Heavy Duty Automatic Pattern Sewing Machine

-

Upload

bill-jiang -

Category

Documents

-

view

24 -

download

0

description

Transcript of Heavy Duty Automatic Pattern Sewing Machine

-

733PLC Series Electronic Pattern Sewing Machine for

Extra-thick Material Parts Catalogue

Taizhou Mingyuan Hightex Special Sewing Machine Co., Ltd

-

Heaviest programmable electric pattern sewing machine for extremely

thick materials and sewing threads

The 733PLC class is one of the most heavy duty programmable electronic pattern sewing machines in

production today. It can be used to stitch many heavy duty applications such as Lifting Slings, Safety

Harnesses, particularly for the Automotive, Aviation and Military Industries.

This heavy duty automatic pattern sewing machines and bar tacking machines will be thoroughly

tested and gone over by our Industrial Sewing Application Center.

Our field engineers configure these sewing automation equipment properly for customer sewing

requirements. This includes building all the necessary clamping, jigging and fixturing to accomplish the

sewing task, testing and checking all pneumatic, electrical, and computer systems for proper operation,

programming the machine with all patterns supplied by the customers, and then testing the machine

on samples that match exact customer specifications.

These operations save the end user many thousands of dollars in extra expense, eliminating the need

for outsourcing the work required to get the machine in operating condition.

Technical Parameters

Model 733PLC Series

Allowable sewing range Direction X (right & left): max 300mm, direction Y (front & back): max 160mm

Highest sewing speed 500s.p.m

Speed setting 100-500r.p.m arbitrary setting

Stitch length 0.1-12.7mm

Needle bar stroke 66mm

Take-up-level stroke 96mm

Presser plate lifting Outer material-press plate 30mm (pneumatic), middle presser foot 25mm

Needle SM1000X250

Shuttle Caracole-type large-scale shuttle hook

X-Y driving mechanism Stepping motor, synchronous belt, linear guide driving interval and continuous

switching mode

Spindle motor 220V 750W servo motor

-

Pattern Sewing Machine Parts Catalogue

Model 733PLC Series

Contents Page

A Structure..............................................................................................................................................1B BodyandAccessories...........................................................................................................................2c SewingMechanism(1).........................................................................................................................4D SewingMechanism(2).........................................................................................................................7E PresserandPullRod.............................................................................................................................9

F UpperTrimmerMechanism(1)............................................................................................................12

k WindingandPassingMechanism........................................................................................................13L XaxisFeedingMechanism..................................................................................................................16M YaxisFeedingMechanism..................................................................................................................18N MaterialpressingPlateMechanism(Splittype)..................................................................................20Q CableandTubeMechanism(1)............................................................................................................24R CableandTubeMechanism(2)............................................................................................................26S Accessories.............................................................................................................................................28

-

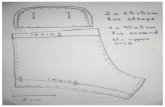

A Structure

-

B Body and Accessories

-

[B] Body and Accessories

No. Fig No. Name Quantity Remarks

1 B101 X-axis cover (L) 1 2 B102 Cover screw M4X10 8 3 B103 Spindle motor cover 1 4 B104 Synchronous belt cover A 1 5 B105 Synchronous cover screw M4X5 8 6 B106 Synchronous belt cover B 1 7 B107 Synchronous belt cover fixed screw M4X10 2 8 B108 Y-axis cover 1 9 B109 Synchronous belt cover coupling screw 2

10 B110 Cover screw M4X10 2 11 B111 Motor cover fixed screw M4X10 4 12 B112 Chassis cover plate screw M5X8 2 13 B113 Chassis cover plate 1 18 B118 Y-axis motor cover 1 19 B119 Oil cup 2 20 B120 Magnetic value holder 1 21 B121 Holder fixed screw M10X18 2 22 B122 X-axis cover (R) 1 23 B123 Sliding plate fixed screw M5X8 4 24 B124 Needle plate 1 25 B125 Sliding plate 1 26 B126 Connecting plate fixed screw M5X16 2 27 B127 Needle plate screw 15/64X28 2 28 B128 Plate 1 29 B129 Panel screw 17/64X32 2 30 B130 Connecting plate 1 31 B131 Side plate 1 32 B132 Hand plate wheel 1 33 B133 Hand plate wheel locating shaft 1 34 B134 Connecting pin 1 35 B135 Manual driving gear 1 36 B136 Horizontal driving sleeve 1 37 B137 Sleeve fixed screw 3 38 B138 Spring 1 39 B139 Hand plate wheel screw 1/4X24L=10 1 40 B140 Take-up lever mounting plate 1 41 B141 Mounting plate screw M6X25 3 42 B142 Front cover 1 43 B143 Front cover screw 9/64x40 2 44 B144 Thread take-up bar shield 1

-

c Sewing Mechanism (1)

-

[C] Sewing Mechanism (1)

No. Fig No. Name Quantity Remarks 1 C101 Arm shaft 1 2 C102 Take-up cam 1 3 C103 Take-up cam screw 2 4 C104 Take-up cam tapered pin 1 5 C105 Arm shaft bushing (Rear) 1 6 C106 Shaft sleeve screw 1 7 C107 Arm shaft bushing (Front) 1 8 C108 Manual transmission gear 1 9 C109 Thread take-up lever 1

10 C110 Take-up lever screw 1 11 C111 Take-up lever pin roller 1 12 C112 Take-up lever pin 1 13 C113 Spring washer 1 GB859-87-8 14 C114 Take-up lever pin nut 1 15 C115 Needle bar connecting rod screw 1 16 C116 Needle bar connecting rod nut 1 17 C117 Needle bar connecting rod 1 18 C118 Needle bar lower shaft cover 2 19 C119 Needle bar upper and lower bush screw 2 20 C120 Connector 1 21 C121 Connector screw 2 22 C122 Needle bar 1 23 C123 Needle bar thread hook 1 24 C124 Thread hook screw 1 25 C125 Needle 1 26 C126 Shuttle big connecting rod 1 27 C127 Shuttle big connecting rod screw 2 28 C128 Felt 2 29 C129 Arm shaft bushing (Middle) 1 30 C130 Fixed screw 1/4X40L=6 7 31 C131 Arm shaft inducting iron 1 32 C132 Fixed plate screw 2 33 C133 Fixed plate 1 34 C134 Needle bar arm shaft cover 1 35 C135 Needle bar protection sleeve 1 36 C136 Locating pin 1 37 C137 Adjusting holder 1 38 C138 Synchronizing belt adjusting successive presser 1 39 C139 Adjusting screw 1 40 C140 Fixed screw M5X12 2 41 C141 Spindle motor adjusting plate 1 42 C142 Spindle motor 2 43 C143 Spindle motor fixed screw M6X20 4

-

44 C144 Spindle motor locating rack 1 45 C145 Motor adjusting screw M10X25 1 46 C146 Arm shaft synchronizing wheel 1 47 C147 Arm shaft synchronizing belt 1 48 C148 Adjusting holder 1 49 C149 Motor adjusting screw gasket 3 50 C150 Hand wheel assembly 1

-

D Sewing Mechanism (2)

-

[D] Sewing Mechanism (2)

No. Fig No. Name Quantity Remarks

1 D101 Lower shaft 1

2 D102 Shuttle hook support 1

3 D103 Shuttle pole screw 1

4 D104 Tapered pin 1

5 D105 Shuttle race stand 1

6 D106 Shuttle race screw 1

7 D107 Bobbin 1

8 D108 Shuttle race 1

9 D109 Shuttle race screw 2

10 D110 Shuttle race ring 1

11 D111 Shuttle race spring 1

12 D112 Shuttle race spring screw 1

13 D113 Shuttle assembly 1

14 D114 Lower shaft ring 1 1

15 D115 Lower shaft ring 2 1

16 D116 Lower shaft ring screw 4

17 D117 Lower shaft crank 1

18 D118 Lower shaft crank taper pin 1

19 D119 Lower shaft crank screw 2

20 D120 Lower shaft crank block axle 1

21 D121 Lower shaft crank block plate 1

22 D122 Lower shaft crank block axle nut 1

23 D123 Lower shaft crank block 1

24 D124 Lower shaft crank block axle screw 1

25 D125 Swing cam holder 1

26 D126 Swing hinge axis pipeline 1

27 D127 Swing hinge axis nut 2

28 D128 Swing hinge axis screw 1

29 D129 Swing hinge axis 1

30 D130 Shuttle big connecting rod screw 1

31 D131 Shuttle big connecting rod nut 1

-

E Presser and Pull Rod

-

[E] Presser Lifting Mechanism

No. Fig No. Name Quantity Remarks

1 E101 Presser foot 1 3 E103 Presser connecting pole 1 4 E104 Presser bar 1 5 E105 Presser bush (Lower) 1 6 E106 Presser bush screw (Lower) 1 7 E107 Presser foot fixed screw 1 8 E108 E-type ring 2 9 E109 Connecting fork shaft 1

10 E110 Fastening screw 2 11 E111 Presser foot lifting cylinder holder 1 12 E112 Presser foot lifting cylinder 1 13 E113 Presser foot cylinder base 1 14 E114 Presser foot cylinder connector 1 15 E115 Presser adjusting screw 1 16 E116 Compressed spring locking nut 1 17 E117 Presser compression spring 1 18 E118 Lifting bar hinge screw 1 19 E119 Lifting bar hinge nut 1 20 E120 Presser lifting rod 1 21 E121 Thread releasing plate screw 2 22 E122 Thread releasing plate 1 23 E123 Presser spanner mounting screw 1 24 E124 Presser foot lifting holder 1 25 E125 Presser foot lifting holder screw 2 26 E126 Holder adjusting nut 1 27 E127 Presser lifting plate 1 28 E128 Connecting block 1 29 E129 Connecting block mounting pin 2 30 E130 Connecting block mounting screw 2 31 E131 Middle spring hook screw 1 32 E132 Middle spring hook screw washer 1 33 E133 Middle spring hook 1 34 E134 Big spring hook screw 1 35 E135 Big spring hook 1 36 E136 Lower thread hook 1 37 E137 Lower thread hook screw 1 38 E138 Presser lifting plate connecting pin 1 39 E139 Presser lifting plate connecting screw 1

-

F Presser Lifting Parts

-

[F] Upper Trimmer Mechanism (1) No. Fig No. Name Quantity Remarks

1 F101 Needle bar crank connecting rod fastening screw

2

2 F102 Needle bar crank connecting rod fastening nut 2 3 F103 Needle bar crank connecting rod 1 4 F104 Lifting crank 1 5 F105 Lifting crank pin 1 6 F106 Lifting crank screw 2 7 F107 Presser lift shaft 1 8 F108 Presser lift shaft mounting plate 1 9 F109 Presser lift shaft mounting plate screw 2

10 F110 Presser lift shaft mounting plate locating pin 2 11 F111 Adjusting screw 1 12 F112 Adjusting sleeve 1 13 F113 Adjusting nut washer 1 14 F114 Adjusting nut 1 15 F115 Presser lifting crank assembly (Front) 1 16 F116 Presser lift crank (Front) 1 17 F117 Presser lifting crank roller shaft (Front) 1 18 F118 Presser lift crank pin (Front) 1 19 F119 Swing plate 1 20 F120 Swing plate connecting pin 1 21 F121 Swing plate nut 1 22 F122 Swing plate gasket 1 23 F123 Swing plate block 1 24 F124 Swing plate screw 1 25 F125 Presser guide frame 1 26 F126 Guide frame mounting screw 1 27 F127 Guide frame adjusting screw 1 28 F128 Guide frame fastening screw 1 29 F129 Presser lifting holder 1 30 F130 Lifting stand clamping screw 2 31 F131 Presser lifting crank roller (Front) 1 32 F132 Spanner backward screw 1 33 F133 Spanner pulling plate 1 34 F134 Spanner pulling plate locating base 1 35 F135 Locking nut 1 36 F136 Locking nut 1 37 F137 Fastening screw 2

-

k Winding and Passing Mechanism

-

[K] Winding Mechanism

No. Fig No. Name Quantity Remarks 1 K101 Winder mounting pad 1 2 K102 2 3 K103 Winding wheel rubber ring 1 4 K104 Winding gear 1 5 K105 Winding wheel screw 1 6 K106 Winding wheel washer 1 7 K107 Winding shaft adjustable shelf 1 8 K108 Clutch cam spring 1 9 K109 Full-thread clutch cam 1

10 K110 Winding shaft adjustable shelf split washer 1 11 K111 Full-thread clutch cam shaft sleeve 1 12 K112 Full-thread cam 1 13 K113 Full-thread cam set screw 1 14 K114 Full-thread bracket spring 1 15 K115 Clutch cam holder 1 K115-1 Full-thread clutch cam fixed shaft 1

16 K116 Winding thread trimmer 1 17 K117 Winding thread trimmer screw 1 18 K118 Thread cam presser 1 19 K119 Thread cam 1 20 K120 Thread cam adjusting bracket 1 21 K121 Thread cam adjusting bracket nut 1 22 K122 Thread cam presser bolt 2 23 K123 Winder mounting plate 1 24 K124 Clutch cam holder bolt 2 25 K125 Winding shaft stopper sleeve 1 26 K126 Winding shaft 1 27 K127 Full-thread springboard shaft 1 28 K128 Full thread springboard 1 29 K129 Full-thread springboard fixed screw 2 30 K130 Winder fixed screw 2 31 K131 Mounting pad fixed screw 2 32 K132 Thread clamping nut 1 33 K133 Thread clamping spring 1 34 K134 Thread clamping plate 1 35 K135 Clamping screw 1 36 K136 Take-up spring bush screw 1 37 K137 Take-up spring shaft sleeve 1 38 K138 Thread passing spring 1 39 K139 Take-up spring 1 40 K140 Thread spring regulating sleeve 1 41 K141 Take-up spring shaft 1 42 K142 Thread passing ring 1

-

43 K143 Clamping spring pressing plate 1 44 K144 Big clamping spring 1 45 K145 Clamping adjusting nut 1 46 K146 Clamping plate holder 1 47 K147 Clamping plate holder fixed screw 1 48 K148 Clamper screw 1 49 3661331 Thread clamper nut 1 50 3661333 Thread clamping bolt 1 51 3661332 Thread passing hook 1 52 3661335 Thread clamping plate 2 53 3661336 Winding and clamping spring 1 54 3661337 Thread clamping nut 1

-

L X-axis Feeding Mechanism

-

[L] X-axis Feeding Mechanism

No. Fig No. Name Quantity Remarks

1 L101 X-axis motor bracket fixed screw M6X15 4

2 L102 X-axis motor bracket 1

3 L103 Direction X guide rail supporting plate 1

4 L104 Direction X active synchronizing wheel 1

5 L105 Motor fixed screw M6X15 4

6 L106 Spring washer 4

7 L107 X-axis motor 1

8 L108 Synchronizing wheel fixed screw 1/4X40L=6 2

9 L109 Supporting plate fixed screw M8X15 8

10 L110 Spring washer 8

11 L111 Direction X synchronizing belt 1

12 L112 Direction X linear guide rail 2

13 L113 Linear guide rail fixed screw M4X12 12

14 L114 Linear slide block 4

15 L115 Reactive belt axle 1

16 L116 Reactive belt wheel holder 2

17 L117 Belt wheel fixed screw 11/64X40L=6 4

18 L118 Synchronizing belt adjusting screw M6X20 2

19 L119 Synchronizing belt adjusting holder 2

20 L120 Reactive synchronizing wheel 2

21 L121 Space ring 2

22 L122 Bearing 4

23 L123 Direction X synchronizing belt pressing plate 2

24 L124 Direction X guide rail connecting plate 1

25 L125 Guide rail fixed screw M4X10 8

26 L126 Synchronizing belt forcing screw M4X20 4

27 L127 Direction Y linear guide rail unit 2

28 L128 Direction Y guide rail installed screw 12

29 L129 Body connecting base 1

30 L130 Spring washer 8

31 L131 Connecting base fixed screw M5X14 8

-

M Y-axis Feeding Mechanism

-

[M] Y-axis Feeding Mechanism

No. Fig No. Name Quantity Remarks

1 M101 Y-axis T-shaped connecting plate 1 2 M102 Connecting plate fixed screw M6X15 2 3 M103 Spring washer 2 4 M104 Direction Y linear shaft 1 5 M105 Direction Y synchronizing belt 1 6 M106 Direction Y synchronizing belt fixed base 1 7 M107 Direction Y synchronizing belt pressing plate screw M4X10 2 8 M108 Direction Y synchronizing belt pressing plate 1 9 M109 Y-axis support 1

10 M110 Direction Y rear bearing fastening screw M4X10 3 11 M111 Direction Y reactive wheel support 1 12 M112 Spring washer 2 13 M113 Support fixed screw M5X15 2 14 M114 Direction Y inducting iron fixed screw M6X6 1 15 M115 Direction Y inducting iron 1 16 M116 Direction Y rear bearing 1 17 M117 Y-axis support fixed screw M5X18 6 18 M118 Inductor adjusting frame fixed screw M5X10 2 19 M119 Inductor adjusting frame 1 20 M120 Direction Y active synchronizing wheel fixed screw 1/4X40L=6 2 21 M121 Direction Y active synchronizing wheel 1 22 M122 Direction Y motor bracket 1 23 M123 Direction Y motor bracket fixed screw M10X25 4 24 M124 Coupling screw M5X12 8 25 M125 Direction Y inducting iron 1 26 M126 Guide rail fixed screw M4X14 6 27 M127 Direction Y guide rail 1 28 M128 Direction Y guide rail supporting plate 1 29 M129 Inducting iron fixed screw M4X10 1 30 M130 Direction Y motor 1 31 M131 Direction Y motor fixed screw M6X15 4 32 M132 Spring washer 4 33 M133 Washer screw M4X15 1 34 M134 Gasket 1 35 M135 Direction Y front bearing 1

-

N Material-pressing Plate Mechanism (Split-type)

-

[N] Material-pressing Plate Mechanism (Split-type)

No. Fig No. Name Quantity Remarks

1 N101 Material-press cylinder 2

2 N102 Washer 2

3 N103 Cylinder connecting horizontal lever 1

4 N104 Direction Z guide rail 1

5 N105 Direction Z guide rail fixed screw M4X12 16

6 N106 Upper tabouret lifting base 1

7 N107 Upper tabouret coupling screw M5X10 8

8 N108 Coupling screw M5X12 8

9 N109 Upper tabouret (L) 1

10 N110 Upper tabouret (R) 1

11 N111 Lower tabouret 1

12 N112 Lower tabouret fixed screw M8X8 2

13 N113 Connecting plate fixed screw 15/64X28L=10 2

14 N114 Lower tabouret connecting plate 1

15 N115 Upper tabouret connecting base 2

16 N116 Direction Z cylinder coupling screw M6X15 2

17 N117 Direction Z guide rail fixed base 2

18 N118 Direction Z cylinder fixed screw M6X15 8

19 N119 Fixed base fastening screw M6X25 4

20 N120 Locking slider 4

-

P Material-pressing Plate Mechanism (Unitary-type)

-

[P] Material-pressing Plate Mechanism (Unitary-type)

No. Fig No. Name Quantity Remarks

1 P101 Side lifting cylinder 2

2 P102 Side lifting cylinder joint 2

3 P103 Connecting pin fixed screw M6X6 2

4 P104 Cylinder fixed screw pin 2

5 P105 Spring washer 2

6 P106 Locking nut 2

7 P107 Cylinder connecting horizontal lever 1

8 P108 Direction Z guide rail fixed screw M4X20 8

9 P109 Lifting plate fixed screw M4X10 8

10 P110 Tabouret connecting plate fixed screw M6X12 4

11 P111 Tabouret connecting plate 2

12 P112 Tabouret right lifting plate 1

13 P113 Upper tabouret right lifting hook 1

14 P114 Connecting pin 2

15 P115 Lifting hook locating pin 2

16 P116 E-type retaining ring 8 2

17 P117 Pressing lever fixed screw M5X12 4

18 P118 Tabouret pressing lever 1

19 P119 Pressing lever connecting pin 2

20 P120 Upper tabouret connecting base 2

21 P121 Connecting base fixed screw M5X8 8

22 P122 Pressing lever connecting pin fixed screw M6X6 2

23 P123 Upper tabouret 1

24 P124 Lower tabouret 1

25 P125 Lower tabouret fixed screw M6X5 2

26 P126 Lower tabouret connecting plate 1

27 P127 Connecting plate fixed screw 15/64X28L=10 2

28 P128 Tabouret left lifting plate 1

29 P129 Upper tabouret left lifting hook 1

30 P130 Direction z linear guide rail 2

-

Q Cable and Tube Mechanism (1)

-

[Q] Cable and Tube Mechanism

No. Fig No. Name Quantity Remarks

1 Q101 Y-axis inductor 1

2 Q102 Inductor fixed screw M4X15 3

3 Q103 Z-axis inductor 1

4 Q104 Inductor connecting cable fixed cover 3

5 Q105 Fixed cover screw M4X10 3

6 Q106 System control electric box 1

7 Q107 Electric trimming control box 1

8 Q108 Circuit board fixed screw M4X20 4

9 Q109 Circuit board 1

10 Q110 Nylon cover 4

11 Q111 Nylon pad 4

12 Q112 X-axis inductor 1

13 Q113 Change-over switch 1

-

R Cable and Tube Mechanism (2)

-

[R] Cable and Tube Mechanism (2)

No. Fig No. Name Quantity Remarks

1 R101 Muffler 2

2 R102 L-shape connector 2

3 R103 Solenoid value assembly 1

4 R104 Speed regulating joint 1

5 R105 Solenoid value assembly fixed screw M4X30 4

6 R106 Trimming power switch 1

7 R107 Fuse 2

8 R108 Connecting cable assembly 2

9 R109 Transformer 1

10 R110 Trimming power cable 4

11 R111 Connector assembly 1

-

S Accessories

-

[S] Accessories

No. Fig No. Name Quantity Remarks

1 S101 Oil box assembly 1

2 S102 Oil box cover screw 1

3 S103 Spring plate 1

4 S104 Oil box felt (Small) 2

5 S105 Felt pressing plate 2

6 S106 Oil box felt (Large) 1

7 S107 Oil box mounting screw 1

8 S108 Shuffle changing pressing plate 1

9 S109 Spline end spanner 1

10 S110 Internal hexagon wrench 1

11 S111 Internal hexagon wrench 1

12 S112 Oil tray 1

13 S113 Oil tray screw 4

14 S114 Machine head holder 2

15 S115 Machine head holder screw 8

16 S116 Machine head holder nut 8

17 S117 Machine head holder gasket 8

18 S118 Oil tank 1

19 S119 Needle 5

20 S120 Small oil can 1

21 S121 F-shaped thread stand assembly 1

22 S122 Straight screwdriver (Large) 1

23 S123 Straight screwdriver (Medium) 1

24 S124 Straight screwdriver (Small) 1

25 S125 Straight screwdriver (Medium) 1

26 S126 Bobbin 5

27 S127 Flat gasket 4