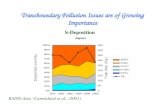

Growing Importance of Materials and Manufacturing Emissions

-

Upload

syaifullah-sulaiman -

Category

Documents

-

view

5 -

download

0

Transcript of Growing Importance of Materials and Manufacturing Emissions

w w w . a u t o s t e e l . o r g

Importance of Materials and Manufacturing Emissions for

Future Vehicle Considerations

George Coates

The Phoenix Group and WorldAutoSteel

w w w . a u t o s t e e l . o r g

Agenda

1. Growing importance of materials emissions

2. Life cycle assessment (LCA)

3. The need for vehicle life cycle thinking (case studies)

4. What the future holds. . .

w w w . a u t o s t e e l . o r g

Tailpipe Emissions Standards Are Becoming

more stringent Across The Globe

Source: International Council on Clean Transportation August 2011

How Do We Get Here?

Combination of technologies,

including lighter materials.

w w w . a u t o s t e e l . o r g

Steel

Aluminium Alloys

Magnesium Alloys

Glass Fiber RP *)

Carbon Fiber RP *)

100 600 500 400 300 200

Mass Reduction Potential of Automotive

Materials with regard to Tensile Stress

Tensile strength / density (σts/ρ in MPa·cm3/g)

Data Sources: Ashby 2005, fka 2006, WorldAutoSteel 2011

AHSS

*) RP: Reinforced polymer

w w w . a u t o s t e e l . o r g

Primary production of low-density automotive materials is GHG-intensive

Mild Steel

Aluminium

Magnesium

Carbon FRP

1575

‘Material’ GHG (in kg CO2e for same component, per 100 kg)

880

811

AHSS 173

230

Mid-Range CO2e Typical Part

Weight (kg)

2.3 100

2.3 75

12.1 67

31.5 50

22.0 40

The Problem with Tailpipe-only GHG

Emission Regulations

w w w . a u t o s t e e l . o r g

Result: overall GHG emissions increase

An unintended consequence of

tailpipe-only regulations

Vehicle Production

emissions

Tailpipe emissions

In the future 50% or more of total emissions unregulated

under the current approach

w w w . a u t o s t e e l . o r g

A different Way to Visualize Net GHG Emission Increase

due to Vehicle Light-weighting

Cumulative GHG emissions

Total

driven

distance

Use phase emissions

Vehicle production emissions

End of

vehicle life

w w w . a u t o s t e e l . o r g

Unintended Consequences –

More Common Than You May Think

w w w . a u t o s t e e l . o r g

Unintended Consequences –

More Common Than You May Think

w w w . a u t o s t e e l . o r g

Life Cycle Assessment

Important methodology to avoid unintended consequences

w w w . a u t o s t e e l . o r g

Who Uses LCA?

Many automotive OEMs, consumer products, material producers and their respective

trade organizations collect and report Life Cycle emissions performance. Here are

A few examples. . .

w w w . a u t o s t e e l . o r g

LCA Applied to Lotus Study of Toyota Venza (future concept)

Baseline Vehicle HD (Al-Mg-CFRP) Body LD (AHSS) Body

Source: International Council on Clean Transportation, Lotus Engineering Inc. study “An Assessment of Mass Reduction Opportunities for a 2017-2020 Model Year Vehicle Program”

12

HSS 9%

Mild Steel/Iron

88%

Paint/NVH 3%

HSS 7%

Al 37%

Composite 21%

Mg 30%

Paint/NVH 5%

HSS 89%

Mg 2%

Mild Steel/Iron

5%

Paint/NVH 4%

The need for vehicle Life Cycle Thinking

Low Development High Development

w w w . a u t o s t e e l . o r g

An independent* LCA evaluation of the Lotus Venza study demonstrates the unintended consequences of using the more CO2 intensive materials vs AHSS:

• Driving (Use Phase) emissions decrease by 6%

• Overall (Life Cycle) emissions increase by 7%

13

The need for vehicle Life Cycle Thinking

A more costly approach yields a less favorable result for the

environment. Use Production Recycling

Lotus HD

Body 1214 36,288 16,524 -5,508 47,304

Lotus LD

Body 1324 38,556 8,428 -3,078 43,902

GHG Emissions (CO2e)

Vehicle

Description

Curb

Wt

Total

Life

Cycle

* AM Kendall, UC-Davis

w w w . a u t o s t e e l . o r g

The need for vehicle Life Cycle Thinking

Let’s take the example of SuperLIGHT-CAR

• The Super LIGHT-Car (SLC) project was initiated in 2005 by a consortium of 38

leading European organizations, with Volkswagen serving as project coordinator.

• The primary goal of SLC was to develop a real, multi-material C-Class body structure

(BIW) that achieved a 30% weight reduction. Actual result - body structure mass was

reduced from 281 kg to 180 kg, a 36% reduction!

• The SLC study included a cost analysis, but did not include a life cycle assessment

(LCA). The cost of lightweighting in SLC was approximately 7.80 €/kg.

w w w . a u t o s t e e l . o r g

The need for vehicle Life Cycle Thinking

UCSB Materials Comparative Life Cycle Analysis of Super LIGHT Car

Emissions Performance (kg CO2e)

Vehicle Mass (kg) Material Recycling Use LifeCycle

Golf V (base) 281 kg 3,079 (1,333) 35,947 37,093

AHSS 230 kg 2,347 (970) 33,383 34,760

SLC 180 kg 4,777 (2,259) 32,165 34,683

Breakeven 187,316 km

w w w . a u t o s t e e l . o r g

Comparative Life Cycle Analysis of Super LIGHT Car

1. Multi-material vehicles have distinct emissions advantages in the use phase, but

distinct disadvantages in the production phase.

2. SuperLIGHT-CAR achieves only slightly lower life cycle emissions compared to the

AHSS-intensive concept, at a significantly higher cost.

It’s important to note that a high percentage of recycling is a fundamental

requirement of energy-intensive materials (magnesium and aluminium), in order to

offset their production emissions.

3. With advances in ICE powertrains, vehicle electrification (BEV, PHEV) and other fuel-

saving technology, dramatic reductions in use phase GHG emissions will occur, and

material production emissions will become an even larger percentage of total life cycle

emissions.

The need for vehicle Life Cycle Thinking

w w w . a u t o s t e e l . o r g

Component Study - GM Liftgate

20,000

25,000

30,000

35,000

40,000

45,000

Conv Steel AHSS Aluminium SMC CompLif

eti

me G

HG

’s (

kg C

O2 e

q/k

g)

LCA GHG Emissions for C-Class Vehicle

Liftgate Material

Emissions Performance (kg CO2e)

Liftgate Mtl Mass (kg) Material Recycling Use Life Cycle

Conv Steel 12.32 3,063 (978) 40,103 42,188

AHSS 7.81 3,046 (970) 40,070 42,146

Al 6.77 3,163 (1,044) 40,062 42,181

SMC 8.05 3,133 (960) 40,072 42,244

Total

Mass (kg)

Mass Savings

(kg) Cost

Difference

Δ $ / Δ kg

Baseline 12.32 --- --- ---

AHSS 7.81 4.51 $ -3.15 **

Aluminum 6.77 5.55 $ 28.54 5.14

Composite 8.05 4.27 $ 3.15 0.74

The need for vehicle Life Cycle Thinking

w w w . a u t o s t e e l . o r g

FSV Fabrication Process Parts Mass (kg)

Mfg Emissions

(kg CO2e/kg mtl) Avg Scrap (%)

Stamping 76 33 55

Stamping -Laser Welded Blanks 72 49 48

Hot Stamping 5 8 50

Hot Stamping - Laser Welded Blanks 17 38 41

Open Rollforming 4 1 3

Closed Rollforming 14 7 3

Total Body Structure Manufacturing 188 135

FSV Complete Assembly Process 66

Total FSV Body Structure 188 201 Avg = 46%

What About Manufacturing Emissions?

Let’s Examine

FutureSteelVehicle

Vehicle Material Use Recycling Fabrication Total CO2e

FSV-BEV 2,337 13,844 (1009) 201 15,373

w w w . a u t o s t e e l . o r g

Affect of alternative fuels and powertrains on carbon footprint

Fuel economy or tailpipe emissions standards are not enough to ensure

overall reductions in automotive GHG emissions.

Battery electric vehicle

What Does The Future Hold?

(BEV) with wind or solar electricity

(PHEV) with low carbon electricity

w w w . a u t o s t e e l . o r g

What Does The Future Hold?

Once we solve the GHG problem, we’ll focus on other impact categories. . .

and thus Life Cycle Assessment (LCA) will be a key strategy for the reduction

of harmful environmental contributors.

LCA assesses the potential environmental impacts of a product or service along

all stages of its life cycle and across a wide range of environmental concerns.

Vehicle

production

Vehicle

use

Vehicle

disposal

Climate Change

Human Toxicity

Acidification

Eutrophication…

w w w . a u t o s t e e l . o r g

Fresh Perspective

How much battery cost can be saved by 1 kg mass reduction?

0 €

2 €

3 €

5 €

7 €

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

5€

3€

2€

7€

1) New European Driving Cycle 2) WorldAutoSteel [EDAG 07/2009] 3) Bosch [Bulander 07/2011] 4) Volkswagen [Leohold 06/2011]

Today

Mid-term

Future

Additional cost for 1 kg mass reduction

• Advanced steel design: from 0 to +2 €/kg

• Light metal design: 4) from +6 to +9 €/kg

• CFRP structure: 4) more than +10€/kg

Input values from 2010 to 2020

– Driving Range NEDC: 1) 150 km

– Rolling resistance: 2) 0.010→0.007

– Battery cost: 3) 500→250 €/kWh

– Battery density: 100→150 Wh/kg

– Useable battery content: 80→90% SOC

– Batt.-to-Wheel efficiency: 68→81%

– Wheel-to-Batt. efficiency: 63→79%

1 kg mass savings at EV can save up to 5€ battery in 2012. This will

decrease year-to-year with advances in battery technology / cost reduction

AND powertrain / tire technology improvements.

Savings

Expenses

+8€/kg

Source: ThyssenKrupp Steel Europe

w w w . a u t o s t e e l . o r g

Lightweight, safe, green

• Expanded AHSS portfolio (22+ new grades)

• Expanded manufacturing technology portfolio for successful fabrication (17 processes)

• Aggressive design optimization technologies for competitive light-weighting

• Life cycle emissions performance showed superior vehicle carbon footprint

• Affordable solution for future vehicles

What Is The Steel Industry Doing?

FutureSteelVehicle

w w w . a u t o s t e e l . o r g

1) Developing Technical Capability

Life Cycle Models

• Enhancing UCSB GHG Materials Comparison Model

Version 3.0 on web at www.worldautosteel.org.

• GaBification for full environmental impact analysis

• Developing case studies for stakeholders

2) Developing Technical Credibility With LCA Experts

• Participation with WRI-WBCSD GHG Protocol Standards

• Member of UNEP-SETAC Life Cycle Initiative

• Working Group member of North American Automotive PCR. . .

3) Communicating With Our Stakeholders • OEM’s

• NGO’s and LCA Partners

• Regulators or Those That Influence Vehicle Emissions Policies

2

3

What Is The Steel Industry Doing?

w w w . a u t o s t e e l . o r g

Why Are We Participating?

• Common concerns regarding LCA include data quality, transparency, and methodology

consistency.

• Regulators are concerned over complexity of modifying fuel economy metric to a Life Cycle

metric.

• A PCR will bring guidance and standards to automotive LCA arguments.

• The steel industry has mature LCA and costing tools that benefit this program.

Prescription for the application of LCA to automotive design and

components selection.

NA – Product Category Rules (PCR) Program

w w w . a u t o s t e e l . o r g

Call to Policymakers in Automotive:

Measuring Automotive Emissions Requires LCA

Because

• LCA is the only accurate

methodology

• Provides the full picture

• Encourages the supply chain

to optimize environmental

performance

• Incentivizes the best design

selections, and hence works

best for the planet

Request for Action:

Shift from tailpipe

emissions regulations to

a life cycle assessment

approach that effectively

measures the carbon

footprint of today’s and

future cars.

w w w . a u t o s t e e l . o r g

Thank You!

w w w . a u t o s t e e l . o r g w w w . a u t o s t e e l . o r g

Great Designs in Steel is Sponsored by:

w w w . a u t o s t e e l . o r g

FSV Steel Portfolio

denotes steel included in ULSAB-AVC

Mild 140/270 DP 350/600

BH 210/340

BH 260/370 SF 570/640 DP 700/1000

IF 260/410 MS 950/1200

IF 300/420

DP300/500

DP 500/800

HSLA 350/450 TRIP 450/800

MS 1250/1500

HSLA 490/600

denotes steel grades added for FSV

Mild 140/270 DP 350/600 TRIP 600/980

BH 210/340 TRIP 350/600 TWIP 500/980

BH 260/370 SF 570/640 HSLA 700/780

BH 280/400 HSLA 550/650 DP 700/1000

IF 260/410 TRIP 400/700 CP 800/1000

IF 300/420 SF 600/780 MS 950/1200

DP300/500 CP 500/800 CP 1000/1200

FB 330/450 DP 500/800 DP 1150/1270

HSLA 350/450 TRIP 450/800 MS 1150/1400

HSLA 420/500 CP 600/900 CP 1050/1470

FB 450/600 CP 750/900 HF 1050/1500

HSLA 490/600 MS 1250/1500

Expanded Range of Steel Grades

w w w . a u t o s t e e l . o r g

Conventional Stamping

Laser Welded Blank

Tailor Rolled Blank

Induction Welded Hydroformed Tubes

Laser Welded Hydroformed Tubes

Tailor Rolled Hydroformed Tubes

Hot Stamping (Direct & In-Direct)

Laser Welded Blank Quench Steel

Tailor Rolled Blank Quench Steel

Roll Forming

Laser Welded Coil Rollformed

Tailor Rolled Blank Rollformed

Rollform with Quench

Multi-Walled Hydroformed Tubes

Multi-Walled Tubes

Laser Welded Finalised Tubes

Laser Welded Tube Profiled Sections

Broad Bandwidth of Manufacturing Options

Automotive Steel Technology