Gaining the AVEVA Bocad Advantage

Transcript of Gaining the AVEVA Bocad Advantage

Gaining the AVEVA Bocad Advantage

How a progressive deployment of AVEVA Bocad has delivered benefits for Dragados Offshore S.A.

MAGAZINE

AVEVA World Magazine Article Reprint 2016 | Issue 1

Dragados Offshore S.A. is a leading EPC contractor for the oil & gas and other energy-related industries. The company provides comprehensive solutions from concept to delivery. Its services include: concept design, detail design, construction engineering, procurement, construction, transportation, commissioning, offshore installation, and hook-up of offshore fixed platforms, offshore floating platforms, offshore wind power, subsea systems, shallow water pipelines and onshore modular fabrication.

It also carries out special projects based on large steel structures, such as structural components for bridges and dam gates. Efficient execution of such projects requires both expertise and powerful tools. Faced with increasingly diverse and complex projects, Dragados Offshore wanted to upgrade to a design system that would not only meet its specialised needs but which would also be flexible enough to enable engineers to use the same software on different types of projects. Dragados chose AVEVA Bocad™.

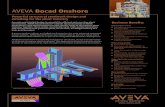

Mariner jacket EPC contract for Statoil – ready for load-out. Photograph courtesy of Dragados Offshore S.A.

AVEVA World Magazine Article Reprint 2016 | Issue 1

Previously, Dragados Offshore had been using AutoCAD for 2D and AVEVA PDMS™ for 3D work. A survey of steel detailing solutions led them to AVEVA Bocad, which stood out, not only for its best-in-class specialised capabilities, but also for being open and customisable. As an existing user of PDMS, Dragados Offshore was naturally very interested in the potential for integrating the two solutions.

The type of complex, high-risk projects in which Dragados Offshore specialises require complete real-time association between the 3D model and its 2D deliverables, so that accuracy is ensured throughout the design and fabrication workflow. AVEVA Bocad not only maintains such an association, but also enables designers to use either the 3D or the 2D design views when editing a design.

In addition, AVEVA Bocad saves time and eliminates many sources of errors by automatically generating high-quality, detailed deliverables that require very little subsequent editing, if any. Importantly for Dragados, it also offers highly productive capabilities for efficiently designing specialised structures such as offshore platforms.

In the contracting business, tendering involves being able to demonstrate the necessary capabilities. AVEVA Bocad’s support for complex geometry eases the process of the first stages of structural design, allowing Dragados Offshore to respond faster in the market.

As a result of in-depth research and collaboration between AVEVA and Dragados, AVEVA Bocad also incorporates valuable features for fabrication quality assurance, such as the treatment of welds as tagged objects instead of manual drawing annotations, and the automatic creation of optimised weld preparations on even the most complex joints.

Mariner jacket EPC contract for Statoil – full 3D detail design. Image courtesy of Dragados Offshore S.A.

Below: Vega Pleyade EPC project for Total – full 3D structural detail design. Image courtesy of Dragados Offshore S.A.

Right: Jasmine project fab contract for ConocoPhillips – WHP structural design. Image courtesy of Dragados Offshore S.A.

Project successesAVEVA Bocad has enabled Dragados Offshore to complete, on time and on budget, a series of extremely complex projects of unprecedented scale for major clients worldwide. These projects, outlined below, comprised both new-build and brownfield work, for hostile environments such as the North Sea or the Southern Atlantic Ocean.

Mariner: bigger than everStatoil’s Mariner offshore field lies in water depths ranging between 97 and 112 metres, approximately 130 km off the British coast. Its production platform separates gas and water from the oil before piping it to an FSU vessel for storage and offloading to shuttle tankers. Dragados Offshore’s scope of work included all of the EPC work, mechanical completion, load-out and sea fastening of the 22,400 tonne Mariner jacket. Delivered in June 2015, this was the largest jacket ever built at Dragados Offshore’s Cadiz yard, and the largest ever commissioned by Statoil.

Vega Pleyade offshore projectVega Pleyade is a gas field located 20 km offshore Tierra del Fuego, Argentina. The field is developed by Total Austral with one platform serving three dry gas wells and piping the gas to the onshore Rio Cullen plant. Dragados performed the complete EPC project of the normally unmanned wellhead platform, including full in-house detail design, covering pre-commissioning and commissioning of the wellhead platform topsides, four-legged jacket and piles.

Eldfisk 2/7S integrated platformAs part of the Greater Ekofisk Area Development, operated by ConocoPhillips Scandinavia, Eldfisk 2/7S is an integrated platform comprising a 154-cabin accommodation module, a wellhead facility and a processing facility, all supported by an eight-leg jacket structure. Dragados completed all EPC work on the project, including onshore commissioning assistance, load-out and sea fastening of the 13,400 tonne jacket, 4,000 tonne bridge support jacket and piles.

Jasmine: old and new The Jasmine field, operated by ConocoPhillips UK, is located in blocks 30/6 and 30/7 in the British part of the North Sea. The project will harness the existing processing capacity of the nearby Judy platform, 240 km east of Aberdeen. The Jasmine development consists of a wellhead platform with 24 well slots, a bridge-linked accommodation platform, a multi-phase pipeline that links Jasmine and Judy, and a brand-new reception and separation platform at the Judy development, as well as modifications to Judy to process the additional fluids once Jasmine comes on line. Dragados undertook the construction and shop engineering of the project, partial procurement, fabrication, mechanical completion, pre-commissioning, commissioning, load-out and sea fastening of the Jasmine wellhead platform topsides (7,425 tonnes), Judy platform topsides (9,320 tonnes), Jasmine wellhead platform bridge (590 tonnes) and the Judy platform bridge (895 tonnes).

This is a clear example of how the ‘know-how’ and expertise of Dragados Offshore can be combined with the potential of AVEVA Bocad to successfully meet users’ requirements and to incorporate new features in response to specific demands.

But capability must be backed up by efficiency, so AVEVA Bocad enables, not only more standardisation, but also the reuse of previous designs and the automation of repetitive or commonly-used designs by developing new macros in house. Together, the new incorporated features and the continuous in-house improvements provide Dragados Offshore with a greater competitive advantage, not only when bidding for new projects, but also in all their processes.

ImplementationImplementing any new software solution is always likely to create disruption. With their heavy workload and tight project deadlines, Dragados Offshore chose to play the long game, implementing AVEVA Bocad progressively over two-and-a-half years. This phased approach proved very successful; the design team began to use the software, enjoying the benefits of the 3D model and design features, while experienced users shared their skills and needs with the AVEVA team on site, to create together a perfect tool to cover all offshore needs with little or no disruption to ongoing projects.

Another advantage of this approach was that it provided the time to fully customise the software to meet Dragados Offshore’s specific requirements. AVEVA worked with the company to detail the respective needs of the fabricator and the builder, deciding together which new features should be implemented into the software, and how AVEVA Bocad’s deliverables could be configured to make their work easier, reducing errors from fabrication right through to completion.

‘It took a while to get internal buy-in,’ said Ramón Núñez, Engineering Director, Dragados Offshore. ‘We had to adapt our long-established ways of working. But it was clear to our management that we had to make the final switch to 3D, not only because we wanted to increase our efficiency, but also because our clients increasingly expect it and we want to continue growing our business. Once our designers saw the software and recognised its potential, they were convinced. Within a year, we had 70 people fully trained on AVEVA Bocad and nowadays we have engineers able to program further customised macros for our needs.’

AVEVA World Magazine Article Reprint 2016 | Issue 1

ResultsThis cooperation between AVEVA Bocad and Dragados Offshore in increasing the program’s features soon showed its worth. The ability to exchange model data with structural analysis programs, and to create detailed, multi-discipline models and accurate layout drawings means better ownership of data, fewer clashes, less rework in construction and shorter schedules. Overall, faster and more efficient steel detailing and creation of fabrication deliverables save Dragados Offshore a considerable percentage of project time; project quality has also been improved. On-demand generation of shop-ready fabrication deliverables makes it possible to delay creation of drawings and CNC data until the last possible moment before fabrication must start. The maximum number of design optimisations can therefore be incorporated to achieve better quality in the fabricated parts and less rework in construction.

AVEVA Bocad’s interoperability, both with AVEVA’s 3D design solutions and with third-party software, adds great value to Dragados Offshore’s projects. ‘It adds value because it allows design integration in the first phases of a project and makes it easier to work on difficult details. In addition, our clients normally work with PDMS and that creates synergies,’ continued Ramón Núñez.

Companies using other systems can spend huge amounts of time manually editing 2D deliverables. But AVEVA Bocad’s fabrication drawings and CNC data are automatically generated and substantially shop-ready. ‘AVEVA Bocad’s CNC files have been optimised for all our CNC machines, and new output types were created to communicate with our automated beam, plate and pipe/tube cutting robots,’ Ramón Núñez explained. ‘This investment has greatly enhanced our performance by eliminating errors and enabling us to reliably deliver on time.’

ConclusionDragados Offshore S.A. is a results-oriented company, committed to offering a best-in-class approach to integrated project execution, safety, quality and schedule compliance,

while maintaining the flexibility to work to each client’s specific needs. It therefore needed a software solution that would continue to support it as its projects become ever larger, more complex and more diverse. AVEVA Bocad has proved its ability to do so and enables Dragados Offshore S.A. to deliver successfully impressive projects the world over.

It is relevant to state that AVEVA’s integrated design and structural detailing solution (PDMS and Bocad) and the acquired experience of Dragados Offshore S.A together have provided maximum benefits from this powerful approach.

About DragadosFounded in 1972, Dragados Offshore S.A. is a leading engineering, procurement and construction (EPC) contractor for the oil & gas and other energy-related industries. Their four decades of experience in both offshore and onshore projects give them a solid track record, ensuring their clients that their most complex and challenging projects will be successfully planned, executed and delivered.

They are a solutions-based company with a lean and effective corporate structure that allows them the flexibility to tailor their work to each client’s specific needs, while providing a best-in-class approach to integrated project execution, safety, quality and schedule compliance. They are committed to excellence in everything they do.

For more information, visit: www.dragadosoffshore.com.

ACS Group (Actividades de Construcción y Servicios)Dragados Offshore is part of the ACS Group. Headquartered in Madrid, Spain, the ACS Group is a global leader in the development, construction and management of infrastructure and related services, with operations and offices worldwide and more than 162,000 employees.

To find out more about ACS and its subsidiaries, please visit the company website at www.grupoacs.com.

Above: The mariner jacket EPC contract for Statoil. The top view of the modelled pile cluster is shown alongside the fabricated pile cluster. Images courtesy of Dragados Offshore S.A.

AVEVA Group plcHigh CrossMadingley RoadCambridgeCB3 0HBUK

Tel +44 (0)1223 556655Fax +44 (0)1223 556666

Headquartered in Cambridge, England, AVEVA Group plc and its operating subsidiaries currently employ staff worldwide in Australia, Austria, Brazil, Canada, Chile, China, Colombia, Denmark, Finland, France, Germany, Hong Kong, Hungary, India, Italy, Japan, Malaysia, Mexico, Norway, Poland, Russia, Saudi Arabia, Singapore, Spain, Sweden, South Korea, the United Arab Emirates, the United Kingdom and the United States of America. AVEVA also has representatives in additional countries around the world.

For more details on AVEVA Worldwide Offices, visit www.aveva.com/offices

www.aveva.com

AVEVA believes the information in this publication is correct as of its publication date. As part of continued product development, such information is subject to change without prior notice and is related to the current software release. AVEVA is not responsible for any inadvertent errors. All product names mentioned are the trademarks of their respective holders.

Copyright © 2016 AVEVA Solutions Limited and its subsidiaries. All rights reserved. AWM/RP/DRA/0116