gtpei 2

-

Upload

sharjeel49 -

Category

Documents

-

view

217 -

download

0

Transcript of gtpei 2

8/6/2019 gtpei 2

http://slidepdf.com/reader/full/gtpei-2 1/8

1701 Military Trail Suite 110Jupiter, Florida 33458-7887

PH: 561-427-6401

FX: 561-427-6191www.fttinc.com

FLORIDA TURBINE TECHNOLOGIES, INC.

Turbine Effic ienc y Improvements for Existing Power Plants

“ How Tec hno log y Ca n Revolution ize Effic ienc y” Ms. Shirley C oates Brostm eyerChief Exec utive Officer, Florida Turbine Tec hno log ies, Inc .

Testimo ny be fore the Selec t Co mm ittee on Energy Inde pe nde nc e a nd Globa l Warming

US House of Representa tives

February 25, 2009

Summary:

• Natural g as-fired turb ines c urrently a c c ount for ove r 40% of the US elec trica l

ge neration c ap ac ity. Existing turbines c an be ma de m ore effic ient b y theinc orporation o f know n and new tec hnologies. Inc rea sing turbine effic ienc ybene fits c onsume rs by red uc ing the a mo unt of CO2 emissions, by red uc ing the

fuel req uired to g enerate the sam e a mo unt of elec tric ity, and by providing

ad ditional ca pa c ity beyond tha t ca used by the efficiency imp rovem ent.

• FTT has inven ted tec hnolog ies tha t c an b e retrofit into na tura l ga s-fired turb inepow er plants wo rldw ide to c rea te up to 15% mo re p ow er from the sam e p lants.Muc h of that p ow er is c om p letely ca rbo n-free and requires no a dditiona l fuel.

Ap p lica tion of this tec hno log y to e xisting US ga s turbine pow er plants c angenerate a n ad ditional 9GW of p owe r replac ing the e quivalent of 13 coa l

plants.

• The inco rporation of Spar-Shell Blade into ga s turb ine p lants ac c ount for two -thirds of the 15% tota l c apa c ity imp rovement and will help p ut our nation a t theforefront of a tec hnolog y that will have world -wide imp lica tions. Effic iency

imp rovements suc h a s these c an have a wo rld-wide imp ac t in CO2 em issionsand fuel usag e a nd so should be included in our nation’s renew ab le e nergy

polic y and plans.

Testimony:

Mr. Cha irma n a nd Mem be rs of the Com mittee, thank you for this op po rtunity to ad dress

you today. I am Shirley Brostmeye r, Chief Exec utive O ffic er of Florida TurbineTec hno log ies—a 185 pe rson sma ll business in Jup iter, Florida , spec ializing in turbinedesign and ma nufac turing. My c om pa ny deve lop s next-ge neration turbo ma c hinery

for the Air Force, Army, NASA, Dep artment of Energy, and as a sec ond -source supp lierto a irc raft a nd industrial turbine m anufa c turers. Florida Turbine Tec hno log ies, or FTT as it

is often c a lled , em p loys ma ny of the w orld ’ s foremo st expe rts in turb ine tec hnolog y.

While FTT ha s bee n in business for only ten years, we ha ve a lrea dy ma de m a jorc ont ributions to our na tion’s environm ent. The turbine effic iency imp rovem ents of my

8/6/2019 gtpei 2

http://slidepdf.com/reader/full/gtpei-2 2/8

FLORIDA TURBINE TECHNOLOGIES, INC. Page 2

sma ll comp any have helped to e liminate 30 million to ns of CO2 from the a tmo sphereeve ry yea r1. This is the eq uiva lent o f eliminat ing e ight c oa l plants from US soil. Suc h

d ram a tic imp rovements a re p ossible b ec ause a lmo st a ll of our pow er toda y isgene ra ted from turb ines. Even a sma ll improve me nt to the effic iency of these

ma c hines results in a huge red uc tion in the a mo unt of fuel burned and in CO 2em issions. For that rea son, turbine efficienc y imp rove me nt tec hnolog ies offer the m ost

nea r-term and c ost effective mea ns for ene rgy inde pe nde nc e. In my testimo ny toda y,I’ d like to share the importanc e o f a te c hnolog y that FTT is deve lop ing, ca lled the “ Spar-Shell Blade” , and othe r tec hnolog ies tha t will inc rea se turbine efficienc y. I wo uld like to

show why turb ine tec hnolog y should b e a n integ ra l pa rt of the d isc ussion regard ing“ How Tec hno logy Can Revo lution ize Effic ienc y ” .

Why is Turbine Efficienc y So Important?

A turb ine is a m ac hine that extrac ts ene rgy from the flow o f a fluid. The fluid c ould b ea ir (in the c ase o f wind turbines), stea m (as in co a l –pow ered turbines and turb ines in

nuc lea r plants), wa ter (as in hyd raulic turb ines), or comb ustion p rod uc ts (as in natural

gas turb ines or ae rospac e jet eng ines).

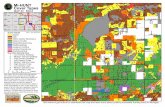

Turbines p rovide 97% of the c urren t USelec tric pow er and are used in a lmo sta ll pow er p lants: ga s-turb ine

combined-cycle, coal-poweredstea m p lants, nuc lea r plants,hydroe lec tric p lants, and eve n solar-

therma l p lants. The breakdown bytype of turb ine,2 shown in Figure 1,revea ls tha t over 80% of t he US

elec tric po wer generation c ap ac ity is

from therma l turb ines, in w hic h a t leastone form o f fuel (for exam ple: coa l,na tural g as, oil, syngas or b iomass) isburned to c rea te the hot g as or

wo rking fluid wh ic h rota te the turb ines.Natural g as-fired turb ines make up

53% of a ll the rma l turb ines, whichme ans tha t app roxima tely 41% of a llUS elec trica l gene ra tion capac ity is by

na tural-ga s fired turbines.

Ac c ording to the DOE’s Energy

Informa tion Ad ministra tion3, the netgene ra tion of elec tric ity from a ll ene rgy c onsumed during pow er gene ra tion is 34.5% .

This mea ns tha t nearly two-thirds of a ll pow er ge neration is lost in the energy c onversionproc ess (see Figure 2). In o ther wo rds, today’s elec trica l gene ra tion is, on the who le,

1 Based on replacement of coal-burning power plants.2 Electric Power Annual 2007, Energy Information Administration, US Dept of Energy, 2008, page 25.3 Annual Energy Review 2001, Energy Information Administration, US Dept of Energy, 2002, page 219.

US Electric Generation Capacity From Turbines(Total is 1053 gigaWatts)

Thermal

(coal, syngas,

natural gas, oil,

biomass)

81%

Wind (air)

2%

Geothermal

(hot gases)

0%

Nuclear

(uranium)

10%

Hydro

(elevated

water)

7%

Ref: Electric Power Annual 2007, Energy Information Administration,

Dept of Energy, 2008.

Figure 1: US Electric Generation Capacity from Turbines

8/6/2019 gtpei 2

http://slidepdf.com/reader/full/gtpei-2 3/8

FLORIDA TURBINE TECHNOLOGIES, INC. Page 3

on ly 34.5% effic ient. Bec ause c onversion losses a re so la rge, relative ly sma ll reduc tionsin losses (or improvem ents in effic ienc y) can yield substantia l increa ses in the energy

outp ut. In other words, for every one p er cent imp roveme nt in effic ienc y, the a vailableenergy is increased by 2.5%. Since turb ines make up nea rly a ll of the w orld’ s elec tric

ge neration c ap ac ity, inc rem enta l turbine effic ienc y imp roveme nts c an ha ve extrem ely

la rge imp ac ts on the bo ttom line of energy produc tion and fuel consump tion.

Energy

ConsumedTo Generate

Electricity100 %

ConversionLosses

65.4 %FossilFuels

70.6 %

Coal

51.6 %

Natural Gas15.2 %Other

Gases0.3 % Petroleum 3.5 %

Nuclear Electric Power

20.8 %

Renewable Energy 8.8 %

Other0.1 %

Hydroelectric

Pumped

Storage0.2 %

Unaccounted for

1.9 %

Electricity

Imports0.3 %

Electricity

Exports

0.2 %

Direct

Use1.8 %

Transportation 0.1 %

Plant Use 1.2 %

T&D Losses 3.1 %

Residential 10.6%

C o m m e r c i a l 10 .6 %

I n d u s t r i a l 8 .8 %

Gross

Generation

Of Electricity

34.6 %

Net

Generation

Of Electricity32.9 %

EndUse

31.9%

RetailSales

30.1%

Energy

ConsumedTo Generate

Electricity100 %

ConversionLosses

65.4 %FossilFuels

70.6 %

Coal

51.6 %

Natural Gas15.2 %Other

Gases0.3 % Petroleum 3.5 %

Nuclear Electric Power

20.8 %

Renewable Energy 8.8 %

Other0.1 %

Hydroelectric

Pumped

Storage0.2 %

Unaccounted for

1.9 %

Electricity

Imports0.3 %

Electricity

Exports

0.2 %

Direct

Use1.8 %

Transportation 0.1 %

Plant Use 1.2 %

T&D Losses 3.1 %

Residential 10.6%

C o m m e r c i a l 10 .6 %

I n d u s t r i a l 8 .8 %

Gross

Generation

Of Electricity

34.6 %

Net

Generation

Of Electricity32.9 %

EndUse

31.9%

RetailSales

30.1%

65% of energy is lost

due to inefficiencies

The m od ern pow er-ge nerating turbine ha s be en undergoing effic ienc y imp roveme ntssinc e its first prod uc tion. Co mb ined c yc le p lants, in whic h exhaust hea t from a g asturb ine is used to ma ke stea m to p ow er a sep arate turbine a lso p rod uc ing elec tric ity,

are the m ost effic ient a nd have be en in use sinc e 1968. Ma ny of tod ay’s op eratingpo we r-generating turbines we re de signe d ba sed on tec hnology tha t is 10 to 50 yea rsold. The la test technolog ies wo uld make them run cleaner and more effic iently. A

typica l la rge older ga s turbine used in c om bined c yc le a pp lic ations produc es 100 to250 me ga wa tts of po we r at 48-52% therma l effic ienc y; new c om bined -cyc le p ow er

p lants (designed w ithin the last ten ye ars) can see effic ienc ies as high a s 59%.

The imp ortanc e o f turb ine effic iency is roo ted in the follow ing points. When efficienc y is

increased:

1. Less fuel is req uired for the same amo unt o f energy p rod uc ed .

2. Less CO2 emissions a re g ene ra ted for the same amo unt of energy p rod uc ed

bec ause less fue l is used .

While co mb ined c yc le turbine p lants a re highly efficient, they are expensive to buildand take m any yea rs from initial co nc ep tion to c om p letion. As our world e nergyreq uirem ents c ontinue to inc rea se a t a la rming rates, our soc iety will nee d to keep o lder

Figure 2: Conversion Losses Account for Two-Thirds of Energy Consumption (Ref: Annual

Energy Review 2001, EIA, page 219, with percentage converted from absolute values by FTT).

8/6/2019 gtpei 2

http://slidepdf.com/reader/full/gtpei-2 4/8

8/6/2019 gtpei 2

http://slidepdf.com/reader/full/gtpei-2 5/8

FLORIDA TURBINE TECHNOLOGIES, INC. Page 5

FTT’ s Spa r-Shell tec hno logy leverages the exc ellent he a t resista nc e o f the refrac to ryme tal and c om b ines it w ith a n a dvanc ed design ap proac h – the Spa r-Shell Blad e – in

wh ic h the externa l surfac e o f the b lade exposed to the turb ine’ s hot g as, “ the Shell” , isc om posed of a refrac tory me tal while a n internal struc ture “ the Spa r” (co mp osed of

mo re c onve ntiona l ma teria ls) p rovides support. The Shell prote c ts the Spa r’ sc onventiona l ma teria ls from the ho t wo rking fluid of the op erating eng ine, as illustra ted

in Figure 3.

The Spar-Shell Blade a llow s the me ta l tem perature of the turb ine b lade to increase b y100 deg rees F, saving 50 - 75% of the a ir req uired to keep the b lad es “ c oo l”. Thesec hanges a llow fo r the o verall turb ine to op erate 3.5% more efficiently. In othe r wo rds, if

a ll the industria l ga s turbines in the US were ret ro fitted with Spa r-She ll b lad es, we wouldred uc e the fuel req uired by our po we r p rod uc ing p lants by 3.5% - essentia lly 12 days of

ene rgy c onsump tion for free . The Dep artme nt Of Energy ha s supported the Spar-ShellBlad e w ith Small Business Inno va tive Research g rants.

What Other Efficienc y Tec hno log ies Does FTT Work On?

FTT is a lso ac tively d eve lop ing o ther tec hnolog ies for imp roving the efficienc y o f

mo dern gas turbine powe r p lants. While a w ind turb ine is op en to the environm ent,ga s, stea m, and w ater turb ines a re c onstruc ted with cases a round the b lades to

c onta in and c ontrol the wo rking fluid . Every mo lec ule o f working fluid that the b lad edoes not e xtrac t wo rk from as it passes by, is c a lled “ lea kag e” wh ich a lso reduc es

turb ine e ffic iency. FTT is c urrently wo rking on m etho ds to c ont rol and limit the amo untof leakag es in turbines throug h advanc ed c lea ranc e c ontrol sc hemes and sea ling

technologies.

There a re o ther wa ys to increase turbine e ffic iency. Imp rove me nts in the surfac e finishof b lad es and c ases he lp to minimize losses in efficienc y. FTT is working on methods to

improve the surfac e finish suc h as bette r b lade c oa tings, imp roved we ar resistanc e,

and other surfac e trea tme nts.

The c om b ination o f a ll these tec hnologieswill help po we r prod uc ers ge t the mo stfrom their investme nts. Co mb ined, these

tec hnologies c ontribute to a tota l of 5%efficienc y imp rove me nts, with the Spa r-She ll Blad e m aking up 70% of the to ta l, as

shown in Figure 4

How Do Tec hnolog ies Lea d to Na tural Gas

Savings, Highe r Plant Ca pa c ity, and Lower

Emissions?

The e ffic ienc y imp rovem ent tec hnologiesde sc ribe d a bo ve ca n be inco rpo ratedinto existing combined cycle gas turbine

po wer plants to g enerate ad ditionalelec tric al ca pa c ity. This c apa c ity stems

from two sources:

Spar-Shell

Construction

with Advanced

Alloys

Total

Clearance

Improvements

Total

Leakage

Improvements

0%

1%

2%

3%

4%

Potential Efficiency Improvements For

Existing Turbine Power Plants

Figure 4: Efficiency Improvements Of Up To 5%

Have Been Identified

8/6/2019 gtpei 2

http://slidepdf.com/reader/full/gtpei-2 6/8

FLORIDA TURBINE TECHNOLOGIES, INC. Page 6

1. Air p reviously req uired for co oling the turb ine b lades is now c om busted with fuel,

to give ad ditional powe r output (“ upg rad ed p ow er c ap ab ility”)

2. The ra tio of c onversion of e lec tric ity from fuel is higher (“ turb ine efficienc y” )

The Spa r-Shell b lade a nd assoc iated efficienc y imp rove ments not o nly yield a dd itiona lelec tric ity for the same am ount o f fuel, these imp roveme nts allow the p ow er plant to

inc rea se the rated ge nerating c apa c ity. For every 100 MW of elec tric ity gene rate dbefo re the imp lem enta tion of Spar-Shell and othe r efficient tec hnolog ies, 5 MW ofad ditiona l elec tric ity is ge nerate d by the increase in e ffic ienc y (no ad ditiona l fuel is

req uired and no e missions a re g ene ra ted ). Further, bec ause o f the increa se in airthroug h the c om bustion p roc ess, an a dditiona l 10 MW of c lea n na tural ga s c om bined

c yc le po we r is gene ra ted to result in a to ta l of 15 MW add itiona l pow er (or 15%

increase).

This is illustra te d in Figure 5. For theUS na tura l ga s insta lled c apac ity

viable for Spar-Shell Blade, 60 GW of

US turbine c ap ac ity bec om es 69 GWof c apac ity. This add itiona l

c apa c ity is enoug h to po we r 4.5million hom es and is eq uiva lent tothe p rod uc tion o f 13 c oa l-fired

p lants. Further, the effic ienc yimp roveme nts c an b e a pp lied on a

wo rld -wide basis, whic h transla tes240 GW tota l world -wide natural gas

elec tric al c ap ac ity5 to 276 GW.

How does this efficienc yimp rovem ent c onvert to red uctionsin CO2 em issions? As mentioned in

the p revious sec tion, when the turbineis more effic ient , less fue l is required to

gene ra te the same amo unt of ene rgy, and less CO2 emissions a re g ene ra ted for thesame amo unt of ene rgy b ec ause less fuel is used . The c a lc ula ted 5% p lant effic iencyimprovem ent app lied to the 60 GW o f US turb ine c apac ity saves 15 million tons in US

CO2 produc tion annua lly due to Spa r-Shell and related te c hno log ies, relative to the

origina l pow er plant (and 60 million to ns of CO 2 saved per yea r wo rld -wide ).

How doe s this efficienc y imp rove me nt c onve rt to savings in oil? Measured in millions of

ba rrels of oil eq uivalent (mb oe ) pe r yea r, the na tura l gas savings due to efficienc yimprovem ents is 25 mb oe on a US basis and 100 mb oe world -wide .

When c om paring these striking numbers to o ther rec overy po lic y op tions, the

imp ortanc e o f turb ine effic ienc y truly stand s out. Developm ent rig a nd e ngineverific a tion will c ost an estimated $25 million. Imp lem enta tion to ge nerate 9GW ofadd itiona l US pow er will c ost $3-$5 billion w hich is a c ost of $300-$500 per kilowatt. One -

5 2005: Energy Information Administration (EIA), International Energy Annual 2005 (June-October 2007).

Figure 5: Efficiency Improvements Can Result in 15%

Increase in Power

8/6/2019 gtpei 2

http://slidepdf.com/reader/full/gtpei-2 7/8

8/6/2019 gtpei 2

http://slidepdf.com/reader/full/gtpei-2 8/8

FLORIDA TURBINE TECHNOLOGIES, INC. Page 8

The inc orporation o f Spar-She ll Blad e into ga s turbine p lants will he lp put our na tion a tthe forefront of a tec hnolog y that will have wo rld -wide imp lica tions. Effic iency

improve me nts suc h as these c an have a world -wide imp ac t in CO2 em issions and fue l

usag e a nd so should b e included in our nation’s renew ab le energy po lic y and plans.