GEOTECHNICAL ENGINEERING REPORT - Durham, NC

Transcript of GEOTECHNICAL ENGINEERING REPORT - Durham, NC

GEOTECHNICAL ENGINEERING REPORT

CoD Solid Waste Management

Truck Wash Building 1833 Camden Avenue

Durham, North Carolina

March 2, 2017

GEOTECHNICAL ENGINEERING REPORT

CoD Solid Waste Management Truck Wash Building 1833 Camden Avenue

Durham, North Carolina

March 2, 2017

Prepared For:

RND Architects PA

3608 University Drive, Suite 204 Durham, NC 27707

Prepared By:

5400 Old Poole Road Raleigh, NC 27610

Stewart Project No.:F17007.00

Chien-Ting Tang, EI, Ph.D

Geotechnical Engineering Intern

Donald W. Brown Jr., PE, LEED AP

Manager of Construction Services NC PE License No. 28422

Stewart License No. C-1051

3/2/2017

TABLE OF CONTENTS

1 EXECUTIVE SUMMARY ................................................................................................ 1

2 PROJECT INFORMATION ............................................................................................ 2 2.1 Project Understanding ...................................................................................... 2 2.2 Site Location and Description ............................................................................. 2 2.3 Geologic Area Overview .................................................................................... 2

3 SUBSURFACE EXPLORATION ...................................................................................... 3 3.1 Field Testing .................................................................................................... 3 3.2 Subsurface Conditions ...................................................................................... 3

3.2.1 Ground Cover ....................................................................................... 3 3.2.2 Fill ...................................................................................................... 4 3.2.3 Residuum ............................................................................................ 4 3.2.4 Weathered Rock .................................................................................... 4 3.2.5 Groundwater ........................................................................................ 4

4 ENGINEERING ASSESSMENT AND RECOMMENDATIONS ............................................. 5 4.1 Site Preparation ............................................................................................... 5

4.1.1 Building Area ........................................................................................ 5 4.1.2 Pond Area ............................................................................................ 5

4.2 Fill Selection and Compaction ............................................................................ 5 4.3 Foundations .................................................................................................... 6

4.3.1 Design ................................................................................................. 6 4.3.2 Construction ......................................................................................... 6

4.4 Slab-On-Grade Recommendations ...................................................................... 7 4.4.1 Design ................................................................................................. 7 4.4.2 Construction ......................................................................................... 7

4.5 Seismic Design Considerations ........................................................................... 7 4.6 Rigid Pavement ................................................................................................ 8

Appendix A

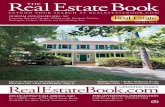

Site Vicinity Map

Boring Location Diagram

Appendix B

Boring Snapshot

Boring Logs

Boring Summary Table

Legend of Soil Descriptions

Appendix C

Site Photographs

CoD Solid Waste Management Truck Wash Building – Durham, North Carolina Page 1

1 EXECUTIVE SUMMARY

Stewart has completed a geotechnical exploration for a proposed single-story truck wash building at the

City of Durham’s Solid Waste Management site in Durham, NC. This Executive Summary is provided as a

brief overview of our geotechnical engineering evaluation for the project and is not intended to replace

more detailed information contained elsewhere in this report. A summary of our findings, opinions, and

recommendations is provided below.

The current plan consists of an approximate 1,600± square foot truck wash building and a

nearby stormwater pond.

A total of three soil test borings were performed for this evaluation: two (B-1 and B-2) of

which are for the truck wash building, and one (B-3) is for stormwater pond. B-1 and B-2

were advanced to approximately 18¾ feet. Boring B-3 was advanced to 15 feet.

The subgrade soils encountered at the boring locations consist of fill and residual soils. The

USCS soil types encountered onsite include Silty SAND (SM), Sandy SILT (ML), Clayey SAND

(SC) and Lean CLAY (CL).

A buried layer of debris was encountered in boring B-3 from approximately 3 feet to 9½ feet

below the current grade. This stratum contained mainly old asphalt, cinders, glass and other

miscellaneous material.

Weathered rock (Triassic Siltstone) was encountered in borings B-1 and B-2 at approximate

depths of 9 feet and 7 feet below the current grade, respectively.

Perched groundwater was encountered in the fill in boring B-3 during drilling, at an

approximate depth of 8 feet below the current grade.

The structure should be designed using a Seismic Site Class C.

Based on the provided loading conditions, we recommend a spread footing foundation for the

proposed building.

The owner/designer/contractor should not rely solely upon the summary above. This report should be

read in its entirety prior to implementing the recommendations in the preparation of design and

construction documents. Stewart should be retained to perform sufficient services to determine

plan/specification compliance with the recommendations in this report.

CoD Solid Waste Management Truck Wash Building – Durham, North Carolina Page 2

2 PROJECT INFORMATION

2.1 Project Understanding

The current plans are for a new single-story truck wash building with a high roof. The building will be

approximately 1,600± square feet with a concrete slab-on-grade. We have assumed 75 kips for

maximum column loads and finished floor elevation (FFE) to be the same as the current ground (pad)

elevation. The wash building is expected to accommodate 60 trucks per day now (5 days per week),

but that capacity could be increased to 80 trucks with future growth.

Site improvement will include a new stormwater pond at the north end of the property, approximately

250 feet from the proposed building.

2.2 Site Location and Description

The project is located at 1833 Camden Ave in Durham, North Carolina. The proposed building site is

located immediately adjacent to an existing building at the Durham Solid Waste Management facility.

This area is currently paved with concrete and used as a wash station for trucks. The proposed

stormwater pond area is currently open and grass-covered.

Please refer to Figure A1 in Appendix A of this report for an aerial site photograph. Site photographs

are also included in Appendix C of this report.

2.3 Geologic Area Overview

The project site is located within Durham County, North Carolina, and lies within the Durham Triassic

Basin of eastern North Carolina. This basin is an ancient system of failed rifts that follow the coastline

of the eastern United States from South Carolina to Newfoundland, Canada. These basins slowly

opened and subsequently were infilled with material eroded from the surrounding landscape

approximately 220 million years ago during the breakup of the supercontinent Pangea. Review of the

Geologic Map of Southwest Durham 7.5-Minute Quadrangle (compiled by the C.W. Huffman and P.E.

Gallager, 1987) shows that the site is characterized by Triassic-age sedimentary rock, primarily

siltstone (Trcs/si).

SITE

CoD Solid Waste Management Truck Wash Building – Durham, North Carolina Page 3

3 SUBSURFACE EXPLORATION

3.1 Field Testing The subsurface conditions at the site were explored with a total of three soil test borings (B-1 through

B-3). Borings B-1 and B-2 were performed for the new truck wash building, while boring B-3 was

performed for the pond. The boring layout is illustrated in Figure A2 in Appendix A of this report. The

borings were advanced to depths of approximately 15 and 18¾ feet below the current ground surface

by Carolina Drilling using an ATV-mounted CME 550 drill rig using 2¼-inch hollow-stem, continuous

flight augers in general accordance with ASTM D6151. Sampling operations were conducted in general

accordance with ASTM D1586. At predetermined intervals, soil samples were obtained with a split-

barrel sampler (standard 2-inch O.D.). The sampler was rested on the bottom of the borehole and

driven to a penetration of 18 inches (or fraction thereof) with blows of a 140-pound automatic drop

hammer falling a distance of 30 inches. Of the 18 inches, the number of hammer blows required to

achieve 6 inches of penetration is recorded for three consecutive segments. The sum of the blow

counts for the second and third 6-inch segment is termed the Standard Penetration Test (SPT)

resistance, or N-value. The N-values presented on the Boring Logs and Boring Snapshot are the

actual, field-recorded blow counts and do not include correction factors for hammer energy or

overburden soil pressures.

The soil samples obtained during the drilling operations were placed in labeled containers and

transported to our laboratory where they were visually-manually classified in general accordance with

ASTM D2488 and logged by Stewart’s geotechnical engineering staff. The Boring Logs are included in

Appendix B of this report. The soil samples will be stored for two months before discarding.

3.2 Subsurface Conditions

The following is a subsurface description of a generalized nature, provided to highlight the major soil

strata encountered. The stratification of the subsurface materials illustrated on the Boring Logs and

Boring Snapshot represent the conditions at the actual test locations; therefore, variations should be

expected between borings. Stratigraphy boundaries only represent the approximate depth/elevation of

a noticed material change but the transition between material types is typically gradual. The soil types

are based on the Unified Soil Classification System (USCS).

Please note that the ground surface elevations in this report, including the logs and other illustrations

in the appendices, were interpolated from the USGS topography and therefore should be considered

approximate. If greater elevation accuracy is necessary, the boreholes should be surveyed by a

professional land surveyor.

3.2.1 Ground Cover

The new building site is located within an existing truck wash station, which according to boring B-1, is

paved with 6 inches of concrete and underlain by 6 inches of stone base. The areas of borings B-2 and B-

3 are topped with a thin veneer of topsoil with depths of approximate 1 to 2 inches. Please note the term

topsoil is used to describe the organic-laden surficial material as mentioned above. No organic or nutrient

testing was performed for this exploration; therefore, the topsoil should not be assumed capable of

establishing or maintaining vegetation of any kind.

CoD Solid Waste Management Truck Wash Building – Durham, North Carolina Page 4

3.2.2 Fill

Fill soils were encountered in borings B-2 and B-3. The thickness of the fill is approximate 3 feet in

boring B-2, which consists of medium dense Clayey SAND (SC). This fill appears to be associated with

past grading of the site. The N-value of 11 blows per foot (bpf) indicates a moderately compacted fill

layer.

The fill material in boring B-3 consists of approximately 3 feet of loose, relatively clean Clayey SAND

(SC) directly below the topsoil. This SC soil appears to be a cap over waste material (cinders, asphalt,

glass, etc.) that was encountered to a depth of approximately 9½ feet below the existing grade. The

waste layer is underlain by soft lean CLAY (CL) that extends to the termination depth of the boring at

15 feet. The N-values within the fill material range from 0 (W.O.H.) to 6 bpf, indicating an

uncompacted to poorly compacted fill layer.

3.2.3 Residuum

Triassic residual soils, which are the product of in-place physical and/or chemical weathering of the

parent bedrock, were encountered in borings B-1 and B-2. This material is present below the stone

base and fill. The residuum encountered was medium dense silty SAND (SM) and very stiff to hard

Sandy SILT (ML), with N-Values ranging from 17 to 59 bpf.

3.2.4 Weathered Rock

Weathered rock (WR) is a transitional geomaterial between the parent rock and soil. Weathered rock

is identified by SPT N-values of 50 blows per 6 inches or less of penetration. Weathered rock was

encountered in borings B-1 and B-2 at depths of approximately 9 feet and 7 feet below the current

grade, respectively. The weathered rock was classified as Triassic siltstone, which was sampled as

Sandy SILT (ML).

3.2.5 Groundwater

Perched groundwater was encountered at boring B-3 during drilling, at the depth of 8 feet below the

current ground surface. This condition is likely the result of water that has infiltrated into the debris fill

and become trapped, rather than true groundwater. All three boring holes were backfilled immediately

after drilling for public safety.

The groundwater conditions represent the conditions at the time of the exploration. Fluctuations in

groundwater levels are common and should be expected. Common factors that influence groundwater

levels include, but are not limited to, soil stratification, climate/weather, nearby bodies of water

(lakes, ponds, etc.), underground springs, streams, rivers and surface water discharge. At the onset,

as well as continually throughout the construction process, the contractor should monitor groundwater

levels if determined to be detrimental to the project. Management of groundwater can significantly

impact construction procedures/practices, schedules and project budgets.

CoD Solid Waste Management Truck Wash Building – Durham, North Carolina Page 5

4 ENGINEERING ASSESSMENT AND RECOMMENDATIONS

4.1 Site Preparation

4.1.1 Building Area

All topsoil, pavement, vegetation, topsoil/root mat and any other unsatisfactory or deleterious

materials should be removed to a lateral distance of at least 5 feet beyond the limits of new

construction. Such material should be considered unsuitable for reuse as structural fill. Old utilities

should be removed and their trenches backfilled with compacted structure soil.

Areas of the site to receive fill or directly support new construction should be proofrolled with a

tandem-axle dump truck weighing between 15 and 20 tons. Proofrolling should occur prior to fill

placement or after reaching final grade in cut areas, but must be in the presence of Stewart so that

recommendations can be provided for areas that rut, pump, or deflect excessively. Proofrolling should

not be performed on frozen or excessively wet subgrades.

The onsite soil may become unstable in the presence of excess moisture (water) and construction

traffic loading. Therefore proper site drainage should be maintained during earthwork operations. If

not, the accumulation of water could result in construction delays. Common approaches to reduce wet

weather delays include grading the area so that surface water flows away from the excavation, sealing

exposed soil surface with a smooth-drum roller prior to precipitation events, and forming temporary

ditches, swales, berms or other surface water diversion features. We also recommend limiting

construction traffic during and after wet weather.

4.1.2 Pond Area

The materials encountered in the upper 9½ feet of boring B-3 (pond area) are not conducive to

constructing a stormwater pond. The material is very soft, debris-laden and saturated with perched

groundwater. Pond construction will require removal of these unsuitable materials and backfilling with

quality backfill material and possibly a clay liner or other impermeable membrane. All material

removed from the pond excavation should be wasted off of the project site.

4.2 Fill Selection and Compaction

Any material utilized as structural fill should not contain rocks greater than 3 inches in diameter or

greater than 30% retained on the ¾-inch sieve. Structural fill material should not contain more than

3% (by weight) of organic matter or other deleterious material. Structural fill should possess a

Maximum Dry Density (MDD) of 95 pounds per cubic foot (pcf) or greater as determined by the

Standard Proctor Compaction Test (ASTM D698).

We recommend that the Plasticity Index (PI) for structural fill soil placed in the upper 3 feet of the

finished subgrade be less than 25 and the Liquid Limit (LL) less than 50, as determined by Atterberg

Limit testing (ASTM D4318). The onsite ML, SC and SM soils should meet these criteria.

The water content of the structural fill should be maintained within ±3% of the material’s optimum water

content as determined by the Standard Proctor Compaction Test (ASTM D698); however, slight deviation

from this can sometimes be tolerated depending on the grading plan and type of material being placed.

Such deviation should be considered by the engineer representing the owner’s/contractor’s material

testing firm.

CoD Solid Waste Management Truck Wash Building – Durham, North Carolina Page 6

When using large, ride-on compactors, fill should be placed in loose lifts measuring 8 to 10-inch thick.

Lifts should be thinned to 6 inches when using smaller, Rammax-type compactors and 4 inches for sled

and jumping-jack tampers. Structural fill should be compacted to 95 percent of the soil’s maximum dry

density as determined by ASTM D698, except for the upper 12 inches of the finished subgrade which

should be compacted to 98 percent of the same standard.

It is recommended that the placement and compaction of structural fill be monitored by an engineering

technician from Stewart working under the direction of a Geotechnical Engineer. Field compaction testing

should be performed in accordance with ASTM D1556 (Sand Cone Method), ASTM D2167 (Rubber Balloon

Method), ASTM D2937 (Drive Cylinder Method), or ASTM 6938 (Nuclear Method).

4.3 Foundations

4.3.1 Design

Following the implementation of the site preparation recommendations discussed in Section 4.1 and 4.2

of this report, the use of conventional spread footings is considered appropriate for the proposed truck

wash building. In designing the foundations for the building, we recommend the design parameters

provided in the Table 1.

Table 1: Foundation Design Parameters

Parameter Value

Net Allowable Bearing Capacity, psf 4,000

Minimum Bearing Depth, in. 18

Minimum Column Footing Width, in. 42

Estimated Post-Construction Settlement, in.

Total

Differential

Up to 1

Up to ½

Moist Soil Unit Weight, pcf 120

Passive Earth Pressure Coefficient* 3.00

Ultimate Friction Factor (tan δ) 0.35

*We recommend that a safety factor of at least 1.5 be used to determine the

soil’s allowable passive resistance and the soil’s allowable friction.

4.3.2 Construction

It is preferable for spread footing excavations in soil to be performed using a bucket with a flat cutting

edge (no teeth) to reduce disturbance of the exposed bearing soil. Regardless, footing bottoms in soil

should be tamped with a jumping-jack or sled compactor prior to the foundation inspection and

placement of reinforcing steel. Footings should be clean of loose material and debris and protected

from disturbance. This includes protection from surface water run-off and freezing. If water is allowed

to accumulate within a footing excavation and soften the bearing soils, or if the bearing soils are

allowed to freeze, the deficient soils should be removed from the excavation and rechecked by the

Owner’s testing agency prior to concrete placement. When concrete cannot be placed immediately, we

recommend placing a mud-mat to protect the bearing soil.

CoD Solid Waste Management Truck Wash Building – Durham, North Carolina Page 7

Foundation bearing materials should be checked by Stewart during construction to verify satisfactory

bearing conditions (i.e. materials and strength). For soil-supported footings, a qualitative assessment

should be performed by Stewart throughout the foundation excavations using a ½-inch diameter, T-

handled probe rod. Probing should be supplemented by strategically-placed hand auger borings and

Dynamic Cone Penetrometer (DCP) testing for quantitative evaluation. Such testing should be

performed in accordance with ASTM STP-399 and completed prior to stone, steel, or concrete

placement. Unsuitable soil detected during this evaluation should be addressed as directed by Stewart.

4.4 Slab-On-Grade Recommendations

4.4.1 Design

In designing the slab-on-grade for office, storage, or other areas that will not be subjected to wheel-

loading, we recommend a minimum 4-inch base layer of washed No. 57 stone to provide uniform

support and to provide a capillary break. We recommend the installation of a vapor barrier as a

measure of protection against water vapor intrusion. Even when groundwater is deep, water vapor

transmission through the slab could damage flooring and/or cause elevated moisture levels within the

structure. We recommend considering the use of a vapor barrier meeting ASTM E1745, which should

be installed per the ACI guidelines (ACI 302.2R) and ASTM E1643.

The design of the concrete slab-on-grade should be based on Westergaard’s modulus of subgrade

reaction (k). Based on the soil conditions encountered at the site and the above-mentioned sub-slab

stone layer, we recommend using an effective value (kef) of 120 pci for slab design. However, if the

floor slab will be heavily loaded or the design is otherwise sensitive to k, we recommend performing

plate load testing in accordance with ASTM D1196 to allow site-specific refinement of the design k-

value.

It is important to point out that cracking of concrete is normal and should be expected. Proper

jointing of slabs is paramount in the control of cracking. The American Concrete Institute (ACI)

recommends a maximum panel size (in feet) equal to approximately three times the thickness of the

slab (in inches) in both directions. Controlling the water-cement ratio of the concrete, particularly after

batching, and including fiber reinforcement in the mix can also help reduce shrinkage cracking.

4.4.2 Construction

The slab support soil should be compacted and then evaluated by Stewart to identify any remaining

weak or excessively unstable areas that require further repair. This is typically accomplished by

proofrolling with heavy, rubber-tired equipment such as a tandem-axle dump truck. In confined areas

that cannot be proofrolled with a dump truck, use of smaller rubber tire equipment, probing, and/or

DCP testing should be considered.

4.5 Seismic Design Considerations

Per the 2012 N.C. State Building Code, the design of a structure must consider dynamic forces

resulting from seismic events, regardless of their likelihood of occurrence. As part of a generalized

procedure to estimate seismic forces, the code assigns a Seismic Site Classification (letter designation

of Class A through F) based on the subgrade soil/rock conditions within the upper 100 feet of the

ground surface at the subject site. Based on our review of the SPT N-values and assumed FFE, we

recommend designing for a Seismic Site Class “C”.

CoD Solid Waste Management Truck Wash Building – Durham, North Carolina Page 8

The following bulleted items briefly discuss our qualitative assessments of the other seismic-related

issues. Detailed quantitative analyses for these items were not included in our Scope of Work and are not

considered necessary at this time given the development plans and the subsurface conditions

encountered.

Liquefaction Hazard – Risk level is low – The soils encountered were of sufficient fines

content and/or density to render them not readily liquefiable during the design

earthquake.

Slope Stability – Risk level is low - Based on the grading plan, neither tall nor overly

steep cut/fill slopes are planned for construction.

Surface Rupture – Risk is low – No active faults underlie the site.

4.6 Rigid Pavement

The truck wash area will include a rigid (concrete) pavement for the building floor. Using AASHTO design

methodology for rigid pavement, we recommend a minimum concrete thickness of 9½ inches to support

an average of 70 trucks per day over a design life of 30 years. The concrete pavement should be

supported by at least 6 inches of ABC stone, compacted to 95% of the material’s maximum dry density as

determined by AASHTO T180, underlain by a stable, non-yielding subgrade.

The concrete used for paving should be specified according to its modulus of rupture. We recommend a

minimum modulus of rupture of 650 psi, as determined by third-point load testing (AASHTO T97 or ASTM

C78). The contractor’s concrete submittal should include the modulus of rupture test data as well as

compressive strength test data. For the purpose of acceptance testing, the mix’s compressive strength

may be verified via test cylinders. For exposure durability, the concrete pavement should be air-

entrained. Air-entrainment is governed by aggregate size and exposure level, which is outlined in Section

4.3 of ACI 330.

Cracking of concrete is normal and should be expected. Proper jointing practices are paramount in the

control of cracking, particularly their location and the time at which they are installed. Concrete

pavements should be jointed according to ACI 330 Section 3.7. Use of welded wire fabric in the concrete

pavement section should also be considered to help reduce cracking caused by initial concrete shrinkage

and long-term thermal expansion and contraction. Joint reinforcing shall be sized and detailed by the

project’s civil engineer.

SIT

E

©2017: All docum

ents including com

puter files and draw

ings

prepared by Stew

art are instrum

ents of professional service

intended for one-tim

e use. They are subject to copyright and

other property right law

s and shall rem

ain the property of

Stew

art. They are not to be copied, m

odified, or changed in any

manner w

hatsoever nor assigned to a third party w

ithout prior

written perm

ission of Stew

art.

Note: All test locations are approxim

ate (unless otherw

ise

reported) and intended for illustration purposes only.

5400

OLD

PO

OLE

RD

RALE

IGH

, NC

2761

0T

9

19

.3

80

.8

75

0

FIRM

LIC

ENSE

#: C

-105

1w

ww

.stew

artin

c.co

m

NO

RTH

SITE VICIN

ITY M

AP

CO

D TR

UC

K W

AS

H B

UILD

IN

G

DU

RH

AM

, N

C

Project N

o.:F17007.00

Scale: N

TS

Prepared by: CTT

Date: FEB. 2017

Figure N

o.:

A1

B-3

B-1

B-2

©2017: All docum

ents including com

puter files and draw

ings

prepared by Stew

art are instrum

ents of professional service

intended for one-tim

e use. They are subject to copyright and

other property right law

s and shall rem

ain the property of

Stew

art. They are not to be copied, m

odified, or changed in any

manner w

hatsoever nor assigned to a third party w

ithout prior

written perm

ission of Stew

art.

Note: All test locations are approxim

ate (unless otherw

ise

reported) and intended for illustration purposes only.

5400

OLD

PO

OLE

RD

RALE

IGH

, NC

2761

0T

9

19

.3

80

.8

75

0

FIRM

LIC

ENSE

#: C

-105

1w

ww

.stew

artin

c.co

m

NO

RTH

BO

RIN

G LO

CATIO

N D

IAG

RAM

CO

D TR

UC

K W

AS

H B

UILD

IN

G

DU

RH

AM

, N

C

Project N

o.: F17007.00

Scale: 1IN

=50FT

Prepared by: CTT

Date: FEB. 2017

Figure N

o.:

A2

340

342

344

346

348

350

352

354

356

358

360

362

340

342

344

346

348

350

352

354

356

358

360

362

344

17

22

24

50/

0.5

50/

0.3

50/

0.3

344.5

11

59

50/

0.4

50/

0.3

50/

0.3

50/

0.2

347

6 4 4 WO

H

3

Elevation (ft)

LIT

HO

LO

GY

GR

AP

HIC

S

Con

cret

eP

oorly

-Gra

ded

San

d(S

P)

Silt

y S

and

(SM

)S

ilt (

ML)

Wea

ther

ed R

ock

Top

soil

/ Org

anic

Laye

rF

ill -

Cla

yey

San

d(S

C)

Fill

Fill

- L

ean

Cla

y (C

L)

PR

OJE

CT

NO

.: F

1700

7.0

0

BO

RIN

G S

NA

PS

HO

T

CO

D S

OL

ID W

AS

TE

MA

NA

GE

ME

NT

TR

UC

K W

AS

H B

UIL

DIN

GD

UR

HA

M, N

C

The

bor

ings

in th

is s

naps

hot a

re a

rran

ged

in a

lpha

betic

al o

rder

and

do

not r

epre

sent

a p

rofil

e or

cro

ss s

ectio

n of

the

subs

urfa

ce c

ondi

tions

.

B-1

B-2

B-3

SS1

SS2

SS3

SS4

SS5

SS6

359.5359.0

354.5

351.0

341.2

17

22

24

50/0.5

50/0.3

50/0.3

SM

ML

WR

0.51.0

5.5

9.0

18.8

4710

81012

4816

1650/0.5

50/0.3

50/0.3

1

2.5

3.5

5

6

7.5

8.5

10

13.5

15

18.5 18.8

CONCRETE (6 INCHES)STONEBASE (6 INCHES)TRIASSIC RESIDUAL - MEDIUM DENSE, TAN AND BROWN, MOIST, SILTYSAND

STIFF, BROWN, MOIST, SILT

WEATHERED ROCK - TRIASSIC SILTSTONE

BORING TERMINATED

344

DRILLING METHOD H.S. AUGER AUGER SIZE 2-1/4 INCH (ID)

HAMMER TYPE AUTODRILL RIG CME 550

DATE DRILLED 2/16/17 LOGGED BY C. T. TANG BORING DEPTH 18.8 ft

CAVE-IN 16 ft

GROUND SURFACE EL. 360 ft

TIME OF DRILLING: WL DRYDRILLING CONTRACTOR CAROLINA DRILLING

CAVE-IN FIADAFTER DRILLING: WL FIAD

DE

PT

H (

ft)

TY

PE

ID N

UM

BE

R

ELE

VA

TIO

N (

ft)

FINES CONTENT (%) 10 20 30 40 50 60 70 80 90

SPT N-VALUE (BPF) 10 20 30 40 50 60 70 80 90

N-V

ALU

E (

bpf)

MA

TE

RIA

L T

YP

E

DE

PT

H (

ft)

SP

TB

LOW

CO

UN

TS

SAMPLE

10 20 30 40 50 60 70 80 90

PL LLWC

MATERIAL DESCRIPTION

WL

/ C

AV

E E

L (f

t)

Note: SPT Blow Counts are per 6 inches of penetration unless otherwise noted.

PAGE 1 OF 1

BORING LOG: B-1

LOCATION DURHAM, NC

PROJECT COD SOLID WASTE MANAGEMENT TRUCK WASH BUILDING

PROJECT NO. F17007.00

CLIENT RND ARCHITECTS PA

SS1

SS2

SS3

SS4

SS5

SS6

359.8

357.0

353.0

341.3

11

59

50/0.4

50/0.3

50/0.3

50/0.2

SC

ML

WR

0.2

3.0

7.0

18.7

247

92138

1936

50/0.4

2550/0.3

50/0.3

50/0.2

1

2.5

3.5

5

6

7.5

8.5

10

13.5

15

18.5 18.7

FILL - MEDIUM DENSE, BROWN AND GRAY, MOIST, CLAYEY SAND, WITHTRACE ROOTS

TRIASSIC RESIDUAL - HARD, BROWN, MOIST, SILT

WEATHERED ROCK - TRIASSIC SILTSTONE

BORING TERMINATED

344.5

DRILLING METHOD H.S. AUGER AUGER SIZE 2-1/4 INCH (ID)

HAMMER TYPE AUTODRILL RIG CME 550

DATE DRILLED 2/17/17 LOGGED BY C. T. TANG BORING DEPTH 18.7 ft

CAVE-IN 15.5 ft

GROUND SURFACE EL. 360 ft

TIME OF DRILLING: WL DRYDRILLING CONTRACTOR CAROLINA DRILLING

CAVE-IN FIADAFTER DRILLING: WL FIAD

DE

PT

H (

ft)

TY

PE

ID N

UM

BE

R

ELE

VA

TIO

N (

ft)

FINES CONTENT (%) 10 20 30 40 50 60 70 80 90

SPT N-VALUE (BPF) 10 20 30 40 50 60 70 80 90

N-V

ALU

E (

bpf)

MA

TE

RIA

L T

YP

E

DE

PT

H (

ft)

SP

TB

LOW

CO

UN

TS

SAMPLE

10 20 30 40 50 60 70 80 90

PL LLWC

MATERIAL DESCRIPTION

WL

/ C

AV

E E

L (f

t)

Note: SPT Blow Counts are per 6 inches of penetration unless otherwise noted.

PAGE 1 OF 1

BORING LOG: B-2

LOCATION DURHAM, NC

PROJECT COD SOLID WASTE MANAGEMENT TRUCK WASH BUILDING

PROJECT NO. F17007.00

CLIENT RND ARCHITECTS PA

SS1

SS2

SS3

SS4

SS5

354.9

352.0

345.5

340.0

6

4

4

WOH

3

SC

CL

0.1

3.0

9.5

15.0

233

122

1WOH

4

11

WOH

WOH12

1

2.5

3.5

5

6

7.5

8.5

10

13.5

15

FILL - LOOSE, BROWN AND GRAY, WET, CLAYEY SAND, WITH TRACEGLASS

FILL - LOOSE, BLACK, ASPHALT, CINDERS AND GLASS FRAGMENTS

FILL - SOFT, GRAY AND BROWN, WET TO SATRUATED, LEAN CLAY

BORING TERMINATED

347

DRILLING METHOD H.S. AUGER AUGER SIZE 2-1/4 INCH (ID)

HAMMER TYPE AUTODRILL RIG CME 550

DATE DRILLED 2/16/17 LOGGED BY C. T. TANG BORING DEPTH 15 ft

CAVE-IN NR

GROUND SURFACE EL. 355 ft

TIME OF DRILLING: WL 8.0 ftDRILLING CONTRACTOR CAROLINA DRILLING

CAVE-IN FIADAFTER DRILLING: WL FIAD

DE

PT

H (

ft)

TY

PE

ID N

UM

BE

R

ELE

VA

TIO

N (

ft)

FINES CONTENT (%) 10 20 30 40 50 60 70 80 90

SPT N-VALUE (BPF) 10 20 30 40 50 60 70 80 90

N-V

ALU

E (

bpf)

MA

TE

RIA

L T

YP

E

DE

PT

H (

ft)

SP

TB

LOW

CO

UN

TS

SAMPLE

10 20 30 40 50 60 70 80 90

PL LLWC

MATERIAL DESCRIPTION

WL

/ C

AV

E E

L (f

t)

Note: SPT Blow Counts are per 6 inches of penetration unless otherwise noted.

PAGE 1 OF 1

BORING LOG: B-3

LOCATION DURHAM, NC

PROJECT COD SOLID WASTE MANAGEMENT TRUCK WASH BUILDING

PROJECT NO. F17007.00

CLIENT RND ARCHITECTS PA

B-1 360 18.8 DRY FIAD 9 351

B-2 360 18.7 DRY FIAD 7 353

B-3 355 15 8.0 347 FIAD

Note: Blank cells indicate not encountered or not measured/recorded. Refer to the individual boring log and report for additional details

BoreholeID

GroundSurface El.

(ft)

BoringDepth

(ft)Depth

(ft)Depth

(ft)El.(ft)

Weathered RockEl.(ft)

El.(ft)

Depth(ft)

Time of Drilling GWEl.(ft)

Auger Refusal

BORING SUMMARY TABLEPAGE 1 OF 1

After Drilling GWDepth

(ft)

LOCATION DURHAM, NC

PROJECT COD SOLID WASTE MANAGEMENT TRUCK WASH BUILDING

PROJECT NO. F17007.00

CLIENT RND ARCHITECTS PA

PROJECT NUMBER: F17007.00

PEAT

PLASTIC

ITY I

ND

EX (

%)

CH

Cu>6 AND 1<Cc<3

Cu>6 AND 1>Cc>3

ORGANIC

GRAVELS WITH FINES>12% FINES

CRITERIA FOR ASSIGNING SOIL GROUP NAMESMATERIALTYPES

CO

ARSE-G

RAIN

ED

SO

ILS

>50%

RETAIN

ED

ON

NO

. 200 S

IEVE

GROUPSYMBOL

WELL-GRADED GRAVEL

POORLY-GRADED GRAVEL

SILTY GRAVEL

CLAYEY GRAVEL

WELL-GRADED SAND

POORLY-GRADED SAND

SILTY SAND

CLAYEY SAND

LOW PLASTICITY (LEAN) CLAY

LOW PLASTICITY SILT

ORGANIC CLAY OR SILT

HIGH PLASTICITY (FAT) CLAY

HIGH ELASTICITY SILT

ORGANIC CLAY OR SILT

UNIFIED SOIL CLASSIFICATION (ASTM D-2487)

LEGEND TO SOILDESCRIPTIONS

SANDS

PT

FIN

E-G

RAIN

ED

SO

ILS

>50%

PASSES

NO

. 200 S

IEVE

SILTS AND CLAYS

LIQUID LIMIT>50

GW

GP

GM

GC

SW

SP

SM

SC

CL

ML

OL

CH

MH

OH

SOIL GROUP NAMES & LEGEND

SILTS AND CLAYS

LIQUID LIMIT<50

>50% OF COARSEFRACTION PASSESON NO 4. SIEVE

>50% OF COARSEFRACTION RETAINED

ON NO 4. SIEVE

GRAVELS

PENETRATION RESISTANCE

SANDS AND FINES>12% FINES

CLEAN SANDS<5% FINES

CLEAN GRAVELS<5% FINES

OH & MH"A

" LIN

E

CL-ML ML & OL

FINES CLASSIFY AS ML OR CL

FINES CLASSIFY AS CL OR CH

0 10 20 30 40 50 60 70 80 90 100 110 1200

10

20

30

40

50

60

70

80

MATERIAL TYPES ENCOUNTERED ONSITE

PLASTICITY CHART

LIQUID LIMIT (%)

FINES CLASSIFY AS ML OR CL

FINES CLASSIFY AS CL OR CH

PI>7 AND PLOTS>"A" LINE

PI>4 AND PLOTS<"A" LINE

LL (oven dried)/LL (not dried)<0.75

PI PLOTS >"A" LINE

PI PLOTS <"A" LINE

LL (oven dried)/LL (not dried)<0.75

Cu>4 AND 1<Cc<3

Cu>4 AND 1>Cc>3

PRIMARILY ORGANIC MATTER, DARK IN COLOR, AND ORGANIC ODOR

INORGANIC

ORGANIC

INORGANIC

HIGHLY ORGANIC SOILS

CL

Concrete Fill

Fill - Lean Clay (CL) Fill - Clayey Sand (SC)

Silt (ML) Silty Sand (SM)

Poorly-Graded Sand (SP) Topsoil / Organic Layer

Weathered Rock

* NUMBER OF BLOWS OF 140 LB HAMMER FALLING 30 INCHES TO DRIVE A 2 INCHO.D. (1-3/8 INCH I.D.) SPLIT-BARREL SAMPLER THE LAST 12 INCHES OF AN 18-INCHDRIVE (ASTM-1586 STANDARD PENETRATION TEST).

SAMPLE TYPES

DRY

MOIST

WET

SAT

TRACE

FEW

LITTLE

SOME

ADDITIONAL ABBREVIATIONS, TERMS, & SYMBOLS

Split Spoon

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

WATER LEVEL AT TIME OF DRILLING

REQUIRES WETTING TO REACH OPTIMUM

AT OR NEAR OPTIMUM

REQUIRES DRYING TO REACH OPTIMUM

SATURATED, NEARLY LIQUID

< 5%

5 - 10%

15 - 25%

30 - 45%

WATER LEVEL AFTER DRILLING(EG. 12 HR, 24 HR, EOD, ETC.)CAVE-IN LEVEL(AT LAST WL READING)

UNDRAINED SHEAR

STRENGTH (KSF)

0 - 0.25

0.26 - 0.50

0.51 - 1.0

1.1 - 2.0

2.1 - 4.0

> 4.0

< 3

3 - 4

5 - 8

9 - 15

16 - 30

>30

VERY SOFT

SOFT

MEDIUM STIFF (FIRM)

STIFF

VERY STIFF

HARD

CONSISTENCY BLOWS/FOOT*

SILT & CLAY

(RECORDED AS BLOWS PER 6 IN.)

SAND & GRAVEL

BLOWS/FOOT*RELATIVE DENSITY

VERY LOOSE

LOOSE

MEDIUM DENSE

DENSE

VERY DENSE

< 4

4 - 9

10 - 30

31 - 50

> 50

STANDARD PENETRATION TEST

BLOWS PER FOOT

PLASTIC LIMIT

LIQUID LIMIT

MOISTURE CONTENT

SPLIT SPOON

AUGER PROBE

WATER LEVEL

UNIFIED SOIL CLASSIFICATION SYSTEM

WEIGHT OF HAMMER

WEIGHT OF RODS

FILLED IMMEDIATELY AFTER DRILLING

END OF DAY

SPT

BPF

PL

LL

MC

SS

AP

WL

USCS

WOH

WOR

FIAD

EOD