HEAT EXCHANGERS - the heat transfer company News · AIC’s expertise and core competence is the...

Transcript of HEAT EXCHANGERS - the heat transfer company News · AIC’s expertise and core competence is the...

HEAT EXCHANGERS

Discover the power behind the heat.

The AIC line of Pool Power Products define innovation with attention to design excellence and uncompromising quality.

These market-proven products excel in the most rigorous and demanding of environments with unsurpassed performance and finesse.

True to the AIC legacy, each heat exchanger design is versatile, yet grounded in rigid standards.

Efficient in nature

& compact in design

Typical Applications

• private and public swimming pools• spa / hot tubs• in-floor heating• oil / glycol coolers• waste water heat recovery systems

Advantages

• simple robust and compact design requires minimum installation space

• perfectly suited for applications with high fluid flows and low temperature variances

• the units can be connected to a varied heat source, e.g. different boiler types, heat pumps or solar panel systems

• large number of heat transfer tubes provides excellent thermal efficiency, reducing overall energy costs

• easy installation into the pool piping system• corrosion-resistant construction materials

vertical or horizontalinstallation

corrugated stainless

heating tubes

or spiral titanium

heating coil

complete stainless steel welded construction

POOL POWER PRODUCTS

Efficiency,

strength and durability

AIC’s expertise and core competence is the design and fabrication of stainless steel and titanium heat exchangers.

The diversity of applications provides unrestrained business opportunities.

AIC products can be found in modern heating, ventilation and air conditioning systems (HVAC industry), they work in domestic and commercial heating boilers, private and public swimming pools, perform as condensers and as pre-heaters.

B line

A product with a purpose. Complete welded construction with high strength 316L stainless steel, underlined by distinctive helically corrugated tubes, this series is formulated for consistent, reliable performance with high fluid velocities and low temperature variations.

Exceptional thermal performance.

TEE W line

Unique heating coil geometry. A revolutionary thermal technology. A one-piece welded pure titanium masterpiece, intrinsically designed for the most aggressive of environments. Exceptional material strength and corrosion resistance, matched with unparalleled quality.

Ultralight construction.

M line

Combined engineering ingenuity with natureʼs vitality, super austenitic marine alloy product series that has continuously demonstrated its superior performance and strength over other commercially marketed marine alloys.

True to form, the M line is a marriage of resistances: superior corrosion resistance with high erosion corrosion resistance, highly valued for its use in the seawater and salt water environments.

Unrivaled in its perfection.

Swimming pool installation

family

POOL LINE

B 1000

B Line M Line TEE W

B 500 B 400 B 300 B 250 B 180 B 130 B 70 B 45 TEE 400 WM 500 M 300 M 180 TEE 300 W TEE 200 W TEE 100 W

911

mm

(35.

90 in

)

402

mm

(15.

8 in

)

651

mm

(25.

60 in

)

1104

mm

(43.

50 in

)

894

mm

(35.

20 in

)

1068

mm

(42.

00 in

)

730

mm

(28.

70 in

)

615

mm

(24.

20 in

)

496

mm

(19.

50 in

)

366

mm

(14.

40 in

)

394

mm

(15.

50 in

)

344

mm

(13.

60 in

)

266

mm

(10.

50 in

)

759

mm

(29.

90 in

)

531

mm

(20.

90 in

)

333

mm

(13.

10 in

)

Heat Exchanger

Filter Chlorine Feeder

Swimming Pool

Pump

Gate Valve

POOL POWER PRODUCTS

About AIC

Established in 2001, AIC S.A. is a renowned specialist in the design, engineering and fabrication of stainless steel and titanium heat exchangers.

With a staff of nearly 250 people and two manufacturing locations in Poland, AIC is leading the way in the field of advanced heat transfer solutions.

With proven design products, “no compromise on quality” attitude and automated production processes, we are able to carry out the most complex and technologically advanced projects.

Our state-of-the-art facilities utilize the most leading edge processes, advanced automated and robotic systems,

and well sourced materials for the most stringent of applications. CFD analysis and simulation softwareimproved our modelling capabilities and helped analyze multiple design variations.

Our own in-house tube mills and sophisticated CNC equipment provide substantial cost savings and shorter product development times.

AIC products are manufactured in accordance with the guidelines of ASME and PED industry design codes.

Our stringent quality management system ensures that we continue our dominance in providing top quality products that clients have come to associate with the AIC brand.

L

B

D

A

F

G

B

DA G

C

F

L

Heat Exchanger

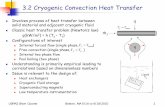

ModelGeometrical dimensions Heat Transfer

Area

L A B C ø D F G

mm in mm in mm in mm in mm in m2 sq ft

B 45 265,7 10.5 106 4.2 111.5 4.4 77,1 3.0 80 3.1 1” ¾” 0,18 1.97B 70 344,2 13.6 106 4.2 175 6.9 84,6 3.3 80 3.1 1½” ¾” 0,26 2.79B 130 394,2 15.5 106 4.2 225 8.9 84,6 3.3 80 3.1 1½” ¾” 0,31 3,30B 180 366 14.4 130 5.1 193 7.6 86.5 3.4 103,6 4.1 1½” 1” 0,47 4.91B 250 496 19.5 130 5.1 323 12.7 86.5 3.4 103,6 4.1 1½” 1” 0,68 7.29B 300 615 24.2 130 5.1 442 17.4 86.5 3.4 103,6 4.1 1½” 1” 0,87 9.38B 400 730 28.7 131,2 5.2 557 21.9 86.5 3.4 103,6 4.1 1½” 1” 1,06 11.39B 500 1 068 42.0 131,2 5.2 884 34.8 92 3.6 103,6 4.1 2” 1” 1,61 17.32B 1000 894 35.2 167 6.6 676 26.6 109 4.3 139,7 5.5 2” 2” 2,20 23.68

M 180 402,1 15.8 160 6.3 193 7.6 104,6 4.1 103,6 4.1 1½” 1” 0,44 4.70M 300 651,1 25.6 160 6.3 442 17.4 104,6 4.1 103,6 4.1 1½” 1” 0,84 9.00M 500 1 104,1 43.5 160 6.3 859 33.8 104,6 4.1 103,6 4.1 1½” 1” 1,56 16.80

TEE 100 W 332,6 13.1 108,9 4.3 134,6 5.3 --- --- 90,4 3.6 1½” 1¼” 0,21 2.24TEE 200 W 530,6 20.9 108,9 4.3 332,6 13.1 --- --- 90,4 3.6 1½” 1¼” 0,38 4.15TEE 300 W 758,6 29.9 108,9 4.3 560,6 22.1 --- --- 90,4 3.6 1½” 1¼” 0,58 6.26TEE 400 W 910,6 35.9 108,9 4.3 712,6 28.1 --- --- 90,4 3.6 1½” 1¼” 0,72 7.71

Heat Exchanger

Model

NominalCapacity Hot Water Side Cold Water Side

flow pressure drop flow pressure drop

kW BTU/h l/min USGPM kPa PSIG l/min USGPM kPa PSIG

B 45 13 45,000 23 6.1 6,2 0.9 150 39.6 7,4 1.1B 70 20 70,000 25 6.6 7,5 1.1 170 44.9 9,2 1.3B 130 38 130,000 27 7.1 8,1 1.2 200 52.8 11,4 1.7B 180 53 180,000 30 7.9 2,7 0.4 210 55.4 7,5 1.1B 250 73 250,000 35 9.2 4,2 0.6 270 71.3 12 1.7B 300 88 300,000 40 10.6 2,7 0.4 300 79.2 17 2.5B 400 117 400,000 46 12.1 7,8 1.1 342 90.3 20 2.9B 500 146 500,000 55 14.5 9,2 1.3 360 95.0 22 3.2B 1000 293 1 000,000 95 25.1 16,2 2.3 705 186.1 29,1 4.2

M 180 53 180,000 30 7.9 2,7 0.4 210 55.4 7,5 1.1M 300 88 300,000 40 10.6 2,7 0.4 300 79.2 17 2.5M 500 146 500,000 55 14.5 9,2 1.3 360 95.0 22 3.2

TEE 100 W 29 98,000 22 5.8 11 1.6 250 66.0 9 1.3TEE 200 W 57 195,000 30 7.9 28 4.1 300 79.2 16 2.3TEE 300 W 87 298,000 35 9.2 38 5.5 350 92.4 20 2.9TEE 400 W 113 385,000 40 10.6 65 9.4 400 105.6 25 3.6

Technical Product Specifications

Nominal values are based on 60°C (140°F) temperature difference between incoming heating and heated water

TEE W

Standard materials

B LINE stainless steel 316 LM LINE Nicrom-24TEE W LINE grade I titanium

Maximum allowable working pressure

B LINE - shell side 13 bar / 190 PSIGB LINE - tube side 16 bar / 235 PSIGM LINE - shell/tube side 10 bar / 150 PSIGTEE W LINE - shell/tube side 10 bar / 150 PSIG

Maximum allowable working temperature

B LINE 208°C / 406°FM LINE 208°C / 406°FTEE W LINE - shell/tube side 120°C / 248°F

B/M

We are certified by renowned international inspection authorities. Our quality process and management systems fulfill the requirements of ISO Quality Management System. AIC heat exchangers are designed, tested and manufactured in accordance with ASME (Section IV and VIII) and PED (//UE) regulations.

AIC s.a.

ul. Rdestowa

- Gdynia, POLAND

T. +

F. +

www.myaic.com

©AI

C S.

A.

03/2

012

JA

NYK

Prod

uct d

esig

ned

and

mad

e in

EU

Performance

Suited for high-pressure applications, the shell and tube exchangers from AIC are distinctive in their heating performance.

They are designed to operate in corrosive environments, with varied fluid flows, high temperatures and high operating pressures.AIC pool heating products guarantee reliability and outstanding lifetime.