+GF+ BS EN 10242

description

Transcript of +GF+ BS EN 10242

-

FM 20478

Patterns Sizes List Prices

Prices effective from 1st January 2012

Exclusive of VAT.

Malleable IronPipe FittingsBS EN 10242

-

2In 1802 Johann Conrad Fischer began producing cast iron in crucibles in a former herb mill in Schaffhausen, Switzerland that now forms the basis of a large industrial undertaking which is operative worldwide. Today George Fischer is a modern company with its headquarters in Switzerland and numerous production sites in Europe and overseas.

The GF Groups' special skills are in engineering, production, marketing and sales of high technology and quality processes, plants, systems and their components. The Group is divided into three operating divisions which cover a large part of the company's activities.

GF also offers competent product training and consultation given by experienced specialists.

Sales companies in all major countries and an extensive and highly qualified dealer network ensure availability at all times in conjunction with a modern logistics system.

Products from GF have become a byword with professionals and form an important part of the range of metal and plastic products necessary for pipeline construction in industry, building services and utility supply networks.

Quality, Standards and ApprovalsThe fittings are manufactured and distributed by GF companies that operate a quality assurance scheme in accordance with EN ISO 9001 & 9002.

The fittings comply with the standards ISO 49 and BS EN 10242, Design symbol A.

GF Malleable Iron Fittings are approved by Factory Mutual Research, for use in fire protection systems. GF are the only European produced fittings to be FM Approved and each fitting carries the FM symbol.

Full technical information is available in our Malleable Iron Pipe Fittings Technical Manual which may be viewed or downloaded from our website www.georgefischer.co.uk

George Fischer Ltd. Profile of a Company

-

Temperature ratings for GF unions

Type Fig. No. Temperature Limit

Flat Seat 92, 95, 100, 101, For GF gasket Fig. No. 202

330, 331, 332, +230C. If other gaskets

335, 336, 338 are used, consult manufacturer.

Taper Seat 96, 98, 102, 103, 300C

340, 341, 344

Bronze/Iron 342 210C

Double Bronze 342a 210C

Spherical Seat 346 300C

3

George Fischer Ltd. Profile of a Company

Working Pressures and Temperatures

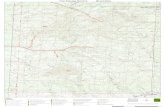

Working temperature and pressure ranges for malleable iron fittingsWorking temperature and pressure ranges for malleable iron fittings

Perm

issable w

orking pressure

bar

25

20

0

-20 0 120 320 C

Working temperature

The technical data given in this publication are for general information purposes only. They imply no warranty of whatever kind. Please consult our General Conditions of Supply, which is available on request.

Permissible working

pressure

-

4Assembly Method

The correct method of assembling a pipe joint is described below.

1. Apply the appropriate jointing compound.2. Engage the threads and tighten to the hand tight

position, which is designed to be at the gauge length.3. Using a wrench, continue to tighten. The number of

turns which are necessary to achieve a pressure tight seal is the wrenching allowance. For example, this is 11/2 turns for a 1 connection.If the size of the internal thread coincides with the

gauge plane on the external thread, then all of the fitting allowance may be used for tightening the joint, 13/4 turns for a 1 connection. Depending on the sizes of both threads, small variations to the number of turns may be required to position the outlet of the fitting or to adjust the length of the pipeline.

Thread Sealing Materials

The choice of thread sealant is dependent on the fluid and operating conditions. GF fittings are compatible with most materials and we would generally recommend using those that comply with BS EN 751.

GF fittings have parallel internal threads (Rp) and taper external threads (R) to ISO 7. During assembly of parallel (Rp) GF fittings, the joint may be turned back up to 45 without leakage, if the thread sealing material complies with BS EN 751, Part 2, Class ARp.

Position after wrenching

Hand tight position

-

5Assembly Method Malleable Iron Pipe Fittings with GF Fig Nos

32a1a 21

545351504140

60 85 87 90

92 94 95 96 97

10398 100 101 102

132130 131121120

-

6133 135134 137 165

180 220 221 223

240 241 245 246

260 270 271 280 281

290 291 294 300 310

312 321 326 329

Malleable Iron Pipe Fittings with GF Fig Nos contd

-

7330 331 332 335 336

342a338 340 342341

344 346 370 371 372

373 374 376 378 471

529a526 534 595536

933a933599a596

-

8 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.1 (ISO G4)Long Sweep Bend 90 M & F Equal

Size Black Galvanised

1/8 600 1046 1/4 414 723 3/8 460 806 1/2 508 887 3/4 811 1267 1 1165 2038 11/4 2351 3707 11/2 3107 4891 2 5296 8337 21/2 10841 17628 3 15187 24698 4 27614 44908

Fig.2 (ISO G1)Long Sweep Bend 90F. Equal

Size Black Galvanised

1/4 414 723 3/8 508 887 1/2 477 836 3/4 827 1452 1 1137 1987 11/4 2427 3822 11/2 2960 4663 2 4118 6484 21/2 11050 17971 3 14995 24386 4 28403 46186

Fig.1a(ISO D4)Short Bend 90 M & F Equal

Size Black Galvanised

1/4 452 791 3/8 539 945 1/2 378 670 3/4 554 1101 1 819 1543 11/4 1407 2718 11/2 2219 3984 2 3880 6865 21/2 7046 11464 3 12651 20589 4 31340 50997

Fig.2a(ISO D1)Short Bend 90 F. Equal

Size Black Galvanised

1/4 539 945 3/8 398 698 1/2 348 685 3/4 496 981 1 702 1373 11/4 1434 2554 11/2 1914 3045 2 2694 4800 21/2 5754 11464 3 11665 19831 4 25571 41607

-

9Prices are per 100Prices are per 100

Size Black Galvanised

1/4 1092 1907 3/8 944 1652 1/2 1141 1991 3/4 1277 2238 1 1877 3287 11/4 4303 6785 11/2 6038 9516 2 7205 11344 21/2 N/A 24915

Fig.40 (ISO G4/45)Long Sweep Bend 45M & F Equal

Size Black Galvanised

1/4 748 1304 3/8 681 1189 1/2 477 936 3/4 721 1258 1 1044 1823 11/4 2187 3446 11/2 2647 4168 2 4172 6571 21/2 11627 18908 3 13272 21584 4 30282 49248

Fig.41 (ISO G1/45)Long Sweep Bend 45 F. Equal

Size Black Galvanised

3/8 831 1453 1/2 819 1430 3/4 1025 1789 1 1352 2359 11/4 2877 4531 11/2 3762 5919 2 5200 8184 21/2 9854 16026 3 12959 21073 4 N/A 46253

Fig.50 Bend 30 M & F Equal

Size Black Galvanised

1/2 N/A 1389 3/4 N/A 1879 1 N/A 3080 11/4 N/A 5310 11/2 N/A 6951 2 N/A 8266 21/2 N/A 17974 3 N/A 25562 4 N/A 51123

Fig.3 (ISO G8)Long Sweep Bend 90M. Equal

-

10 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.51Bend 30F. Equal

Size Black Galvanised

1/2 N/A 1879 3/4 N/A 2591 1 N/A 3452 11/4 N/A 5796 11/2 N/A 7095 2 N/A 10377

Fig.53Bend 15 M & F Equal

Size Black Galvanised

1/2 N/A 1690 3/4 N/A 2253 1 N/A 2740 11/4 N/A 4134 11/2 N/A 5514 2 N/A 7216 21/2 N/A 15620

Fig.54 Bend 15 F. Equal

Size Black Galvanised

1/2 N/A 2216 3/4 N/A 2779 1 N/A 4055 11/4 N/A 6604 11/2 N/A 8104 2 N/A 10537

Fig.60ISO kb1 Return BendF. Equal

Size Black Galvanised

1/2 2004 3508 3/4 3240 5672 1 4042 7073 11/4 6767 9370 11/2 8060 12692 2 12300 19371

Fig. 85 CrossoverF. Equal

Size Black Galvanised

3/8 1003 1755 1/2 705 1384 3/4 1216 2126 1 2187 3822 11/4 5417 8527 1/2 - 3/4 1541 2693

-

11Prices are per 100Prices are per 100

Fig. 87 Tee with Crossover BranchF. Equal

Size Black Galvanised

1/2 N/A 3354

Fig.90 (ISO A1)Elbow 90F. Equal

Size Black Galvanised

1/8 309 681 1/4 219 384 3/8 219 384 1/2 194 338 3/4 267 463 1 410 719 11/4 810 1432 11/2 1361 2146 2 1594 2509 21/2 3442 5601 3 5057 8226 4 12408 16697

Fig.90 (ISO A1)Elbow 90F. Reducing

Size Black Galvanised 1 2

1/4 - 1/8 794 1384 3/8 - 1/4 436 795 1/2 - 1/4 698 1268 1/2 - 3/8 420 771 3/4 - 3/8 592 925 3/4 - 1/2 366 810 1 - 1/2 421 839 1 - 3/4 567 1106 11/4 - 1/2 883 1708 11/4 - 3/4 1359 2339 11/4 - 1 849 1564 11/2 - 3/4 1618 3013 11/2 - 1 1546 2877 11/2 - 11/4 2188 4076 2 - 1 2721 5068 2 - 11/4 3561 6632 2 - 11/2 3010 5134 21/2 - 2 N/A 13463

1

-

12 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.92 (ISO A4)Elbow 90M & F Equal

Size Black Galvanised

1/8 352 619 1/4 231 406 3/8 261 489 1/2 217 381 3/4 291 507 1 483 846 11/4 956 1831 11/2 1603 2527 2 2064 3252 21/2 4458 9230 3 7753 12620 4 13557 22066

Fig.94 Elbow 90M. Equal

Size Black Galvanised

3/8 849 1482 1/2 628 1149 3/4 683 1341 1 1198 2092 11/4 2146 3449 11/2 3925 6305 2 4050 6508

Size Black Galvanised 1 2

1/2 - 3/8 1171 2048 3/4 - 1/2 1097 1923 1 - 1/2 911 1473 1 - 3/4 1516 2657 11/4 - 3/4 N/A 3547 11/4 - 1 1799 2890 11/2 - 1 4724 7438 11/2 - 11/4 3399 5354

1

2Fig.92 (ISO A4)Elbow 90M & F Reducing(reducing male thread)

Size Black Galvanised 1 2

3/8 - 1/2 800 1396 1/2 - 3/4 1258 2854 3/4 - 1 1841 4190 1 - 11/4 3319 5381

1

2Fig.92(ISO A4)Elbow 90M & F Reducing(reducing female thread)

-

13Prices are per 100Prices are per 100

Fig.96(ISO UA11) Union Elbow 90Taper Seat F. Equal

Size Black Galvanised

1/4 2148 3754 3/8 1949 3405 1/2 1620 2947 3/4 1893 3443 1 2737 4738 11/4 4068 6407 11/2 4610 7261 2 7110 12571 21/2 19646 31946 3 25381 41276

Size Black Galvanised 374(G)

3/8 (3/4) 1874 3269 1/2 (1) 1566 2735 3/4 (11/4) 1719 3004 1 (11/2) 1937 3383 11/4 (2) 3955 6227 11/2 (21/4) 6249 9842 2 (23/4) 9228 14532

95ET

374

372

G

Fig.95(ISO UA1) Union Elbow 90Flat Seat F. Equal

Size Black Galvanised Rp G

1/2 1 N/A 1073 3/4 11/4 765 1336 1 11/2 1132 1980 11/4 2 2549 4016 11/2 21/4 3660 5766 2 23/4 5312 8363

Rp

GFig.95ET Union Elbow Body 90

Size Black Galvanised 374(G)

3/8 (3/4) 1582 2766 1/2 (1) 1432 2501 3/4 (11/4) 1949 3405 1 (11/2) 2184 3813 11/4 (2) 4545 7156 11/2 (21/4) 6801 10709 2 (23/4) 10220 16098

95ET

374

371

Fig.97(ISO UA2) Union Elbow 90Flat Seat M & F. Equal

-

14 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.98(ISO UA12) Union Elbow 90Taper Seat M & F Equal

Size Black Galvanised

1/4 1841 3219 3/8 1688 2950 1/2 1727 3024 3/4 2163 3788 1 3037 5317 11/4 4278 6734 11/2 5178 8158 2 8365 13176 21/2 22116 35967 3 29943 48695

Size Black Galvanised 374(G)

1/2 (1) 2320 4054 3/4 (11/4) 2702 4721 1 (11/2) 3139 3890

100ET

374

372

G

Fig.100 Union Elbow 90Flat Seat M & F. Equal

Fig 10 0 are supplied without gaskets, which should be ordered separately. See page 36 for gaskets (Fig. 202)

Size Black Galvanised 374(G)

1/2 (1) 2320 4054 3/4 (11/4) 2865 5006 1 (11/2) 3302 5768

100ET

374

371

G

Fig.101Union Elbow 90Flat Seat M. Equal

Size Black Galvanised R G

1/2 (1) 1365 2386 3/4 (11/4) 1719 3004 1 (11/2) 2102 3890

R

GFig.100 ETUnion Elbow Body 90

Fig.102 Union Elbow 90Taper Seat M & F. Equal

Size Black Galvanised

1/2 2402 4197 3/4 2950 5152 1 3494 6103

Fig 101 are supplied without gaskets, which should be ordered separately. See page 36 for gaskets (Fig. 202)

-

15Prices are per 100Prices are per 100

Fig.120(ISO A1/45) Elbow 45F. Equal

Size Black Galvanised

3/8 586 1073 1/2 462 875 3/4 569 1079 1 846 1483 11/4 1868 3302 11/2 2292 3881 2 3145 5323 21/2 4598 8160 3 8797 14316

Fig.121 (ISO A4/45)Elbow 45M & F Equal

Size Black Galvanised

3/8 523 915 1/2 473 902 3/4 595 1181 1 903 1771 11/4 1997 3857 11/2 2287 4109 2 3273 5387 21/2 6382 10383 3 9310 15144

Fig.130 (ISO B1)Tee 90F. Equal

Size Black Galvanised

1/8 396 724 1/4 341 597 3/8 288 540 1/2 267 463 3/4 387 678 1 556 973 11/4 1100 1962 11/2 1690 2685 2 2433 3868 21/2 5334 9889 3 6493 10567 4 14976 20894

Fig.103 Union Elbow 90Taper Seat M. Equal

Size Black Galvanised

1/2 2456 4292 3/4 3056 5341 1 3494 6103

-

16 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.130 (ISO B1) Tees 90Reducing on branch

Size Method b UK Size Method a Black Galvanised (1)=(2) - (3) 1=3 - 2

3/8 - 1/4 3/8 - 1/4 988 1599 1/2 - 1/4 1/2 - 1/4 692 1169 1/2 - 3/8 1/2 - 3/8 537 869 3/4 - 1/4 3/4 - 1/4 909 1469 3/4 - 3/8 3/4 - 3/8 666 1076 3/4 - 1/2 3/4 - 1/2 348 694 1 - 1/4 1 - 1/4 1591 2785 1 - 3/8 1 - 3/8 1029 1798 1 - 1/2 1 - 1/2 483 946 1 - 3/4 1 - 3/4 574 1079 11/4 - 3/8 11/4 - 3/8 1792 2822 11/4 - 1/2 11/4 - 1/2 956 1831 11/4 - 3/4 11/4 - 3/4 1048 2024 11/4 - 1 11/4 - 1 1083 1994 11/2 - 3/8 11/2 - 3/8 2432 3833 11/2 - 1/2 11/2 - 1/2 1217 2167 11/2 - 3/4 11/2 - 3/4 1473 2498 11/2 - 1 11/2 - 1 1432 2527 11/2 - 11/4 11/2 - 11/4 1872 4044 2 - 1/2 2 - 1/2 1882 3216 2 - 3/4 2 - 3/4 2553 4931 2 - 1 2 - 1 2129 3355 2 - 11/4 2 - 11/4 2553 5753 2 - 11/2 2 - 11/2 3168 6637 21/2 - 1/2 21/2 - 1/2 3604 7463 21/2 - 3/4 21/2 - 3/4 7265 11827 21/2 - 1 21/2 - 1 5163 8400 21/2 - 11/4 21/2 - 11/4 5855 9953 21/2 - 11/2 21/2 - 11/2 6292 10239 21/2 - 2 21/2 - 2 6292 10239 3 - 1/2 3 - 1/2 7515 14439 3 - 3/4 3 - 3/4 8069 15508 3 - 1 3 - 1 9574 15575 3 - 11/4 3 - 11/4 9574 15575 3 - 11/2 3 - 11/2 8242 13412 3 - 2 3 - 2 8508 13845 3 - 21/2 3 - 21/2 15389 25048 4 - 1 4 - 1 19946 32456 4 - 11/2 4 - 11/2 16925 27544 4 - 2 4 - 2 14085 22921 4 - 21/2 4 - 21/2 N/A 35362 4 - 3 4 - 3 21729 35362

1 (1)

2 (3)

3 (2)

All Tees shown follow the U.K. convention for numbering outlets. (Method "b"). This will be phased out from the year 2000 in favour of the international method "a".NB. In the U.K. the convention for numbering Tees is to show the first and second sizes as the run and the third size as the branch. (method "b")The international convention for numbering Tees is to show the first and third sizes as the run with the second size as the branch. (method "a")For both Method "a" and "b", if the outlets on the run are the same size and the branch is increasing or reducing, the Tee is specified by the size of the run followed by the branch, e.g. 1 x 3/4.

-

17Prices are per 100Prices are per 100

Size Method b UK Size Method a Black Galvanised (1)=(2) - (3) 1=3 - 2

3/8 - 1/2 3/8 - 1/2 730 1055 1/2 - 3/4 1/2 - 3/4 547 1041 1/2 - 1 1/2 - 1 1147 2028 3/4 - 1 3/4 - 1 960 1816 1 - 11/4 1 - 11/4 1634 3184 1 - 11/2 1 - 11/2 2187 3732 11/4 - 11/2 11/4 - 11/2 2860 4504 11/4 - 2 11/4 - 2 3510 5993 11/2 - 2 11/2 - 2 3254 6060 2 - 21/2 2 - 21/2 5339 9410

1 (1)

2 (3)

3 (2)

Fig.130(ISO B1)Tee 90Increasing on branch

Size Method b UK Size Method a Black Galvanised (1) (2) (3) 1 2 3

1/2 - 3/8 - 1/2 1/2 - 1/2 - 3/8 995 1441 3/4 - 3/8 - 3/4 3/4 - 3/4 - 3/8 870 1522 3/4 - 1/2 - 3/4 3/4 - 3/4 - 1/2 586 1297 1 - 3/8 - 1 1 - 1 - 3/8 1294 2262 1 - 1/2 - 1 1 - 1 - 1/2 865 1915 1 - 3/4 - 1 1 - 1 - 3/4 978 1849 11/4 - 1/2 - 11/4 11/4 - 11/4 - 1/2 1874 3492 11/4 - 3/4 - 11/4 11/4 - 11/4 - 3/4 2204 4108 11/4 - 1 - 11/4 11/4 - 11/4 - 1 1874 3492 11/2 - 1/2 - 11/2 11/2 - 11/2 - 1/2 2667 4967 11/2 - 3/4 - 11/2 11/2 - 11/2 - 3/4 3209 5478 11/2 - 1 - 11/2 11/2 - 11/2 - 1 2978 5545 11/2 - 11/4 - 11/2 11/2 - 11/2 - 11/4 3154 5873 2 - 1/2 - 2 2 - 2 - 1/2 5865 10921 2 - 3/4 - 2 2 - 2 - 3/4 4011 6848 2 - 1 - 2 2 - 2 - 1 3752 6985 2 - 11/4 - 2 2 - 2 - 11/4 4584 8535 2 - 11/2 - 2 2 - 2 - 11/2 4252 7258 21/2 - 1 - 21/2 21/2 - 21/2 - 1 N/A 20449 21/2 - 11/2 - 21/2 21/2 - 21/2 - 11/2 9831 17329 21/2 - 2 - 21/2 21/2 - 21/2 - 2 N/A 20954 3 - 2 - 3 3 - 3 - 2 N/A 25997

1 (1)

2 (3)

3 (2)

Fig.130 (ISO B1)Tees 90Reducing on run

Size Method b UK Size Method a Black Galvanised (1) (2) (3) 1 2 3

1/2 - 3/8 - 3/8 1/2 - 3/8 - 3/8 705 1020 3/4 - 1/2 - 1/2 3/4 - 1/2 - 1/2 450 1072 1 - 1/2 - 1/2 1 - 1/2 - 1/2 1095 1911 1 - 3/4 - 3/4 1 - 3/4 - 3/4 770 1461 11/4 - 3/4 - 3/4 11/4 - 3/4 - 3/4 1845 2906 11/4 - 1 - 1 11/4 - 1 - 1 1198 2807 11/2 - 1 - 1 11/2 - 1 - 1 2088 3560 11/2 - 11/4 - 11/4 11/2 - 11/4 - 11/4 1872 4381 2 - 11/4 - 11/4 2 - 11/4 - 11/4 3595 6693 2 - 11/2 - 11/2 2 - 11/2 - 11/2 3344 6230 21/2 - 2 - 2 21/2 - 2 - 2 7349 15217 3 - 2 - 2 3 - 2 - 2 N/A 19027

1 (1)

2 (3)

3 (2)

Fig.130(ISO B1) Tees 90Reducing on run/branch

-

18 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Size Method b UK Size Method a Black Galvanised (1) (2) (3) 1 2 3

3/4 - 1/2 - 3/8 3/4 - 3/8 - 1/2 811 1171 1 - 3/4 - 1/2 1 - 1/2 - 3/4 661 1461 11/4 - 1 - 1/2 11/4 - 1/2 - 1 1125 2637 11/4 - 1 - 3/4 11/4 - 3/4 - 1 1642 2807 11/2 - 11/4 - 1/2 11/2 - 1/2 - 11/4 1448 3392 11/2 - 11/4 - 3/4 11/2 - 3/4 - 11/4 2432 3833 11/2 - 11/4 - 1 11/2 - 1 - 11/4 1916 4005 2 - 11/2 - 1/2 2 - 1/2 - 11/2 2830 5272 2 - 11/2 - 3/4 2 - 3/4 - 11/2 3590 6129 2 - 11/2 - 1 2 - 1 - 11/2 3308 6163 2 - 11/2 - 11/4 2 - 11/4 - 11/2 3151 6129

1 (1)

2 (3)

3 (2)

Fig.130 (ISO B1) Tees 90Reducing on runReducing on branch

Size Method b UK Size Method a Black Galvanised (1) (2) (3) 1 2 3

3/4 - 3/8 - 1/2 3/4 - 1/2 - 3/8 1419 2049 3/4 - 1/2 - 1 3/4 - 1 - 1/2 1139 2028 1 - 1/2 - 3/4 1 - 3/4 - 1/2 960 1678 1 - 3/4 - 11/4 1 - 11/4 - 3/4 1930 3402 11/4 - 3/4 - 1 11/4 - 1 - 3/4 1805 2968 11/4 - 1 - 11/2 11/4 - 11/2 - 1 2848 4575 11/2 - 1 - 11/4 11/2 - 11/4 - 1 2968 4675 11/2 - 11/4 - 2 11/2 - 2 - 11/4 4135 7851

1 (1)

2 (3)

3 (2)

Size Method b UK Size Method a Black Galvanised (1) = (2) = (3) 1 = 2 = 3

1/2 1/2 812 1872 3/4 3/4 1011 2309 1 1 1517 3464 11/4 11/4 2490 5005 11/2 11/2 3849 7737 2 2 5405 10865 21/2 21/2 9117 15455 3 3 14229 24118 4 4 32013 54265

1 (1)

2 (3)

3 (2)

Fig.131(ISO E1) Pitcher Tee 90F. Equal

All Tees shown follow the U.K. convention for numbering outlets. (Method "b"). This will be phased out from the year 2000 in favour of the international method "a".NB. In the U.K. the convention for numbering Tees is to show the first and second sizes as the run and the third size as the branch. (method "b")The international convention for numbering Tees is to show the first and third sizes as the run with the second size as the branch. (method "a")For both Method "a" and "b", if the outlets on the run are the same size and the branch is increasing or reducing, the Tee is specified by the size of the run followed by the branch, e.g. 1 x 3/4.

Fig.130 (ISO B1) Tees 90Reducing on run Reducing or increasing on branch

-

19Prices are per 100Prices are per 100

Size Method b UK Size Method a Black Galvanised (1) (2) (3) 1 2 3

3/4 - 1/2 - 1/2 3/4 - 1/2 - 1/2 1109 2905 3/4 - 1/2 - 3/4 3/4 - 3/4 - 1/2 1423 3583 1 - 3/4 - 1/2 1 - 1/2 - 3/4 1201 3253 1 - 3/4 - 3/4 1 - 3/4 - 3/4 1526 3791

1 (1)

2 (3)

3 (2)

Fig.131(ISO E1) Pitcher Tee 90 Reducing on branch

Size Method b UK Size Method b Black Galvanised (1) = (2) - (3) 1 = 2 - 3

3/4 - 1/2 3/4 - 1/2 975 2552 1 - 1/2 1 - 1/2 1420 3720 1 - 3/4 1 - 3/4 1242 3226 11/4 - 1/2 11/4 - 1/2 2772 6391 11/4 - 3/4 11/4 - 3/4 2767 6314 11/4 - 1 11/4 - 1 3373 7699 11/2 - 1/2 11/2 - 1/2 2701 5904 11/2 - 3/4 11/2 - 3/4 3341 7624 11/2 - 1 11/2 - 1 3801 8072 11/2 - 11/4 11/2 - 11/4 4489 9530 2 - 1/2 2 - 1/2 5011 N/A 2 - 3/4 2 - 3/4 4617 10540 2 - 1 2 - 1 4892 10392 2 - 11/4 2 - 11/4 6159 13078 2 - 11/2 2 - 11/2 7215 15323 21/2 - 11/4 21/2 - 11/4 N/A 22510 3 - 2 3 - 2 17872 30293

1 (1)

2 (3)

3 (2)

All above tees are numbered according to the UK convention. (i.e. (1) & (2) are the run). method "b" International numbering shows outlet (2) & (3) reversed. (i.e. 1 & 3 are the run). method "a"

Fig.132(ISO E2) Twin Elbow 90F. Equal

Size Black Galvanised

1/2 1114 2585 3/4 1233 2857 1 2227 4625 11/4 4832 8645 11/2 6118 10944 2 7863 14065

Fig.133 Tee 90 F. Run - M. Branch Equal

Size Black Galvanised

3/8 1050 1837 1/2 847 1478 3/4 1075 1900 1 2184 3813

Fig.131(ISO E1) Pitcher Tee 90Reducing on run/branch

-

20 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.134 Tee 90 M & F Run F. Branch Equal

Size Black Galvanised

1/4 1038 1811 3/8 1038 1453 1/2 1018 1786 3/4 1446 1964 1 2000 3504 11/4 2861 4598 11/2 4314 6932 2 5524 8874

Fig.135 Tee 90 M . Equal

Size Black Galvanised

1/2 1255 2217 3/4 1841 3219 1 2013 3560

Size Method b UK Size Method a Black Galvanised (1) = (2) (3) 1 = 2 3

1/2 - 1/4 1/2 - 1/4 2086 3647 3/4 - 1/2 3/4 - 1/2 1664 2909 1 - 1/2 1 - 1/2 2348 4101

1 (1)

2 (3)

3 (2)

Fig.134 Tee 90 M & F Run F. Branch Reducing

All above tees are numbered according to the UK convention. (i.e. 1 & 2 are the run). method "b" International numbering shows outlet (2) & (3) reversed. (i.e. 1 & 3 are the run). method "a"

Fig.137 Distribution Tee M & F. Reducing on Branch

Size Black Galvanised

11/4 x 3/4 N/A 6322 11/4 x 1 N/A 6971 11/2 x 1 N/A 9120

-

21Prices are per 100Prices are per 100

Fig.165 Tee 45F. Equal

Size Black Galvanised

3/8 1406 N/A 1/2 1761 3077 3/4 2020 3528 1 3029 5294 11/4 4314 6794 11/2 5951 9370 2 8892 14001

Fig.221 (ISO Za1)Side Outlet ElbowF. Equal

Size Black Galvanised

3/8 1171 2047 1/2 983 1718 3/4 1174 1827 1 2046 3576 11/4 4249 6694 11/2 6178 9730 2 9447 14878

Fig.220 Y PieceF. Equal

Size Black Galvanised

3/8 1352 2359 1/2 1188 2075 3/4 1870 3267 1 2654 4637

Fig.180 (ISO C1)Cross 90F. Equal

Size Black Galvanised

1/4 854 1495 3/8 1137 1990 1/2 963 1616 3/4 1446 2530 1 1835 3214 11/4 2827 4451 11/2 3639 5993 2 5908 9313 21/2 8168 13293 3 10864 17680 4 18985 30873

Size Black Galvanised 1=3 2=4

3/4 - 1/2 1459 2550 1 - 1/2 2865 5006 1 - 3/4 2865 5006 11/4 - 1 3710 5842 11/2 - 1 5163 8134 2 - 1 5851 94021

2

3

4

Fig.180(ISO C1) Cross 90F. Reducing

-

22 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.223(ISO Za2) Side Outlet TeeF. Equal

Size Black Galvanised

1/2 1325 2313 3/4 1664 2909 1 2469 4315

Fig.240 (ISO M2)SocketF. Reducing

* Mild Steel

Size Black Galvanised 1 2

*1/4 - 1/8 300 527 *3/8 - 1/8 383 669 *3/8 - 1/4 306 600 1/2 - 1/4 309 602 1/2 - 3/8 245 463 3/4 - 1/4 478 838 3/4 - 3/8 385 671 3/4 - 1/2 297 526 1 - 3/8 644 1126 1 - 1/2 348 685 1 - 3/4 370 646 11/4 - 3/8 1361 2147 11/4 - 1/2 753 1506 11/4 - 3/4 770 1486 11/4 - 1 755 1187 11/2 - 1/2 1471 2531 11/2 - 3/4 1265 2276 11/2 - 1 948 1708 11/2 - 11/4 983 1897 2 - 1/2 1987 3572 2 - 3/4 2114 3633 2 - 1 1834 3286 2 - 11/4 1707 3065 2 - 11/2 1377 2435 21/2 - 1 3880 7105 21/2 - 11/4 2964 5425 21/2 - 11/2 2964 5425 21/2 - 2 2500 5215 3 - 11/2 4797 7531 3 - 2 4144 6501 3 - 21/2 4254 6677 4 - 2 8264 12968 4 - 21/2 7665 12031 4 - 3 7665 12031

2

1

-

23Prices are per 100Prices are per 100

Fig.241 (ISO N4)Bush M & F Reducing

Size Black Galvanised 1 2

*1/4 - 1/8 l 227 399 *3/8 - 1/8 l 274 428 *3/8 - 1/4 l 199 348 1/2 - 1/8 ll 204 384 1/2 - 1/4 l 147 233 1/2 - 3/8 l 147 260 3/4 - 1/4 ll 279 489 3/4 - 3/8 ll 220 384 3/4 - 1/2 l 169 296 1 - 1/4 ll 370 695 1 - 3/8 ll 366 716 1 - 1/2 ll 204 403 1 - 3/4 ll 217 381 11/4 - 3/8 ll 854 1347 11/4 - 1/2 ll 470 806 11/4 - 3/4 ll 426 720 11/4 - 1 ll 301 488 11/2 - 3/8 ll 1085 1709 11/2 - 1/2 ll 605 1025 11/2 - 3/4 ll 655 1109 11/2 - 1 ll 476 731 11/2 - 11/4 l 436 773 2 - 1/2 lll 1244 2107 2 - 3/4 lll 1302 2050 2 - 1 ll 983 1548 2 - 11/4 ll 950 1610 2 - 11/2 ll 908 1445 21/2 - 1 lll 2185 3554 21/2 - 11/4 lll 2185 3554 21/2 - 11/2 ll 2090 3554 21/2 - 2 ll 1521 2659 3 - 1 lll 3703 6027 3 - 11/4 lll 3601 5858 3 - 11/2 lll 3601 5858 3 - 2 ll 2467 4743 3 - 21/2 ll 2739 4654 4 - 2 lll 6746 10982 4 - 21/2 lll 6746 10982 4 - 3 ll 5616 9139 6 - 4 20177 N/A

2

1

Form lll

Form ll

Form l

2

1

* Mild Steel

-

24 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.245(ISO N8)Nipple (Hexagon)M. Reducing

Size Black Galvanised 1 2

*1/4 - 1/8 322 563 *3/8 - 1/8 459 799 *3/8 - 1/4 322 563 1/2 - 1/4 414 778 1/2 - 3/8 371 697 3/4 - 1/4 1038 1811 3/4 - 3/8 736 1292 3/4 - 1/2 341 597 1 - 1/2 633 1105 1 - 3/4 341 641 11/4 - 1/2 1289 2031 11/4 - 3/4 1165 1833 11/4 - 1 722 1137 11/2 - 3/4 1454 2337 11/2 - 1 1711 2695 11/2 - 11/4 914 1506 2 - 1 1745 2520 2 - 11/4 2187 3445 2 - 11/2 1743 2871 21/2 - 11/2 2684 4310 21/2 - 2 2735 4452 3 - 2 3703 6027 3 - 21/2 4937 8035 4 - 3 16208 26054

2

1

Fig.246(ISO M4)SocketM & F. Reducing

* Mild Steel

Size Black Galvanised 1 2

*1/4 - 1/8 390 682 *3/8 - 1/4 323 566 1/2 - 1/4 445 780 1/2 - 3/8 356 623 3/4 - 3/8 568 993 3/4 - 1/2 328 572 1 - 1/2 615 1073 1 - 3/4 521 909 11/4 - 1/2 1834 2943 11/4 - 3/4 1431 2253 11/4 - 1 798 1410 11/2 - 3/4 1719 2761 11/2 - 1 1895 2987 11/2 - 11/4 1485 2625 2 - 1 2483 3989 2 - 11/4 2681 4222 2 - 11/2 2780 4376 21/2 - 11/2 5322 8658 21/2 - 2 3566 5730 3 - 21/2 7620 12392

2

1

* Mild Steel

-

25Prices are per 100Prices are per 100

Fig.260 (ISO M3)Socket EccentricF. Reducing

Size Black Galvanised 1 2

3/4 - 1/2 529 1437 1 - 1/2 1517 4089 1 - 3/4 1722 4642 11/4 - 1/2 2498 5521 11/4 - 3/4 2540 6025 11/4 - 1 2358 5594 11/2 - 1/2 3489 5948 11/2 - 3/4 1925 3732 11/2 - 1 2905 6413 11/2 - 11/4 1457 3461 2 - 1/2 1883 4158 2 - 3/4 1966 4158 2 - 1 1883 4158 2 - 11/4 1883 4158 2 - 11/2 1751 4158 21/2 - 2 3552 7106

2

1

Fig.270(ISO M2) SocketF. Equal

Size Black Galvanised

1/8 229 403 1/4 201 350 3/8 201 350 1/2 187 326 3/4 227 428 1 314 548 11/4 682 1158 11/2 993 1566 2 1436 2265 21/2 2411 4580 3 3988 6491 4 6578 10710

Fig.271(ISO M2 R-L) Socket F. Equal (R & L. Hand Thread)

Size Black Galvanised

3/8 394 691 1/2 355 622 3/4 504 881 1 615 1073 11/4 1470 2317 11/2 1636 2575 2 2974 4684

-

26 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.280 (ISO N8)Hexagon NippleM. Equal

Size Black Galvanised

1/8 299 521 1/4 268 475 3/8 314 590 1/2 179 318 3/4 204 360 1 291 507 11/4 649 1032 11/2 755 1187 2 1363 2167 21/2 2632 3626 3 3805 5928 4 6460 10515

Fig.290 (ISO T9)Plug (Beaded Hollow)

* Solid Mild Steel

Size Black Galvanised

*1/8 245 428 *1/4 151 268 3/8 139 242 1/2 187 323 3/4 215 348 1 275 482 11/4 532 840 11/2 660 1041 2 1140 2124 21/2 2662 4327 3 3454 5617 4 6084 9894

Fig.291 (ISO T8)Plug (Plain Hollow)

* Solid Mild Steel

Size Black Galvanised

*1/8 87 159 *1/4 87 147 *3/8 114 200 1/2 131 260 3/4 169 330 1 229 403 11/4 346 665 11/2 649 1032 2 908 1445 21/2 1484 2751 3 2739 4453 4 5042 8204

Fig.281 (ISO N8 R-L)Hexagon Nipple (R & L. Hand Thread)

Size Black Galvanised

3/8 N/A 1455 1/2 394 691 3/4 490 859 1 847 1478 11/4 1470 2317 11/2 1731 2726 2 3271 5148

-

27Prices are per 100Prices are per 100

Fig.300 (ISO T1)Cap

* Mild Steel

Size Black Galvanised

*1/8 437 764 *1/4 172 323 *3/8 243 323 1/2 190 335 3/4 217 384 1 272 514 11/4 511 840 11/2 605 1070 2 1265 1997 21/2 2300 4362 3 3035 4940 4 6646 10816

Fig.291S Plug (Plain Solid)

Size Black Galvanised

1/8 87 159 1/4 87 147 3/8 114 200 1/2 410 724 3/4 396 778 1 588 1027 11/4 997 1643 11/2 1288 2216 2 1847 2908

Fig.294 Plug (Beaded)Square Head with Hole

Size Black Galvanised

1/2 547 955 3/4 671 1169 1 859 1500 11/4 1308 2060 11/2 1389 2187 2 2223 3501

Fig. 595 Plug with One Machined Face

Size Black Galvanised G a

1/2 23 798 1395 3/4 24 892 1554 1 28 952 1663

G

R

a

a

Fig.596(ISO T11) Plug (Recessed)

* Solid Mild Steel

Size Black Galvanised R a

*1/8 8** 299 524 *1/4 10** 276 481 *3/8 10** 313 548 1/2 15 220 404 3/4 17 279 509 1 20 338 619 11/4 22 559 985 11/2 22 1213 2175 2 27 1862 3575

**Hexagonal recess

-

28 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.310(ISO P4) Backnut

Size Black Galvanised

1/8 422 739 1/4 233 406 3/8 261 451 1/2 204 357 3/4 218 381 1 288 500 11/4 539 850 11/2 623 978 2 1242 1956 21/2 2723 4432 3 3230 5256

Fig.312 (ISO P4)Backnut Recessed

Size Black Galvanised

1/4 171 330 3/8 224 391 1/2 162 262 3/4 165 319 1 220 359 11/4 438 693 11/2 493 886 2 1183 1863

Fig.310a (ISO P4)BacknutOne Machined Face

Size Black Galvanised

1/2 628 1097 3/4 394 691 1 734 1288 11/4 963 1518 11/2 995 1570 2 2223 3501

Fig.310b (ISO P4)Backnut Strongly Chamfered on One Side

Size Black Galvanised

1/2 N/A 524 3/4 N/A 524 1 N/A 828 11/4 N/A 1177 11/2 N/A 1298 2 N/A 3736

Fig.321 Screwed FlangeUndrilled

Size Black Galvanised

1/2 1151 2100 3/4 1419 2377 1 1584 2776 11/4 2550 4016 11/2 3226 4867 2 3739 5886

-

29Prices are per 100Prices are per 100

Fig.326 Screwed Flange with 2 Bolt Holes

Size Black Galvanised

1/2 PN10 1868 3264 3/4 PN10 2414 4220 1 PN10 2482 4339 11/4 PN10 3692 5818 11/2 PN10 4119 6487 2 PN10 4314 6794

Fig.329 Screwed Flange with 4 Bolt Holes

Size Black Galvanised

1/2 PN16 4803 8392 3/4 PN16 5239 9155 1 PN16 6032 10537 11/4 PN16 9283 14620 11/2 PN16 9904 15597 2 PN16 11476 18070 21/2 PN16 13025 21178 3 PN16 15055 24476 3* PN16 15781 25662 4* PN16 18189 29575

Fig.330 (ISO U1)Union Flat SeatF. Equal

Size Black Galvanised 374 (G)

1/4 5/8 1497 2615 3/8 3/4 1099 1921 1/2 1 812 1425 3/4 11/4 954 1667 1 11/2 1104 1934 11/4 2 2246 3532 11/2 21/4 2848 4487 2 23/4 4246 6685 21/2 31/2 10992 17875 3 4 16447 26744 4 5 37849 62399

370

G

374

372

Fig.331 (ISO U2) Union Flat SeatM & F. Equal

Size Black Galvanised 374 (G)

1/4 5/8 1570 2740 3/8 3/4 1310 2290 1/2 1 997 1741 3/4 11/4 1120 1960 1 11/2 1365 2386 11/4 2 3005 4736 11/2 21/4 3628 5713 2 23/4 5687 8958 21/2 31/2 12675 20610 3 4 18561 30145

370

G

374

371

Fig 331 are supplied without gaskets, which should be ordered separately. See page 36 for gaskets (Fig. 202)

*8 holes

1/2 to 2 inclusive are supplied with gaskets.See page 36 for spare gaskets (Fig. 202)

-

30 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.332 Union Flat SeatM & F. Equal

Size Black Galvanised Rp/G 374 (G)

3/4 11/4 1802 3148 1 11/2 1965 3432 11/4 2 3335 5253

373 (G)G

374

372(Rp) Fig.332 are supplied without gaskets, which should be ordered separately. See page 36 for gaskets (Fig. 202)

Fig.335 Union Flat SeatM & F. Equal

Size Black Galvanised 374 (G)

1/2 1 1555 2717 3/4 11/4 1555 2717 1 11/2 1732 3030 11/4 2 3175 4998 11/2 21/4 3990 6281

376G

374

372Fig 335 are supplied without gaskets, which should be ordered separately. See page 36 for gaskets (Fig. 202)

Fig.336 Union Flat SeatM. Equal

Size Black Galvanised 374 (G)

1/2 1 1672 2862 3/4 11/4 1732 3030 1 11/2 2008 3505 11/4 2 3762 5919 11/2 21/4 4509 7105

376

G

374

371 Fig 336 are supplied without gaskets, which should be ordered separately. See page 36 for gaskets (Fig. 202)

Fig.338 Distribution Union Flat Seat

Size Black Galvanised 374 (G)

3/4 11/4 N/A 6458 1 11/2 N/A 7547 11/4 2 N/A 10780

372

G378

Rp1/2

374

Fig.338 are supplied without gaskets, which should be ordered separately. See page 36 for gaskets (Fig. 202)

-

31Prices are per 100Prices are per 100

Fig.340 (ISO U11)Union (Iron to iron)Taper SeatF. Equal

Size Black Galvanised

1/8 3111 5435 1/4 1086 2217 3/8 903 1977 1/2 775 1514 3/4 846 1659 1 990 1944 11/4 2012 3200 11/2 2271 3613 2 3763 5386 21/2 8117 15052 3 12739 23219 4 24252 44204

Fig.341(ISO U12) Union (Iron to Iron) Taper SeatM & F Equal

Size Black Galvanised

1/4 1299 2277 3/8 1029 1955 1/2 885 1593 3/4 1084 1952 1 1354 2270 11/4 2427 4694 11/2 3104 6008 2 4890 9457 21/2 13002 21155 3 17875 29086 4 37393 60802

Fig.342(ISO U11)Union (Bronze to Iron)Spherical / Taper Seat F. EqualRailroad Pattern

Size Black Galvanised

1/2 1501 3420 3/4 1693 4026 1 2212 4161 11/4 3667 7670 11/2 4784 9313 2 5633 11274

Fig.342a(ISO U11)Union (Bronze to Bronze)Spherical / Taper Seat F. Equal Navy Pattern

Size Black Galvanised

1/2 2058 3635 3/4 2273 4318 1 3003 5306 11/4 4965 9257 11/2 6002 10260 2 7622 12126

-

32 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig.346Mac Union2 Spherical Seats F. Equal

Size Black Galvanised

1/2 1696 2967 3/4 2077 3384 1 2562 4174 11/4 3975 6259 11/2 5278 8318 2 7446 11734

Fig.370 Union Bush Equal

Size Black Galvanised Rp G

1/2 1 356 623 3/4 11/4 367 645 1 11/2 504 881 11/4 2 847 1336 11/2 21/4 1113 1752 2 23/4 2027 3193 21/2 31/2 3927 6388 3 4 5766 9377

Rp

G

Fig.371 Union EndMale

Size Black Galvanised Rp D to suit G on 374

1/2 1 588 1028 3/4 11/4 547 955 1 11/2 671 1169 11/4 2 1389 2187 11/2 21/4 1552 2444 2 23/4 2271 3578 21/2 31/2 4644 7549 3 4 8237 13398 1-11/4 11/2* 1353 N/A

R

D

* Union end for 374 1" 42.5 (770 374 121)

Fig.344Union (Iron to Iron) Taper Seat M. Equal

Size Black Galvanised

1/4 2375 4150 3/8 1884 3290 1/2 1992 3480 3/4 2293 4008 1 2702 4721 11/4 5524 8700 11/2 6307 9936 2 11538 18173

-

33Prices are per 100Prices are per 100

Fig.373 Union BushM. Equal

Size Black Galvanised R G

3/4 11/4 997 1741 1 11/2 1119 1953 11/4 2 1815 2856

R

G

Fig.372 Union End, Flat Seat,F. Equal

F. Reducing

Size Black Galvanised Rp D to suit G on 374

1/2 1 355 622 1/2 11/8 355 622 3/4 11/4 382 667 1 11/2 354 692 11/4 2 719 1133 11/2 21/4 1013 1421 2 23/4 1636 2575 21/2 31/2 3468 5642 3 4 6339 10306 Size Black Galvanised D to suit G on 374

1 - 3/4 11/2 615 1073 11/4 - 3/4 2 984 1546 11/4 - 1 2 995 1646

Rp

D

D

Rp

Fig. 374(ISO P1) Union Nut

Size Black Galvanised R G

3/8 7/8 299 524 1/2 1 273 479 1/2 11/8 299 524 3/4 11/4 301 595 3/4 11/4 355 N/A 1 11/2 340 667 1 11/2 340 N/A 11/4 2 639 1133 11/2 21/4 898 1415 2 23/4 1338 2111 21/2 31/2 3169 6619 3 4 4183 6801

G

d

d=34.4

d=42.5

Union nut for 371 1 - 11/4 (770 371 115)

-

34 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig. 376Union BushM. Equal

Size Black Galvanised R G

1/2 1 986 1336 1/2 11/8 986 1336 3/4 11/4 1159 1573 1 11/2 1177 1596 11/4 2 2081 2523 11/2 21/4 2589 3139

R

G

Fig. 378 Distribution Union Bush

Size Black Galvanised R G

3/4 11/4 N/A 6025 1 11/2 N/A 6831 11/4 2 N/A 9585

R

Rp1/2

G

Fig. 471 Bracket Elbow

Size Black Galvanised

3/8 N/A 3716 1/2 N/A 2365 3/4 N/A 4581

Fig. 526 Extension Tube

Size Black Galvanised a

3/8 - 100mm 1161 2029 1/2 - 30mm 518 908 1/2 - 50mm 490 859 1/2 - 60mm 671 1169 1/2 - 70mm 888 1551 1/2 - 80mm 683 1192 1/2 - 100mm 927 1620 1/2 - 120mm 1435 2538 3/4 - 30mm 573 1000 3/4 - 40mm 642 1120 3/4 - 60mm 915 1596 3/4 - 70mm 1174 2049 3/4 - 80mm 1132 1980 3/4 - 100mm 1219 1980 1 - 40mm 900 1573 1 - 80mm 1435 2504 1 - 100mm 2157 3768

a

-

35Prices are per 100Prices are per 100

Fig. 529a (ISO M4)Extension Socket

Size Black Galvanised a

1/4 - 28mm 888 1551 3/8 - 35mm 410 717 1/2 - 43mm 451 787 3/4 - 48mm 655 1146 1 - 55mm 1038 1811 11/4 - 60mm 1617 2548 11/2 - 60mm 2255 3552 2 - 70mm 3692 5818

a

Fig. 536 Long Screw SocketHot dip galvanised Thread also electroplated.

Size Black Galvanised a

1/2 - 79mm N/A 3785 3/4 - 90mm N/A 4700 1 - 102mm N/A 6884 11/4 - 116mm N/A 11643 11/2 - 125mm N/A 13423 2 - 143mm N/A 22255

Fig. 534 Long Screw Hexagon NippleHot dip galvanised Thread also electroplated.

Size Black Galvanised a

1/2 - 77mm N/A 3432 3/4 - 82mm N/A 4536 1 - 92mm N/A 6436a

R

G

a

Rp

G

See page 27 for full details

See page 27 for full detailsFig.596(ISO T11) Plug (Recessed)

Fig. 595 Plug with One Machined Face

-

36 Prices are per 100Prices are per 100

Malleable Iron Pipe Fittings

Fig. 599a Regulating Socket

Size Black Galvanised Rp G

1/2 3/8 2757 4815 3/4 1/2 3712 6484 1 3/4 6331 11062 11/4 11/8 12259 N/A 11/2 11/4 14353 N/A 2 23/4 24811 N/A

588 (Brass)

587 (Brass)

Rp

GasketG

Fig. 933aCounter Flange

Size Black Galvanised Rp

3/4 N/A 17042 1 N/A 16367 11/4 N/A 13835 11/2 N/A 15487

Rp

Fig. 933 Water Meter Bend

Size Black Galvanised Rp a

3/4 x 115mm N/A 27222 1 x 90mm N/A 27222 11/4 x 90mm N/A 31616

Rp

a

126

Fig. 202Spare Gaskets(Compressed Non-Asbestos Fibre)

Fitting Price Size

1/4 82 1/2 74 3/4 90 1 93 11/4 174 11/2 240 2 269

-

37

Time saving pipe jointing systems

for steel pipework

DRAW-LOCKSystem

PRIMOFITCompression Fittings

-

38

PRIMOFIT System

Coupling

1/2 to 3" STL 20 to 63mm PE

Steel to Steel, PE to PE and Steel to PE

Reducing Coupling

1/2 to 2" Steel

Cap

1/2 to 2" Steel

Equal Tee

1/2 to 2" Steel 20 to 63mm PE

Female Adaptor

1/2 to 3" Steel 20 to 63mm PE

-

39Prices are per 100

PRIMOFIT System

Steel to Steel, PE to PE and Steel to PE

Male Adaptor

1/2 to 3" Steel 20 to 63mm PE

Elbow

1/2 to 2" Steel 20 to 63mm PE

Threaded Outlet Tee

1/2 to 2" Steel

Two Piece Under Pressure Swivel Tee

11/2" x 63mm 2" x 63mm

Under Pressure Swivel Tee

3/4" x 25mm 1" x 32mm 3/4" x 20mm1" x 20mm 1" x 25mm3/4" x 32mm

-

40 Prices are per 100

DRAW-LOCK Tooling

Draw-Tool with Expander16mm20mm25mm32mm

Expander (spare)

16mm20mm25mm32mm

Draw-Tool Stem

20mm25mm32mm Adaptor Bush

16mm20mm25mm32mm

Combination Tool with Cap

3/4"

1

* for joint making with service insertion adaptors

Cap (spare)

3/4"

1"

-

41Prices are per 100

DRAW-LOCK System

Meter-Box Adaptor

20mm25mm32mm

Service InsertionAdaptor (Screwed)

Range from 16 - 32mm

Service InsertionAdaptor (Compression)

16 - 32mm

One Piece Male Transition Fitting

25mm

32mm

Combination Tool Stem

3/4"

1"

-

42 Prices are per 100

Notes

-

43Prices are per 100

Notes

-

44 Prices are per 100

Notes

-

Stockist

George Fischer Sales LimitedParadise Way, Coventry CV2 2STTel. 024 7653 5535, Fax. 024 7653 0450email [email protected] website www.georgefischer.co.uk

LITGF0659 (December 2011) George Fischer Sales Limited.