Harmonic hpgp specsheet

-

Upload

electromate -

Category

Technology

-

view

35 -

download

2

Transcript of Harmonic hpgp specsheet

827149373885

3,222

0.883.016.842.1100364

84286

1,6204,0019,52334,518

9.5032.3183452

1,0763,900

9191,5873,8897,374

17,08533,272

40.970.6173328760

1,480

7011,1492,3834,6099,352

20,368

31.251.1106205416906

0.0060.0110.01150.0140.0190.023

0.02750.04050.0640.0850.1230.170

Nm lb-in x104

Nm/radx104

lb-in/rad111420325065

x102Nm m lb x102N lb

4M16260255

2,2575,180

45,847

4M12190103912

2,03017,967

4M1013551.5456868

7,682

4M810526.1231428

3,788

4M3461.412

26.3233

114

M5706.356110974

14 20 32 50 65

mmNmlb-inNmlb-in

65503220114

M4184.540

25.3224

148

M4304.54084743

8M645

15.3135286

2,531

8M860

37.2329697

6,169

8M1290

128.41,1362,40621,295

8M16120319

2,8235,972

52,857

mmNmlb-inNmlb-in

HPGP

HPGP

HPGP

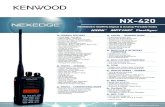

The HPGP series has achieved higher torque while maintaining high precision through use of our innovative ring-gear technology and high moment stiffness through use of an integral cross-roller output bearing. The HPGP series achieves longer life and can allow smaller gearheads to be used.

Harmonic Drive™

HPGP Series – High Performance Gearhead for ServomotorsHarmonic Drive now offers a NEW high-torque planetary gearhead based upon our high precision HPG Series HarmonicPlanetary® gears.

Application Examples

Robot linear axis (rack and pinion) Machine tool gantry robot SCARA robot

Machine Tools Industrial Automation Industrial robots

Cross roller bearing

rack and pinion

belt

chain

Shielded input bearing

Motor mounting flange

Quick-Connect input couplingInnovative Ring Gear

The HPGP Series has 33% higher torque than the original HarmonicPlanetary® HPG SeriesSizeNumber of ScrewsSize of ScrewsPitch Circle Diameter

Torque TransmittingCapacity

Screw Tightening Torque

Number of ScrewsSize of ScrewsPitch Circle Diameter

Torque TransmittingCapacity

Screw Tightening Torque

Size

Pitch Circledp

OffsetR Basic Dynamic Load Rating C

Basic Load Rating

Basic Static Load Rating Co

Allowable Moment Load Mc Moment Stiffness Km

Specification for Crossroller Bearing

Bolt Connection to Output Flange and Resulting Transmission Torque

Installation and Transmission Torque

HPGP Series HPG Series (Original product)

Output Flange Bolt Pattern Reference Drawing

The number of bolts, size of bolts & PCD vary depending on the size of the gear. Additionally, the HPGP Series has an added dowel pin hole.

Please refer to the Gearhead Series Catalog or contact our Sales Division for more information.

Harmonic Drive is a trademark of Harmonic Drive LLC.

Harmonic Drive LLCBoston US Headquarters247 Lynnfield StreetPeabody, MA 01960

New York Sales Office100 Motor ParkwaySuite 116Hauppauge, NY 11788

Group CompaniesHarmonic Drive Systems, Inc.6-25-3 Minami-Ohi, Shinagawa-kuTokyo 141-0013, Japan

Harmonic Drive AGHoenbergstrasse, 14, D-6555Limburg/Lahn Germany

San Jose Sales Office333 W. San Carlos Street Suite 1070San Jose, CA 95110

T: 800.921.3332T: 978.532.1800F: 978.532.9406www.HarmonicDrive.net

Rev_03_13

• The moment stiffnesses are average values.

Recommended bolt : JIS B 1176 socket head cap screw, Bolt strength: JIS B 1051, 12.9 or higher

The torque of the HPGP is higher than HPG Series and has a different number of bolts, size of bolts & PCD. Detailed drawings are available upon request.Recommended bolt : JIS B 1176 socket head cap screw, Bolt strength: JIS B 1051, 12.9 or higher

High Performance Gearhead for Servo Motors

ELECTROMATEToll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099www.electromate.com

Sold & Serviced By:

Nm lb-in lb-in lb-in lb-inNm Nm Nm r/min r/min

A

5,21,37,45

5,11,15,21,33,45

4,5,12,15,20,25

FO : Output FlangeJ20 : Shaft without a keyJ60 : Shaft with a key and center tapped hole

FO : Output Flange J2 : Shaft without a key J6 : Shaft with key and center tapped hole (J2 & J6 for size 65 are by special order only)

This code represents the motor mounting configuration. This code differs depending on the motor to be used. Please contact the Sales Division for the mounting codes of motors not listed in the matching table.

BL 1 : Backlash less than 1 arc-min. (Available size # 14-65)D : Input side contact sealed bearing (DDU)NR6 : Noise reduction, backlash less than 6 arc-min (Available size # 14-50 )Blank : Standard productSP : Custom Specification

HPGP,High-Torque,

11

14

20

32

50

65

11

14

20

32

50

65

52137455

11152133455

11152133455

11152133455

111521334545

12152025

3.4

4.6

7.810

12

13

21263233

39

87104122130

143

226266306346

359

665705798971

1,0601,130

30

41

6989

106106115115186230283292345345770920

1,0801,1511,2661,2662,0002,3542,7083,062

3,177

5,8866,2407,0638,5949,382

10,001

6.7

8

17

20

47607073

80

200

226

266

452532600

665

1,2001,3301,4601,730

2,000

59

71

150177177177177177416531620646708708

1,7702,0002,0002,0002,3542,3544,0014,7095,3105,8865,8865,886

10,62111,77112,92215,31217,70117,701

10

13

30

133

400

1,130

2,920

89

115

266

1,177

3,540

10,001

25,844

20

56

217

650

1,850

4,500

177

496

1,921

5,753

16,374

39,828

3,000

3,000

3,000

3,000

2,000

2,000

10,000

6,000

6,000

6,000

4,500

2,500

3,000

0.00400.0019

0.000690.00050

0.0230.0190.017

0.00930.00300.0028

0.200.170.16

0.0730.0300.023

1.1

0.770.370.170.126.24.23.71.7

0.750.5246*9

30*9

22*9

20*9

7.8*9

7.2*9

0.00240.0018

0.000660.00048

0.0170.0180.016

0.00900.00290.0027

0.160.170.15

0.0710.0290.022

0.81.0

0.740.350.170.124.94.03.51.6

0.720.50312120197.36.8

0.18

0.24

0.54

0.63

1.6

1.9

2.01.94.4

5.1

5.45.113

15

32*9

47*9

0.14

0.20

0.42

0.51

1.2

1.5

1.61.53.0

3.7

4.03.710

12

22

37

11

14

20

32

50

65

5

4

4

4

3

3

14.5

11.6

11.6

11.6

8.7

8.7

±30

±20

±15

±15

±15

±15

4.02.91.61.48.68.07.45.23.32.41915129.36.44.7332725221511804540362420

2882401251109584

0.350.260.140.120.760.710.70.50.30.21.71.31.10.80.60.42.92.42.21.91.31.07.14.03.53.22.11.82521111087

0.20

0.60

0.640.430.90

1.1

0.931.71.82.0

2.1

1.72.93.74.74.85.14.05.06.07.67.88.9

12

15171921

1.785.335.335.693.828.009.89.89.89.88.3

15.116.017.818.718.715.125.832.941.842.645.335.544.453.367.569.379.1107107133151169187

5.01.3

0.900.809.84.9

2.9

2.0

2815118.85.94.9733829241413

1306047402420

420360190160130110

0.440.120.080.070.90.40.30.30.20.22.51.31.00.80.50.46.53.42.62.11.21.2

11.55.34.23.52.11.8373217141210

arc min x10-4rad arc sec Ncm lb-in Nm lb-in Ncm lb-in5

2137455

11152133455

11152133455

11152133455

111521334545

12152025

HPGP 14 A 05 FO XXX SP

Rating Table

Performance Table High Performance Gearhead for Servo Motors

Dimensions

Ordering Code

Size

Size RevisionModel

Ratio

Ratio Output Shaft Options Special OptionsInput Shaft Configuration

Rated Torque at 3000rpm*1

Limit for RepeatedPeak Torque*3

Limit for Average Torque*2

Limit for Momentory

Torque*4

MaximumInput Speed*6

Max. Average Input Speed*5

Moment of Inertia*7

Input Shaft TypeWeight*8

Shaft x 10-4kg.m2 Shaft kgf Flange kgfFlange x 10-4kg.m2Gearheads w/Output

Positioning Accuracy *1 Backdriving Torque *4 No Load Running Torque *5Repeatability *2 Starting Torque *3

Size Ratio

Please contact our sales office for detailed dimensions.

Quick couple input shaft and motor flange allow easy mounting to a servo motor, the same as the conventional HPG series.

Easy mounting to a wide variety of servo motors.

Please contact our sales office for servo motors not listed in this brochure.In the future, additional motor manufacturers will be listed in the catalog and on our website.

Yaskawa Electric, Mitsubishi Electric, Fanuc, Panasonic, Sanyo Electric, Tamagawa Seiki, Fuji Electric, Omron, Toshiba Machine, Keyence.*1: Rated torque is based on an L10 life of 20,000 hours with an input speed of 3,000 rpm, which is the typical rated speed of servo motors. Rated input speed for sizes 50

and 65 are 2,000 rpm.*2: The limit for average torque is calculated based on the load torque pattern. *3: The limit for torque seen during start and stop cycles.*4: The limit for torque resulting from an emergency stop or from external shock loads. Always operate below this value. Calculate the permissible number of events to assure it meets the required operating conditions.*5: Maximum instantaneous input speed.*6: Maximum average input speed depends on the operating environment, but it is the limiting value for the continuous operating speed or the average input speed of a motion profile. Average input speed is limited due to heat generated in the reducer. *7: Inertia value is for the gearhead only*8: The weight is for the gearhead only. (Without input shaft coupling and motor flange )*9: Flange output is standard for the size 65 gearhead. Shaft type (J2 & J6) is available by special order only.

*1: Positioning accuracy represents the error between the theoretical and actual output angle. The values in the table are maximum values. *2: Repeatability is the difference in position measured after multiple movements to the same desired position from the same direction. The repeatability is defined as one half the value of the maximum difference measured, preceded by a ± sign. The values in the table are maximum values. *3: Starting torque is the torque required to begin rotation of the input element (high speed side), with no load applied to the output. The values in the table are maximum values. *4: Backdriving torque is the torque applied at the output side (low speed side) to begin rotation of the input element (high speed side). The values in the table are maximum values. *5: No-load running torque is the input torque required to rotate the input at 3,000 rpm with no load applied to the output.

ELECTROMATEToll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099www.electromate.com

Sold & Serviced By:

Nm lb-in lb-in lb-in lb-inNm Nm Nm r/min r/min

A

5,21,37,45

5,11,15,21,33,45

4,5,12,15,20,25

FO : Output FlangeJ20 : Shaft without a keyJ60 : Shaft with a key and center tapped hole

FO : Output Flange J2 : Shaft without a key J6 : Shaft with key and center tapped hole (J2 & J6 for size 65 are by special order only)

This code represents the motor mounting configuration. This code differs depending on the motor to be used. Please contact the Sales Division for the mounting codes of motors not listed in the matching table.

BL 1 : Backlash less than 1 arc-min. (Available size # 14-65)D : Input side contact sealed bearing (DDU)NR6 : Noise reduction, backlash less than 6 arc-min (Available size # 14-50 )Blank : Standard productSP : Custom Specification

HPGP,High-Torque,

11

14

20

32

50

65

11

14

20

32

50

65

52137455111521334551115213345511152133455111521334545

12152025

3.4

4.6

7.810

12

13

21263233

39

87104122130

143

226266306346

359

665705798971

1,0601,130

30

41

6989

106106115115186230283292345345770920

1,0801,1511,2661,2662,0002,3542,7083,062

3,177

5,8866,2407,0638,5949,382

10,001

6.7

8

17

20

47607073

80

200

226

266

452532600

665

1,2001,3301,4601,730

2,000

59

71

150177177177177177416531620646708708

1,7702,0002,0002,0002,3542,3544,0014,7095,3105,8865,8865,886

10,62111,77112,92215,31217,70117,701

10

13

30

133

400

1,130

2,920

89

115

266

1,177

3,540

10,001

25,844

20

56

217

650

1,850

4,500

177

496

1,921

5,753

16,374

39,828

3,000

3,000

3,000

3,000

2,000

2,000

10,000

6,000

6,000

6,000

4,500

2,500

3,000

0.00400.0019

0.000690.00050

0.0230.0190.017

0.00930.00300.0028

0.200.170.16

0.0730.0300.023

1.1

0.770.370.170.126.24.23.71.7

0.750.5246*9

30*9

22*9

20*9

7.8*9

7.2*9

0.00240.0018

0.000660.00048

0.0170.0180.016

0.00900.00290.0027

0.160.170.15

0.0710.0290.022

0.81.0

0.740.350.170.124.94.03.51.6

0.720.50312120197.36.8

0.18

0.24

0.54

0.63

1.6

1.9

2.01.94.4

5.1

5.45.113

15

32*9

47*9

0.14

0.20

0.42

0.51

1.2

1.5

1.61.53.0

3.7

4.03.710

12

22

37

11

14

20

32

50

65

5

4

4

4

3

3

14.5

11.6

11.6

11.6

8.7

8.7

±30

±20

±15

±15

±15

±15

4.02.91.61.48.68.07.45.23.32.41915129.36.44.7332725221511804540362420

2882401251109584

0.350.260.140.120.760.710.70.50.30.21.71.31.10.80.60.42.92.42.21.91.31.07.14.03.53.22.11.82521111087

0.20

0.60

0.640.430.90

1.1

0.931.71.82.0

2.1

1.72.93.74.74.85.14.05.06.07.67.88.9

12

15171921

1.785.335.335.693.828.009.89.89.89.88.3

15.116.017.818.718.715.125.832.941.842.645.335.544.453.367.569.379.1107107133151169187

5.01.3

0.900.809.84.9

2.9

2.0

2815118.85.94.9733829241413

1306047402420

420360190160130110

0.440.120.080.070.90.40.30.30.20.22.51.31.00.80.50.46.53.42.62.11.21.211.55.34.23.52.11.8373217141210

arc min x10-4rad arc sec Ncm lb-in Nm lb-in Ncm lb-in5

2137455111521334551115213345511152133455111521334545

12152025

HPGP 14 A 05 FO XXX SP

Rating Table

Performance Table High Performance Gearhead for Servo Motors

Dimensions

Ordering Code

Size

Size RevisionModel

Ratio

Ratio Output Shaft Options Special OptionsInput Shaft Configuration

Rated Torque at 3000rpm*1

Limit for RepeatedPeak Torque*3

Limit for Average Torque*2

Limit for Momentory

Torque*4

MaximumInput Speed*6

Max. Average Input Speed*5

Moment of Inertia*7

Input Shaft TypeWeight*8

Shaft x 10-4kg.m2 Shaft kgf Flange kgfFlange x 10-4kg.m2

Gearheads w/Output

Positioning Accuracy *1 Backdriving Torque *4 No Load Running Torque *5Repeatability *2 Starting Torque *3

Size Ratio

Please contact our sales office for detailed dimensions.

Quick couple input shaft and motor flange allow easy mounting to a servo motor, the same as the conventional HPG series.

Easy mounting to a wide variety of servo motors.

Please contact our sales office for servo motors not listed in this brochure.In the future, additional motor manufacturers will be listed in the catalog and on our website.

Yaskawa Electric, Mitsubishi Electric, Fanuc, Panasonic, Sanyo Electric, Tamagawa Seiki, Fuji Electric, Omron, Toshiba Machine, Keyence.*1: Rated torque is based on an L10 life of 20,000 hours with an input speed of 3,000 rpm, which is the typical rated speed of servo motors. Rated input speed for sizes 50

and 65 are 2,000 rpm.*2: The limit for average torque is calculated based on the load torque pattern. At this torque, life will be 2,000 hours or more when operated at an input speed of 2,000 rpm. *3: The limit for torque seen during start and stop cycles.*4: The limit for torque resulting from an emergency stop or from external shock loads. Always operate below this value. Calculate the permissible number of events to assure it meets the required operating conditions.*5: Maximum instantaneous input speed.*6: Maximum average input speed depends on the operating environment, but it is the limiting value for the continuous operating speed or the average input speed of a motion profile. Average input speed is limited due to heat generated in the reducer. *7: Inertia value is for the gearhead only*8: The weight is for the gearhead only. (Without input shaft coupling and motor flange )*9: Flange output is standard for the size 65 gearhead. Shaft type (J2 & J6) is available by special order only.

*1: Positioning accuracy represents the error between the theoretical and actual output angle. The values in the table are maximum values. *2: Repeatability is the difference in position measured after multiple movements to the same desired position from the same direction. The repeatability is defined as one half the value of the maximum difference measured, preceded by a ± sign. The values in the table are maximum values. *3: Starting torque is the torque required to begin rotation of the input element (high speed side), with no load applied to the output. The values in the table are maximum values. *4: Backdriving torque is the torque applied at the output side (low speed side) to begin rotation of the input element (high speed side). The values in the table are maximum values. *5: No-load running torque is the input torque required to rotate the input at 3,000 rpm with no load applied to the output.

ELECTROMATEToll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099www.electromate.com

Sold & Serviced By:

827149373885

3,222

0.883.016.842.1100364

84286

1,6204,0019,52334,518

9.5032.3183452

1,0763,900

9191,5873,8897,374

17,08533,272

40.970.6173328760

1,480

7011,1492,3834,6099,352

20,368

31.251.1106205416906

0.0060.0110.01150.0140.0190.023

0.02750.04050.0640.0850.1230.170

Nm lb-in x104

Nm/radx104

lb-in/rad

111420325065

x102Nm m lb x102N lb

4M16260255

2,2575,180

45,847

4M12190103912

2,03017,967

4M1013551.5456868

7,682

4M810526.1231428

3,788

4M3461.412

26.3233

114

M5706.356110974

14 20 32 50 65

mmNmlb-inNmlb-in

65503220114

M4184.540

25.3224

148

M4304.54084743

8M645

15.3135286

2,531

8M860

37.2329697

6,169

8M1290

128.41,1362,40621,295

8M16120319

2,8235,972

52,857

mmNmlb-inNmlb-in

HPGP

HPGP

HPGP

The HPGP series has achieved higher torque while maintaining high precision through use of our innovative ring-gear technology and high moment stiffness through use of an integral cross-roller output bearing. The HPGP series achieves longer life and can allow smaller gearheads to be used.

Harmonic Drive™

HPGP Series – High Performance Gearhead for ServomotorsHarmonic Drive now offers a NEW high-torque planetary gearhead based upon our high precision HPG Series HarmonicPlanetary® gears.

Application ExamplesRobot linear axis (rack and pinion) Machine tool gantry robot SCARA robot

Machine Tools Industrial Automation Industrial robots

Cross roller bearing

rack and pinion

belt

chain

Shielded input bearing

Motor mounting flange

Quick-Connect input couplingInnovative Ring Gear

The HPGP Series has 33% higher torque than the original HarmonicPlanetary® HPG SeriesSizeNumber of ScrewsSize of ScrewsPitch Circle Diameter

Torque TransmittingCapacity

Screw Tightening Torque

Number of ScrewsSize of ScrewsPitch Circle Diameter

Torque TransmittingCapacity

Screw Tightening Torque

Size

Pitch Circledp

OffsetR Basic Dynamic Load Rating C

Basic Load Rating Basic Static Load Rating Co

Allowable Moment Load Mc Moment Stiffness Km

Specification for Crossroller Bearing

Bolt Connection to Output Flange and Resulting Transmission Torque

Installation and Transmission Torque

HPGP Series HPG Series (Original product)

Output Flange Bolt Pattern Reference Drawing

The number of bolts, size of bolts & PCD vary depending on the size of the gear. Additionally, the HPGP Series has an added dowel pin hole.

Please refer to the Gearhead Series Catalog or contact our Sales Division for more information.

Rev_05_13

• The moment stiffnesses are average values.

Recommended bolt : JIS B 1176 socket head cap screw, Bolt strength: JIS B 1051, 12.9 or higher

The torque of the HPGP is higher than HPG Series and has a different number of bolts, size of bolts & PCD. Detailed drawings are available upon request.Recommended bolt : JIS B 1176 socket head cap screw, Bolt strength: JIS B 1051, 12.9 or higher

High Performance Gearhead for Servo Motors

ELECTROMATEToll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099www.electromate.com

Sold & Serviced By: