Headcut migration prediction of the cohesive embankment breach

-

Upload

johannes-k -

Category

Documents

-

view

217 -

download

2

Transcript of Headcut migration prediction of the cohesive embankment breach

Engineering Geology 164 (2013) 18–25

Contents lists available at SciVerse ScienceDirect

Engineering Geology

j ourna l homepage: www.e lsev ie r .com/ locate /enggeo

Headcut migration prediction of the cohesive embankment breach

Gensheng Zhao a,⁎, Paul J. Visser a, Patrik Peeters a,b, Johannes K. Vrijling a

a Department of Hydraulic Engineering, Faculty of Civil Engineering and Geosciences, Delft University of Technology, Stevinweg 1, 2628 CN Delft, the Netherlandsb Flanders Hydraulics Research, Berchemlei 115, 2140 Antwerp, Belgium

⁎ Corresponding author. Tel.: +31 15 27 83426; fax:E-mail address: [email protected] (G. Zhao).

0013-7952/$ – see front matter © 2013 Elsevier B.V. Allhttp://dx.doi.org/10.1016/j.enggeo.2013.06.012

a b s t r a c t

a r t i c l e i n f oArticle history:Received 13 August 2012Received in revised form 22 May 2013Accepted 15 June 2013Available online 3 July 2013

Keywords:Headcut erosionIncipient VelocityBreach slopeMinimum moment

Headcut erosion occurs in the development of a cohesive embankment breach and plays an important role inthe breaching process. The headcut development is a mixed process of sediment erosion and mass failure.Based on momentum equilibrium, the critical incipient velocity is derived from the forces of particle weightunder water, cohesive force among particles around the clay particle, uplift force, and drag force. Via theturbulent boundary layer flow theory, the critical stress can be connected with these forces. The formulaefor the incipient stress and the critical velocity have been calibrated and validated with the results ofundisturbed clay tests. A moment equilibrium-based method is proposed to simulate the headcut develop-ment and migration in a cohesive embankment breach due to overtopping flow. The hypothesis is giventhat the particle andmass are removed in the minimummoment on the breach slope. It is found that the test-ed results give good predictions of the headcut erosion development on the breach slope by validating labo-ratory data. The proposed method can be important and valuable to predict the breaching process in cohesiveembankments.

© 2013 Elsevier B.V. All rights reserved.

1. Introduction

Breaching is the most frequent form of embankment failure. Dueto overtopping and/or piping, an embankment starts to breachwhen part of the embankment actually breaks away, leaving a largeopening for water to flood the land protected by the embankment.A breach can be a sudden or gradual failure that is caused by surfaceerosion and/or headcut erosion in the embankment.

Ralston (1987) gave a good description on the mechanics of em-bankment erosion. For cohesive embankments, breach takes place dueto headcut erosion. At the beginning, the headcut is typically formed atthe toe of the embankment and then advances upslope until the crestof the embankment is reached. In some cases a series of stair-stepheadcut forms on the downslope face of the embankment. The actionis similar to that described by Dodge (1988) for model testing of em-bankment overtopping. The relevant processes are headcut initiationand advance by hydrodynamic and geotechnical mass wasting.

Zhu et al. (2004) summarized ongoing research efforts by severalentities aimed at developing newmethods for protecting embankmentsfrom erosion during overtopping flow, and for predicting erosion ofprotected and unprotected embankments. All of the studies indicatethat embankment erosion is a multivariable, multidisciplinary problem.Random influences can be substantial, and thus, repetition of modeltests is essential. Fread (1988) developed a breach erosion model(BREACH) for an earthen dam to predict the breach size, shape, and

+31 15 27 85124.

rights reserved.

time of formation and breach outflow hydrograph. In the model, ero-sion is assumed to occur equally along the bottom and sides of thebreach channel unless the sides of the breach channel collapse andthe valley floor has been reached. Thus further downward erosion isnot allowed and the discharge could reach the peak discharge.

In the model of Visser (1998) for sand-dikes, a relatively smallinitial breach is assumed at the top of the dike that is so large thatwater flows through it triggering the breach erosion process. By as-suming a trapezoidal shape of the initial breach with the angle of re-pose, five stages can be distinguished in the process of breach erosion(Figure 1):

1. Steepening of the inner slope from the initial value up to a criticalvalue.

2. Backward erosion of the inner slope of the dike in the breach,yielding a decrease in dike crest width.

3. Lowering of the top of the dike in the breach, with constant angle ofthe critical breach side slopes, resulting in an increase of the width ofthe breach.

4. Critical flow stage, in which the flow is virtually critical throughoutthe breach, and the breach continues to grow mainly laterally.

5. Subcritical flow stage, in which the breach continues to grow,mainlylaterally.

In the first three stages the initial breach cuts itself into the dike;most of the discharge through the breach happens in stages 4 and 5.

Corresponding to the study of sand-dike breaching by Visser (1998),Zhu (2006) investigated thebreaching process of clay-dikes. Thedistinct

Fig. 1. Schematic illustration of breach growth in a sand-dike (Visser, 1998).

19G. Zhao et al. / Engineering Geology 164 (2013) 18–25

difference from sand-dike breaching is the headcut erosion that occursduring the breaching process of clay-dikes. Similarly, by assuming aninitial breach in the top of the dike that is relatively small andtrapezoidal-shaped, Zhu (2006) classified the breach erosion processin clay-dikes into the five following stages:

1. Stage I (t0 b t b t1): Floodwater flows through the initial breach inthe dike crest and erodes soil away from the inner slope of thedike. Both flow shear erosion as well as small-scale headcut ero-sion can occur along the inner slope (Figure 2(a)(b)).

2. Stage II (t1 b t b t2): The steepened inner slope of the dike holds thecritical slope angleβ1 throughout Stage II and acts like a headcut dur-ing the erosion process owing to its large steepness (Figure 2(b)(c)).

3. Stage III (t2 b t b t3): The headcut still maintains the critical slopeangle β1. The breach enlarges rapidly, accordingly also the flow ratethrough the breach, which in turn accelerates the breach erosionprocess in the dike. At the end of this stage, the dike body in thebreach has been washed away completely down to the dike founda-tion or to the toe protection on the dike outer slope (Figure 2(c)(d)).

4. Stage IV (t3 b t b t4): In this stage the flow in the breach is critical.Breach erosion takes place mainly laterally, with flow shear ero-sion along the side-slopes of the breach and the resulting discreteside slope instability being the main mechanisms for the breachenlargement. Vertical erosion in this stage relies mainly on thegeometrical and material features of the dike (Figure 2(d)(e)).

5. Stage V (t4 b t b t5): In this stage the breach flow is subcritical. Thebreach erosion still occurs mainly laterally and at the end, the ve-locity of the breach flow is reduced to such an extent that itcan no longer erode away soil material from either the dike bodyor the dike foundation, hence the breach growth process stops(Figure 2(e)(f)).

According to Fread (1988) and Zhu et al. (2004, 2005), the headcuterosion plays a significant role in the breaching process in cohesive em-bankments. The mechanism of headcut erosion, however, still needsfurther understanding. A variety of breaching experiments have beenconducted in the past (Zhu et al., 2004), however, most of them

generally focused on the breaching process. As part of the breachingprocess, the mechanism of the headcut erosion is not understood suffi-ciently to describe the breaching process and to simulate it with math-ematical models.

2. Incipient motion of clay

Clay erosion is an important issue in many hydraulic engineeringproblems, such as the stability of clay coasts, the stability of clay layersin river beds and flood plains, scour around bridge piers, the stabilityof embankments, and the breach development in dikes and dams(Gaskin et al., 2003; Merritt et al., 2003; Julian and Torres, 2006;Knapen et al., 2007; Zhu et al., 2008). Clay offers resistance due to itsstrength, in particular its cohesive strength (Panagiotopoulos et al.,1997; Houwing and Van Rijn, 1998; Houwing, 1999). Resistance ofclay to erosion depends on a large number of parameters (Rose et al.,2007; Trenhaile, 2009), i.e. size and shape of the grains, grain size distri-bution, mineral composition, chemical properties, water temperature,etc. and the characteristics of the flow over the sediments. Undisturbedclay has a large range of densities, i.e., from about 1500 kg/m3 to about2000 kg/m3, while the density of non-cohesive sediment in streams isusually about 2000 kg/m3.

2.1. Forces in clay incipient motion

Due to the large number of parameters involved, the identifica-tion and prediction of undisturbed clay erosion is a complicatedproblem in geomorphology and hydraulic engineering (Teisson etal., 1993). While the pickup of non-cohesive sediment through dis-crete particle entrainment may be quantified (if the flow velocitiesare not very large) by the magnitude of shear stress and particlesize, undisturbed clay, in contrast, is eroded through entrainmentof aggregates. The cohesive strength between and within aggregatescauses the erosion to be complex (Zhao et al, 2010). For a single clayparticle, there are two forces on it, i.e. weight under water and cohe-sive forces (Figure. 3).

2.1.1. WeightThe weight of a single clay particle under water is

Ws ¼ a1π6

ρs−ρð ÞgD3 ð1Þ

where Ws is the weight of a clay particle under water, a1 is the shapecoefficient, ρs is the density of clay, ρ is the density of water, and D isthe diameter of a clay particle.

2.1.2. Shear strength among soil particlesThe clay's resistance originates from the bonding forces that hold

clay particles together and other material in the soil matrix, such asorganic matter, plant roots, and rock fragments. The various mechan-ical, adhesive, cohesive, and electrostatic bonding forces acting on theundisturbed clay increase the resistance to erosion, and these cangenerally be considered as cohesive forces,

τ f ¼ σ tanφþ c ð2Þ

where τf is the shear stress, σ is the normal stress on the clay particle,φ is the angle of friction, and c is the cohesive force of clay particles,and

N ¼ πD2

4τ f ð3Þ

where N is the shear strength force among clay particles.Particle movement will occur when the instantaneous fluid force

on a particle is just larger than the instantaneous resisting force

Fig. 2. Breach development process in clay dike (Visser, 1998; Zhu, 2006).

20 G. Zhao et al. / Engineering Geology 164 (2013) 18–25

related to the submerged particle weight and the friction coefficient(Figure 3). The driving forces are strongly related to the local near-bedvelocities. In turbulent flow conditions the velocities are fluctuating inspace and time. Considering the randomness of particle size, shape,and position incipient motion is not merely a deterministic phenome-non but also a stochastic process (Van Rijn, 1993 and 2006).

2.1.3. Uplift forceThe uplift force (Van Rijn, 1993) can be described with

Fy ¼ a2cyπD2

4ρv2

2ð4Þ

d4

d3

d2d1

O

NWs

Fx

Fy

Flow

Fig. 3. Sketch of forces on the clay particle submerged flow.

21G. Zhao et al. / Engineering Geology 164 (2013) 18–25

where Fy is the uplift force acting on the clay particle, a2 is the shapecoefficient, cy is the friction coefficient in the direction of y, and v isthe velocity over the clay particle.

2.1.4. Drag forceSimilarly, the drag force (Van Rijn, 1993) can be described as

Fx ¼ a3cxπD2

4ρv2

2ð5Þ

where Fx is the drag force on a clay particle, a3 is the shape coefficient,and cx is the friction coefficient in the direction of x.

2.2. Incipient motion due to moment

Considering O as a fulcrum, according to the moment equilibrium,an equation can be written as

Fxd1 þ Fyd2−Wsd3−Nd4≥0: ð6Þ

where d(s) with subscripts are the vectors from point O to the positionwhere quantity forces are applied.

The incipient velocity of a clay particle can be written as

v ¼ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

2

a3cxd1 þ a2cyd2� �

ρa1

2π3

ρs−ρð ÞgDd3 þ τ f d4

� �vuut : ð7Þ

Supposing C′ ¼ 4πa1d33 a3cxd1þa2cyd2ð Þ and C ¼ 2d4

a3cxd1þa2cyd2ð Þ, then

v ¼ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiC′ ρs−ρð ÞgDþ Cτ f

ρ

s: ð8Þ

According to Prandtl Law (Chow, 1959), the shear stress at anypoint in a turbulent flow over a solid surface can be given as

v ¼ κffiffiffiffiffiτ0ρ

rln

yy0

ð9Þ

where κ is 0.40 according to many experiments. Consequently,

ρv2 ¼ κ2τ0 lnyy0

� �2: ð10Þ

Substituting Eq. (10) into Eq. (8) yields

κ2τCc lnyy0

� �2¼ C0 ρs−ρð ÞgDþ Cτ f ð11Þ

τCcρs−ρð ÞgD ¼ 1

κ2

1

ln yy0

� �2 C0 þ Cτ f

ρs−ρð ÞgD� �

ð12Þ

where τCc y is equal to 0.5D under this hypothesis, y0 depends on thecharacteristics of the clay particle surface, such as roughness, andboundary layer transition. In Eq. (12), the term 1

κ21

ln yy0

� �2 C0 is associ-

ated with particle weight and C τ f

ρs−ρð ÞgD is associated with cohesive

stress. In clay particle erosion, cohesion plays a far more importantrole than weight. If the weight is ignored, then Eq. (12) can be writtenas

τCcρs−ρð ÞgD ¼ 1

κ2

1

ln yy0

� �2 Cτ f

ρs−ρð ÞgD : ð13Þ

In the non-cohesive sediment incipient motion, shields numbercan be expressed as

θc ¼τc

ρs−ρð ÞgD ð14Þ

where θc is the critical mobility parameter or the Shields parameterand τc is the critical shear stress of non-cohesive sediment particle'sincipient with the same size. The clay is generally eroded as blocksor lumps not in the format of particles. The size of clay block orlump is equivalent to the size of the non-cohesive sand or gravel. Ac-cording to this hypothesis of Eqs. (9) and (14), Eq. (13) can be writtenas

τCcρs−ρð ÞgD ¼ C

τ f

ρv2θc ð15Þ

or

τCc ¼ Cτcρv2

τ f : ð16Þ

The new clay incipient motion theory is a model coupled by hy-drodynamics and soil mechanics. It can reflect the clay incipient mo-tion based on the physical mechanics. The formulae (Eqs. (15) and(16)) have the same formats with the clay incipient motion empiricalformula of van Rijn (2006), however, the new incipient motionformulae are based on the hydrodynamic and geotechnical theory.

3. New headcut migration model

Robinson and Hanson (1994), Hanson (1996), and Hanson et al.(2001) proposed a stress balanced headcut migration model. Butthe headcut migration is a three-dimensional phenomenon that de-pends on the embankment geometry, the hydraulic load and soilproperties, and it is not even a statics problem. What's more, theheadcut migration is a dynamic process involving variation of theflow and geometry. So the moment balanced model is proposed todescribe the dynamic process of the headcut migration using thenew clay incipient method (Eq. (15) and (16)).

3.1. Erosion rate

In the headcut process of the breach, the maximum time-averagedhydraulic shear stresses in the vertical and horizontal direction areused to predict the rate of erosion. Based on the dimensionless anal-ysis, the erosion rate can be expressed with an excess stress equation(Hanson et al., 2001)

ε ¼ ζ τe−τCcð Þm ð17Þ

P

G0

N1

N2 L

GN1

o

T0

F

hθ

H

T

Fig. 4. Sketch of headcut migration.

22 G. Zhao et al. / Engineering Geology 164 (2013) 18–25

where ε is erosion rate, ζ is erodibility coefficient, τe is effective stress,m is an empirical parameter.

3.2. Headcut migration due to moment

The schematic in Fig. 4 illustrates the forces on the eroded blockduring headcut migration as water weight G0, flow stress F and tailwater pressure P from water as well as the block weight G and em-bankment cohesion forces N1 and N2. As for N1 and N2, they are nottensile strengths but the cohesive forces among soil particles.

According to the moment principle, a moment equation can beobtained if O is seen as the fulcrum:

m ¼ F � d5−G0 � d6−N1 � d7−N2 � d8−G � d9−P � d10 ð18Þ

where d(s)with subscripts are the vectors from point O to the positionwhere quantity forces are applied and can be expressed as follows:

d5 ¼ H ð19Þ

d6 ¼ 0:5T−T0 ð20Þ

d7 ¼ 0:5 H þ L sinθð Þ ð21Þ

d8 ¼ 0:5L ð22Þ

d9 ¼ H3H−L sinθð Þ

3 2H−L sinθð Þ−T0 ð23Þ

d10 ¼ 23h ð24Þ

Fig. 5. Sketch of eros

where T0 is the headcut toe erosion required to cause the failure, L isthe length of the failure plane, θ is the failure plane angle, H is the em-bankment height, and h is the tail water height.

From the relationship of T, T0 and L:

T ¼ T0 þ L sinθ ð25Þ

Eq. (21), Eq. (22) and Eq. (23) can be rewritten as

d7 ¼ 0:5 H þ T−T0ð Þ ð26Þ

d8 ¼ 0:5 T−T0ð Þ= sinθ ð27Þ

d8 ¼ H3H−T þ T0ð Þ

3 2H−T þ T0ð Þ−T0: ð28Þ

The moment “m” should be larger than 0 if the block can bemoved, therefore the headcut migration occurs if:

m≥0: ð29Þ

The relationship between T0 and T can be given as

T0 ¼ f Tð Þ: ð30Þ

Headcut migration rate can be described with headcut movementT and the time interval t as follows (Hanson et al., 2001):

dxdt

¼ Tt: ð31Þ

ion test set-up.

0

200

400

600

800

1000

1200

1400

0 50 100 150 200 250 300 350 400

Time[min]

Spe

ed[r

pm]

Fig. 6. Sketch of operation procedure of rotating cylinder erosion device.

15

17

19

21

23

25

27

29

0 0.5 1 1.5 2 2.5 3

Velocity (m/s)

Shea

r St

ress

(N

/m2 )

Measured data

Calculated data

Fig. 7. Comparison of shear stress between measured data and calculated data for EG.

80Measured data

23G. Zhao et al. / Engineering Geology 164 (2013) 18–25

As the headcut develops, erosion occurs at the toe of the headcut.The embankment block fails and the headcut advances when the ver-tical erosion T0 exceeds a certain amount and the base of the embank-ment cannot ensure the potential failure block. The time interval offailures is monitored by the erodibility and strength of the embank-ment. It is based at the erosion on the vertical toe of the headcutface, which stimulates the headcut to become unstable. Therefore,the time interval can be expressed via Eq. (17):

t ¼ T0

ε: ð32Þ

Headcut migration rate can be expressed by Eq. (30), Eq. (31) andEq. (32):

dxdt

¼ Tf Tð Þ ε: ð33Þ

Based on the moment balanced method, the headcut migrationmodel can be expressed by Eq. (33) which is different from the stressbalanced model (Hanson et al., 2001) in form. Eq. (30) can be iteratedto get a deterministic T and f(T). The headcut migration process willstop when the toe erosion rate ε = 0, i.e., the headcut cannot be infi-nitely tall if there is no erosion in the model, which well fits theheadcut development in prototype.

Headcut migration is a hydrodynamic progress in the cohesiveembankment breach. The newmodel based on the moment equilibri-um principle and new clay incipient formula (Eqs. (15) and (16)) aswell as the erosion rate with excess stress method (Eq. (17)).The new headcut migration model is developed to predict the keyprogress of the cohesive embankment breach.

Table 1Properties of the clay samples. Notation: “EG” stands for the clay sample fromElisabethgroden and “CG” stands for clay sample from Cäciliengroden. “Cs13” standsfor sandy clay; and “Csi2” stands for silt clay.

Clay type EG CG

Soil type Cs13 Csi2

Particle size distribution b2 μm 24.2 48.8b16 μm 38.6 77.3N2 μm and b63 μm 36.8 40.4N63 μm 39.0 10.8

Water content in-situ [%] 23 45Undrained shear strength [kN/m2] 29.32 35.55Specific density [g/cm3] 2.66 2.72

3.3. Incipient velocity test and validation

Undisturbed clay erosion experiments were conducted by GeoDelft(2003). The rotating cylinder erosion device (Figure 5) consists of a ver-tically placed metal cylinder with 1 cm wide blades attached on theinside. The internal diameter of the metal cylinder is 16 cm. The cylin-drical soil sample, having a diameter of 6.6 cm and a height of 5 cm, isplaced between two spindles with spikes which penetrate the samplea fewmillimeters. The sample and the two spindles are placed on a ver-tical metal axis. The axis is pierced through the center of the sampleand the spindles. The spindles arefixed onto the axiswhich is placed be-tween two ferrules, ensuring an independent rotation of the samplewith respect to the rest of the apparatus.

By rotating the metal cylinder, the water inside it flows around thesample, which applies torsion on the sample. Due to the fact that thesample is independently hung from the rest of the apparatus, this tor-sion can be measured constantly. The erosion rate is measured every10 min by measuring the weight of the sample.

The rotating cylinder erosion device is controlled by a computer.The test procedure is generally such that the rotation speed is keptconstant during a certain period of time and increases in steps. Theworking procedure is shown in Fig. 6.

Clay samples EG and CG were collected from Elisabethgroden andCäciliengroden, respectively. Their relevant properties are given inTable 1.

In the experiment two clay samples (EG and CG) were tested withthe rotating cylinder erosion device. The shear stress was measuredevery 10 min. The shear stress to velocity was plotted for EG and CGin Figs. 7 and 8, respectively.

0

10

20

30

40

50

60

70

0 1 2 3 4 5 6

velocity(m/s)

Shea

r st

ress

(N/m

2 )

Calcultated data

Fig. 8. Comparison of shear stress between measured data and calculated data for CG.

Fig. 9. Shields curve.

24 G. Zhao et al. / Engineering Geology 164 (2013) 18–25

In Eqs. (15) and (16), the shear stress for the non-cohesive sedi-ment should be used with the same diameter of undisturbed clayparticle. Therefore, the Shields curve (Figure 9) should be used toconfirm the Shields parameter θc in the calculation of shear stress ofclay particle. For simplicity, D50 is used to represent the particle diam-eter. Then the shear stress on clay particles can be calculated withEq. (16) for EG and CG, and are plotted in Figs. 7 and 8.

In the calculation of shear stress for sample clay, the calculateddata can be fitted to the measured data with reasonable accuracy.Therefore, Eqs. (15) and (16) can be used to calculate the shear stresson undisturbed clay. The relationships between shear stress and ve-locity of EG and CG are plotted in Figs. 7 and 8. These relationshipscan be used to predict for other conditions without doing tests.

4. New migration model validation

4.1. Headcut migration tests (Robinson and Hanson, 1995; Hanson et al.,2004)

The tests were conducted in a flume with a length of 29.0 m and awidth of 2.4 m. The properties of the series of tests are shown inTable 2. The materials included stratified and homogenous types. Dur-ing the constructions of the headcut models, the soil materials wererolled layer by layer to build the model. Every layer used the samema-terial in the homogenous type, but the materials were changed everylayer in the stratified type, i.e., the first layer was made of sand andthe next layer was made of clay.

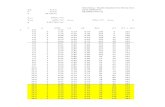

Table 2Parameters for the headcut migration tests (Robinson and Hanson, 1995; Hanson et al., 20

Test Material type ρs (Kg/m3) ε (m/s) τc (Pa) Wc

Clay Sand Clay Sand

1 Stratified 1540 0.172 0.04 0.01 0.11 9.22 Homogeneous 1540 0.172 – 0.01 – 9.23 Stratified 1680 0.078 0.04 0.01 0.11 9.24 Homogeneous 1680 0.078 – 0.01 – 9.25 Stratified 1590 0.068 0.04 0.08 0.11 11.66 Homogeneous 1590 0.068 – 0.08 – 11.67 Stratified 1790 0.006 0.04 1.32 0.11 14.48 Homogeneous 1790 0.006 – 1.32 – 14.49 Stratified 1790 0.007 0.04 1.21 0.11 14.210 Homogeneous 1790 0.007 – 1.21 – 14.211 Stratified 1710 0.009 0.04 0.72 0.11 14.312 Homogeneous 1710 0.009 – 0.72 – 14.313 Stratified 1780 0.002 0.04 2.46 0.11 15.914 Homogeneous 1780 0.002 – 2.46 – 15.9

There are 14 runs of headcut migration tests done. The headcutmigration rate appears to be different for each type of materialunder the same hydraulic parameters. The model materials playedan important role in the headcut progress.

4.2. Model validations

The clay incipient model (Eq. (15)) and headcut model (Eq. (33))were validated by the headcut tests above. According to the materialproperties and hydraulic parameters, the headcut migration rateswere calculated based on the hydraulic parameters and the materialproperties. The calculated headcut migration rates were plotted inFig. 10 to compare with the measured data from the 14 tests. Forthe model built with high erodibility rate (ε = 0.172 m/s) materials,the headcut migration rates are close to but a little lower than themeasured data. As for the moderate erodibility rate materials, the cal-culated headcut migration rates are almost close to the measureddata. But for the low erodible materials, the calculated headcut migra-tion rates are much lower than the measured data since the erosionrate is impacted by many factors from the materials, especially sincethe materials are not homogenous.

It can be concluded that the calculated results are slightly lowerthan the measured data, however, the agreements are reasonableconsidering the variability of the materials. The new headcut migra-tion model has applied the equilibrium moment principle and thenew clay incipient motion theory. It can simulate and predict the hy-drodynamic erosion process of the headcut on the breach slope. Themoment based method is a good approach to describe the dynamicheadcut process, and more realistic than the static state methodapplied by the former researchers (Robinson and Hanson, 1994).

5. Conclusions

An erosion and moment equilibrium-based method is proposed tosimulate the headcut development and migration in a cohesive em-bankment breach induced by overtopping. The new headcut model(Eqs. (16) and. (33)) can simulate the hydro-dynamic and morpho-logic headcut migration. It can be applied to calculate the incipientmotion of the soil and migration of the headcut movement in thebreach of cohesive embankment.

The newmethod has been validated using laboratory data (Robinsonand Hanson, 1995; Hanson et al., 2004; GeoDelft, 2003). It is found thatthe calculated results give good predictions of the development of theheadcut erosion on the breach slope. The proposedmethod is significantand valuable to estimate the breach growth in a cohesive embankment.

04).

(%) Qu (KPa) Q (m3/s) H (m) h (m) U (m/s) dx/dt (m/h)

4 29 0.86 1.3 1.1 2.0 17.64 29 0.86 1.3 1.1 2.0 18.60 58 0.84 1.2 1.0 2.0 4.70 58 0.84 1.2 1.0 2.0 5.40 21 0.86 1.3 1.0 2.0 9.10 21 0.86 1.3 1.0 2.0 6.80 89 0.86 1.3 1.0 2.0 1.70 89 0.86 1.3 1.0 2.0 0.23 83 0.85 1.2 1.0 2.0 1.73 83 0.85 1.2 1.0 2.0 0.36 63 0.85 1.3 1.0 2.0 2.26 63 0.85 1.3 1.0 2.0 0.93 40 0.88 1.2 0.9 2.0 3.63 40 0.88 1.2 0.9 2.0 0.1

0

5

10

15

20

0 5 10 15 20

Cal

cula

ted

Mig

rati

on r

ate(

m/h

)

Measured Migration Rate (m/h)

Fig. 10. Comparison between measured migration rate and calculated migration rate.

25G. Zhao et al. / Engineering Geology 164 (2013) 18–25

Acknowledgments

The authors would like to thank Ir. Henk J. Verheij (Deltares andDelft University of Technology, the Netherlands) for providing valu-able suggestions to the article.

References

Chow, V.T., 1959. Open-channel Hydraulics. McGraw-Hill College Press, New York.Dodge, R.A., 1988. Overtopping Flow on Low Embankment Dams— Summary Report of

Model Tests. REC-ERC-88-3 U.S. Bureau of Reclamation, Denver, USA.Fread, D.L., 1988. BREACH: An Erosion Model for Earthen Dam Failures. National

Weather Service (NWS) Report, NOAA, Silver Spring, Maryland, USA.Gaskin, S.J., Pieterse, J., Al Shafie, A., Lepage, S., 2003. Erosion of undisturbed clay sam-

ples from the banks of the St. Lawrence River. Canadian Journal of Civil Engineering30, 585–595.

GeoDelft, 2003. Erosion Tests on Hannover Clay. Delft Cluster Publication, Delft (1-322-6).Hanson, G.J., 1996. Investigating soil strength and stress–strain indices to characterize

erodibility. Transactions of ASAE 39, 883–890.Hanson, G.J., Robinson, K.M., Cook, K.R., 2001. Prediction of headcut migration using a

deterministic approach. Transactions of the American Society of Civil Engineers V44, 525–531.

Hanson, G.J., Robinson, K.M., Cook, K.R., Temple, D.M., 2004. Modeling of erosionfrom headcut development in channelized flow. Advances in Hydro-Science and-Engineering, vol. VI. University of Mississippi Press, Oxford.

Houwing, E.J., 1999. Determination of the critical erosion threshold of cohesive sedi-ments on intertidal mudflats along the Dutch Wadden Sea coast. Estuarine, Coastaland Shelf Science 49, 545–555.

Houwing, E., Van Rijn, L.C., 1998. In Situ erosion flume (ISEF): determinationof bed-shear stress and erosion of a kaolinite bed. Journal of Sea Research 39,243–253.

Julian, J., Torres, R., 2006. Hydraulic erosion of cohesive riverbanks. Geomorphology 76,193–206.

Knapen, A., Poesen, J., Govers, G., Gyssels, G., Nachtergaele, J., 2007. Resistance of soilsto concentrated flow erosion: a review. Earth-Science Reviews 80, 75–109.

Merritt, W.S., Letcher, R.A., Jakeman, A.J., 2003. A review of erosion and sediment transportmodels. Environmental Modelling & Software 18, 761–799.

Panagiotopoulos, I., Voulgaris, G., Collins, M.B., 1997. The influence of clay on thethreshold of movement of fine sandy beds. Coastal Engineering 32, 19–43.

Ralston, D.C., 1987. Mechanics of embankment erosion during overflow. Proceedings ofthe 1987 ASCE National Conference on Hydraulic Engineering, Williamsburg, USA,pp. 733–738.

Robinson, K.M., Hanson, G.J., 1994. A deterministic headcut advance model. Transactionsof ASAE 37, 1437–1443.

Robinson, K.M., Hanson, G.J., 1995. Large- scale headcut erosion testing. Transactions ofASAE 38, 429–434.

Rose, C.W., Yu, B., Ghadiri, H., Asadi, H., Parlange, J.Y., Hogarth, W.L., Hussein, J.,2007. Dynamic erosion of soil in steady sheet flow. Journal of Hydrology 333,449–458.

Teisson, C., Ockenden, M., Le Hir, P., Kranenburg, C., Hamm, L., 1993. Cohesive sedimenttransport process. Coastal Engineering 21, 129–162.

Trenhaile, A.S., 2009. Modeling the erosion of cohesive clay coasts. Coastal Engineering56, 59–72.

Van Rijn, L.C., 1993. Principles of Sediment Transport in Rivers, Estuaries and CoastalSeas. Aqua Publications, Amsterdam the Netherlands.

Van Rijn, L.C., 2006. Principles of Sediment Transport in Rivers, Estuaries and CoastalSeas. Aqua Publications, Amsterdam, the Netherlands.

Visser, P.J., 1998. Breach Growth in Sand-dikes. . PhD thesis Delft University of Technology,Delft, the Netherlands.

Zhao, G., Visser, P.J., Vrijling, J.K., 2010. Hydrodynamic erosion process of undisturbedclay. Proceedings of 34th IAHR World Congress, pp. 3869–3877.

Zhu, Y.H., 2006. Breach growth in clay-dikes. PhD thesis. Delft University of Technology,Delft, the Netherlands.

Zhu, Y., Visser, P.J., Vrijling, J.K., 2004. Review on embankment dam breach modeling.Proceedings of the 4th International Conference on Dam Engineering, 18–20 October,Nanjing, China.

Zhu, Y.H., Visser, P.J., Vrijling, J.K., 2005. A model for headcut erosion during embank-ment breaching. Proceedings of the 4th IAHR Symposium on River, Coastal andEstuarine Morphodynamics, pp. 1183–1190.

Zhu, Y., Lu, J., Liao, H., Wang, J., Fan, B., Yao, S., 2008. Research on cohesive sediment ero-sion by flow: an overview. Science in China Series E: Technological Sciences 51,2001–2012.