Heat Transmission HVAC CNST 305 Environmental Systems 1 Dr. Berryman.

-

date post

19-Dec-2015 -

Category

Documents

-

view

222 -

download

3

Transcript of Heat Transmission HVAC CNST 305 Environmental Systems 1 Dr. Berryman.

Temperature GradientsThe temperature differential between two

separate surfaces as heat transmits across them.

A Proportional calculation Uses IA OA Temperatures R values

Purpose Determine surface temperatures

• MRT• Dew Point

Develop Thermal Resistant Values

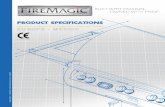

AL Siding

¼” USB

R19 Batt

3/8” Gyp Board

IA Air Film

OA Air Film

21.37RTOTAL =

0.17

0.61

0.66

19.00

0.32

0.61

R values

Wall Section

Note: This is an actual construction in Grand Island

Determine Design Temperatures (winter)

AL Siding

¼” USB

R19 Batt

3/8” Gyp Board

IA Air Film

OA Air Film 0.17

0.61

0.66

19.00

0.32

21.37

0.61

RTOTAL =

R values Lincoln, NEOA –5oF

IA 75oF

t = 80oF

Calculate GradientsLincoln, NE

OA –5oFIA 75oF

t = 80oF

OA Air film:

80oF x0.17

21.37=0.6 oF

0.61

21.37=

AL Siding:

80oF x 2.3 oF

19.0

21.37=80oF x

71.1 oF R19 Batt:

AL Siding

¼” OSB

R19 Batt

3/8” Gyp Bd

IA Air Film

OA Air Film 0.17

0.61

0.66

19.00

0.32

21.37

0.61

RTOTAL =

R values

And so forth…

[ t x R

RTOTAL

]

Surface TemperaturesLincoln, NE

OA –5oF

t = 80oF

IA 75oF

AL Siding

¼” OSB

R19 Batt

3/8” Gyp Bd

IA Air Film

OA Air Film 0.17 0.6oF

0.61 2.3oF

0.66 2.5oF

19.00 71.1oF

0.32 1.2oF

21.37 80oF

0.61 2.3oF

RTOTAL =

R values Gradients

H

C

Gypsum Board Room Side Surface:

75oF – 2.3 =

72.7oF

[ t x RSUM

RTOTAL

]IA -

Surface Temps (cont.)Lincoln, NE

OA –5oF

t = 80oF

AL Siding

¼” OSB

R19 Batt

3/8” Gyp Bd

IA Air Film

OA Air Film 0.17 0.6oF

0.61 2.3oF

0.66 2.5oF

19.00 71.1oF

0.32 1.2oF

21.37 80oF

0.61 2.3oF

RTOTAL =

R values Gradients

H

C

Gypsum Board Wall Cavity Surface:

75oF – (2.3+1.2) =71.5oF

IA 75oF

Surface Temps (cont.)Lincoln, NE

OA –5oF

t = 80oF

AL Siding

¼” OSB

R19 Batt

3/8” Gyp Bd

IA Air Film

OA Air Film 0.17 0.6oF

0.61 2.3oF

0.66 2.5oF

19.00 71.1oF

0.32 1.2oF

21.37 80oF

0.61 2.3oF

RTOTAL =

R values Gradients

OSB Board Cavity Surface:

75oF–(2.3+1.2+71.1)=

0.4oF

IA 75oF

Heat Transmission

-20o

10o

0o

-10o

20o

30o

40o

50o

60o

70o

80oF

TemperatureLincoln, NE

OA –5oF

IA 75oF

AL Siding

¼” OSB

R19 Batt

3/8” Gyp Bd

IA Air Film

OA Air Film 0.17 0.6oF

0.61 2.3oF

0.66 2.5oF

19.00 71.1oF

0.32 1.2oF

21.37 80oF

0.61 2.3oF

RTOTAL =

R values Gradients

H

C

OSB Cav Side 0.4oF

Gyp Cav Side 71.5oF

OSB OA Side -2.1oF

Siding Surface -4.4oF

Gyp Rm Side 72.7oF

Application?

Case StudyScenario:

You have been called in as a consultant to find out why a certain building is having the following problems:

• On the south side of the building, the sheathing is warping between studs

• Same side…AL siding is popping loose• During the winter they occupants cannot keep the building

any warmer than 65oF (in fact, some liquid items near the north facing wall have froze)

• Also, at different point of time in the winter, all of the insulated double pane glass has frosted over on the inside

• Snow has accumulated on the inside during heavy blustery snow storms

• High electric bills for heating and cooling

Wall inspection Nothing behind AL siding but bare

OSB sheathing R19 batt insulation not properly

installed

mmhhh…..

Request Blower Door Test

Blower Door Test A blower door is a large

calibrated fan that is temporarily mounted in a house door to measure the "leakiness" of the house Smoke puffer Infrared camera Calculate room air change

A recreation of a 20 mph wind

You discover… Air leaks

Around doors and windows Behind plumbing fixtures Between sill plate and floor

Infrared Shows air infiltrating around each insulation batt

and at sill plate Calculations from pressure differentials

133 CFM infiltration (ASHRAE recommends 10 cfm for residential)

35 CFM ventilation

Your Notes after Inspection Heating/Cooling sized correctly You sketch the wall construction Determine R values

Wall Window

IA conditions: DB=75oF WB = 56oF

Calculation winter surface wall temps

Check for condensation w/in walls

-20o

10o

0o

-10o

20o

30o

40o

50o

60o

70o

80oF

Temperature Heat Transmission and Exfiltration (ventilation)

Infiltration

IA: DB=75oF WB = 56oF

OA: DB=-5oF

DP: 39oF

DS Glass

Air Space

DS Glass

IA Air Film

OA Air Film 0.17

0.01

1.00

0.01

0.61

1.8RTOTAL =

R valuesLincoln, NE

OA: –5oF

t = 80oF

IA:DB=75oF WB = 56oF

Check Windows

Inside Surface Temperature?

48oF

W/30% RH DP=39oF

What about 40% or 50% RH