HENKE ALL-HYDRAULIC WINGhenkemfg.com/.../AHW_CASE_845TO885_NH...8510301_02.pdf · For Case 845-885...

Transcript of HENKE ALL-HYDRAULIC WINGhenkemfg.com/.../AHW_CASE_845TO885_NH...8510301_02.pdf · For Case 845-885...

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCX

HENKE ALL-HYDRAULIC WING Models: AHW 42BH, AHW 66BH For Case 845-885 & New Holland RG140-RG200 Series Graders

PARTS BOOK AND INSTALLATION MANUAL Serial Number: _______________ VERSION 3.3, APRIL 2015

HENKE MANUFACTURING CORPORATION MANUFACTURERS OF SNOW REMOVAL EQUIPMENT FOR 95 YEARS 3070 WILSON AVE. LEAVENWORTH, KS 66048 PHONE (913)682-9000 FAX(913)682-0300 WEBSITE ADDRESS : WWW.HENKEMFG.COM EMAIL: [email protected]

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 2 of 67

<THIS PAGE IS INTENTIONALLY LEFT BLANK>

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 3 of 67

Introduction

Thank you for your purchase of a Henke All Hydraulic Wing for your Case or New Holland motor grader. The bolt-up/bolt-up attaching structure design of this wing allows greater rotation of the main grader blade than other designs, which improves snow moving capability. The All Hydraulic Wing consists of four main subassemblies: 1. Wing Post and Attachment Assemblies

2. Moldboard and Pushbeam Assemblies

3. Rear Attachment Assembly (either: Elevating Rear, Fixed Rear,

Manually Elevating Rear, or Rear Ripper Attachment)

4. Hydraulic Hoses and Fittings Before beginning your installation, please check that all of the appropriate ship-loose parts and hardware listed in Table 1 was received. In the unlikely event that any parts are missing, please contact Henke Manufacturing Corporation for replacements. The cutting path, defined as the distance perpendicular to the motion of the vehicle, of the snow wing is approximately 80% of the moldboard length. Therefore, an AHW-12’ would have a cutting path of almost 10 feet. The parts lists for the AHW Case/NH snow wing are listed in Tables 2 thru 12 (if applicable). These lists are important and should be referred to when ordering replacement parts from your local dealer or Henke Manufacturing Corporation. The parts diagrams for the snow wing are shown in Figures 1 thru 7. This Product Manual should be read in its entirety before using your Henke AHW Case/NH snow wing to minimize mounting problems. For customer service, replacement parts, or answers to questions about your Henke plow, please call Henke Manufacturing at (913) 682-9000.

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 4 of 67

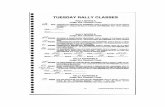

Table of Contents

Introduction ..................................................................................................................... 3

Wing Installation Loose Hardware ................................................................................. 10

Parts Figures and Parts Lists ........................................................................................ 11

Mounting Instructions .................................................................................................... 53

Henke Warranty ............................................................................................................ 66

Dealer Warranty Procedure ........................................................................................... 67

List of Tables

Table 1 – Wing Installation Loose Hardware ................................................................. 10

Table 2 - Front Post Assembly and Attachments, Parts List ......................................... 12

Table 3 - AHW Moldboard Assembly & Attachments, Parts List ................................... 14

Table 4 - Elevating Rear Assembly, Parts List .............................................................. 16

Table 5 - Rear Ripper Assembly, Parts List .................................................................. 17

Table 6 - Fixed Rear Assembly, Parts List .................................................................... 18

Table 7 - 2-Section Valve & Controls Kit 6182602 ........................................................ 25

Table 8 - 3-Section Valve & Controls Kit 6182603 ........................................................ 26

Table 9 - Special 3-Section Valve & Controls Kit 6182604 ............................................ 27

Table 10 - Hydraulic Tie-In Kit 7080465 ........................................................................ 28

Table 11 - Cylinder Hose Kit 7080464........................................................................... 29

Table 12 - Elevating Rear Hose Kit 7080466 ................................................................ 30

Table 13 - DRY Torque Values for Toplock (All-Metal) or Nylock Nuts Only ................. 62

Table 13 - DRY Torque Values for Standard Non-Locking Nuts ONLY ........................ 62

Table 14 - Henke Cutting Edges ................................................................................... 63

Table 15 - Henke Cutting Edge Hardware ..................................................................... 64

Table 16 - Henke Curb Guards and Wear Guards ........................................................ 65

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 5 of 67

List of Figures Figure 1. Henke All Hydraulic Wing on CASE Grader .......................................... COVER

Figure 2. Front Post Assembly & Attachments ............................................................. 11

Figure 3. AHW Moldboard Assembly & Attachments ................................................... 13

Figure 4. AHW Elevating Rear Assembly .................................................................... 15

Figure 5. Rear Ripper Assembly .................................................................................. 17

Figure 6. Fixed Rear Assembly .................................................................................... 18

Figure 7. Welded-On Mounting Plate Installation ......................................................... 19

Figure 8. Hydraulic Hoses and Fittings Running From Henke Valve ............................ 20

Figure 9. Plumbing of 7080340 Load Sense Shuttle Valve .......................................... 21

Figure 10. Hydraulic Schematic from Bulkhead Plate to Wing ..................................... 22

Figure 11. Mounting of Henke MUDROC Valve on Wing Post ..................................... 23

Figure 12. REQUIRED ADJUSTMENT! - MUDROC Relief Valve Adjustment ............. 24

Figure 101. Installation of Post Attaching Structure on Grader .................................... 31

Figure 102. Front Pipe Brace Ear Mounting ................................................................. 32

Figure 103. Rear Pipe Brace Ear Mounting .................................................................. 33

Figure 104. Front Pipe Brace Mounting ........................................................................ 34

Figure 105. Rear Pipe Brace Mounting ........................................................................ 35

Figure 106. Elevating Rear Assembly (View 1 of 2) ..................................................... 36

Figure 107. Elevating Rear Assembly (View 2 of 2) ..................................................... 37

Figure 108. Fixed Rear Assembly ................................................................................ 38

Figure 109. Rear Ripper Attachment ............................................................................ 39

Figure 110. Henke Control Valve Mounting .................................................................. 40

Figure 111. Henke Control Valve Mounting & Load Sense Hose Attachment .............. 41

Figure 112. Drilling of Hole in Cab Floor ...................................................................... 42

Figure 113. Installation of Control Handles & Cables ................................................... 43

Figure 114. Installation of Load Sense Shuttle Valve (View 1 of 2) .............................. 44

Figure 115. Installation of Load Sense Shuttle Valve (View 2 of 2) .............................. 45

Figure 116. Henke Pressure Hose Attachment to Case System .................................. 46

Figure 117. Case Hard Line Replace with Customized Hard Line ............................... 47

Figure 118. Attachment of Henke Return Hose to Case Tank ..................................... 48

Figure 119. Henke Bulkhead Plate, Unbolted .............................................................. 59

Figure 120. Henke Bulkhead Plate, Installed. .............................................................. 50

Figure 121. Looping of Hoses on Rear of Wing Post ................................................... 51

Figure 122. Attachment of Hoses to Clamp on Wing Slide Assembly .......................... 52

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 6 of 67

<THIS PAGE IS INTENTIONALLY LEFT BLANK>

SAFETY

Wings and High Gate Safety Section 1-2

© 2009 Alamo Group Inc.

SA

FE

TY

GENERAL SAFETY INSTRUCTIONS AND PRACTICES

A careful operator is the best operator. Safety is of primary importance to the manufacturer and should be tothe owner/operator. Most accidents can be avoided by being aware of your equipment, your surroundings, andobserving certain precautions. The first section of this manual includes a list of Safety Messages that, iffollowed, will help protect the operator and bystanders from injury or death. Read and understand these SafetyMessages before assembling, operating or servicing this Implement. This equipment should only be operatedby those persons who have read the manual, who are responsible and trained, and who know how to do soresponsibly.

The Safety Alert Symbol combined with a Signal Word, as seen below, is used throughout thismanual and on decals which are attached to the equipment. The Safety Alert Symbol means:“ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!” The Symbol and Signal Wordare intended to warn the owner/operator of impending hazards and the degree of possible injuryfaced when operating this equipment.

Indicates an imminently hazardous situation that, if not avoided, WILL result in DEATH ORVERY SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, COULD result in DEATHOR SERIOUS INJURY.

Indicates an imminently hazardous situation that, if not avoided, MAY result in MINORINJURY.

Identifies special instructions or procedures that, if not strictly observed, could result indamage to, or destruction of the machine, attachments or the environment.

NOTE: Identifies points of particular interest for more efficient and convenient operation or repair.(SG-1)

Practice all usual and customary safe working precautions and above all---remember safety isup to YOU. Only YOU can prevent serious injury or death from unsafe practices.

READ, UNDERSTAND, and FOLLOW the following Safety Messages. Serious injury ordeath may occur unless care is taken to follow the warnings and instructions stated in theSafety Messages. Always use good common sense to avoid hazards. (SG-2)

SAFETY

Wings and High Gate Safety Section 1-3

© 2009 Alamo Group Inc.

SA

FE

TY

Repeated or substantial breathing of hazardous dusts, includingcrystalline silica, could cause fatal or serious respiratory disease includingsilicosis. Concrete, masonry, many types of rock, and various othermaterials contain silica sand. California lists respirable crystalline silica asa substance known to cause cancer. Operation of this equipment undercertain conditions may generate airborne dust particles that could containcrystalline silica. In those conditions, personal protective equipmentincluding an appropriate respirator must be used. If excessive dust isgenerated, a dust collection or suppression system should also be usedduring operation. (SG-41)

Si no lee ingles, pida ayuda a alguien que si lo lea para que le traduzca lasmedidas de seguridad. (SG-3)

Never operate the Snow Plow unti l you have read and completelyunderstand this Manual, the Truck or Power units Operator ’sManual, and each of the Safety Messages found in these Manualsand those aff ixed to the Snow Plow, Truck, or Power units and itscomponents. Learn how to stop the power unit engine suddenly inan emergency. Never al low inexperienced or untrained personnelto operate the Truck or Power unit and Snow Plow withoutsupervision. Make sure the operator has ful ly read and understoodthe manuals prior to operation. (SPNG-4)

In addition to the design and configuration of this Snow Plow, including Safety Signs and Safety Equipment,hazard control and accident prevention are dependent upon the awareness, concern, prudence, and propertraining of personnel involved in the operation, transport, maintenance, and storage of the machine. Referalso to Safety Messages and operation instruction in each of the appropriate sections of the Truck or Powerunit Manuals. Pay close attention to the Safety Signs affixed to the Snow Plow. (SNPG-5)

PARTS INFORMATION

HENKE Snow Plows use balanced and matched system components for plows, carriers, and othercomponents. These parts are made and tested to HENKE specifications. Non-genuine or “will fit" parts donot consistently meet these specifications. The use of non-genuine or “will fit” parts may reduce Snow Plowperformance, void HENKE warranties, and present a safety hazard. Use genuine HENKE parts for economyand safety. (SNPG-6)

SEE YOUR HENKE DEALER

Always maintain the safety signs in good readable condition. If the safety signs are missing,damaged, or unreadable, obtain and install replacement safety signs immediately. (SG-5)

SAFETY

Wings and High Gate Safety Section 1-4

© 2009 Alamo Group Inc.

SA

FE

TY

OPERATOR SAFETY INSTRUCTIONS AND PRACTICES

All Safety Shields, Guards and other Protective Safety devices should be used andmaintained in good working condit ion. All safety devices should be inspectedcareful ly at least daily for missing or broken components. NEVER REMOVEPROTECTIVE SHIELDS AND GUARDS! NEVER MODIFY OR CUT PROTECTIVE SHIELDS ORGUARDS! When shields or guards are removed to access areas for maintenance, they must bereplaced and be in good condition before operating. Missing, broken, or worn shields,guards, and other protective devices must be replaced at once and prior to operationto reduce the possibil i ty of injury. (SNPS-02)

The Snow Plow power unit should be equipped with a fire extinguisher, rated for all fires, inan accessible and visible area. The fire extinguisher should be inspected routinely by acertified inspector for operational use and replaced as needed. Never obstruct access tothe fire extinguisher. (SNPS-6)

NEVER use drugs or alcohol immediately before or while driving or operating the SnowPlow. Drugs and alcohol will affect an operator’s alertness and coordination and thereforeaffect the operator’s ability to operate the Equipment safely. Before operating theEquipment, an operator on prescription or over-the-counter medication mustconsult a medical professional regarding any side effects of the medicationthat would hinder their ability to operate the Equipment safely. NEVERknowingly allow anyone to operate this Equipment when their alertness orcoordination is impaired. Serious injury or death to the operator or otherscould result if the operator is under the influence of drugs or alcohol. (SNPD-3)

Always wear OSHA approved Personal Protective Equipment (PPE) while operating,servicing, repairing, and/or cleaning the Equipment. PPE is designed to provide bodilyprotection during such activities.

Personal Protective Equipment includes:-Protective Eye Wear-Steel Toed Safety Footwear-Gloves-Hearing Protection-Close Fitted Clothing-Hard Hat-When working around a raised hopper.-Respirator-Depending on conditions and material being swept or cleaned.

Specialized protective equipment may be required if dangerous or hazardous material is being moved by theplow. (SNPD-4)

SAFETY

Wings and High Gate Safety Section 1-5

© 2009 Alamo Group Inc.

SA

FE

TY

Prolonged operation of the Snow Plow may cause operator boredom and/or fatigueaffecting the safe operation of the Snow Plow and Truck or Power unit. It is recommendedthat the operator take scheduled work breaks to help prevent these potentially impairedoperating conditions. If possible, completely shut down the Equipment, exit the cab andmove around stretching your arms and legs. Never operate the Equipment in a fatigued orbored mental state that impairs proper and safe Equipment operation. (SNPD-5)

PROLONGED EXPOSURE TO LOUD NOISE MAY CAUSEPERMANENT HEARING LOSS! Equipment operation can oftenbe noisy enough to cause permanent hearing loss. Werecommend that you always wear hearing protection if the noise inthe Operator ’s posit ion exceeds 80db. Noise over 85db over anextended period of t ime will cause severe hearing loss. Noiseover 90db adjacent to the Operator over an extended period oft ime wil l cause permanent or total hearing loss. Note: Hearingloss from loud noise [from sweepers, chain saws, radios, andother such sources close to the ear] is cumulative over a l ifetimewithout hope of natural recovery. (SNPD-6)

Prolonged operation of the Equipment in cold weather may cause operator hypothermiaaffecting the safe operation of the Snow Plow and Truck or Power unit. It is recommendedthat the operator wear appropriate clothing take scheduled work breaks to help preventthese potentially impaired operating conditions. If possible, completely shut down theEquipment, exit the cab and warm the body in a properly heated area. Never operate theEquipment in a fatigued or impaired mental state that effects the proper and safeEquipment operation. (SNPD-8)

Use both hands for support when getting on and off the truck or power unit. Use handlesand steps on the equipment for support when boarding. Never use the Truck or Snow Plowcontrol levers for support when boarding the equipment. (SNPO-01)

Use available truck or power unit handles and steps to exit the operator’s station. Makesure you have solid footing before stepping down. Be careful of your step and use extracaution when mud, ice, snow, or other matter has accumulated on the steps or handrails.Never rush to exit or jump off the truck or power unit. (SNPO-02)

Do not attempt to mount the Truck or Power Unit while the machine is moving.Never attempt to mount a runaway Snow Plow. Serious injury or death mayoccur from being run over by a moving Truck, Power Unit, or Snow Plow.(SNPO-03)

BEFORE leaving the operator’s seat, always engage the parking brake and/or set theTruck’s or Power Unit’s transmission in the park position, stop the engine, remove the key,and wait for all moving parts to stop. Never dismount a Truck or Power Unit that is movingor while the engines are running. Operate the equipment controls from the Operator’sseat only. (SNPO-04)

SAFETY

Wings and High Gate Safety Section 1-6

© 2009 Alamo Group Inc.

SA

FE

TY

Always wear a seat belt while driving the equipment during operation and transport.Serious injury or even death could result from falling from the operator’s station or frombeing involved in a collision. (SNPO-05)

Start the engines only when seated and belted in the operator’s seat. Operate theequipment controls only while properly seated with the seat belt secured around you.Inadvertent movement of the power unit or attachment components may cause seriousinjury or death to the operator and passersby. Read the truck or Power Unit operator’smanuals for proper starting instructions. (SNPO-06)

Do not operate, or perform maintenance to, the Equipment while wearing loose fittingclothing. Entanglement of loose clothing with the rotating elements can result in seriousinjury or death. Stay clear of all rotating elements at all times. (SNPD-7)

Operate only in conditions where you have clear visibility of the area in daylight or withadequate artificial lighting. Never operate in darkness of foggy conditions where youcannot clearly see at least 50 feet in front and to the sides of the equipment. Make surethat you can clearly see and identify passersby, steep slopes, ditches, drop-offs, overheadobstructions, power lines, oversized debris and foreign objects. If you are unable to seethese types of items, discontinue operation until visibility improves. (SNPO-8)

When transporting the Snow Plow between locations, follow all local traffic laws andregulations. (SNPO-10)

Operate at a speed that allows you to safely operate and control the Truck and Snow Plow.Safe plowing speed depends on street condition and the type and amount of debris beingmoved. Slow down for corners, curbs, parked cars, protruding signs and other obstacles.Use slow traveling speeds when operating on or near steep slopes, ditches, drop-offs,overhead obstructions, power lines, or when debris and foreign objects are to be avoided.(SNPO-13)

Do not operate the Equipment if excessive vibration or noise exists. Shutdown the equipment and the Truck or Power Unit engine. Inspect theEquipment to determine the source of the vibration or noise. If parts areloose, damaged, or missing, replace them immediately. Do not operate theEquipment until all necessary repairs have been performed. To reduce thepossibil ity of property damage, serious injury, or even death, never operatethe Equipment with missing or damaged components. (SNPO-16)

Never attempt to plow debris that is too large for the Snow Plow (oversized objects such asbroken limbs and discarded tires). Such objects may damage the snow plow componentsand cause serious mechanical damage to the equipment. If possible, carefully place suchobjects out of the Snow Plow and traffic path until properly removed by another means.(SNPO-17)

SAFETY

Wings and High Gate Safety Section 1-7

© 2009 Alamo Group Inc.

SA

FE

TY

Unplowed snow, piled ice and debris, and snow drifts left behind the equipment might posea driving hazard to vehicle traffic colliding with the debris or losing traction on the material.It is recommended to post warning signs alerting driver’s of the equipment operationpresence and the need to reduce vehicle speed. If such hazards are left behind followingthe Snow Plows passage, the area should be plowed a second time and any remaininghazards removed by an alternative method. (SNPO-19)

Use extreme caution when lowering the Snow Wing. Make sure no bystanders are closeby or underneath the wing while lowering. Allow ample clearance around the equipmentwhen lowering or raising the wing. Use extreme caution around obstructions includingbystanders, passersby, curbs, buildings, and other property. Use the Truck’s or PowerUnit’s horn to warn of danger when the wing is being lowered. Lower wing slowly andcarefully. Sudden or unexpected dropping of wing could result in serious injury. (SNPO-24)

Do not allow the Snow Plow to come in contact with potentially dangerous and/orhazardous material. Such hazards may include, but are not exclusively limited to, thefollowing:

• Fire Hazards- Fuel spills, burning material,• Chemical Hazards- Chemical spills, discarded chemical containers, batteries, • Biological Hazards- Decaying Carcasses, BioMedical Waste,• Radioactive Hazards-Radioactive Waste, Radioactive Material,• Carcinogenic Materials-Asbestos,• Corrosive Materials-Batteries, Acids and Bases.

In most areas, these types of material require special handling requirements for safe and proper disposal andshould not be plowed by the Snow Plow, nor can they be disposed of in a general landfill site like most sweptwaste. Contact the appropriate authority for the collection and disposal requirements of such dangerous and/or hazardous material. (SNPO-25)

Always wear required OSHA approved Personal Protective Equipment (PPE) when comingin contact with and removing potentially dangerous and hazardous material that hascollected on the Snow Plow equipment or which is obstructing one or more components.Pay close attention to dangerous and hazardous material including, but not exclusivelylimited to, chemicals, decaying carcasses and sharp objects. (SNPO-26)

Verbal communication near a Truck or Power Unit and Snow Plow is difficult anddangerous. Operating instructions and directions should be made prior to starting theequipment. Unclear and misunderstood communication may lead to operator andbystander injury or death and equipment damage. If communication by the operator isnecessary, completely shutdown and exit the equipment. Never allow anyone to approachthe equipment while in operation. (SNPO-28)

Never allow children to play on, under, or around the Truck or Power Unit nor allow childrento operate equipment controls. Children can slip or fall off the equipment and be injured orkilled. Children can cause the equipment components to shift or fall crushing themselvesor others. (SNPO-29)

SAFETY

Wings and High Gate Safety Section 1-8

© 2009 Alamo Group Inc.

SA

FE

TY

Allow passengers only in situations where their presence is involved in the operation(operator training, supervision, maintenance inspection). Never carry passengers whosepresence distracts from the safe operation or transport of the equipment. Passengersmust be seated securely and belted in the cab’s passenger seat. Never allow any personto ride on any other location of the Truck, Power Unit or Snow Plow during operation ortransport. (SNPO-30)

Extreme caution should be used by the operator when operating near passersby. Stopsnow plowing if a passerby comes within 25 feet of the plow to prevent possible passerbyinjury or death from being struck by the equipment or from a thrown object. (SNPO-31)

Under certain conditions, the Snow Plow is capable of propelling objects up to 75 feet. Beextremely careful when plowing at higher speeds and hitting large dense objects, such asrocks, chucks of frozen ice, metal objects, broken glass, or other solid objects that mightbecome propelled and cause bodily injury to passersby or damage to property such aswindows and vehicles. (SNPO-32)

Make sure that no bystander, animal or obstruction such as a vehicle, building, orstreet sign are within the width of the Snow Plow. The design of the Snow Plow mayimpair the operator vision when operating. Use extreme caution to ensure that theSnow Plow is not driven into the path of pedestrian or vehicle traff ic. Serious injuryor death and property damage could result from running into, being crushed by, orrun over by a Snow Plow. (SNPO-33)

Make sure no bystanders or animals are within 25 feet of the equipmentbasket when dumping contents from or cleaning the Snow Basket. Bucketcontents, which may exceed several thousand pounds, could fall and crush abystander or an animal resulting in possible injury or death. (SNPO-34)

On fully assembled unit, do not remove the wing retaining chain until hosesare attached to the power unit and the wing folding cylinders have been fil ledwith oil. Lower wings slowly and carefully. Keep bystanders clear of areawhen lowering wings. Sudden or unexpected dropping of wing could result inserious injury. (SNPO-36)

Use extreme caution when operating the Equipment in traffic. To alert motorist of theEquipment’s presence, use all equipped warning signals to alert motorist and pedestriansof the equipment’s presence and relatively slow speed. Serious injury or death andproperty damage may occur if a vehicle collides with this Equipment. (SNPS-3)

Before starting a snow plowing operation, make sure all the warning signal lights areconnected, visible and working. Routinely inspect the equipment’s headlights, brake lights,backup lights, and turn signal lights for operational condition. Immediately repair non-functioning lighting. Always follow all local traffic regulations while operating the SnowPlow. (SNPS-4)

SAFETY

Wings and High Gate Safety Section 1-9

© 2009 Alamo Group Inc.

SA

FE

TY

CONNECTING OR DISCONNECTING IMPLEMENT SAFETY INSTRUCTIONS AND PRACTICES

Always turn on all safety lights and flashers when you operate the Snow Plow. (SNPS-5)

Be particularly careful in transport. The Implement has raised and moved the center ofgravity to the front of the Power Unit increasing the possibility of overturn and tippingforward. Turn curves or go up slopes only at low speed and using a gradual turning angle.Go up slopes with the Implement located uphill. Slow down on rough or uneven surfaces.(SPU-2)

Do not stand or allow bystander or coworkers between the attachmentand the truck or power unit while installing or disconnecting theattachment. Keep hands and body clear of the attachment and theattachment mounts. Serious injury or death can result from a personbeing crushed between the attachment and truck or power unit. (SNPC-01)

Reset the tripped snow plow edge by raising the snow plow off the ground. DO NOTattempt to reset the trip edge by hand. The trip edge is spring loaded and sudden andunexpected movement can occur resulting in serious injuries. Keep and hands and feetaway from the trip edge. If the trip edge does not reset, stop plowing and have the snowplow repaired before resuming snow plowing. (SNPO-12)

Make sure the implement is properly attached to the Power Unit and the retaining pinssecurely lock the Implement into position. Improper mounting of the Implement onto thePower Unit can result in the Implement falling causing serious injury. (SNPC-02)

The operator of the equipment must be trained in the operation and safe use of thismachine. The operator must read and completely understand the operator’s manuals ofthe Snow Plow, Truck or Power unit manufacturers. New operators should be trained in anopen area clear of obstructions before operating on public roadways. If operation of theentire Snow Plow unit (Truck or Power unit) is not completely understood, consult yourauthorized sales representative for a detailed explanation. Never allow an untrained orunqualified driver to operate the Snow Plow. (SNPD-1)

The Snow Plow driver must meet the requirements and possess a Motor Vehicle Licenseas determined by the state in which the Snow Plow is operated if used on public roadways.Contact your local State Department of Public Safety office for special licensingrequirements to operate the Snow Plow in your area. (SNPD-2)

SAFETY

Wings and High Gate Safety Section 1-10

© 2009 Alamo Group Inc.

SA

FE

TY

MAINTENANCE AND SERVICE SAFETY INSTRUCTIONS AND PRACTICES

Perform service, repairs and lubrication according to the maintenance section. Ensure theunit is properly lubricated as specified in the lubrication schedule and all bolts and nuts areproperly torqued. Failure to properly service, repair and maintain this Implement in goodoperating condition could cause component failure and possible serious injury or evendeath. (SG-35)

Periodically inspect all moving parts for wear and replacewhen necessary with authorized service parts. Look for loosefasteners, worn or broken parts, and leaky or loose fitt ings.Make sure all pins are properly secured. Serious injury mayoccur from not maintaining this equipment in good workingorder. (SNPM-01)

Inspect the entire Snow Plow before each use. Accidents may occur or damage to theequipment may result if the Snow Plow is not maintained in good mechanical workingorder.

• Check for loose bolts, worn or broken parts, pinched hydraulic hoses, and leaky or loose fittings.• Make sure all pins are secure and safety pin equipped.• Make sure replacement parts are the correct size and properly installed.• Make sure all fluid levels are full and replenish as necessary.• Make sure fuel, oil, and coolant caps are replaced and tightened.• Check tire condition for tread wear and tire pressure at the rated PSI.• Make sure that all safety shields and guards are attached and in good condition.• Make sure all scheduled maintenance is up to date. (SNPM-02)

Do not modify or alter this Snow Plow. Do not permit anyone to modify oralter this equipment, any of its components or any Snow Plow function.Modification can result in equipment failure and cause serious injuries to theoperator, coworkers, or bystanders. (SNPM-03)

Use extreme care when climbing onto the equipment to perform repairs, maintenance,and cleaning. Use proper stands and ladders to access areas that cannot be reached fromground level. Slipping and falling off the equipment can cause serious injury or death.(SNPM-04)

Never attempt to repair, lubricate, adjust, clean, remove obstructions or perform any othertype of service to any component while the Snow Plow is in motion or while the engine isrunning. Completely shut down the engine and wait for all motion to come to a completestop before servicing the Snow Plow. (SNPM-05)

SAFETY

Wings and High Gate Safety Section 1-11

© 2009 Alamo Group Inc.

SA

FE

TY

Never leave the Snow Plow unattended while the plow is in the raised position. Accidentaloperation of the lifting lever or a hydraulic failure may cause a sudden drop of the unitwhich could result in injury or death by crushing. If the plow must be raised for inspectionor service securely block up and support the Plow to prevent it falling. (SNPM-06)

Never crawl under the Snow Plow or any raised component unless it is properly blockedup and support to prevent it from falling. Accidental operation of a lifting lever or hydraulicfailure may cause a sudden drop of the unit with injury or death by crushing. (SNPM-07)

Use proper protective equipment including gloves, safety eye wear, arm protection whenhandling plow blades and components during replacement, adjustment, and maintenance.Plow edges and components can become sharp and have burrs that could inflict punctureand cuts to the hands, arms, and/or eyes if proper protective equipment is not worn. (SNPM-08)

Replace bent, cracked, or broken plow blade with a new blade. Never attempt tostraighten or weld on plow blades because this will likely crack or otherwise damage theblade with subsequent failure and possible serious injury from broken blade being ejectedfrom plow. (SNPM-10)

Escaping pressurized hydraulic oil generated by hydraulic pumps has the potential toinflict serious injury and possible death. Never attempt to repair a pump or hose or tightena connection while the system is pressurized. Always shut down the engine and relievehydraulic oil pressure before performing any repairs to the hydraulic system. (SNPM-11)

Hydraulic pressure must be relieved from the hydraulic circuit prior to doing anymaintenance or repair work and when the Snow Plow is parked at the end of the day.Place the Snow Plow(s) on the ground or securely blocked up. Turn off the Truck enginethen engage the hydraulic remote cylinders several times to relieve hydraulic pressureprior to performing any maintenance or repair work. (SNPM-12)

Never remove debris from or unclog jams in the plow or lifting components until the enginehave been completely shutdown and all components have come to a complete stop andare lowered to ground level and hydraulic pressure relieved. Always wear PPE whenremoving collected material and debris from the equipment. Serious injury or death mayoccur if any of these precautions are not followed when removing plugged or entangleddebris. (SNPM-15)

Engine Exhaust, some of its constituents, and certain vehicle components contain or emitchemicals known to the state of California to cause cancer and birth defects or otherreproductive harm. (SNPM-20)

SAFETY

Wings and High Gate Safety Section 1-12

© 2009 Alamo Group Inc.

SA

FE

TY

Do not operate this equipment with hydraulic oil or fuelleaking. Oil and fuel are expensive and their presencecould present a hazard. Do not check for leaks with yourhand! High-pressure oil streams from breaks in the linecould penetrate the skin and cause tissue damage includinggangrene. To check for a hose leak, SHUT the ENGINE OFF andremove all hydraulic pressure. Wear oil impenetrable gloves, safetyglasses and use Cardboard to check for evidence of oil leaks. If yoususpect a leak, REMOVE the HOSE and have it tested at a Dealer.If oil does penetrate the skin, have the injury treatedimmediately by a physician knowledgeable and skil led inthis procedure. (SNPM-21)

Always read carefully and fully comply with the manufacturers instructions when handlingfuels, oils, solvents, cleansers, and any other chemical agent. (SNPM-22)

Battery posts, terminals and related accessories contain lead and lead compounds,chemicals known to the state of California to cause cancer and birth defects or otherreproductive harm. Wash Hands after handling. (SNPM-23)

Avoid contact with hot surfaces on the bottom of the skid shoes or plow cuttingedges. Use gloves and eye protection when servicing hot components. Contactwith a hot surface can cause serious injury from burns or scalding. (SNPM-24)

Remove the negative battery cable from the battery before performing any maintenance onthe electrical system to prevent an accidental circuit shorting and sparks. Sparks canresult in wiring damaged, fire or personal injury. (SNPM-25)

DO NOT allow any person under a folded wing unless wing is securely supported or lockedup with the safety chain. Never work under a lifted component unless the component issecurely supported or blocked up. Keep bystanders clear of area when lowering wings.Sudden or unexpected dropping of wing could result in serious injury. (SNPM-26)

Before conducting maintenance on the Snow Plow stop the truck or Power Unit, place thetransmission in the park position and set the parking brake. Turn the engine off andremove the key to prevent inadvertent or accidental starting of the engine. Unexpectedengine start up or vehicle movement can result in serious bodily injuries or death. (SNPM-27)

SAFETY

Wings and High Gate Safety Section 1-13

© 2009 Alamo Group Inc.

SA

FE

TY

TRANSPORTING SAFETY INSTRUCTIONS AND PRACTICES

Secure the wing for transport when not plowing. Secure wing in transportposition using wing transport safety chain. Sudden or unexpected dropping ofwing could result in serious injury. (SNPO-35)

Transport the Truck, Power Unit, and Snow Plow only at safe speeds. Serious accidentsand injuries can result from driving this equipment at unsafe speeds. Become familiar withthe driving characteristics of the equipment and how it handles before operating ortransporting on streets and highways. Make sure the Truck’s or Power Unit’s steering,brakes, and wheels are in good condition and operate properly)

Before transporting the Equipment determine the safe transport speeds for you and the machine. Make sure you abide by the following rules:

• Test the Truck or power unit and Snow Plow at a slow speed and increase the speed slowly. Apply the brakes smoothly to determine the stopping characteristics of the Truck equipped with the Snow Plow. As you increase the speed of the Truck, the stopping distance increases. Determine the maximum safe transport speed for you and the equipment. When driving down a hill or on wet or icy roads, the braking distance increases: use extreme care and reduce your speed. Do not operate the equipment with weak or faulty brakes.

• Obey all traffic laws and regulations. Never exceed the posted speed limit.• The Snow Plow has moved the center of gravity of the equipment forward. Use extreme caution when

transporting at highway speeds. Slow down for sharp corners or on slopes to avoid loss of steering con-trol.

• Only transport the equipment at the speeds determined as safe and which allow for proper control of the machine while driving and stopping during an emergency.

• When operating in traffic, use the Truck’s or Power Units directional indicator or signal lights to indicate your movement. Always use the flashing warning lights and other equipped warning features to alert motorist of your presence and slow moving speed when operating in traffic. Be Aware of Traffic Around You and Watch Out for the Other Guy. (SNPO-09)

SAFETY

Wings and High Gate Safety Section 1-14

© 2009 Alamo Group Inc.

SA

FE

TY

Federal Laws and Regulations

This section is intended to explain in broad terms the concept and effect of federal laws and regulations concerning

employer and employee equipment operators. This section is not intended as a legal interpretation of the law and

should not be considered as such.

Employer-Employee Operator Regulations

U.S. Public Law 91-596 (The Williams-Steiger Occupational and Health Act of 1970) OSHA

This Act Seeks:

“...to assure so far as possible every working man and woman in the nation safe and healthful workingconditions and to preserve our human resources...”

DUTIESSec. 5 (a) Each employer-

(1) shall furnish to each of his employees employment and a place of employment which are free fromrecognized hazards that are causing or are likely to cause death or serious physical harm to his employees;

(2) shall comply with occupational safety and health standards promulgated under this Act.

(b) Each employee shall comply with occupational safety and health standards and all rules, regulations andorders issued pursuant to this Act which are applicable to his own actions and conduct.

OSHA Regulations

OSHA regulations state in part: “At the time of initial assignment and at least annually thereafter, the employershall instruct every employee in the safe operation and servicing of all equipment with which the employee is,or will be involved.”

Employer Responsibilities:

To ensure employee safety during plow and truck or other power unit operation, it is the employer’s responsibility to:

1. Train the employee in the proper and safe operation of the plow and truck or other power unit.

2. Require that the employee read and fully understand the plow and truck or other power unit Operator’s manual.

3. Permit only qualified and properly trained employees to operate the plow and truck or other power unit.

4. Maintain the plow and truck or other power unit in a safe operational condition and maintain all shields and guards

on the equipment.

5. Ensure the truck or other power unit is equipped with a functional ROPS and seat belt and require that the

employee operator securely fasten the safety belt and operate with the ROPS in the raised position at all times.

6. Forbid the employee operator to carry additional riders on the Tractor or Implement.

7. Provide the required tools to maintain the plow and truck or other power unit in a good safe working condition and

provide the necessary support devices to secure the equipment safely while performing repairs and service.

8. Require that the employee operator stop operating equipment if bystanders or passersby come within 25 feet.

Child Labor Under 16 Years of Age

Some regulations specify that no one under the age of 16 may operate power machinery. It is your responsibility to

know what these regulations are in your own area or situation. (Refer to U.S. Dept. of Labor, Employment Standard

Administration, Wage & Home Division, Child Labor Bulletin #102.)

Chamfer All Wing Cutting EdgesFigure 1-1:Chamfer All Wing Cutting Edges

NOTE:

1. When deploying wing, always lower rear of wing before front of wing.

2. Henke recommends that all side wing cutting edges are chamfered on lower inboard corner, asshown above.

Non- compliance could result in damage to, or destruction of the machine,attachments, or the environment

DECALS

Folding Vee Decals Safety Section 1-15

All Hydraulic Wings for Graders

Henke Part No.

Qty. Description

7331003 1 Use genuine Henke replacement parts7331004 1 Secure body with blocks7331005 1 Stop Engine Stay clear of moving parts

7331007 1Read and understand operator's manualIf you cannot read English get assistance

7331008 1 Chain wing in transport position7331012 1 Raise plow before backing

7330012 1 Serial Number Tag7330023 4 Tack - Serial Tag7300047 1 Product Manual Canister7300048 1 Can Plug7020391 3 Stud, 1/4-20 X 5/8 Non-Flange7040002 3 Flat Washer, 1/4 USS7030044 3 Nylock Nut, 1/4-207330014 1 Henke Logo Decal - 2000

7331006 2Do not use hands to check for oil leaks

High Pressure oil leak-injection7331010 3 Keep clear, Pinch Point

Other Attachments and Decals

Use the following decals from sheet 7332006-010.

(NOTE: Some decals on sheet 7332006-010 are not needed on this product. Discard decals not needed.)

Instructions: Follow these instructions to position the above items to your Henke product for safety and professional appearance. Apply on clean surfaces only. They should be properly applied and kept in good condition. If a decal is worn out, torn, or otherwise defaced, call us for an immediate replacement at 1-913-682-9000, or 1-888-682-9010.

DECALS

Folding Vee Decals Safety Section 1-16

1. Position 7331008, 7331007, 7331005, 7331004, 7331003, 7331012 at the TOP Right

of the Wing Moldboard as shown. 2. Position one of 7331010 above Push Arm Knuckle on Wing as shown.

3. Position 7300047 Product Manual Canister as shown.

3/4"

3/4"

Centered above

Knuckle 3/4" 3/4"

3/4"

3/4"

3/4"

Protected Here In Line with

Highest Point

DECALS

Folding Vee Decals Safety Section 1-17

4. Position 7331010 below float box and 7331006 on Hydraulic Cylinder as shown.

5. Position 7331005 on Push Arm as shown.

7331006

7331010 Centered Below Float Box

3/4"

DECALS

Folding Vee Decals Safety Section 1-18

6. Position 7331010 on post as shown.

7. Position 7331006 decal on Post as shown.

Outboard Side of

Post

Centered In Given

Above Bottom

Rib

Rear Side of Post

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 7 of 67

In Season Maintenance

Snow removal equipment must be cared for and maintained regularly. Daily or pre-route inspection and maintenance are necessary. Failure to do so may affect efficiency and safety. A visual inspection must be carried out after every 8 hours of operation. Look for damaged components, bends, cracked welds or hydraulic leaks. REPAIR IMMEDIATELY! It is recommended to re-torque all bolts after the first 8 hours of use and to regularly check for loosened or missing fasteners. Replace any damaged or missing fasteners immediately. Because of the environment in which snow equipment is expected to operate, hydraulic lines, fasteners, wearable or replaceable items and warning decals may become damaged by snow, ice and road debris. These items must be inspected daily and replaced if necessary to avoid equipment damage or personal injury. Lubrication of moving parts is of the utmost importance. Exposure to snow, ice, salt and road debris will wash away lubrication quickly and it may be necessary to inspect and reapply lubrication more than once a day.

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 8 of 67

End of Season Maintenance

GROUND ENGAGING COMPONENTS CUTTING EDGES & GUARDS Replace any broken cutting edges, unevenly or excessively worn cutting edges, and

broken or worn wear guards. RUNNING GEAR Replace broken, worn, or missing running gear shoes, and any damaged adjuster leg

components. Grease internal threads and sliding members (it’s best to disassemble and grease directly; zerks aren’t as effective at greasing these areas).

HARDWARE Replace missing or broken bolts. Proper torque is important! Use grade 8 plow bolts

for steel cutting edges.

HYDRAULICS HOSES Plug or cap any QC fittings or any open hose ends. Inspect hoses for any leaks or

potential leaks. Secure hoses with hose clamps. CYLINDERS Check for leaks, and any chrome rod dents or scratches. Apply a light coat of oil or

grease on exposed rod surfaces.

FRAME AND MOLDBOARD JOINTS

Check pins, bushings, and pivot bolts for wear. Make sure all keepers are in place. Make sure shear bolts and pins are same as original equipment (usually grade 2). Some drivers don’t like replacing shear pins and will install grade 8 replacements to avoid replacing during a storm. These items are designed to shear to protect the driver and the equipment. CHECK WELDMENTS FOR CRACKS.

REPLACE WORN OR BROKEN PARTS FOUND BY ABOVE INSPECTIONS.

The installation hardware provided for the All Hydraulic Wing is listed below. If any hardware is missing please contact Henke Manufacturing Corporation. All installation hardware is yellow zinc plated for long-term corrosion resistance.

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 9 of 67

<THIS PAGE IS INTENTIONALLY LEFT BLANK>

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 10 of 67

BAG A - ATTACHMENT STRUCTURE HARDWARE (Henke #249-0725) Part No. Description Qty. 7020082 Hex Capscrew, 3/4-10 x 3.5 Gr. 8 12 7030013 Nut, 3/4-10 Gr. 8 12 7040007 Flat washer, 3/4 Heat Treated SAE 24

BAG B – POST ATTACHMENT HARDWARE (Henke #249-0726)

Part No. Description Qty. 7020090 Hex Capscrew, 1-8 x 4 Gr. 8 8 7030016 Nut, 1-8 Gr. 8 8 7040013 Flat washer, Hardened, 1” SAE 16

BAG C – PIPE BRACE HARDWARE (Henke #249-0727)

Part No. Description Qty. 7020081 Hex Capscrew, 3/4-10 x 3.25 Gr. 8 4 7030013 Nut, 3/4-10 Gr. 8 4 7040021 Lock Washer, 3/4 SAE 4

ITEMS PACKED SEPARATELY

Part No. Description Qty. 249-0598 Ear Assembly for Front Pipe Brace 1 249-0833 Ear Assembly for Rear Pipe Brace 1 2400-1061 Bottom Plate 1 2100-0532 Lower Pipe Brace, 36" Length, 2.38” Outside Dia. 1 2400-1105 Upper Pipe Brace, 108" Length, 2.88” Outside Dia. 1 7070042 Ball Joint, 2” Diameter, .78” hole 2 7070043 Ball Joint, 2.5” Diameter, .78” hole 2

MUDROC VALVE WITH HARDWARE (Henke #249-0392)

Part No. Description Qty. 7090282 Henke MUDROC Valve 1 7020265 Hex Capscrew, 5/16-18 X 4 2 7030086 Nylock Nut 5/16-18 2

CHAIN ASSEMBLY

(Henke #249-0196 – 66”BH, OR Henke #249-0845 – 42”BH) Part No. Description Qty. 7060001 Shackle 7/16 Round Pin 1 7060016 Chain hook & Latch 2

7060021 3/8” Chain GR. 70 56” (w/ 66”BH) 42” (w/ 42”BH)

7060037 Double Clevis 3/8 1

TABLE 1 – Wing Installation Loose Hardware

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 11 of 67

FIGURE 2 – Front Post Assembly & Attachments

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 12 of 67

Item No. Qty. Part No. Description

1 1249-0706249-0574

Slide Assembly, 42"BH orSlide Assembly, 66"BH

2 1 249-0215 Banjo Hinge Pin Assembly3 1 7020131 Hex Capscrew, 5/8-11 x 2.75 GR. 84 13 7030084 Toplock Nut, 5/8-11 GR. C5 1 249-0188 Knuckle Pin Assembly6 1 7040004 Flat Washer, 3/8 Hardened, USS7 1 7040018 Lock Washer, 3/88 1 7020029 Hex Capscrew, 3/8-16 x 1 GR. 59 2 7300006 Nylatron Slide Guide10 12 7020128 Hex Capscrew, 5/8-11 x 4.5 GR. 811 12 7040006 Flat Washer, 5/8

12 1249-0887249-0588

Post Assembly, 42"BH orPost Assembly, 66"BH

13 1 249-0590 Attaching Structure Assembly14 8 7020090 Hex Capscrew, 1-8 x 4 GR. 815 16 7040013 Flat Washer, 1” Hardened, SAE16 8 7030016 Nut, 1-8 GR. 817 1 2400-1061 Weld-On Mounting Plate18 12 7020082 Hex Capscrew, 3/4-10 x 3.5 GR. 819 24 7040007 Flat Washer, 3/4 Hardened, SAE20 16 7030013 Nut, 3/4-10 GR. 8

21 170808117080809

Hydraulic Cylinder, 3.5 x 42 x 1.75, 42"BHHydraulic Cylinder, 3.5 x 66 x 1.75, 66"BH

22 1 7040024 Flat Washer, 1 1/2 Hardened, SAE23 1 7030024 Slotted Nut, 1 1/2-6 GR. 224 1 7050001 Cotter Pin, 1/4 x 325 1 249-0200 Pin Assembly26 1 7050003 Cotter Pin, 3/16 x 227 2 7070042 Ball Joint, 2” dia. with 0.78” Hole28 1 249-0598 Pipe Brace Ear Assembly, Front29 1 249-0833 Pipe Brace Ear Assembly, Rear30 2 7070043 Ball Joint, 2.5” dia.with 0.78” hole31 1 2100-0532 Pipe Brace, 36”32 1 2400-1105 Pipe Brace, Large, 108”33 4 7020081 Hex Capscrew, 3/4-10 x 3.25 GR. 834 4 7040021 Lock Washer, 3/435 2 7090111 Grease Fitting, Straight, 1/4-2836 2 2400-1054 Slide Keeper (Purchased as part of Item #1)50 1 249-0192 Banjo Hinge Assembly (Also shown in Fig. 3)52 1 249-0185 Knuckle Assembly (Also shown in Fig. 3)

Not Shown 1249-0845249-0196

Safety Chain Assembly 42"BHSafety Chain Assembly 66"BH

Not Shown 6 7050048 Roll Pin for Slide Assembly

TABLE 2 – Front Post Assembly & Attachments, Parts List This list is important and should be referred to when ordering replacement parts from your local dealer or Henke Manufacturing Corporation. The parts diagram for the front post assembly is shown in Figure 2.

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 13 of 67

FIGURE 3 – Moldboard Assembly & Attachments

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 14 of 67

This list is important and should be referred to when ordering replacement parts from your local dealer or Henke Manufacturing Corporation. The parts diagram for the

moldboard and push tube assemblies is shown in Figure 2.

TABLE 3 – Moldboard Assembly & Attachments, Parts List

Item No. Qty. Part No. Description50 1 249-0192 Banjo Hinge Assembly51 1 2400-0062 Hinge Plate Bushing52 2 7040024 Flat Washer, 1 1/2 Hardened, SAE53 1 7030024 Slotted Nut, 1 1/2-654 1 7050001 Cotter Pin, 1/4 x 355 1 2400-0183 Moldboard Attaching Bolt56 2 2400-1870 Clevis Pin, 1 . 4.5, Modified 57 2 7020019 Hex Capscrew, 5/16-18 X 1.5 GR. 558 2 7030086 Nylock Nut, 5/16-1859 1 249-0185 Knuckle Assembly60 1 7080808 Hydraulic Cylinder, 3.5 x 37.5 x 1.75N/A N/A 7080908 Seal Kit for Cylinder 7080808

61 1

249-0705249-0878249-0199249-0209

Moldboard Assembly, 10'Moldboard Assembly, 11'Moldboard Assembly, 12'Moldboard Assembly, 14'

62 1 249-0189 Float Link Assembly63 1 139-0918 Float Link Pin Assembly64 1 7040005 Flat Washer, 1/2 Hardened, SAE65 1 7040019 Lock Washer, ½66 1 7020130 Hex Capscrew, 1/2-13 x 1.5 GR. 867 Varies Varies Cutting Edge (1/2 x 8 Standard)68 Varies Varies Plow Bolt, 5/8-11 GR. 869 Varies 7030084 Toplock Nut, 5/8-11 GR. C70 1 2000-0126 Bumper71 1 2000-0125 Bumper Bracket72 2 7030031 Toplock Nut, 1/2-13 GR. C73 2 7020051 Hex Capscrew, 1/2-13 x 3.5 GR. 574 1 249-0193 Pushbeam Moldboard Joint75 1 2400-1784 Clevis Pin, 1-1/4 x 3.5 AHW76 3 7030006 Nylock Nut, 3/8-1677 1 2300-0160 Pin, 1.25 x 778 3 7020034 Hex Capscrew, 3/8-16 x 2

79 1

249-0777

249-0783

Outer Tube Assembly, Std Length(Rear Ripper Machines Only)

Outer Tube Assembly, Short Length(Fixed and Elevating Rear Machines)

80 1 249-0779 Inner Tube Assembly81 1 7070103 Compression Spring82 1 7020500 Hex Capscrew, 5/8-11 x 5.5

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 15 of 67

FIGURE 4 – Elevating Rear Assembly

All wings are supplied with one of the following: an elevating rear (ER), a rear ripper (RR), a fixed rear (FR) attachment or a manually elevating rear (MR). The parts lists and exploded views for all four rear attachment options are given in the next four pages.

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 16 of 67

TABLE 4 – Elevating Rear Assembly, Parts List

Item No. Qty. Part No. Description

1 1 249-0615 Elevating Rear Assembly2 1 249-0383 Lift Tube Weldment3 1 7080236 Hydraulic Cylinder, 3.5 x 10 x 1.75

N/A N/A Seal Kit for Cylinder 70808104 1 249-0193 Push Beam Joint Assembly5 1 2300-0188 Knuckle Bolt6 1 2400-0273 Lift Tube Pin7 2 7020267 Hex Capscrew, 1-8 x 4.5 GR. 88 1 7020034 Hex Capscrew, 3/8-16 X 2 GR. 2 (Note 1)9 1 7030006 Nylock Nut, 3/8-16

10 4 7040014 Flat Washer, Hardened, 1 1/4 SAE11 1 7030023 Slotted Nut, 1-1/4 – 712 2 7050003 Cotter Pin, 3/16 x 2.0013 1 7050043 Cotter Pin, 3/16 x 2.50

14 Varies 7040013Flat Washer, Hardened, 1” SAE(Use Original Case Hardware)

15 Varies 7020233Hex Capscrew, 1-8 x 3 GR. 8(Use Original Case Hardware)

16 1 2400-1784 Clevis Pin, 1 1/4 X 3.517 1 7090113 Grease Fitting, 90°, 1/4-28 (Note 2)18 2 7040051 Flat Washer, 1-8 GR. C19 2 7030049 Toplock Nut, 1-8 GR. C

Notes for Table 4: 1. 7020034 IS A SHEAR BOLT. DO NOT REPLACE WITH HIGHER GRADE BOLT! 2. 7010021 and 7090111 are included with weldment purchases.

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 17 of 67

FIGURE 5 – Rear Ripper Assembly

TABLE 5 – Rear Ripper Assembly, Parts List

Item No. Qty. Part No. Description

1 1 249-0488 Ear Assembly - Rear Ripper

2 1 2300-0188 Knuckle Bolt

4 4 7040014 Flat Washer, 1 1/4 Hardened, SAE

3 1 249-0193 Pusbheam- Moldboard Joint

5 1 7030023 Slotted Nut, 1 1/4-7

6 1 7050043 Cotter Pin, 3/16 X 2.5

8 1 7030006 Nylock Nut, 3/8-16

7 1 2400-1784 Clevis Pin, 1-1/4 X 3.5

9 1 7020034 Hex Capscrew, 3/8-16 X 2

10 1 7090113 Grease Fitting, 90°, 1/4-28

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 18 of 67

FIGURE 6 – Fixed Rear Assembly

TABLE 6 – Fixed Rear Assembly, Parts List

Item No. Qty. Part No. Description1 1 249-0632 Fixed Rear Weldment2 4 249-0193 Knuckle Assembly3 1 2300-0188 Knuckle Bolt4 4 7040014 Flat Washer, Hardened, 1 1/4 SAE5 1 7030023 Slotted Nut, 1 1/4-76 1 7050043 Cotter Pin, 3/16 x 2.57 1 2400-1784 Clevis Pin, 1 1/4 X 3.58 1 7030006 Nylock Nut, 3/8-16

9 8 N\AHex Capscrew, M24 x 65mm GR.10.9

RE-Use Existing Case Hardware

10 8 N\AFlat Washer, Hardened, M24

Re-Use Existing Case Hardware11 1 7020034 Hex Capscrew, 3/8-16 X 2 GR.212 1 7090113 Grease Fitting, 90°, 1/4-28

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 19 of 67

FIGURE 7 – WELD-ON MOUNTING PLATE INSTALLATION

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 20 of 67

FIGURE 8 – Hydraulic Hoses & Fittings Running From Henke Valve

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 21 of 67

FIGURE 9 – Plumbing of 7080340 Load Sense Shuttle Valve

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page

FIGURE 10 – Hydraulic Schematic, from Bulkhead Plate to Wing, Case/NH AHW

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 23 of 67

FIGURE 11 – Mounting of MUDROC Valve on Wing Post

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 24 of 67

FIGURE 12 – MUDROC Relief Valve Adjustment

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 25 of 67

TABLE 7 – 2-Section Valve & Controls Kit

Henke Kit No. 6182602

Note:

1. All hose assembly lengths are total lengths which include the fittings.

Qty. Part No. Description1 7080098 Hydraulic Valve, Load Sense, 2-Section1 279-0474 Valve Bracket Assembly1 7080340 Load Sense Shuttle Valve1 2700-1225 Bulkhead Plate2 2700-1278 Control Handle, Bent2 7080502 Control Cable, 66”2 7080119 Remote Valve Control Kit (“Bonnet Kit”)1 279-0503 Handle Bracket Assembly2 7090558 Clamp Pair, Beringer PP-H41001 7090559 Clamp Cover Plate, Beringer DCP-H44 7020314 Hex Capscrew, 3/8-16 x 2.25 Gr. 53 7020024 Hex Capscrew, 5/16-18 x 3 Gr. 26 7030086 Nylock Nut, 5/16-18 Gr. 24 7020063 Hex Capscrew, 5/8-11 x 3.5 Gr. 24 7030084 Toplock Nut, 5/8-11 Gr. C8 7040006 Flat Washer, Hardened, 5/8 SAE1 7300037 Decal Sheet – “Wing”1 7300038 Decal Sheet – “Plow”3 7020125 Hex Capscrew, 5/16-18 x 4.5 Gr. 22 7210018 Cable Tie, .30 x 24”, UV Black

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 26 of 67

TABLE 8 – 3-Section Valve & Controls Kit

Henke Kit No. 6182603

Note:

1. All hose assembly lengths are total lengths which include the fittings.

Qty. Part No. Description1 7080351 Hydraulic Valve, Load Sense, 3-Section1 279-0474 Valve Bracket Assembly1 7080340 Load Sense Shuttle Valve1 2700-1225 Bulkhead Plate3 2700-1278 Control Handle, Bent3 7080502 Control Cable, 66”3 7080119 Remote Valve Control Kit (“Bonnet Kit”)1 279-0503 Handle Bracket Assembly2 7090558 Clamp Pair, Beringer PP-H41001 7090559 Clamp Cover Plate, Beringer DCP-H44 7020314 Hex Capscrew, 3/8-16 x 2.25 Gr. 53 7020024 Hex Capscrew, 5/16-18 x 3 Gr. 26 7030086 Nylock Nut, 5/16-18 Gr. 24 7020063 Hex Capscrew, 5/8-11 x 3.5 Gr. 24 7030084 Toplock Nut, 5/8-11 Gr. C8 7040006 Flat Washer, Hardened, 5/8 SAE1 7300037 Decal Sheet – “Wing”1 7300038 Decal Sheet – “Plow”3 7020125 Hex Capscrew, 5/16-18 x 4.5 Gr. 22 7210018 Cable Tie, .30 x 24”, UV Black

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 27 of 67

TABLE 9 – Special 3-Section Valve & Controls Kit with Detent on Wing Slide & Wing Lift

Henke Kit No. 6182604

Note:

1. All hose assembly lengths are total lengths which include the fittings.

Qty. Part No. Description1 7080578 Hydraulic Valve, Load Sense, 3-Section w/2 Detents1 279-0474 Valve Bracket Assembly1 7080340 Load Sense Shuttle Valve1 2700-1225 Bulkhead Plate3 2700-1278 Control Handle, Bent3 7080502 Control Cable, 66”3 7080119 Remote Valve Control Kit (“Bonnet Kit”)1 279-0503 Handle Bracket Assembly2 7090558 Clamp Pair, Beringer PP-H41001 7090559 Clamp Cover Plate, Beringer DCP-H44 7020314 Hex Capscrew, 3/8-16 x 2.25 Gr. 53 7020024 Hex Capscrew, 5/16-18 x 3 Gr. 26 7030086 Nylock Nut, 5/16-18 Gr. 24 7020063 Hex Capscrew, 5/8-11 x 3.5 Gr. 24 7030084 Toplock Nut, 5/8-11 Gr. C8 7040006 Flat Washer, Hardened, 5/8 SAE1 7300037 Decal Sheet – “Wing”1 7300038 Decal Sheet – “Plow”3 7020125 Hex Capscrew, 5/16-18 x 4.5 Gr. 22 7210018 Cable Tie, .30 x 24”, UV Black

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 28 of 67

TABLE 10 – Hydraulic Tie-In Kit

Henke Kit No. 6182600

Note:

1. All hose assembly lengths are total lengths which include the fittings.

2. Items marked with an * are included in Henke Kit 7080465.

Qty. Part No. Description1 7110634* Hose Assembly, 3/8-2 x 36”, -6 JIC F x -6 JIC F 90° Elbow

1 7110635*Hose Assembly, 1/2-2 x 24.5", -8 JIC F x -8 JIC F 90° Tube Elbow (Long Drop)

1 7110636* Hose Assembly, 1/2-2 x 110", -8 JIC F e/e2 7090235* Elbow, 90, -8 JIC M x -8 JIC F2 7090285* Straight Adapter, -8 JIC M x -12 ORB M2 7090258* Tee, -8 JIC M, -8 JIC F Run1 7090488* Elbow, 90, -6 JIC M x -4 ORB Adj. M1 7090225* Straight Adapter, -6 JIC M x -6 ORB M1 7090477* Elbow, 90, -6 JIC M x -6 ORB Adj. M1 7090471* Straight Adapter, -6 ORB M x -6 JIC F1 7090009* Cap, -8 JIC1 7090551 Custom Tube Assembly (design on file at Tompkins)

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 29 of 67

TABLE 11 – Cylinder Hose Kit

Henke Kit No. 6182609

Note:

1. All hose assembly lengths are total lengths which include the fittings.

2. All Items marked with an * are included in Henke Kit 7080464.

Qty. Part No. Description

2 7110605*Hose Assembly, 98", -8 JIC F e/e, Nylon Sleeve Full Length

2 7110596*Hose Assembly, 62", -8 JIC F x -8 JIC F 90° Tube Elbow (Short Drop)

2 7110808*Hose Assembly, 64", -8 JIC F x –8 JIC F 90° Tube Elbow (Long Drop), Nylon Sleeve Full Length

1 7110809*Hose Assembly, 57", -8 JIC F x –8 JIC F 90° Tube Elbow (Short Drop)

2 7110810*Hose Assembly, 86", -8 JIC F x –8 JIC F 90° Tube Elbow (Long Drop), Nylon Sleeve Full Length

2 7110811*Hose Assembly, 73", -8 JIC F x –8 JIC F 90° Tube Elbow (Short Drop), Nylon Sleeve Full Length

1 7110812*Hose Assembly, 69", -8 JIC F x –8 JIC F 90° Tube Elbow (Short Drop), Nylon Sleeve Full Length

6 7090014* Straight Adapter, -8 JIC M x –10 ORB M5 7090443* Bulkhead Fitting, -8 JIC M4 7090290* Straight Adapter, -8 JIC M x –8 ORB M1 7090117* Elbow, 90, -8 JIC M x –10 ORB Adj. M2 7090283* Elbow, 45, -8 JIC M x –8 ORB Adj. M5 7090009* Cap, -8 JIC5 7090435* Plug, -8 JIC1 7090493* Clamp Pair (must be marked “3087” or “7/8T”)1 7090429* Cover Plate1 7020277* Bolt, 5/16-18 x 1.75, GR. 2, Zinc Plated1 2700-1433 Valve Bracket for 7080344

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 30 of 67

TABLE 12 – Elevating Rear Hose Kit

Henke Kit No. 7080466

Note:

1. All hose assembly lengths are total lengths which include the fittings.

Qty. Part No. Description

1 7110692Hose Assembly, 221", -8 JIC F x -8 JIC F 90° Tube

Elbow (Short Drop)

1 7110693Hose Assembly, 213", -8 JIC F x –8 JIC F 90° Tube

Elbow (Long Drop)2 7090014 Straight Adapter, -8 JIC M x –10 ORB M2 7090257 Elbow, 90, -8 JIC M x –8 ORB Adj. M1 7090428 Clamp Pair (must be marked “30840” or “1/2P”)1 7090429 Cover Plate1 7020277 Bolt, 5/16-18 x 1.75, Gr. 2, Zinc Plated1 N/A Spiral Hose Wrap, Cut to 22” Length1 N/A Spiral Hose Wrap, Cut to 16” Length

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 31 of 67

FIGURE 101 – INSTALLATION OF POST ATTACHING STRUCTURE ON GRADER

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 32 of 67

Case Ears

249-0598 Front Pipe Brace Assembly

5.00”

1.75”

FIGURE 102 – FRONT PIPE BRACE EAR MOUNTING

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 33 of 67

19” from Rear edge of Cab Mount

249-0833 Rear Pipe Brace

Ear Assembly

1” Down from top lip of Case Frame

FIGURE 103 – REAR PIPE BRACE EAR MOUNTING

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 34 of 67

FIGURE 104 – FRONT PIPE BRACE MOUNTING

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 35 of 67

FIGURE 105 – REAR PIPE BRACE MOUNTING

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 36 of 67

FIGURE 106 – ELEVATING REAR ASSEMBLY (View 1 of 2)

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 37 of 67

FIGURE 107 – ELEVATING REAR ASSEMBLY (View 2 of 2)

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 38 of 67

FIGURE 108 – FIXED REAR ASSEMBLY

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 39 of 67

FIGURE 109 – REAR RIPPER ATTACHMENT

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 40 of 67

Mudroc Return Hose 7110630

Main Return Hose7110636

Pressure Hose 7110635

FIGURE 110 – HENKE CONTROL VALVE MOUNTING (View 1 of 2)

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 41 of 67

Load Sense Hose AttachmentTo Henke Valve (Hose 7110634)

FIGURE 111 – HENKE CONTROL VALVE MOUNTING & LOAD SENSE HOSE ATTACHMENT (View 2 of 2)

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 42 of 67

1.25” Diameter

3.5”

3.5”

FIGURE 112 – DRILLING OF HOLE IN CAB FLOOR

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 43 of 67

FIGURE 113 – INSTALLATION OF CONTROL HANDLES & CABLES

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

P

of 67

Load Sense Shuttle Valve

FIGURE 114 – INSTALLATION OF LOAD SENSE SHUTTLE VALVE (View 1 of 2)

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 45 of 67

Load Sense Shuttle Valve

FIGURE 115 – INSTALLATION OF LOAD SENSE SHUTTLE VALVE (View 2 of 2)

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 46 of 67

Connect Pressure Hose (7110635) To Customized Hard Line (7090551) Here

FIGURE 116 – HENKE PRESSURE HOSE ATTACHMENT TO CASE SYSTEM

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 47 of 67

Case Hard Line Replaced With Customized Hard Line

FIGURE 117 – CASE HARD LINE REPLACE WITH CUSTOMIZED HARD LINE

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 48 of 67

Henke Return Hose 7110636

FIGURE 118 – ATTACHMENT OF HENKE RETURN HOSE TO CASE TANK

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 49 of 67

FIGURE 119 – HENKE BULKHEAD PLATE, UNBOLTED

AH

W_C

AS

E_845T

O885_N

H_R

G140T

OR

G200_E

FF

_JAN

2013_TO

_PR

ES

_8510301_02_033.DO

CX

Page 50 of 67

FIGURE 120 – HENKE BULKHEAD PLATE, INSTALLED

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 51 of 67

FIGURE 121 – LOOPING OF HOSES ON REAR OF WING

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 52 of 67

42”

FIGURE 122 – ATTACHMENT OF HOSES TO CLAMP ON WING SLIDE ASSEMBLY

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 53 of 67

6. Mounting Instructions for Henke All-Hydraulic Wing on Case & New Holland Graders

6.1 Ladder Removal 1. Remove the ladder on the side where the wing will be mounted. The ladder can not be used when the wing is installed. The ladder should be re-installed if the wing is removed.

6.2 Installation of Weld-On Mounting Plate Under Grader

Notes: (a) Before welding, disconnect electrical system components as directed in the Case grader manual. (b) Refer to Figures 1, 7, & 101. 1. Remove paint from the bottom of the grader to provide a clean welding surface at least 3/4" in

each direction from the corner of all weld joints. Also ensure that the mounting plate itself is clean and free of mill scale at least 3/4" in each direction from the corner of all weld joints.

2. Position the mounting plate as shown in Figure 7. Ensure that it is tight against the bottom of

the grader. Weld the frame ready plate securely in place as shown in Figure 7. The two plug weld holes should be welded first to prevent warping of the plate. Also note that no weld is required on the rear side of the plate. Allow to cool fully.

6.3 Mounting of Pipe Brace Ears on Grader Frame

Note: Refer to Figures 1, 102, & 103. 1. Position the front pipe brace ear assembly (249-0598) on the side of the grader frame as

shown in Figure 102. Mark its position, then remove the paint from the grader frame at least 1/2" in each direction. Cover the area under the pipe brace ear to avoid weld spatter damaging the paint or grader components. Weld the front pipe brace ear in place using min. 5/16" fillet welds all around.

2. Position the rear pipe brace ear assembly (249-0619) on the side of the grader frame as shown

in Figure 103. Mark its position, then remove paint from the grader neck at least 1/2" in each direction. Weld the rear pipe brace assembly in place using min. 5/16" fillet welds all around.

3. Prime and paint pipe brace ears and surrounding area to match grader. 6.4 Installation of Attaching Structure and Wing Post 1. Using a fork truck or other secure method, lift the 249-0590 attaching structure (Item 13,

Figure 1) into position under the grader. Fasten to grader using (12) 3/4-10 x 3.5" Gr. 8

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 54 of 67

bolts, (12) 3/4-10 Gr. 8 nuts, and (24) 3/4" heat treated washers. Starting at the center and working outward, torque all (12) 3/4" nuts per Table 13.

2. Securely install a chain or strap through the two large holes at the top of the post assembly

(Item 12, Figure 1). Raise the post into position. Fasten post to attaching structure using (8) 1-8 x 4 Gr. 8 bolts, (8) 1-8 Gr. 8 nuts, and (16) 1” heat treated washers. Starting at the center and working outward, torque all (12) 1” nuts per Table 13.

3. Prime and paint weld-on mounting plate and surrounding area to match grader. 6.5 Installation of Pipe Braces on Wing Post Note: Refer to Figures 1 and 102 thru 105 1. Front pipe brace: Install (1) 7070042 ball joint (2” diameter ball) on bottom of the lower

pipe brace ear on the post, and one on top of the front pipe brace ear assembly on the grader. Secure with (1) 3/4-10 x 3.25" Gr. 8 bolt, (1) 3/4-10 nut, and (1) 3/4” lock washer per ball joint. Tighten finger-tight only.

2. Rear pipe brace: Install (1) 7070043 ball joint (2.5” diameter ball) on bottom of the upper

pipe brace ear on the post, and one on front of the rear pipe brace ear assembly on the grader. Secure with (1) 3/4-10 x 3.25" Gr. 8 bolt, (1) 3/4-10 nut, and (1) 3/4” lock washer per ball joint. Tighten finger-tight only.

3. Orient each pair of ball joints so that a straight line is formed (as much as possible) between

the bolts, ball joints, and pipe (bolt-ball joint-pipe-ball joint-bolt all in a straight line). Tighten each ball joint slightly, but do not fully torque.

4. Test fit each pipe brace between one pair of ball joints. Trim each pipe brace as necessary to

obtain a snug fit, but be careful not to trim too much. When pipe braces have been trimmed properly, install between ball joints. Double check straightness of bolts, ball joints, and pipe, then tack weld ball joints to pipe on both ends. Remove pipe/ball joint assemblies and fully weld ball joints to pipe using minimum 1/4" fillet welds all around. Prime and paint each assembly and allow to dry. Re-install pipe brace assemblies, and fully torque all (5) nuts per Table 13.

Note: All wings will be supplied with one of the following options: elevating rear, fixed rear, or rear ripper attachment. Determine which option your wing was supplied with and proceed to the correct section -- 6.6, 6.7, or 6.8. 6.6 Installation of Optional Elevating Rear Assembly Note: Refer to Figures 106 & 107. 1. Remove the (2) Case tie-down plates bolted to the rear of the grader.

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 55 of 67

2. Lift the elevating rear into position, then fasten to grader using the same hardware that was removed in the previous step. Fully torque per Table 13.

6.7 Installation of Optional Fixed Rear Assembly Note: Refer to Fig. 108. 1. Remove the (2) Case tie-down plates bolted to the rear of the grader. 2. Lift the fixed rear into position, then fasten to grader using the same hardware that was

removed in the previous step. Fully torque per Table 13. 6.8 Installation of Optional Rear Ripper Attachment Note: Refer to Figures 4 & 109. 1. The rear ripper attachment will be welded to the right hand side of the grader’s rear ripper. If the grader does not have a rear ripper, then a different type of rear assembly option must be used. 2. Mark the location at which the rear ripper ear weldment (Item 1, Figure 4) will be welded to the rear ripper. It should be approximately centered on the end of the rear ripper. Remove the paint from the Case/New Holland rear ripper and the Henke ear weldment at least 1/2” in every direction from the corners of the weld joints. 3. Weld the Henke ear weldment to the right side of the Case/New Holland rear ripper using minimum 3/8” fillet welds all around. 6.9 Mounting of Henke Control Valve Note: Refer to Figures 110 & 111. 1. Attach valve to 279-0474 valve bracket assembly using (3) 5/16-18 x 3 bolts and (3) nylock nuts. 2. Attach valve bracket assembly to top side of 2400-1061 weld-on mounting plate (Item 17, Fig. 1) using (4) 5/8-11 x 3.5 bolts, (8) flat washers, and (8) toplock nuts. 6.10 Installation of Auxiliary Controls in Grader Cab Note: Refer to Figures 112 & 113 & Tables 7 thru 9. 1. Attach 2700-1278 handles to 279-0503 bracket assembly using (3) 5/16-18 bolts (4.5” length for 2 handles, 6” length for 3 handles) and (3) nylock nuts. 2. Attach this assembly to the R/H vertical handle bar in the cab using (2) 7090558 clamp pairs, (1) 7090559 cover plate, and (4) 3/8-16 x 2.25” bolts. The bottom of the bracket should be

AHW_CASE_845TO885_NH_RG140TORG200_EFF_JAN2013_TO_PRES_8510301_02_033.DOCXPage 56 of 67