VAC

/In

Su

lAt

Ion

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

-

11

Structural Bonding

Seam Sealing

Vibration damping

Water-Based adhesives

MA

rk

et

SH

VAC

/InS

ulA

tIo

n

Surface Preparation, Cleaning & Conversion Coating

Metalworking Fluids

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

-

12

Medical devices & equipment

OverviewTo bring todays increasingly complex medical equipment, device and utensil designs to life, Henkel offers 132 years of experience in the industry. Our metalworking fluids provide the precision required when cutting utensils are forged, ground and polished. Our assembly adhesives allow medical device manufactures to bond difficult substrates without mechanical fasteners, welds or brazing. For medical devices, our products help form, coat and protect against wear and tear.

Featured Products

Alodine EC2 extreme corrosion protective coating Page 34

Aquence 930 extreme corrosion protective coating Page 38

Multan B-400 semi-synthetic metal removal fluid Pages 42, 43

Henkels metal removal lubricants are used in precision grinding applications to create precise

instruments for the medical industry.

MA

rk

et

SM

ed

ICA

l d

eV

ICe

S

& e

qu

IPM

en

t

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

-

13

Metalworking Fluids

Hot Melt adhesive Bonding

Structural Bonding

MA

rk

et

SM

ed

ICA

l de

VIC

eS

&

eq

uIP

Me

nt

Water-Based adhesives

Surface Preparation, Cleaning & Conversion Coating

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

-

14

outdoor Power equipment

OverviewOutdoor power equipment such as lawnmowers, snowblowers, generators and chainsaws must reliably perform in challenging conditions that include torrential rains, blistering heat, and frigid temperatures. Our coatings, treatments, adhesives, and sealants help deliver the required robustness, power, performance and dependability.

From precision cutting lubricants to temperature-resistant adhesives, Henkel products streamline the manufacturing process and reduce material consumption. Our coatings, adhesives and sealants extend paint life, resist corrosion, and ensure reliability throughout the life of your equipment.

Featured Products

Alodine EC2 extreme corrosion protective coating Page 34

Aquence 930 extreme corrosion protective coating Page 38

Bonderite NT-1 phosphate-free conversion coating Page 31

Multan B-400 semi-synthetic metal removal fluid Pages 42, 43

P3 Polyprep 110 Cleaner low temp plastics cleaner Pages 40

Terokal 4555B structural bonding adhesive Pages 58, 59, 68, 69

Multan F 2004 synthetic metal forming lubricant Pages 44, 45

Henkels metalworking and plastics cleaners are used throughout the industry on a host

of products to produce lasting results in harsh environments.

MA

rk

et

So

ut

do

or

Po

we

r

eq

uIP

Me

nt

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

-

15

Metalworking Fluids

Structural Bonding

Vibration damping

reinforcing

Water-Based adhesives

Seam Sealing

Surface Preparation, Cleaning & Conversion Coating

Hot Melt adhesive Bonding

MA

rk

et

So

ut

do

or

Po

we

r

eq

uIP

Me

nt

Surface Preparation, Cleaning & Conversion Coating

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

-

16

Pump & Compressor

OverviewPumps and compressors operate in extremely corrosive environments, delivering power and pressure on demand. From appliance compressors to industrial water pumps, manufacturers rely on Henkel metalworking fluids, surface treatments, metal cleaning fluids, and assembly adhesives to cut, form, shape, and assemble these hard-working machines. Our seam sealants and NVH products protect these machines and keep them running smoothly without damage from vibration.

Featured Products

Bonderite NT-1 phosphate-free conversion coating Page 31

Macromelt 2384 fuel/oil resistant hot melt adhesive Pages 48, 49

Multan B-204 semi-synthetic metal removal fluid Pages 42, 43

Multan B-414 low foam semi-synthetic removal fluid Pages 42, 43

Multan F 2004 synthetic metal forming lubricant Pages 44, 45

Multan PL 298 hydroforming-die side, replace chlorinated oils, heavy stampings Pages 44, 45

Alodine EC2 extreme corrosion protective coating Page 34

Terokal 4555B structural bonding adhesive Pages 58, 59, 68, 69

Henkels precision grinding and heavy forming lubricants keep pump and compressor

manufacturers running smooth and clean.

MA

rk

et

SP

uM

P &

C

oM

Pr

eS

So

r

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

-

17

Surface Preparation, Cleaning & Conversion Coating

Vibration dampingStructural Bonding

Metalworking Fluids

MA

rk

et

SP

uM

P &

C

oM

Pr

eS

So

r

Seam Sealing

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

-

18

recreational Vehicle

OverviewFrom chassis to roof system, end cap to front bumper, Henkel adhesives, sealants, and surface treatments help make RV designs more reliable, dependable, and comfortable. Our solutions range from metal pretreatment systems for frames to adhesives for panel laminations to plastic cleaners for paint preparation. Our products reduce rattles and noises, minimize water leakage, seal out weather, and improve the structural strength of these homes on wheels.

Featured Products

Bonderite NT-1 phosphate-free conversion coating Page 31

Macroplast SIA-110 laminating moisture cure adhesive Page 56, 57

P3 Parcosol 283 Wipes aluminum wipes for cleaning Page 41

P3 Polyprep 110 Cleaner low temp plastics cleaner Page 40

Terokal 4555B structural bonding adhesive Pages 58, 59, 68, 69

Henkel Hot Melt adhesives are key to a lasting laminated wall and are designed to bond

dissimilar materials as in wall manufacturing.

MA

rk

et

Sr

eC

re

At

Ion

Al

Ve

HIC

le

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

Henkel is proud to feature the FIBRECYCLE K.E.G. (Keep Earth Green) Packaging Solution a 100% recyclable drum for many of our PUR-FECT LOK and PURMELT panel laminating adhesives.

-

19

reinforcing

air/Water & energy Management

Surface Preparation, Cleaning & Conversion Coating

Seam Sealing

Vibration damping

Metalworking Fluids

Hot Melt adhesive Bonding Structural

Bonding

Water-Based adhesives

MA

rk

et

Sr

eC

re

At

Ion

Al

Ve

HIC

leCategory Pages

Surface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

-

20

Smart Cards

OverviewSmart cards can be simple readable electronic ID badges or complex storage, retrieval and cataloging systems. In smart card manufacturing, Henkel adhesives are used to laminate layers of thin plastic films and to attach microprocessors. As a final step, our surface treatments can be used to clean and prepare the card for printing. Henkel has helped expand the global smart card market by simplifying the manufacturing and laminating process.

Leading Product Chemistries

Polyurethane Adhesives

Polyurethane Dispersions

Polyamides

Plastic Coatings

Typical Applications Include

Layer Lamination

Chip Bonding

Scratch Resistant Coating

Plastic Cleaning

Henkels laminating adhesives are designed for permanent bonding of thin layers.

MA

rk

et

SS

MA

rt

CA

rd

S

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

Henkels custom formulating capabilities allow smart card manufacturers the flexibility to assemble difficult substrates.

-

21

Hot Melt adhesive Bonding

Surface Preparation, Cleaning & Conversion Coating

Water-Based adhesives

MA

rk

et

SS

MA

rt

CA

rd

S

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

-

22

Solar energy

OverviewLeading solar technology companies turn to Henkel to formulate and deliver innovative compounds, solutions, and systems that reduce processing time, increase efficiency, and ease installation. Our R&D in the solar industry has allowed us to develop surface treatment products that make difficult substrates easier to bond, coating products that allow for extended solar panel life, and adhesives and sealants that facilitate assembly of photovoltaic modules and solar concentrators.

Featured Products

Alodine EC2 extreme corrosion protective coating Page 34

Bonderite NT-1 phosphate-free conversion coating Page 31

P3 Polyprep 110 Cleaner low temp plastics cleaner Page 40

Multan F 2004 synthetic metal forming lubricant Pages 44, 45

Terostat MS 930 adhesive/sealant for elastic bonding Pages 60, 61, 68, 69

Terostat 2761 sealant for moisture barrier*

Purmelt QR-4663 adhesive for junction box bonding Pages 52, 53

Purmelt Purfect Glaze 91-822A adhesive for junction box attachment Pages 52-53

Macromelt 6208S polyamide potting hot melt sealant Pages 48, 49

* Currently available in Europe only, contact Henkel marketing for more information.

Henkels Terostat branded sealants keep photovoltaic cells sealed from the

elements for lasting results.

MA

rk

et

SS

olA

r e

ne

rG

y

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

-

23

Structural Bonding

Metalworking Fluids

Surface Preparation, Cleaning & Conversion Coating

MA

rk

et

SS

olA

r e

ne

rG

y

Potting & encapsulating

Seam Sealing

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

Hot Melt adhesive Bonding

-

24

Specialty Vehicle

OverviewAs specialty vehicles such as boom trucks, forklifts and portable warehouses become more advanced, so do the processes that go into manufacturing them. Henkel adhesives, sealants and surface treatments help reduce vehicle weight, decrease corrosion, improve aesthetics, and eliminate visible assembly fasteners. From environmentally responsible metal pretreatments to fracture toughened structural bonding adhesives, Henkel technology leads the way on these unique vehicles.

Featured Products

Bonderite NT-1 phosphate-free conversion coating Page 31

Alodine 5700 aluminum conversion coating Page 34

P3 Polyprep 110 Cleaner low temp plastics cleaner Page 40

Aquence 930 extreme corrosion protective coating Page 38

Macromelt 2384 fuel/oil resistant hot melt adhesive Pages 48, 49

Terokal 4555B structural bonding adhesive Pages 58, 59, 68, 69

Henkels metal pretreatment technologies lead the industry in green, phosphate-free, conversion

coating systems such as Bonderite NT-1.

MA

rk

et

SS

Pe

CIA

lty

V

eH

ICle

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

-

25

Surface Preparation, Cleaning & Conversion Coating

Vibration damping

Structural Bonding

Seam Sealing

reinforcing

Metalworking Fluids

Hot Melt adhesive Bonding

air/Water & energy Management

Water-Based adhesives

MA

rk

et

SS

Pe

CIA

lty

V

eH

ICle

autodeposition Process

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

-

26

Wind energy

OverviewHenkel offers innovative solutions for wind blade bonding, gearbox sealing and tower corrosion protection. Our reduced-VOC adhesives and sealants, energy saving surface preparation coatings, and weight-reducing reinforced structural products are shortening product development cycles, lowering carbon footprints, reducing fossil fuel consumption, and generating increasingly more efficient means to transport energy.

Featured Products

Alodine EC2 extreme corrosion protective coating Page 34

Bonderite NT-1 phosphate-free conversion coating Page 31

P3 Polyprep 110 Cleaner low temp plastics cleaner Page 40

Multan B-400 semi-synthetic metal removal fluid Pages 42, 43

Terostat MS 939 adhesive/sealant for bonding Pages 60, 61, 68, 69

Terostat 2761 sealant for vacuum infusion process

Macroplast UK-1340 polyurethane blade bonding adhesive Pages 56, 57

Macroplast UK-5401 polyurethane blade bonding hardener Pages 56, 57

Application

Henkels structural urethane adhesive technology is used in blade bonding

specifically formulated to withstand the requirements of the wind energy industry.

MA

rk

et

Sw

Ind

en

er

Gy

For additional product offerings and the markets we serve, please visit: www.henkelna.com/industrial

-

27

Structural Bonding

Surface Preparation, Cleaning & Conversion Coating

air/Water & energy Management

Metalworking Fluids

Seam Sealing

Vibration damping

MA

rk

et

Sw

Ind

en

er

Gy

Category PagesSurface Preparation, Cleaning & Conversion Coating 28 - 35

autodeposition Process 36 - 39

Metalworking Fluids 42 - 47

Hot Melt adhesive Bonding 48 - 53

Structural Bonding 54 - 59

elastomeric Bonding & Sealing 60 - 61

Potting & encapsulating 62 - 65

Seam Sealing 66 - 67

reinforcing 68 - 69

Vibration damping 68 - 69

air/Water & energy Management 68 - 69

Water-Based adhesives 70 - 75

-

28

Substrate etch Temperature Builders

ProductsLi

quid

Spra

y

Imm

ersi

on

Stee

l/He

avy

duty

alum

inum

/M

agne

sium

Mul

ti-M

etal

Heav

y et

ch

on a

l & Z

n

oper

atin

g Te

mpe

ratu

re

Sodi

um

Pota

ssiu

m

Phos

phat

e

gluc

onat

e

Inte

r-st

age

Prot

ectio

n

Parco Cleaner 305 X X X X X 100F - 140F X X X

Parco Cleaner 319 X X X X X 120F - 180F X X X

Parco Cleaner HCS10 X X X X X 140F - 210F X X X

Parco Cleaner Zx-1 X X X 120F - 180F X X X X

Parco Cleaner Zx-3 X X X X 140F - 200F X X X

ridoline 412 X X X X 130F - 180F X X

ridoline rT-153 X X X X X 80F - 153F X X X

ridoline rT-163 X X X X 80F - 160F X Low X

ridoline rT-173 & rT-173s

X X X X 80F - 160F X X

alkaline CleanersApplied by spray, immersion and stripline units, these strong alkaline treatments are particularly recommended for use before Bonderite processes. Alkaline cleaners are used to remove organic soils such as dirt, oils and grease.

Parco Cleaner 305 Alkaline cleaner designed to prepare aluminum, steel, hot-dip galvanized and electrogalvanized steel surfaces.

Parco Cleaner 319 Alkaline cleaner designed to prepare aluminum, steel, electrogalvanized and hot-dip galvanized surfaces to receive a conversion coating, or used prior to a plating operation.

Parco Cleaner HCS10 A heavy duty alkaline cleaner for ferrous parts.

Parco Cleaner Zx-1 Alkaline cleaner designed to prepare aluminum, steel, electrogalvanized and hot-dip galvanized surfaces to receive a conversion coating, or used prior to a plating operation.

Parco Cleaner Zx-3 Alkaline cleaner designed to prepare ferrous surfaces to receive a conversion coating. Can be used to strip phosphate and lubed parts prior to a coating, plating or machining operation.

ridoline 412 This concentrated alkaline cleaner, liquid, silicate-free, mildly alkaline cleaner removes oils and light oxide films from aluminum and its alloys.

ridoline rT-153 A room temperature cleaner designed to prepare aluminum, steel, hot-dip galvanized and electrogalvanized steel surfaces.

ridoline rT-163 A unique surfactant system able to clean tenacious soils at low temperatures; provides in-plant rust protection.

ridoline rT-173 & rT-173s A two-package, low temp cleaning system effective in spray or immersion for the removal of metalworking fluids and soils.

aLkaLIne CLeaner aCId CLeaner ConVerSIon CoaTIngCondITIoner PoST TreaTMenT

Pr

od

uC

tS

Su

rFA

Ce

Pr

eP,

C

leA

nIn

G &

Co

AtIn

G

Henkels groundbreaking nanotechnology metal pretreatment products provide extended paint life, improved aesthetics and enhanced corrosion resistance for a range of industrial manufacturers. These continuous coating processes clean, convert surfaces, and seal metals while minimizing in-plant energy consumption, reducing waste, and lowering footprint requirements.

With more than 80 years of experience in surface treatment, Henkel has developed technologies for most ferrous, non-ferrous and polymer substrates. These products range from traditional iron phosphates to green, heavy metal and phosphate-free nanotechnologies that work on a variety of metals.

Surface Preparation, Cleaning & Conversion Coating

For a comprehensive list of package sizes and product offerings, call us at: 1-800-521-1355

NEW!

NEW!

NEW!

NEW!

-

29

acid CleanersAcid cleaners are used prior to conversion coating and are designed to remove inorganic soils such as weld and laser scale, and other oxides such as rust. Acid cleaners are also widely used as maintenance cleaners.

deoxidine 182B A phosphoric acid-based, detergent-type metal cleaner designed to remove rust and oxides left from laser cutting and welding on steel surfaces.

Parco Cleaner 2530 This acidic cleaner is specifically formulated to remove scale from closed loop stainless steel heat transfer systems.

Parco Purge 2520 This acid cleaner for heat-exchanger cleaning has an ambient operating temperature, is acidic, and is specifically formulated to remove scale from closed-loop stainless steel heat transfer systems.

deoxidine a-500 This specially formulated inhibited liquid acid cleaner cleans power-spray processing equipment and relatively inaccessible areas (such as pump intakes), minimizing labor required for cleaning and prolonging equipment life.

Temperature Contents

Products

Liqu

id

Spra

y

Imm

ersi

on

Heav

y du

ty/f

or S

teel

oper

atin

g Te

mpe

ratu

re

Phos

phor

ic a

cid

Hydr

ochl

oric

aci

d

nitr

ic a

cid

Sulfu

ric

deoxidine 182B X X X X Ambient - 180F X

Parco Cleaner 2530 X X X 120F - 150F X

Parco Purge 2520 X X X Ambient X

deoxidine a-500 X X X Ambient X

aLkaLIne CLeaner aCId CLeaner ConVerSIon CoaTIngCondITIoner PoST TreaTMenT

Alodine

Pr

od

uC

tS

Su

rFA

Ce

Pr

eP,

Cle

An

InG

& C

oAtIn

G

For a comprehensive list of package sizes and product offerings, call us at: 1-800-521-1355

-

30

Surface Preparation, Cleaning & Conversion Coating

aLkaLIne CLeaner aCId CLeaner ConVerSIon CoaTIngCondITIoner PoST TreaTMenT

Fixodine M A powdered conditioning agent used for articles of iron and steel, ahead of a Parco Lubrite treatment.

Prepalene x This patented, easy to handle liquid conditioning rinse prepares iron, steel, aluminum, zinc and zinc-alloy surfaces for subsequent phosphate coating applications for use with zinc phosphate conversion coating systems.

application

Products

Liqu

id

Pow

der

Spra

y

Imm

ersi

on

Man

gane

se C

oatin

gs

Zinc

Coa

tings

Tem

pera

ture

ran

geFixodine M X X X X Ambient - 180F

Prepalene x X X X X Ambient - 120F

ConditionersUse of these conditioners promotes the formation of a dense, fine-grained phosphate coating that is preferred as a paint base for the automotive industry, and offers superior adhesion and durability in corrosive environments. Surfaces may be treated individually or in mixed production by either spray or immersion processing.

Pr

od

uC

tS

Su

rFA

Ce

Pr

eP,

C

leA

nIn

G &

Co

AtIn

G

For a comprehensive list of package sizes and product offerings, call us at: 1-800-521-1355

-

31

Bonderite nT-1 This zirconium-based nanotechnology provides a green alternative to traditional iron phosphate. It runs at low temperatures and is completely phosphate- and regulated heavy metal-free, to reduce energy consumption and waste removal.

Bonderite TecTalis This zirconium-based nanotechnology provides a green alternative to traditional zinc phosphate. It runs at low temperatures and is completely phosphate- and regulated heavy metal-free, to reduce energy consumption and waste removal.

Substrate

Products

Spra

y

Imm

ersi

on

Stee

l

Zinc

alum

inum

Crys

tal T

ype

Tem

pera

ture

ra

nge

Bonderite nT-1 X X X X X Nano 55F - 100F

Bonderite TecTalis X X X X X Nano 55F - 100F

Phosphate-Free Conversion CoatingsAn environmentally responsible process that converts the metal surface to a nano-thin coating containing no heavy metals or phosphates. The metals may be treated individually or in mixed production.

aLkaLIne CLeaner aCId CLeaner ConVerSIon CoaTIngCondITIoner PoST TreaTMenT

Alodine

Pr

od

uC

tS

Su

rFA

Ce

Pr

eP,

Cle

An

InG

& C

oAtIn

G

NEW!

For a comprehensive list of package sizes and product offerings, call us at: 1-800-521-1355

-

32

Surface Preparation, Cleaning & Conversion Coating

Iron Phosphate Conversion CoatingsThese processes convert the metal surface to a nonmetallic, iron phosphate coating that inhibits corrosion, and increases the adhesion and durability of paint finishes. These substantial increases in the life of the paint result from the fact that the coating provides a clean, grease-free/oil-free surface, corrosion-inhibiting base for paint, and a non-conducting bond between the base metal and the paint.

Five-Stage Products

Bonderite 1090 This iron phosphate is for use in five-stage processes and imparts an amorphous, non-heavy metal phosphate conversion coating that treats steel and multi-metal substrates simultaneously.

Three-Stage Products

Bonderite 1070 This iron phosphate is for use in three-stage processes, and formulated for spray and immersion application to steel, aluminum and zinc surfaces to simultaneously clean and develop a conversion coating.

Cleaner/Coater Products

Prep-n-Cote 500 LT This iron phosphate cleaner- and coater-in-one has been formulated for spray application of steel surfaces to simultaneously clean and coat metal surfaces.

Spray Wand Products

Parco Spray Wand 200 Designed to simultaneously clean and impart an iron phosphate conversion coating on aluminum and zinc surfaces by use of a spray wand application.

Substrate acceleration Temperature

Products

Liqu

id

Spra

y

Imm

ersi

on

Spra

y W

and

Stee

l

Mul

ti-M

etal

orga

nic

Fluo

ride

Sufa

ctan

t

Tem

pera

ture

ra

nge

Five-Stage Products

Bonderite 1090 X X X X X X X 110F - 150F

Three-Stage Products

Bonderite 1070 X X X X X X X X 110F - 150F

Cleaner / Coater Products

Prep-n-Cote 500 LT X X X X X X 90F - 140F

Spray Wand Products

Parco Spray Wand 200

X X X X X X X 130F - 190F

aLkaLIne CLeaner aCId CLeaner ConVerSIon CoaTIngCondITIoner PoST TreaTMenT

Pr

od

uC

tS

Su

rFA

Ce

Pr

eP,

C

leA

nIn

G &

Co

AtIn

G

For a comprehensive list of package sizes and product offerings, call us at: 1-800-521-1355

-

33

Manganese Phosphate Conversion CoatingsThese corrosion-resistant coatings consist chiefly of iron and manganese phosphates, and reduce wear on such articles as pistons, rings, liners, camshafts, tappets, motor blocks and similar bearing surfaces. Other beneficial effects are: permits rapid break-in of moving parts without scuffing or welding by preventing metal-to-metal contact between the bearing surfaces; increases lubrication of treated surfaces due to the oil-absorptive coating; and removes light metal scratches remaining from machining operations.

Parco Lubrite LT-10 An energy saving, low operating temperature manganese phosphate conversion coating formulated to produce a nonmetallic, corrosion resistant coating on iron and steel surfaces. Extremely effective for use where there is metal-to-metal contact.

Temperature

Products

Liqu

id

Pow

der

Spra

y

Imm

ersi

on

Stee

l

acce

lera

tion

Tem

pera

ture

ra

nge

Parco Lubrite LT-10 X X X Internal 135F - 155F

Bonderite ZM-1 This zinc phosphate conversion coating converts metallic substrate surfaces to a fine-crystalline, non-metallic zinc phosphate coating that inhibits corrosion, and increases the adhesion and durability of organic paints and finishes.

Bonderite ZM-2 A lower concentrate version of Bonderite ZM-1, which requires less diluent when adding to process tanks.

Bonderite 2010 This zinc phosphate is formulated for immersion application to steel, galvanized steel, electrogalvanized steel, zinc-alloy coated steel and aluminum. Provides high alkaline resistance and is preferred as a paint base, offering superior adhesion and durability.

Bonderite 2101 Nickel-free zinc phosphate chemistry.

Substrate Contents Temperature

Products

Spra

y

Imm

ersi

on

Stee

l

Zinc

alum

inum

acce

lera

tion

Crys

tal T

ype

Man

gane

se

nick

el

Tem

pera

ture

ra

nge

Bonderite ZM-1 X X X X X Internal Micro X 120F - 135F

Bonderite ZM-2 X X X X X Internal Micro X 120F - 135F

Bonderite 2010 X X X X X Internal Micro X X 120F - 135F

Bonderite 2101 X X X X X Internal Micro X 120F - 135F

Zinc Phosphate Conversion CoatingsThe process converts the metal surface to a nonmetallic, polycrystalline coating containing iron, manganese, nickel and zinc phosphates. The metals may be treated individually or in mixed production.

aLkaLIne CLeaner aCId CLeaner ConVerSIon CoaTIngCondITIoner PoST TreaTMenT

Alodine

Pr

od

uC

tS

Su

rFA

Ce

Pr

eP,

Cle

An

InG

& C

oAtIn

G

-

34

Surface Preparation, Cleaning & Conversion Coating

aLkaLIne CLeaner aCId CLeaner ConVerSIon CoaTIngCondITIoner PoST TreaTMenT

Pr

od

uC

tS

Su

rFA

Ce

Pr

eP,

C

leA

nIn

G &

Co

AtIn

G

Light Metals Conversion Coatings

Products

Liqu

id

Spra

y

Imm

ersi

on

Mag

nesi

um

Zinc

alum

inum

Inte

rnal

exte

rnal

reac

tive

dry

in P

lace

70F

- 1

20F

85F

- 1

20F

100

F -

135

F

Mili

tary

ap

prov

als

non-Chrome Technology

alodine 5200 X X X X X X X X X X X

alodine 5700 X X X X X X X X X X X

alodine 2600 X X X X X X X

alodine 4595 X X X X X X X

alodine eC2 X X X X X

Chrome Technology

alodine 1600 X X X X X X X X

alodine 1500 X X

alodine 407 X X X X X X X

alodine T 5900 X X X X X X X

non-Chrome Technology

alodine 5200 A chromium-free titanium/polymer conversion coating for non-ferrous alloys for bonding and organic finishes.

alodine 5700 A ready-to-use version of Alodine 5200, also available in convenient wipes.

alodine 2600 A cobalt-based conversion coating for aluminum.

alodine 4595 A chromium-free zirconium/polymer product for treating aluminum to provide an excellent base for organic finishes and bonding.

alodine eC2 An electro-ceramic coating that is chromium-free and formulated for coating aluminum, titanium and their alloys, and can function as the final finish to provide extreme corrosion protection.

Chrome Technology

alodine 1600 A liquid MIL-DTL-81706/MIL-DTL-5541F approved chromate to Class 1A and 3 to produce a protective coating on aluminum.

alodine 1500 A liquid MIL-DTL-81706/MIL-DTL-5541F approved chromate to Class 3 to produce a protective coating on aluminum.

alodine 407 A chrome phosphate conversion coating for architectural applications.

alodine T 5900 A trivalent chrome conversion coating approved to MIL-DTL-81706/MIL-DTL-5541F Class 1A and 3.

NEW!

For a comprehensive list of package sizes and product offerings, call us at: 1-800-521-1355

-

35

Alodine

aLkaLIne CLeaner aCId CLeaner ConVerSIon CoaTIngCondITIoner PoST TreaTMenT

Post-Treatment

Parcolene 99x A patented, chromium and phosphate-free post treatment that increases paint adhesion and corrosion resistance of metal surfaces for use over all types of conversion coatings used in the pretreatment of steel, zinc, and aluminum surfaces.

Substrate Paint System

Products

Liqu

id

reac

tive

Spra

y

Imm

ersi

on

Stee

l

galv

aniz

ed

alum

inum

non-

Chro

me

orga

nic

ambi

ent

dIW

rin

se/

afte

r

Wet

Pow

der

e-Co

at

Parcolene 99x X X X X X X X X X X X X X XX

Pr

od

uC

tS

Su

rFA

Ce

Pr

eP,

Cle

An

InG

& C

oAtIn

G

For a comprehensive list of package sizes and product offerings, call us at: 1-800-521-1355

-

36

autodeposition Coatings

Henkels patented Aquence autodeposition process chemistries deliver extreme corrosion protection while increasing process efficiency over traditional finishing methods. The Aquence process coats complex parts evenly and can stand alone as the finished surface or accept topcoat paint for aesthetics. The Aquence process combines metal pretreatment, coating and finishing, and provides a lasting finish both inside of parts and out.

By streamlining the metal finishing process, the Aquence process reduces in-plant space requirements, energy consumption and processing steps, while increasing corrosion resistance and life expectancy of critical components. We offer our customers a full pilot line capable of running prototype trials to demonstrate the benefits of the Aquence process.

Cleaners

ProductsLi

quid

Pow

der

alka

line

acid

Spra

y

Imm

ersi

on

Stee

l

galv

aniz

ed/Z

inc

Ligh

t dut

y

Med

ium

dut

y

Wel

dmen

ts/S

cale

rem

oves

Fla

sh

rust

draw

ing

Com

poun

ds

Tem

pera

ture

ra

nge

emul

sify

Split

-out

Phos

phat

es

aquence Cleaner 1772

X X X X X O X O 140F - 190F

X X

aquence 2592

X X O X X X O X180F - 200F

X

aquence 2599

X X X O X X O120F - 160F

X

aquence 2600

X X X O X O X150F - 180F

X

aquence 2810

X X O X X X O120F - 160F

X trace

aquence Cleaner 2819

X X X X X X X O O140F - 180F

X X

aquence 2860

X X X O X X O X150F - 200F

X X

aquence 182a

X X X X X X O X80F - 180F

X X

aquence 7005

X X X X O X X120F - 190F

X X

aquence 7150

X X X O X X X O X135F - 165F

X trace

aquence 7310

X X X O X X O O X145F - 175F

X

aquence 7320

X X X O X O X O X145F - 175F

X

Pr

od

uC

tS

Au

to

de

Po

SIt

Ion

C

oA

tIn

GS

X = Primary AttributeO = Secondary Attribute

For more information, please visit:

www.autophoretic.com

For additional product offerings to fit your specific needs, call us at: 1-800-521-1355

-

37

alkaline Cleaners

aquence Cleaner 1772 A powdered, non-silicated, strongly alkaline cleaner formulated for use in spray process equipment for heavy duty cleaning of ferrous metals prior to autodeposition.

aquence 2592 A liquid, alkaline cleaner formulated for heavy duty, general purpose cleaning of ferrous metals and is used to remove soils, oils, and forming lubricants from steel prior to the application of autodeposited coatings.

aquence 2599 An alkaline cleaner designed to prepare steel surfaces to receive an Aquence coating.

aquence 2600 A liquid, phosphate and silicate free, strong alkaline cleaner formulated for heavy duty cleaning of ferrous metal surfaces prior to autodeposition.

aquence 2810 A non-silicated, liquid, alkaline cleaner formulated for heavy duty, general purpose cleaning of ferrous metals used to remove a variety of soils, oils and forming lubricants from steel prior to the application of autodeposited coatings.

aquence Cleaner 2819 Prepares steel, electrogalvanized and hot-dip galvanized surfaces to receive an Aquence coating. This strongly alkaline treatment can be applied by spray or immersion.

aquence 2860 A liquid, non-silicated, strongly alkaline cleaner formulated for use in immersion process equipment for heavy duty cleaning and oxide removal from ferrous metal surfaces prior to autodeposition.

acid Cleaners

aquence 182a This phosphoric acid-based, detergent-type metal cleaner and rust remover with biodegradable organic surfactants destroys corrosion stimulators and can be used in spray or immersion systems to remove rust and light deposits of mill oil on steel parts.

aquence 7005 An acidic composition, which when diluted with water, produces a mixed mineral acid-solvent-detergent liquid metal cleaner and rust remover. It will effectively remove rust, scale, and light deposits of mill oil from the surface of metals and properly condition steel surfaces.

aquence 7150 An acidic composition, for use in spray washing systems prior to Aquence paint films and for removing light rust and oxidation from iron and steel surfaces. For effective derusting, articles must be free from grease and oil before cleaning.

aquence 7310 An acidic composition, spray cleaning solution for removing light rust and oxidation from iron and steel surfaces prior to the application of an Aquence paint film.

aquence 7320 An acidic composition, which when diluted with water, produces a spray/dip cleaning solution for removing light rust, oxidation and oily soils from iron and steel surfaces prior to the application of Aquence Coating Chemicals. The performance of the coated part is improved when cleaning is followed by ultrasonic-assisted rinsing.

CLeaner CoaTIng reaCTIon rInSe

Pr

od

uC

tS

Au

to

de

Po

SIt

Ion

C

oA

tIn

GS

For additional product offerings to fit your specific needs, call us at: 1-800-521-1355

-

38

autodeposition Coatings

Products

resi

n Ba

se

High

ope

ratin

g Te

mpe

ratu

re

resi

stan

ce

glos

s ra

nge

Flex

ibili

ty

Salt

Spra

y re

sist

ance

Cycl

ic C

orro

sion

VoC

Impa

ct r

esis

tanc

e (in

./lb

s.)

Penc

il Ha

rdne

ss

Proc

ess

effic

ienc

y

Flas

h-of

f ove

n

Cure

Tem

pera

ture

ra

nge

Pain

t Sol

ids

(%

wei

ght)

aquence 866 PVDC 5 - 10 X X X None 120 - 160 4H - 7HMedium -

HighNo

200F - 220F

38%

aquence 866Ix

PVDC 5 - 10 X X X None 120 - 160 4H - 7H Very High No200F - 220F

38%

aquence 915Epoxy / Acrylic

UrethaneX 40 - 80 X X X

Very Low

60 - 80 H - 3HMedium -

HighYes

350F - 385F

33%

aquence 915Ix

Epoxy / Acrylic Urethane

X 40 - 80 X X XVery Low

60 - 80 H - 3H Very High Yes350F - 385F

33%

aquence 925g

Epoxy / Acrylic Urethane

X 40 - 80 X X XVery Low

60 - 80 H - 3HMedium -

HighYes

325F - 365F

33%

aquence 930

Epoxy / Acrylic Urethane

X 30 - 80 X X XVery Low

60 - 100 H - 3HMedium -

HighYes

350F - 385F

33%

Coatings

aquence 866 A smooth, black, water-based, organic coating for ferrous metal surfaces. When deposited uniformly on the metal surface, it will coat recessed or partially enclosed surfaces to provide low cure solvent and heavy metal-free coatings with good corrosion resistance, solvent resistance, adhesion, flexibility and hardness.

aquence 866Ix A high efficiency replenisher used to produce a smooth, black, water-based, organic coating on ferrous metal surfaces. When deposited uniformly on the metal surface, it will coat recessed or partially enclosed surfaces to provide low cure coating with good corrosion resistance, solvent resistance, adhesion, flexibility and hardness free of solvents or heavy metals.

aquence 915 A concentrated liquid chemical used to produce a black, water-based, organic coating on ferrous metal surfaces. When deposited uniformly on the metal surface, it will coat recessed or partially enclosed surfaces.

aquence 915Ix A high efficiency, concentrated, water-based, liquid chemical used to produce a black organic coating on ferrous metal surfaces. When deposited uniformly on the metal surface, it will coat recessed or partially enclosed surfaces.

aquence 925g Coating chemicals consist of two components of concentrated, liquid chemicals used to produce a grey, organic, water-based coating on ferrous metal surfaces. When deposited uniformly on the metal surface, it will coat recessed or partially enclosed surfaces. Design of this coating is for a lighter, non-black primer for accepting color specific topcoats.

aquence 930 This epoxy-acrylic urethane coating is environmentally responsible, heavy metal-free, with low VOC that delivers enhanced corrosion performance for demanding applications like frames and chassis components.

CLeaner CoaTIng reaCTIon rInSe

Pr

od

uC

tS

Au

to

de

Po

SIt

Ion

C

oA

tIn

GS

X = Primary AttributeO = Secondary Attribute

For additional product offerings to fit your specific needs, call us at: 1-800-521-1355

NEW!

NEW!

-

39

reaction rinses

Products

Coat

ing

Serie

s

Mul

ti-Co

mpo

nent

neut

ral

alka

line

acid

CrS

HrS

Forg

ings

Cast

ings

Phos

phon

ate

Zirc

oniu

m

Calc

ium

/Pho

spha

te

Salt

Spra

y re

sist

ance

Cycl

ic C

orro

sion

re

sist

ance

Chem

ical

Flu

id

resi

stan

ce

Solv

ent r

esis

tanc

e

Bend

ing/

Form

ing

glos

s

Surf

ace

Smoo

thne

ss

Conc

entr

atio

n

Proc

ess

Tank

Te

mpe

ratu

re

aquence 2150

800 X X X O O X O X O X Low Low 1% - 3% RT

aquence 3416

800 X X X X X X X O O O X Medium High 1% - 10% RT

aquence e2 900 X X X X X X X O X X X Medium Medium 1% - 4%125F - 140F

aquence e3 900 X X X X X X X X X O O X High Medium0.36% E3A3.6% E3B1% E3C

125F

aquence 2150 A liquid chemical used to improve the water resistance, corrosion resistance and adhesion properties of cured Aquence 800 series coatings.

aquence 3416 An alkaline liquid chemical used as an immersion reaction rinse for surfaces treated with Aquence coating chemicals to improve the uniformity and gloss of coating appearance.

aquence e2 A liquid chemical used to improve the water and corrosion resistance along with improved adhesion properties of cured Aquence 900 series coatings.

aquence e3 A liquid chemical used to improve the corrosion resistance, coverage and appearance of cured Aquence ACC 900 series coatings.

CLeaner CoaTIng reaCTIon rInSe

Pr

od

uC

tS

Au

to

de

Po

SIt

Ion

C

oA

tIn

GS

For more information, please visit:

www.autophoretic.com

X = Primary AttributeO = Secondary Attribute

For additional product offerings to fit your specific needs, call us at: 1-800-521-1355

-

40

Pr

od

uC

tS

CH

eM

ICA

l S

Pe

CIA

ltIe

S

Chemical Specialties

Our extensive line of chemical specialty products ranges from plastic cleaners to paint strippers that are designed to treat, clean and maintain working areas, equipment and assembly surfaces. Our chemists have developed technologies that make your working environment safer, cleaner and more productive. We are leading green initiatives to lower carbon footprint, reduce VOCs, eliminate solvents and develop HAPS-free chemistries. Whether you need floor cleaner or paint line purge solutions, our chemical specialties product line has you covered.

application/System Temperature Contents

Products

Spra

y

Conc

entr

atio

n (%

by

volu

me)

Mild

Ste

el

etch

oper

atin

g Te

mpe

ratu

re

Liqu

id

Phos

phat

e-Fr

ee

Solu

tion

Mod

ifier

Surf

ace

Mod

ifier

Phos

phor

ic

acid

Citr

ic a

cid

Cleaners

P3 Polyprep 110 Cleaner X 2%-5% X 110F-160F X X X

P3 Polyprep 3293 Cleaner X 2%-5% X 130F-150F X X

P3 Polyprep 2615 Cleaner X 2%-5% X 130F-150F X X X

rinse aids

P3 Polyprep rinse 400 X 0.03%-0.07% 70F-110F X X X

P3 Polyprep rinse 205 X 0.15%-0.35% 70F-110F X X X

P3 Polyprep 110 Cleaner A low temperature, phosphate-free plastics cleaner designed for plastics pretreatment process prior to paint. Minimizes utility costs such as energy and water consumption.

P3 Polyprep 3293 Cleaner Phosphate containing (acid) An acidic cleaner formulated primarily for cleaning plastic surfaces.

P3 Polyprep 2615 Cleaner Phosphate-free (acid) An acidic cleaner formulated primarily for phosphate-free cleaning of plastic surfaces.

P3 Polyprep rinse 400 Designed for use after plastic cleaning in plastic pretreatment operations and assists in the displacement and removal of solids-laden water, thereby minimizing water spotting on cleaned plastic and painted plastic parts.

P3 Polyprep rinse 205 Specially designed for use on Thermal Plastic Olefin (TPO) after plastic cleaning in plastic pretreatment operations, and assists in the displacement and removal of solids-laden water, thereby minimizing water spotting on cleaned plastic and painted plastic parts.

application/System Temperature Characteristics

Products

Pres

sure

Pot

Wip

e

Solv

ent-

born

e Pa

int

Wat

erbo

rne

Pain

t

gene

ral S

oil

Clea

nup

oper

atin

g Te

mpe

ratu

re

Wat

er

redu

cabl

e

VoC

(H,M

,L)

Purge Solvent

P3 Parcosol 577WB X X X X ambient-130F X L

Line Cleaner

P3 200WB Paint Line Cleaner X X X ambient-130F X L

P3 Parcosol 577WB This HAPs-free, low-VOC, water-soluble proprietary activator/amine purge blend, used for internal and external cleaning of waterborne paint application equipment, is the next generation of Parcosol 277WB. Very effective at removing wet, semi-dry and dry waterborne paint from bell or air-atomized paint delivery equipment.

P3 200WB Paint Line Cleaner Used for cleaning internally the re-circulating paint lines for waterborne and solvent-borne paint systems and specially developed to be compatible with all types of Viton seals.

For additional product offerings to fit your specific needs, call us at: 1-800-521-1355

Plastic Cleaners and rinses

Purge and Line Cleaners

NEW!

-

41

Pr

od

uC

tS

CH

eM

ICA

l S

Pe

CIA

ltIe

S

application/System Temperature Characteristics

Products

Spra

y

roll

or B

rush

dry

Tim

e

Wet

Mil

appl

ied

oper

atin

g Te

mpe

ratu

re

grey

Whi

te

Clea

r

Wat

er

rem

ovab

le

Visc

osity

(H

, M, L

)

VoC

(H, M

, L)

Maskings

P3 2474 Peelable Masking X X 1 hour 5.5-6.0 ambient X M L

P3 2486 Peelable Masking X X 1 hour 5.5-6.0 ambient X M L

P3 2498 Peelable Masking X X 1 hour 6.0-8 ambient X M L

P3 Clear Masking 2484 X X NA as needed ambient X X H L

Baffle Coating

P3 Baffle Coating 2451 X X NA 8-10 ambient X X H L

Cold Strippers

P3 110 Cold Stripper X X NA as required to remove paint X X H H

P3 200WB Stripper X X NA as required to remove paint X X H L

P3 2474, 2486 and 2498 Peelable Masking Water-based and solvent-based peelable protective coatings used for temporary protection of parts, spray booths and equipment.

P3 Clear Masking 2484 This water-based transparent masking forms a tacky, clear coating designed to maximize the trapping of dust, dirt and other airborne debris, while not altering the appearance of the original substrate.

P3 Baffle Coating 2451 This water-resistant, grease-type product is formulated for application to baffles, back sections, stacks, underbooth areas and other locations where a greasy coating is desired to prevent adhesion of paint overspray.

P3 110 Cold Stripper This solvent-based, thickened paint stripper for removing uncured paint from the walls, windows, grates, and floors of spray booths and paint rooms is also effective in the removal of heavy paint build-up.

P3 200WB Stripper A water-based thickened paint stripper for removing uncured paint from walls, windows, grates, and floors of spray booths and paint rooms. Effective in the removal of heavy paint build-up.

application/System Temperature Characteristics

Products

Scru

bber

Mop

/Pai

l

Wip

e

Solv

ent-

Born

e Pa

int

Wat

erbo

rne

Pain

t

e-Co

at

Syst

em

gene

ral S

oil

Clea

nup

oper

atin

g Te

mpe

ratu

re

Wat

er

redu

ceab

le

VoC

(H, M

, L)

Floor or General Purpose Cleaner

P3 116 Saf-T-Clean X X X X X X ambient-130F X L

P3 104 Saf-T-Clean X X X X ambient H

P3 Parco 2280 Cleanup X X X X ambient X L

P3 222 rik X X X X ambient X L

P3 2226 Maintenance Cleaner X X X X ambient-130F X L

P3 Parcosol 283 Wipes X X ambient H

System Cleaners

P3 2250uF e-Coat Cleaner X

-

42

Metalworking Fluids

Metal removal Henkels line of high-quality metal removal products for cutting and grinding are available in a variety of chemistries including synthetics, semi-synthetics, soluble oils or straight oils.

Synthetic

Multan 9103 An oil-rejecting synthetic metal removal fluid that has multiple uses in todays manufacturing environment. For use on ferrous alloys only.

Multan 3105 An oil-rejecting, synthetic fluid designed for machining, grinding and roll-forming ferrous and non-ferrous alloys. It is also suitable for use on brass, copper and other exotic metals.

Semi-Synthetic

Multan B-204 A semi-synthetic metal removal lubricant with a combination of lubricity additives and cooling ability for light to moderate applications and is bio-resistant for applications where lubricity, cooling and finish are critical.

Multan B-236 A low foam, water soluble semi-synthetic fluid designed for machining and grinding ferrous and aluminum alloys. It is designed for use in areas where soft water or process requirements make foam difficult to control. Ideal for applications where RO/DI water is used.

Multan B-400 This semi-synthetic, bio-resistant product can be used in industrial metal removal applications and is suitable for use on brass, copper and other exotic metals. Typical applications are machining and grinding of ferrous and aluminum alloys.

Multan B-414 A low foam, water soluble, semi-synthetic fluid designed for machining and grinding ferrous and non-ferrous alloys. It is designed for use in areas where soft water or process requirements make foam difficult to control. Its wide applicability makes it suitable for use on brass, copper and other exotic metals. It is also suitable on harder to machine alloys such as stainless steel, titanium or inconel.

Soluble oil

Multan 5600d This all-purpose soluble oil, designed for machining and grinding ferrous and aluminum alloys provides excellent lubricity for various types of difficult operations.

Straight oil

Multan Cr 10 This moderate viscosity straight oil with an additive package is useful in general machining applications such as hobbing, milling or shaping, ranging from steel gear machining to cutting tool manufacturing.

Multan Cr 26 This unique composition of corrosion inhibitors, Extreme Pressure (EP) additives, anti-mist agents and lubricity additives provides a durable straight oil product for todays moderate broaching operation.

AdditionAl product offerings Are AvAilAble, see product list on pAges 78-79 for descriptions.

Henkel offers a full line of metalworking fluids designed to extend tool life, reduce wastes, improve quality and increase throughput. From straight oils to synthetics, our products for metal forming, metal removal and rust prevention contain necessary additives that meet the needs of light to heavy duty industry applications.

Pr

od

uC

tS

Me

tAlw

or

kIn

G

Flu

IdS

For additional product offerings to fit your specific needs, call us at: 1-800-521-1355

-

43

eP addITIVeS SuBSTraTe CoMPaTIBILITY

Products

orde

r IT

eM

nuM

Ber

ConT

aIne

r W

eIgH

T (k

g)

ConT

aIne

r SI

Ze

ConC

enTr

aTe

CoLo

r

ruST

-Fre

e Co

nC.

(%) -

CaS

T Ir

on

VIS

CoSI

TY -

H2o

So

LuBL

eS (c

P), o

ILS

(SuS

@ 1

00F

)

oIL

ConT

enT

ra

nge

(%)

TYPI

CaL

Co

nCen

TraT

Ion

PHoS

PHor

uS

SuLF

ur

STee

L

CaST

Iron

aLuM

InuM

**

YeLL

oW (C

oPPe

r /

BraS

S)**

SYnTHeTIC

Multan 9103

596262 20 PAIL

Blue 3 35 0 5%-10% A b A b593832 213 DRUM

952802 1258 330 GAL. TOTE

Multan 3105

599088 18 PAIL

Pale Amber 4 70 0 5%-10% a b a b A B c A B c598807 211 DRUM

596467 1041 275 GAL. TOTE

SeMI-SYnTHeTIC

Multan B-204

1052097 18 PAIL

Amber 2 200 20-25 5%-10% X A B c A B c A b A b 1052551 202 DRUM

1052099 1198 330 GAL. TOTE

Multan B-236 1052099 18 PAIL

Amber 2 200 20-25 5%-10% X A B c A B c A b A b1052099 202 DRUM

1052099 1198 330 GAL. TOTE

Multan B-400

706695 18 PAIL

Amber 2 275 25-30 5%-10% X X a B C b C a B C a B C677532 197 DRUM

802380 1180 330 GAL. TOTE

Multan B-414 1183211 18 PAIL

Amber 2 275 25-30 5%-10% X X a B C b C a B C a B C1183199 197 DRUM

1183248 1180 330 GAL. TOTE

SoLuBLe oIL

Multan 5600d

598193 17 PAIL

Amber N/A 170 85-90 5%-10% a B C a B C b c b c594510 192 DRUM

665576 904 275 GAL. TOTE

STraIgHT oIL

Multan Cr 10

628510 16 PAIL

Amber N/A 120 90-95 100% X A B A B a b a b 593816 181 DRUM

820117 1078 330 GAL. TOTE

Multan Cr 26

910772 16 PAIL

Amber N/A 220 75-80 100% X X A B c A B c a b a b 910511 174 DRUM

910480 1040 330 GAL. TOTE

A Highly Recommend for Grindinga Recommend for GrindingB Highly Recommend for General Machining Turning, Drilling, Milling, Reaming, Sawing, Cuttingb Recommend for Medium General Machining Turning, Drilling, Milling, Reaming, Sawing, CuttingC Highly Recommend for General Machining Threading, Broaching, Deep Hole Drilling, Reamingc Recommend for General Machining Threading, Broaching, Deep Hole Drilling, Reaming

** Individual alloys should be tested prior to recommendation.

Pr

od

uC

tS

Me

tAlw

or

kIn

G

FluId

S

For additional product offerings to fit your specific needs, call us at: 1-800-521-1355

NEW!

NEW!

-

44

Metalworking Fluids

Metal Forming Synthetic

Multan F 2004 A synthetic compound designed for deep drawing and stamping of ferrous and aluminum alloys. Its unique composition of corrosion inhibitors, Extreme Pressure (EP) additives and lubricity additives provide a durable product for todays moderate to heavy drawing and stamping operations.

Multan F 4510 A chlorinated synthetic stamping fluid designed for press forming of steel alloys. High EP level offers extreme lubrication in high speed, high heat operations.

Multan F 4768 A chlorine-free synthetic stamping fluid designed for severe press forming of multi-metal alloys. It is non-staining in the presence of mixed metals.

Multan F 6740 A synthetic based compound designed for forming, punching and machining ferrous to galvanized alloys. Multan F 6740 can also be used on various aluminum and stainless steel alloys.

Multan F 7270 A synthetic compound designed for drawing and stamping of ferrous and aluminum alloys. Excellent performance in high speed progressive die applications.

Soluble oil

Multan F 981nd A versatile chlorinated soluble oil fluid capable of stamping, drawing, machining and grinding both ferrous and nonferrous alloys. It is not recommended for zinc-coated materials.

Multan F 985 Another versatile soluble oil fluid designed for stamping, drawing, machining and grinding both ferrous and nonferrous alloys. This material is safe on zinc coated metals and performs well in stainless steel applications.

oil Base

Multan PL 1439 A low VOC lubricant designed for light high-speed stamping. It was designed primarily for fin stamping, used in the heating, cooling and radiator industry where excellent hydrolytic stability and refrigerant compatibility is required. Multan PL 1439 provides superior performance with low coating weights when used in conjunction with Henkels Appli-Coater lubricant delivery system.

Multan PL 298 An oil based compound designed for tube hydroforming of ferrous and aluminum alloys. Its moderate viscosity allows for a wide range of additional uses in heavy metal forming operations.

Pr

od

uC

tS

Me

tAlw

or

kIn

G

Flu

IdS

For additional product offerings to fit your specific needs, call us at: 1-800-521-1355

AdditionAl product offerings Are AvAilAble, see product list on pAges 78-79 for descriptions.

-

45

BoundarY eP addS SuBSTraTe

Products

orde

r IT

eM

nuM

Ber

ConT

aIne

r W

eIgH

T (k

g)

ConT

aIne

r SI

Ze