Grain Boundaries - mme.iitm.ac.in · Tilt and Twist Boundaries •Consider what happens when the...

Transcript of Grain Boundaries - mme.iitm.ac.in · Tilt and Twist Boundaries •Consider what happens when the...

• The grains in a single-phase polycrystalline specimen are generally in manydifferent orientations and many different types of grain boundary aretherefore possible.

• The nature of any given boundary depends on the misorientation of thetwo adjoining grains and the orientation of the boundary plane relative tothem.

• The lattices of any two grains can be made to coincide by rotating one ofthem through a suitable angle about a single axis.

• In general the axis of rotation will not be simply oriented with respect toeither grain or the grain-boundary plane, but there are two special types ofboundary that are relatively simple.

• These are pure tilt boundaries and pure twist boundaries,

Grain Boundaries

Tilt and Twist Boundaries

A tilt boundary occurs when the axis ofrotation is parallel to the plane of the boundary

A twist boundary is formed when the rotation axis is perpendicular to the boundary

Tilt and Twist Boundaries

• Consider what happens when the misorientation between two grains is smalI

• This type of boundary can be simply considered as an array of dislocations betweenthe grains

• Two idealized boundaries are symmetrical low-angle tilt and low-angle twistboundaries

• The low-angle tilt boundary is an array of parallel edge dislocations

• The twist boundary is a cross-grid of two sets of screw dislocations.

• In each case the atoms in the regions between the dislocations fit almost perfectlyinto both adjoining crystals whereas the dislocation cores are regions of poor fit inwhich the crystal structure is highly distorted.

• The tilt boundary need not be symmetrical with respect to the two adjoiningcrystals

Diagram of symmetric low-angle tilt grain boundary. (a) Two grains having a common [001] axis and angular difference in orientation of (b) two grains joined together to form a low-angle grain boundary made up of an array of edge dislocations.

Low angle Tilt and Twist Boundaries

Low-angle symmetric tilt boundary is an array of parallel edge dislocations

Low angle Tilt and Twist Boundaries

• The misorientation at the boundary is related to spacing between dislocations, D, by the following relation:

where b is the Burgers vector.

• As the misorientation increases, the spacing between dislocations is reduced, until, at large angles, the description of the boundary in terms of simple dislocation arrangements does not make sense.

bb

D

=

2sin2

(for very small)

Low angle Tilt and Twist Boundaries

The tilt boundary need not be symmetrical with respect to the two adjoining crystals. If the boundary is unsymmetrical dislocations with different Burgers vectors are required to accommodate the misfit

Low angle Tilt and Twist Boundaries

• A boundary consisting entirely of screw dislocations is called twist boundary, because the misorientation can be described by a relative rotation of two grains about an axis.

• Figure shows a twist boundary consisting of two groups of screw dislocations.

• It is possible to produce misorientations between grains by combined tilt and twist boundaries. In such a case, the grain boundary structure will consist of a network of edge and screw dislocations.

Low angle tilt and twist boundaries

Low-angle twist boundary.

Low angle tilt and twist boundaries

HRTEM picture of a small-angle tilt grain boundary

Low angle tilt and twist boundaries

Low angle tilt and twist boundaries

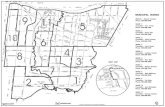

In general, a grain boundary has 5 degrees of freedom (macroscopic).

We need three degrees to specify the orientation of one grain with respect to the other

We need the other two degrees to specify the orientation of the boundary plane with respect to one of the grains.

The GB has 3 microscopic degrees of freedom (translation along x, y and z direction)

Grain Boundaries

Grain Boundaries

The energy of a low-angle grain boundary is simply the total energy of the dislocations within unit area of boundary

This depends on the spacing of the dislocations which, for the simple arrays is given by

Grain boundary energy

bb

D

=

2sin2

(for very small)

At very small values of the dislocation spacing is very large and the grain boundary energy is approximately proportional to the density of dislocations in the boundary (1/D) i.e.,

However as increases the strain fields of the dislocations progressively cancel out so that increases at a decreasing rate

Grain boundary energy

In general when > 10-15° the dislocation spacing is so small that the dislocation cores overlap and it is then impossible to physically identify the individual dislocations

At this stage the grain-boundary energy is almost independent of misorientation

When > 10-15° the boundary is known as a random high-angle grain boundary.

Grain boundary energy

High angle boundaries contain large areas of poor fit and have a relatively open structure. The bonds between the atoms are broken or highly distorted and consequently the boundary is associated with a relatively high energy.

Rafts of soap bubbles showing several grains of varying misorientation.

Grain boundary energy

Measured high-angle grain boundary energies Yb are often found to be roughly given by

b ~ 1/3 SV

Measured Grain Boundary Free Energies: Values selected from compilation given in Interfacial Phenomena in Metals and Alloys, by L.E. Murr, Addison-Wesley, London, 1975

Special High-Angle Grain Boundaries

Not all high-angle boundaries have an open disordered structure. There are somespecial high-angle boundaries which have significantly lower energies than therandom boundaries.

These boundaries only occur at particular misorientations and boundary planeswhich allow the two adjoining lattices to fit together with relatively littledistortion of the interatomic bonds.

The simplest special high-angle grain boundary is the boundary between twotwins.

If the twin boundary is parallel to the twinning plane the atoms in the boundaryfit perfectly into both grains

Special High-Angle Grain Boundaries

In fcc metals this is a {111} c1ose-packed plane. Because the atoms in theboundary are essentially in undistortedpositions the energy of a coherent twinboundary is extremely low incomparison to the energy of a randomhigh-angle boundary.

If the twin boundary does not lieexactly parallel to the twinning plane,the atoms do not fit perfectly into eachgrain and the boundary energy is muchhigher. This is known as an incoherenttwin boundary.

The energy of a twin boundary is therefore very sensitive to the orientation of the

boundary plane.

Special High-Angle Grain Boundaries

Twin-boundary energy as a function of the grain boundary orientation

Special High-Angle Grain Boundaries

Twin orientations in fcc metals correspond to a misorientation of 70.5° about a(110) axis. Therefore a twin boundary is a special high-angle grain boundary,and a coherent twin boundary is a symmetrical tilt boundary between the twotwin-related crystals.

Special High-Angle Grain Boundaries

Measured grain boundary energies for symmetric tilt boundaries in Al (a) when the rotation axis is parallel to [100], (b) when the rotation axis is parallel to [110].

G. Hasson and C. Goux, Scripta Metallurgica, 5 (1971) 889.

Special High-Angle Grain Boundaries

When the two grains are related by a rotation about a (100) axis, it can be seen thatmost high-angle boundaries have about the same energy

The structure is possibly a relatively disordered structure characteristic of randomboundaries

When the two grains are related by a rotation about a (110) axis there are severallarge-angle orientations which have significantly lower energies than the randomboundaries. = 70.5° corresponds to the coherent twin boundary,

Low-energy boundaries are also found for several other values of . The reasons forthese other special grain boundaries are not weIl understood.

However, it seems reasonable to suppose that the atomic structure of theseboundaries is such that they contain extensive areas of good fit.

This is a symmetrical tilt boundary between grains with a misorientation of 38.2°.

The boundary atoms fit rather weIl into both grains leaving relatively little freevolume. A small group of atoms (shaded) are repeated at regular intervals alongthe boundary.

Special High-Angle Grain Boundaries

Stacking Faults

Atomic packing CCP and HCP structures

Stacking Faults

Stacking Faults

(a) An edge dislocation with a Burgers vector b = a/6 [112] on (111). (Shockleypartial dislocation.) (b) The same dislocation locally changes the stackingsequence from fcc to hcp.

The gliding of Shockley partial dislocations therefore disrupts the crystal lattice andcauses a stacking fault over the area of glide plane swept by the dislocation

In thermodynamically stable fcc lattices the stacking fault is a region of high freeenergy.

On the other hand if the fcc lattice is only metastable with respect to the hcpstructure the stacking fault energy will be effectively negative and the gliding ofShockley partial dislocations will decrease the free energy of the system.

A sequence of Shockley partial dislocations between every other (111) plane willcreate a glissile interface separating fcc and hcp crystals

If the dislocation network glides into the fcc crystal it results in a transformation offcc to hcp, whereas a hcp to fcc transformation can be brought about by the reversemotion

Stacking Faults

Stacking Faults

Passage of Shockley partial dislocation on alternating slip planes results in fcc → hcp transition

Stacking Faults

An important characteristic of glissile dislocation interfaces is that they can produce a macroscopic shape change in the crystal

There are, however, two other Shockley partials which can also be used to transform fcc to hcp stacking, and if the transformation is achieved using all three partials in equal numbers there will be no overall shape change,

The formation of martensite in steel and other alloy systems occurs by the motion of sessile-dislocation interfaces.

These transformations are characterized by a macroscopic shape change and no change in composition.

However, the interface must be more complex than the fcc/hcp case

Stacking Faults

Deformation Twinning

Plastic deformation of all crystals is accomplished bythe moving dislocations through the crystal !

Sometimes crystals under stress deform by what iscalled twinning on just a few planes, and that looksquite different from the usual mechanisms wheredislocations provide for glide on many glide planes

Twinning happens very quickly. A specimendeforming by twinning often elongates by emittingaudible "shrieks". Bend a piece of zinc or tin and youhear it

The stress-strain curves then are serrated

Ref: https://www.tf.uni-kiel.de/matwis/amat/iss/kap_5/illustr/s5_4_3.html

Twinning leaves typical structures easily recognized. Typically, you see a lot ofstraight and parallel lines inside grains.

Deformation by twinning is more likely to occur at low temperatures.

Deformation by twinning is more likely to occur at high strain rates.

Deformation by twinning is more likely to occur in crystals with not so many glidesystems.

Crystals with fcc, bcc or hex lattices have 12, 12, or 3 glide systems, respectively,and that means that hexagonal crystals like Cd, Co, Mg, Ti, Zn or Zr will be morelikely to twinning than bcc and fcc metals

Deformation Twinning

The straight lines show "twins", while the curved lines denote regular grainboundaries. Dislocations ending at the surface give rise to the black dots.

Regular grain boundaries form during solidification when two independentlynucleated grains grow and finally meet.

Twin boundaries must have been formed by a twinning deformation, induced bythermal stresses induced during cooling.

Defect-etched surface of poly-crystalline silicon (Si).

Deformation Twinning

The region between two twin boundaries is the "twin". Note that the series of 4 twin boundaries / 3 "twins" is just about 20 nm wide and does not change the orientation of the crystal from the left to part to the right part. You wouldn't see it by light microscopy.

The bands (some of them striped) show twin boundaries.

The picture below shows that "one" black line of the picture above consists of several twins

Deformation Twinning

A perfect fcc element crystal projected along a <110> direction

Deformation under shear stress with dislocation glide

Deformation Twinning

Deformation by twinning

Deformation Twinning

The process of forming a four-layer deformation twin by the slip of four partials with the same Burgers vector (b1) on successive slip planes. (b) The process of forming a four-layer deformation twin by the slip of four partials with a mixture of Burgers vectors b1, b2, and b3 on successive slip planes

Deformation Twinning

The schematic of Hall–Petch relationship for twinning and full dislocation slip in coarse-grained metals and alloys. is the shear stress and d is the grain size. The higher slope for twinning indicates that twinning is more difficult than the slip of full dislocations in smaller grains.

Deformation Twinning

Annealing twins should be distinguished from mechanical twins.

In mechanical / deformation twins, the twin orientation is generated by a large deformation of a single grain. There is a lot of strain energy associated with the formation of a mechanical twin, whose shape is determined strictly by the need to minimise strain energy. Mechanical twins tend to be lenticular, i.e., lens shaped with sharp edges, since this reduces the long range elastic strains.

This contrasts with annealing twins where the shape is determined by the need to minimise interfacial energy.

Annealing twins, as you will see below, are not pointed since there is no deformation associated with their formation.

Annealing twins are formed as a consequence of growth accidents during the recrystallisation of deformed cubic-close packed metals such as alpha-brass, copper, nickel and austenitic iron

Annealing or recrystallization Twinning

•grain size;•temperature and time of annealing; •grain boundary velocity; •grain boundary energy; •twin boundary or stacking fault energy; •crystallographic texture; •degree of prior deformation; •presence of inclusions.

Annealing or recrystallization Twinning

Annealing twins were seen in gold as early as 1897

A great deal of empirical evidence suggests that the important factors determining the frequency with which they occur are

http://www.phase-trans.msm.cam.ac.uk/abstracts/annealing.twin.html

Annealing or recrystallization Twinning

Shows a recrystallised grain which is relatively free of dislocations, surrounded by a deformed matrix which has a high dislocation density. The recrystallised grain contains annealing twins

Twins are generated by adding {111} layers in a mirror-symmetric way,

There are other ways of doing it, too:

We can consider the twin boundary as a pure twist boundary

Twin Boundaries

https://www.tf.uni-kiel.de/matwis/amat/def_en/kap_7/backbone/r7_1_1.html

Twin Boundaries

We can consider the twin boundary as a pure tilt boundary also

Grain boundary can be generated by some coordinate transformation of one grain, and analyze its properties with respect to the necessary transformation matrix.

If there are several possible matrices, all producing the same final result, we have a problem in picking the "right" one

Grain Boundary Orientation and Energy

Grain boundary energy (= the energy needed to generate 1 cm2 of grain boundary) isa function of the 5 parameters needed to describe the boundary

For a given orientation, a small change in the three angles describing thatorientation could induce large changes in the energy

Lets assume a twist angle of e.g. 58° instead of 60°. We then make a boundary witha similar, but distinctly different orientation.

Nothing will fit any more; a lot of bonds must be stretched or shortened and bent tomake them fit and the energy will increase dramatically

The energy of a grain boundary is dependent very much on the precise orientationrelationship

Grain Boundary Orientation and Energy

Lets imagine the generation of a twin boundary where the twist or tilt angle is exactly right, but where the cut-plane is slightly off {111}.

The energy will be much higher than for a {111} plane

The energy of a grain boundary may dependent very much on the Miller Indices of its plane

Optimization of Grain Boundary Energies

Decompose the grain boundary plane into planes with low energies. If that cannot be done, form at least large areas on low-energy planes and small areas of connecting high-energy planes. In other words, approximate the plane by a zig-zag configuration of planes.

This process is called facet forming or facetting, the boundary plane forms facets

Facetting involves, of course, the movement of atoms. However, only small movements or movements over small distances are needed, so facetting is not too difficult if the temperatures are not too low.

So the crystal has an option - it can change the boundary plane by moving a few atoms around