G-9 DEPOSIT, CAMPO MORADO PROJECT TECHNICAL REPORT ON THE 2007 PROGRAM AND PRELIMINARY ASSESSMENT OF...

Transcript of G-9 DEPOSIT, CAMPO MORADO PROJECT TECHNICAL REPORT ON THE 2007 PROGRAM AND PRELIMINARY ASSESSMENT OF...

REVISED TECHNICAL REPORT ON THE

2007 PROGRAM AND PRELIMINARY ASSESSMENT OF THE

G-9 DEPOSIT, CAMPO MORADO PROJECT

GUERRERO STATE MEXICO

Latitude 18° 12’ N Longitude 100° 08’ W

for Farallon Resources Ltd.

Qualified Persons:

David M.R. Stone, P.Eng. Stephen J. Godden, F.I.M.M.M., C.Eng.

MINEFILL SERVICES, INC. P.O. Box 725, Bothell, Washington, USA 98041

Telephone: (425) 486-0992 Fax: (425) 486-0882

and J. David Gaunt, P. Geo.

Hunter Dickinson Inc.

Report as Revised and Amended: December 27, 2007 Data Effective Date: September 23, 2007

MINEFILL SERVICES, INC. Page i CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

TABLE OF CONTENTS Contents Page 3 EXECUTIVE SUMMARY 1

3.1 Mineralization 1 3.2 Exploration Activity 1 3.3 Campo Morado Priorities 1 3.4 Metallurgical Studies 2 3.5 Mineral Resource Estimates 3 3.6 G-9 Project Pre-Development 4 3.7 Preliminary Mining Scoping Study 6 3.8 Preliminary Assessment 6 3.9 Financial Highlights (EBITDA) 8 3.10 Conclusions and Recommendations 9 4 INTRODUCTION 11

4.1 Qualified Persons 11 4.2 Site Visits by the Authors 12 4.2 Data Sources 12 5 RELIANCE ON OTHER EXPERTS 14 6 PROPERTY DESCRIPTION AND LOCATION 15

6.1 Property Location 15 6.2 Mineral Rights 15 6.2.1 Campo Morado and Reducción La Alina Concessions 17 6.2.2 La Trinidad Concession 19 6.2.3 Reducción El Mil, 2A Reducción Farallon and Farallon 2 Concessions 19 6.3 Mining Law 19 6.3.1 Legal Framework 20 6.3.2 Government Agencies 20 6.3.3 Foreign Investment 20 6.3.4 Concessions 21 6.3.5 Surface Rights and Obligations 22 6.3.6 Mining Obligations 22 6.4 Taxes and Royalties 22 6.5 Metal Sales 23 6.6 Environmental Regulations 23 6.6.1 Legal Framework 23 6.6.2 Government Agencies 24 6.6.3 Environmental Studies 24

MINEFILL SERVICES, INC. Page ii CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Contents continued…. Page 6.7 Permits 25 6.7.1 Exploration Activities (including preliminary mine development) 25 6.7.2 Construction Phase 26 6.7.3 Mining Phase 26 6.8 Environmental Liabilities 28 7 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY 28

7.1 Topography, Vegetation and Elevation 28 7.2 Accessibility 29 7.3 Climate 30 7.4 Infrastructure 31 7.4.1 Surface Facilities 31 7.4.2 Electricity 31 7.4.3 Potable Water 31 7.4.4 Operations’ Water 31 7.5 Local Resources 32 7.6 Socio-Economic Impact 32 8 HISTORY 33

8.1 Overview 33 8.2 Past Production 33 8.3 Historical Resource Estimates 34 9 GEOLOGICAL SETTING 34

9.1 Regional Geology 34 9.2 Property Geology 36 9.3 Deposits’ Geology 36 9.3.1 Reforma Deposit 36 9.3.2 El Rey Deposit 37 9.3.3 Naranjo Deposit 37 9.3.4 El Largo Deposit 37 9.3.5 G-9 Deposit 37 9.4 G-9 Comparisons 39 9.5 Structure 39 10 DEPOSIT TYPE 40 11 MINERALIZATION 40

MINEFILL SERVICES, INC. Page iii CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Contents continued…. Page 12 EXPLORATION 41

12.1 Overview – November 1995 to November 1998 41 12.2 Overview – August 2004 to May 2005 42 12.3 Overview - June 2005 to September 23, 2007 42 13 DRILLING 43

13.1 Overview – June 1996 to May 1998 44 13.2 Overview – August 2004 to May 2005 45 13.3 Overview - June 2005 to September 23, 2007 46 14 SAMPLING METHOD AND APPROACH 51

14.1 Core Sampling 51 15 SAMPLE PREPARATION, ANALYSIS AND SECURITY 52

15.1 Chain-of-Custody 52 15.2 Assay Method 56 15.3 Assay Validation 56 15.4 Specific Gravity Data 56 16 DATA VERIFICATION 57

16.1 Database Description 57 16.2 Verification Approach 57 16.3 Check Analyses 58 17 ADJACENT PROPERTIES 62

18 MINERAL PROCESSING AND METALLURGICAL TESTING 63

18.1 Overview 63 18.1.1 El Largo, Naranjo and Reforma Mineralization 63 18.1.2 G-9 Mineralization 64 18.2 Scope of G-9 Metallurgical Test Programs 65 18.3 G&T Services Report #1 – March 2006 66 18.3.1 Chemical and Mineralogical Analysis 67 18.3.2 Metallurgical Results 69

MINEFILL SERVICES, INC. Page iv CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Contents continued…. Page 18.4 G&T Services Report #2 – April 2006 70 18.4.1 Chemical and Mineralogical Analysis 71 18.4.2 Metallurgical Results 73 18.5 G&T Services Report #3 – October 2006 73 18.5.1 Chemical and Mineralogical Analysis 75 18.5.2 Metallurgical Results 76 18.5.3 Comments 77 18.5.3 Water Impacts 78 18.6 G&T Services Report #4 – April 2007 78 18.6.1 Chemical and Mineralogical Analysis 79 18.6.2 Metallurgical Results 79 18.6.3 Mineral Fragmentation 81 18.7 Ancillary Test Programs 82 19 MINERAL RESOURCE ESTIMATES 83

19.1 El Largo, El Rey, Naranjo and Reforma Deposits 83 19.1.1 Summary of Methodology 83 19.1.2 Resource Summary 84 19.2 G-9 Deposit 84 19.2.1 Geological Modelling 86 19.2.2 Assay Statistics, Grade Capping and Compositing 87 19.2.3 Block Model Definition and Estimation 92 19.2.4 Grade Estimation Validation 94 19.2.5 Resource Classification 94 19.2.6 Resource Summary 95 19.3 Other Factors That May Affect Mineral Resources 96 19.3.1 Non-Technical Issues 96 19.3.2 Technical Issues 97 20 OTHER RELEVANT DATA AND INFORMATION 98

20.1 Project Development 98 20.1.1 Parallel-Track Strategy 98 20.1.2 Current Status 100 20.2 Budget Review 101 20.3 Preliminary Mining Study 103 20.3.1 Access Development 103 20.3.2 Waste Development Plan 104 20.3.3 Stoping and Ore Handling 105 20.3.4 Preliminary Production Schedule 105 20.3.5 Working Production Schedule 106 20.3.6 Mill Feed Processing Model 108 20.3.7 Tailings Disposal 109

MINEFILL SERVICES, INC. Page v CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Contents continued…. Page 20.4 Preliminary Assessment 109 20.4.1 Key Assumptions 110 20.4.2 Operating Costs 111 20.4.3 Pre-Production Capital Costs 112 20.4.4 Sustaining Capital Costs 112 20.4.5 Smelter Recoveries 114 20.4.6 Metal Prices 114 20.4.7 Financial Highlights 114 20.4.8 Sensitivity Analyses 118 21 INTERPRETATION AND CONCLUSIONS 119 22 RECOMMENDATIONS 123 23 REFERENCES 125 24 DATE AND SIGNATURE PAGE 127

MINEFILL SERVICES, INC. Page vi CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

LIST of TABLES Table Page Table 3.1 Total Mineral Resources Estimated by Zinc Grade Cut-off, Campo Morado Deposits, November 2006 3

Table 3.2 Summary of Estimated Metal Prices, September 2007 7

Table 3.3 Summary of EBITDA Financial Highlights, G-9 Operation 8

Table 3.4 Sensitivity Analysis (NPV[0], in US$ millions) of Capital and Operating Costs 9

Table 3.5 Sensitivity Analysis (IRR) of Capital and Operating Costs 9

Table 3.6 Sensitivity Analysis of Zinc Metal Prices 9

Table 3.7 Summary of The Company’s Planned Technical Program, October 2007 to end March 2008, G-9 Project 10

Table 6.1 Campo Morado Project Concessions held by Farallon Resources Limited, through its wholly owned Mexican subsidiary Farallon Minera

Mexicana S.A. de C.V. 16

Table 6.2 A Summary of the Mexican Tax Regime 23

Table 6.3 Applicable Environmental Standards, Campo Morado Project 27

Table 7.1 Access Roads from Mexico City to the Campo Morado Project Site 30

Table 13.1 Summary of Campo Morado Drilling Campaigns, June 1996 to May 1998 45

Table 13.2 Summary of Assay Results, G-9 Drillhole Intersections, June 1996 to May 1998 45

Table 13.3 Summary of Campo Morado Drilling Campaigns, August 2004 to May 2005 46

Table 13.4 Summary of Assay Results, G-9 Drillhole Intersections, August 2004 to May 2005 46

Table 13.5 Summary of Campo Morado Drilling Campaigns, June 2005 to September 2006 47

Table 13.6 Summary of Significant Assay Results, G-9 Drillhole Intersections, June 2005 to September 2006 48

Table 13.7 Summary of Significant Assay Results, G-9 Drillhole Intersections, November 2006 to September 23, 2007 50

Table 16.1 Summary of G-9 Primary vs. Check Assay Results, 2004 to 2006 58

Table 18.1 Precious Metal Distribution for the 1997 Composite Sample 64

MINEFILL SERVICES, INC. Page vii CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

List of Tables continued…. Page Table 18.2 Source of Report #1 Metallurgical Samples 66

Table 18.3 Chemical Composition of the Report #1 Composites 67

Table 18.4 Mineral Composition of the Report #1 Composites 67

Table 18.5 Report #1 - Mineral Liberation in Two Dimensions 68

Table 18.6 Report #1 – Preliminary Metallurgical Test Data 69

Table 18.7 Source of Report #2 Metallurgical Samples 70

Table 18.8 Chemical Composition of the Report #2 Composites 71

Table 18.9 Mineral Composition of the Report #2 Composites 72

Table 18.10 Report #2 - Mineral Liberation in Two Dimensions 72

Table 18.11 Report #2 – Preliminary Metallurgical Test Data 74

Table 18.12 Chemical Composition of the Report #3 Average-Grade Composite 75

Table 18.13 Mineral Composition of the Report #3 Average-Grade Composite 75

Table 18.14 Nominal Flotation Test Conditions, Report #3 Average-Grade Composite 76

Table 18.15 Average Metallurgical Balance, Report #3 Average-Grade Composite 77

Table 18.16 Chemical Composition of the Report #4 High-Grade Composite 79

Table 18.17 Mineral Composition of the Report #4 High-Grade Composite 79

Table 18.18 Nominal Flotation Test Conditions, Report #4 High-Grade Composite 80

Table 18.19 Average Metallurgical Balance, Report #4 High-Grade Composite 80

Table 18.20 Product Grinds for Report #4 Locked Cycle Tests, K80 Microns 81

Table 18.21 Distribution of Minerals in the Report #4 High-Grade and Report #3 Average-Grade Composites 81

Table 19.1 Mineral Resources Estimated by Zinc Grade Cut-off, El Largo, El Rey, Naranjo and Reforma Deposits, November 2006 85

Table 19.2 G-9 Drillholes Used For Geological Modelling and Resource Estimation, November 2006 Resource Estimate 87

Table 19.3 Metal Capping Grades within the VMS Solids, November 2006 Resource Estimate 87

Table 19.4 Block Model Definition, G-9 Deposit 93

Table 19.5 ID2 Search Parameters for G-9 Grade Estimation 93

MINEFILL SERVICES, INC. Page viii CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

List of Tables continued…. Page Table 19.6 Inferred Mineral Resources Estimated by Zinc Grade Cut-off, G-9 Deposit, November 2006 95

Table 20.1 Summary of Planned and Actual Expenditures, January 01 to September 20, 2007, G-9 December 2006 Budget 102

Table 20.2 Summary of Key Elements of the Preliminary Scoping Study 103

Table 20.3 Summary of the Preliminary Production Schedule, August 2006 106

Table 20.4 Summary of the Working Production Schedule, June 2007 107

Table 20.5 Summary of the Company’s Mill Feed Processing Model, June 2007 108

Table 20.6 Summary of the Operating Cost Estimates, MineFill’s September 2007 Preliminary Cashflow Model 112

Table 20.7 Summary of the Company’s Capital Cost Estimates, June 2007 113

Table 20.8 Assumed Average Smelter Recoveries, G-9 Concentrates, September 2007 114

Table 20.9 Summary of Estimated Average Metal Prices, September 2007 114

Table 20.10 Summary of EBITDA Financial Highlights, G-9 Operation 115

Table 20.11 Summary Page, MineFill’s G-9 Preliminary Cashflow Model 115

Table 20.12 Metal Produced, MineFill’s G-9 Preliminary Cashflow Model 116

Table 20.13 Net Smelter Return, Copper Concentrate, MineFill’s G-9 Preliminary Cashflow Model 116

Table 20.14 Net Smelter Return, Lead Concentrate, MineFill’s G-9 Preliminary Cashflow Model 117

Table 20.15 Net Smelter Return, Zinc Concentrate, MineFill’s G-9 Preliminary Cashflow Model 117

Table 20.16 Sensitivity Analysis (NPV[0], in US$ millions) of Capital and Operating Costs 118

Table 20.17 Sensitivity Analysis (IRR) of Capital and Operating Costs 118

Table 20.18 Sensitivity Analysis of Zinc Metal Prices 118

Table 21.1 Summary of Significant Assay Results, Drillhole Intersections, High-Grade Southeast Zone, G-9 Deposit 120

Table 21.2 Summary of Significant Assay Results, Drillhole Intersections, High-Grade Abajo Zone, G-9 Deposit 122

Table 22.1 Summary of The Company’s Planned Technical Program, October 2007 to end March 2008, G-9 Project 124

MINEFILL SERVICES, INC. Page ix CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

LIST of FIGURES Figure Page Figure 3.1 The G-9 Processing Flowsheet 2

Figure 3.2 The G-9 Project Site 4

Figure 3.3 The G-9 Underground Access Development Layout 5

Figure 3.4 The Company’s Parallel-Track Approach to the G-9 Project 5

Figure 6.1 General Location Maps 15

Figure 6.2 Concession Plan, in UTM Co-ordinates 16

Figure 6.3 Deposits’ Location Plan 17

Figure 7.1 Accommodation Blocks at the Campo Morado Exploration/ Administration Camp 28

Figure 7.2 The Campo Morado District, Showing the Location of the Various Deposits 29

Figure 7.3 A General View, Looking West, from Farallon’s Campo Morado Exploration/Administration Camp 29

Figure 9.1 Regional Geology Plans 35

Figure 13.1 General Deposit Thickness Isopach Plan Showing all Holes Drilled to September 23, 2007 43

Figure 13.2 G-9 Deposit Thickness Isopach Plan Showing all Holes Drilled to September 23, 2007 44

Figure 14.1 A General View of Farallon’s Core Storage and Logging Facility, from the Campo Morado Exploration/Administration Camp 52

Figure 15.1 1996 to 1998 Sampling and Analytical Flow Chart, Host Rock Samples 53

Figure 15.2 1996 to 1998 Sampling and Analytical Flow Chart, Mineralized Samples 54

Figure 15.3 2004 to 2007 Sampling and Analytical Flow Chart 55

Figure 16.1 Check Analysis Results for Gold (2004 to 2006) 59

Figure 16.2 Check Analysis Results for Silver (2004 to 2006) 59

Figure 16.3 Check Analysis Results for Copper (2004 to 2006) 60

Figure 16.4 Check Analysis Results for Lead (2004 to 2006) 60

Figure 16.5 Check Analysis Results for Zinc (2004 to 2006) 61

Figure 18.1 The G-9 Processing Flowsheet 65

Figure 18.2 Metallurgical Samples, G-9 Deposit, Reports #1 to #3 Test Cycles 66

MINEFILL SERVICES, INC. Page x CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

List of Figures continued…. Page Figure 18.3 Report #1 Flotation Test Flowsheet 69

Figure 18.4 The Report #3 Flotation Test Flowsheet 76

Figure 18.5 The Report #4 Flotation Test Flowsheet 80

Figure 19.1 Modelled Massive Sulphide and Replacement Bodies, November 2006 Resource Estimate 86

Figure 19.2 Probability Plots for Gold – All Domains 88

Figure 19.3 Probability Plots for Silver – All Domains 89

Figure 19.4 Probability Plots for Copper – All Domains 90

Figure 19.5 Probability Plots for Lead – All Domains 91

Figure 19.6 Probability Plots for Zinc – All Domains 92

Figure 20.1 The G-9 Project Site 98

Figure 20.2 The Company’s Parallel-Track Approach to the G-9 Project 99

Figure 20.3 The Developing G-9 Plant Site and Mill Access/Ore Haul Road, June 2007 100

Figure 20.4 The G-9 Portal Site (San Agustin) and Six Cubic Yard Scoop/LHD 101

Figure 20.5 The G-9 Underground Access Development Layout 104

Figure 20.6 Sensitivity of NPV(0) and IRR to Capital and Operating Costs 118

Figure 20.7 Sensitivity of NPV(0) and IRR to the Zinc Price 119

Figure 21.1 G-9 Deposit Thickness Isopach Plan Showing the Recently Drilled Holes into the Southeast and Abajo (New) Zones 122

MINEFILL SERVICES, INC. Page xi CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

NOMENCLATURE, ABBREVIATIONS and ACRONYMS

Abbreviation Unit or Description Ag silver amsl above mean sea level Au gold B.C. British Columbia, Canada CONAFOR Mexican National Forestry Commission (Comisión Nacional Forestal) CONALEP

Mexican National College of Technical Education (Colegio Nacional de Educación Profesional Técnica)

ERA Environmental Risk Assessment CAN Mexican National Water Commission (Comisión Nacional del Agua) CFE Mexican Federal Electricity Commission (Comision Federal de Electricidad) CGM Coordinación General de Mineria C$ Canadian Dollars Cu copper CUS Change of Use of Soil Permit (Cambio de Uso de Suelo) g/t grams per tonne ha hectare INAH

Mexican National Anthropological and Historical Institute (Instituto Nacional de Antropología e Historia)

INE Mexican National Institute of Ecology (Instituto Nacional de Ecologia) IRR internal rate of return km kilometre LAN Mexican Law of National Waters (Ley de Aguas Nacionale) lb pound (weight) LHD Load-Haul-Dump (trackless mining) unit LGEEPA

Mexican General Law of Ecologic Equilibrium and Environmental Protection (Lay General de Equilibrio Ecológico y Protección al Ambiente)

m metre MIA-P Environmental Impact Manifest (Spanish) Mt million tonnes μm micron NI National Instrument (43-101) NPV net present value NSR net smelter return oz Troy ounce Pb lead % percent PROFEPA

Mexican Federal Agency for the Protection of the Environment (Procuraduría Federal de Protección al Ambiente)

SEMARNAT

Mexican Secretariat of Environmental and Natural Resources (Secretaría de Medio Ambiente y Recursos Naturales)

SG specific gravity SGM Mexican Geological Service (Servicio Geologico Mexicano) stpd short tons per day t tonne (metric) US$ United States Dollars VMS volcanogenic massive sulphide (type mineral deposit) Zn zinc

All dollar figures are in United States Dollars (US$), unless otherwise stated.

MINEFILL SERVICES, INC. Page 1 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

3 EXECUTIVE SUMMARY

Farallon Resources Limited (the “Company”) is the 100 percent owner of the Campo Morado Project in Mexico, through its wholly owned Mexican subsidiary Farallon Minera Mexicana S.A. de C.V. The Project area is some 160 kilometres south-southwest of Mexico City, it comprises 11,813.9 hectares in six mining concessions. The Campo Morado concession has been the focus of the Company’s exploration activity to date. Five primary mineral deposits (El Largo, El Rey, G-9, Naranjo and Reforma) and a number of other, less well-defined mineralized occurrences have been identified.

3.1 Mineralization

Campo Morado mineralization is of the volcanogenic massive sulphide (“VMS”) type. The massive sulphide horizons host polymetallic (base metal and precious metal) mineralization within a complex, layered sequence of felsic to intermediate volcanics. The metals with economic potential include gold, silver, copper, lead and zinc (not listed in order of economic significance).

3.2 Exploration Activity

The Company’s exploration activities have covered two main periods: from November 1995 to November 1998, when their exploration activities temporarily ceased due to unfavorable metal prices; and from August 2004 to present. Up to the data cut-off date for this Technical Report of September 23, 2007, the Company had completed 649, exploration diamond drillholes (194,547.30 metres), including 194 G-9 exploration diamond drillholes (95,585.61 metres).

3.3 Campo Morado Priorities

High-grade mineralization in the G-9 deposit was intersected in drillhole 5420 in June 2005 (13.96 metres true width grading 1.06 g/t Au, 67 g/t Ag, 1.76% Cu, 0.69% Pb and 14.16% Zn). Further drilling established the presence of a persistent zone of high-grade material in the so-called Southeast Zone. A preliminary resource estimate for G-9 was completed in late 2005. Metallurgical testing confirmed the amenability of G-9 mineralization to conventional flotation methods to recover selective copper, lead and zinc concentrates, with important by-products of gold and silver. These results together identified the G-9 deposit as being distinctly different from the other four primary Campo Morado VMS deposits that contain comparatively lower grade mineralization and require the use of hydrometallurgical methods to produce gold, silver, copper and zinc.

In 2006, the G-9 deposit became the primary target for Campo Morado Project development. An updated resource estimate was completed in November 2006, following infill and step-out drilling. G-9 continued to be the main focus of work during 2007 and it is the technical details of

MINEFILL SERVICES, INC. Page 2 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

the G-9 deposit that are the primary focus of this Technical Report. The other four primary deposits are still considered an important aspect of the Campo Morado property, insofar as they have longer-term development potential.

3.4 Metallurgical Studies

The fourth in a series of G-9 metallurgical studies was completed in April 2007. Its purpose was to investigate the metallurgical response of a composite of high-grade mineralization from the G-9 Southeast Zone (the average grades of the so-called High-Grade Composite were 1.13 g/t Au, 100 g/t Ag, 0.70% Cu, 0.42% Pb and 14.80% Zn). In the opinion of MineFill, the samples used in the second, third and fourth metallurgical study programs were representative of the mineralization that the studies intended to test. The Study One samples might not have been representative of large amounts of the resource, due to the limited amount of drilling that at the time had been completed. The results of the fourth series of tests indicate that:

• a zinc concentrate grade of 54% Zn can be achieved with a 94 percent zinc recovery; and

• a copper concentrate grade of 24% Cu can be produced with an 84 percent copper recovery.

The Study Four results reflect a significant overall improvement in the metallurgical response of high-grade G-9 mineralization compared with average-grade mineralization/the Average Grade Composites considered within the scope of the third metallurgical study (that was completed during the third quarter of 2006). In particular, copper and zinc recoveries were significantly higher (84 percent versus 69 percent for copper and 94 percent versus 86 percent for zinc) and a modest improvement in silver recovery was achieved (63 percent versus 48 percent).

Figure 3.1 summarizes the G-9 processing flowsheet defined as a result of the metallurgical test programs to date (September 2007). Detailed mill and process plant engineering is being carried out by M3 Engineering & Technology Corporation of Tucson, Arizona (see the Company’s news release dated March 22, 2007).

Figure 3.1 – The G-9 Processing Flowsheet

Feed

Zinc 1 ClTail

st

Zinc RoTail36µm K80 MBS

3418A

10µm K80

Cu/Pb Circuit Zn Circuit

Bulk Conto reverse circuit

ZincCon

MBS

10µm K80

LimeCuSO4SIPXReverse Circuit

Rev ConPb Con

Bulk Con

Rev TailCu Con

40°CNaCN

MINEFILL SERVICES, INC. Page 3 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

3.5 Mineral Resource Estimates

The Company has compiled and reported mineral resource estimates at different zinc grade cut-offs for each of the five primary Campo Morado deposits, which estimates are summarized on Table 3.1. The G-9 estimates were compiled from the results of all surface exploration diamond drilling to October 2006 that included 134 exploration holes (67,893.44 metres). In the opinion of MineFill, the mineral resource estimates summarized on Table 3.1 are fully compliant with:

• the definitions stated in the Canadian Institute of Mining and Metallurgy and Petroleum Standards on Mineral Resources and Mineral Reserves adopted by the CIM Council on December 11, 2005; and

• the CIM Best Practice guidelines for Estimation of Mineral Resources and Mineral Reserves dat November 23, 2003.

Table 3.1 Total Mineral Resources Estimated by Zinc Grade Cut-off,

Campo Morado Deposits, November 2006 Resource

Class Zinc

Cut-off (%) Tonnes Au (g/t) Ag (g/t) Cu (%) Pb (%) Zn (%) Totals for G-9 Deposit

Inferred

2.0 4.0 6.0 8.0

10.0

5,570,000 3,840,000 2,590,000 1,770,000 1,250,000

2.8 3.0 3.0 2.9 2.6

186 200 205 201 195

1.3 1.5 1.7 1.9 2.0

1.0 1.2 1.3 1.3 1.2

7.3 9.3 11.4 13.4 15.3

Totals for El Largo, El Rey, Naranjo and Reforma Deposits Indicated

3.0 4.0 5.0 6.0 7.0 8.0

13,243,000 8,577,000 4,933,000 2,507,000 1,212,000

511,000

2.03 2.12 2.14 1.79 1.54 1.27

138 153 166 163 167 171

0.49 0.47 0.45 0.40 0.37 0.36

1.25 1.41 1.59 1.70 1.88 2.05

4.84 5.57 6.37 7.26 8.11 9.06

Inferred

3.0 4.0 5.0 6.0 7.0 8.0

1,222,000 554,000 241,000 114,000 70,000 41,000

1.51 1.51 1.41 1.31 1.16 0.90

121 137 151 153 155 144

0.60 0.53 0.42 0.36 0.32 0.28

0.86 1.03 1.30 1.53 1.73 1.96

4.33 5.28 6.43 7.48 8.09 8.58

The reader should be aware that Inferred mineral resources are considered too speculative geologically to have economic considerations applied to them that would enable them to be categorized as mineral reserves.

Exploration drilling during 2007 continues to enlarge the defined areas of G-9 mineralization. The average overall grade of intersected G-9 mineralization also appears to be increasing. This may stated because since the November 2006 mineral resource estimates were compiled, and up to the data cut-off date for this Technical Report of September 23, 2007, an additional 59 exploration holes (27,097.51 metres) had been drilled into the G-9 deposit. 33 Of the additional

MINEFILL SERVICES, INC. Page 4 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

holes intersected significant, high-grade sulphide mineralization in the so-called Southeast and Abajo Zones, many of which holes define extensions to the mineralized zones that were delimited for purposes of the November 2006 resource estimates.

More surface infill and step-out drillholes are planned for completion during 2007 (i.e. post the data cut-off date for this Technical Report of September 23, 2007). Underground drilling is also planned, it will commence once the required access development is complete. It is anticipated that the Company will publish updated mineral resource estimates for the G-9 deposit early in 2008.

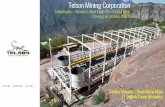

3.6 G-9 Project Pre-Development

Planning and design for G-9 (mine, processing plant, infrastructure and tailings dam) was initiated to establish the appropriate parameters for designing the underground access decline and to prepare the site, based on a parallel-track approach. Figure 3.2 is an overview of the underground access and ventilation declines, as well as other site facilities. Figure 3.3 summarizes the underground access development layout. At the time of writing (September 2007) surface preparation (plant site, access roads, etc) was actively underway and the underground access ramps were actively being developed. Key equipment had also been ordered.

Figure 3.2 – The G-9 Project Site

MINEFILL SERVICES, INC. Page 5 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Figure 3.3 – The G-9 Underground Access Development Layout Underground access development and other engineering activity is continuing at the same time as step-out and infill surface drilling because a parallel-track, G-9 development program is being pursued by the Company, in the manner suggested by Figure 3.4. The work is directed towards completion of the technical work required to allow a production decision to be made prior to the target date of July 01, 2008 for start-up production at G-9. The Company has verbally reported to MineFill that it will commence work on feasibility-level studies for G-9 once Measured and Indicated resources for the deposit have been established.

Figure 3.4 – The Company’s Parallel-Track Approach to the G-9 Project

MINEFILL SERVICES, INC. Page 6 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

3.7 Preliminary Mining Scoping Study

Preliminary production planning, based on the Company’s November 2006 resource estimate, has identified a total diluted production tonnage for the G-9 deposit of 3,130,133 tonnes at an average grade of 9.69% Zn, for a five percent zinc grade cut-off. This includes high-grade mineralization from the Southeast Zone that contains:

• 1.46 million tonnes of Inferred mineral resource at 2.7 g/t Au, 202 g/t Ag, 1.9% Cu, 1.2% Pb and 11.5% Zn, above a two percent zinc grade cut-off; or

• 0.89 million tonnes of Inferred mineral resource at 2.3 g/t Au, 179 g/t Ag, 2.1% Cu, 1.3% Pb and 15.7% Zn above an eight percent zinc grade cut-off.

A mill feed production schedule has been compiled, which schedule incorporates the reasonable assumption of selective stoping in the high-grade Southeast Zone during the first few production years. A mill feed processing schedule has also been defined, it is based on the mill feed production schedule and the results of metallurgical tests on G-9 mineralized material.

The results of the preliminary mining scoping study were used to establish the planned production rate of 1,500 tonnes per day, hence the diluted production depletion and mill feed processing schedules, as well as optimum dimensions for the access development ramp (4.5 metres by 4.5 metres). The dimensions of the access ramp were based on an (mining engineering) experience- and industry precedent-based preliminary planning process. In the opinion of MineFill, the dimensions and layout of the underground access development are fit for purpose and the planned production rate is appropriate, albeit that a modest increase may be justified, given the expanding size of the G-9 mineral deposit.

Details of the stoping method have not been finalized; cut & fill and room & pillar methods have instead been assumed. In the opinion of MineFill, the provisional nature of the stoping designs is not a limitation of current planning because it may reasonably be construed as both usual and preferable, in areas where new deposits and/or new mines are being developed, to retain a strong element of flexibility in stope planning and design ahead of site-specific knowledge of rockmass conditions experienced underground.

3.8 Preliminary Assessment

This Technical Report includes a preliminary cashflow analysis of mining and processing G-9 mineralized material, based in part on the production and processing schedules earlier outlined. The cashflow model was compiled as part of MineFill’s internal due diligence carried out as part of the investigations presented in the Technical Report. The model assumes the metal prices summarized on Table 3.2, that copper, lead and zinc concentrates will be toll-smelted and that the metals (gold, silver, copper, lead and zinc) will likely be refined in Asia, for sale in Asia. The option of toll-smelting and metal refining within Mexico is being investigated by the Company. The option that yields the better financial return will ultimately be employed.

MINEFILL SERVICES, INC. Page 7 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Table 3.2

Summary of Estimated Average Metal Prices, September2007 Production Year End (same as fiscal year end)

Metal June 30, 2009

June 30, 2010

June 30, 2011

June 30, 2012

June 30, 2013

June 30, 2014

June 30, 2015

Gold (US$/oz) Silver (US$/oz) Copper (US$/lb) Lead (US$/lb) Zinc (US$/lb)

550 8.00 2.59 0.49 1.30

500 7.00 2.33 0.44 1.10

500 6.00 2.11 0.40 0.88

500 6.00 1.40 0.40 0.75

500 6.00 1.40 0.40 0.75

500 6.00 1.40 0.40 0.75

500 6.00 1.40 0.40 0.75

MineFill’s preliminary assessment does not include:

• potential additional G-9 resources outlined by diamond drilling that has been completed since the mineral resource estimates summarized on Table 3.1 were estimated, since when –

o the Company has announced in various news releases significant intersections of massive sulphides that include intersections in step-out holes in the high-grade Southeast Zone, and

o the discovery of a new mineralized zone (the Abajo Zone) of high-grade material that is immediately to the north of the area in which the November 2006 resources are located;

• the upside benefit of processing, at some future date, mineralized material from the El Largo, El Rey, Naranjo and Reforma deposits; or

• the cost of rehabilitation that has not yet been defined due to further anticipated changes to the production schedule for a G-9 operation (grade and tonnes, the latter leading to a longer life-of-mine that is currently 6.3 years), as well as the likely continued use of the G-9 plant site for future processing operations.

As regards the first preceding point, it is emphasized that since the November 2006 resource estimates were reported, and up to the data cut-off date for this Technical Report of September 23, 2007, an additional 59 surface exploration holes were drilled into the G-9 deposit, 33 of which holes intersected significant sulphide mineralization in the Southeast and Abajo Zones. Additional infill and step-out drillhole intersections in the Southeast and Abajo Zones are planned for completion during 2007. A changing G-9 production schedule may, therefore, reasonably be expected on the back of future changes to the resource base, including an increase in the available tonnes (hence a longer G-9 life-of-mine) and a more prolonged, initial production period of high-grade mineralization.

MINEFILL SERVICES, INC. Page 8 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

3.9 Financial Highlights (EBITDA)

The Earnings Before Interest, Taxes, Depreciation and Amortization (“EBITDA”) highlights of MineFill’s preliminary G-9 cashflow model are summarized on Table 3.3. The results reflect a robust project and support the continued parallel-track development of the G-9 Project.

Table 3.3 EBITDA Financial Highlights, G-9 Operation

Tonnes Milled 3,130,133 tonnes Average Grade 3.05 g/t Au

200 g/t Ag 1.58% Cu 1.15% Pb 9.69% Zn

Total Recovered Metal 52,800 oz Au 6,970,000 oz Ag 70,010,000 lb Cu 32,884,000 lb Pb 456,530,000 lb Zn

Average Annual Metal Recovery (Life-of-Mine = 6.3 years)

8,400 oz Au 1,106,000 oz Ag 11,113,000 lb Cu 5,213,000 lb Pb 72,450,000 lb Zn

Average On-site Operating Cost $48.22 per tonne milled Start-up Capital Cost US$124.3 million Net Cashflow US$223.6 million NPV (8%) US$141.8 million NPV (12%) US$113.1 million IRR 54% Payback Period Slightly more than one year

It should be noted that there have been no feasibility studies in support of mining or mine development in the G-9 deposit. The preliminary financial results summarized on Table 3.3 must, therefore, be considered in the context of a Preliminary Assessment. Furthermore, the reader is cautioned that the results are based on the use of the Company’s Inferred resource estimates that are considered geologically speculative. There is no guarantee that either the resources will be upgraded to reserve status or that the calculated project returns will ever be realized. Mineral resources that are not mineral reserves do not have demonstrated economic viability.

The robustness of the preliminary financial results was explored using sensitivity analyses to examine the impact of varying the capital costs, operating costs and zinc metal prices. The results are presented on Tables 3.4 to 3.6, inclusive.

MINEFILL SERVICES, INC. Page 9 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Table 3.4 Sensitivity Analysis (NPV[0], in US$ millions) of Capital and Operating Costs

Variable Changed -20% -10% 0% 10% 20% Operating Cost 253.1 238.4 223.6 208.9 194.1

Capital Cost 255.6 239.6 223.6 207.6 191.6

Table 3.5 Sensitivity Analysis (IRR) of Capital and Operating Costs

Variable Changed -20% -10% 0% 10% 20% Operating Cost 58% 56% 54% 52% 51%

Capital Cost 72% 62% 54% 47% 41%

Table 3.6 Sensitivity Analysis of Zinc Metal Prices

Variable -20% -10% 0% 10% 20% NPV (0), in US$ millions 135.1 179.4 223.6 267.8 312.1

IRR 37% 46% 54% 62% 69%

The following statement relates to the implications of work completed since the effective date for this Technical Report (September 23, 2007): Following discussions with the Company and a review of publicly released information, MineFill does not anticipate any material changes to the scope of the G-9 project that might render the results of the September 2007 cashflow model unrepresentative.

3.10 Conclusions and Recommendations

The Company’s continued parallel-track development of the G-9 project is supported. The approach may be justified from consideration of:

• the robust metallurgical results for G-9 mineralization over four programs;

• the VMS nature of the deposit (VMS deposits tend to be consolidated into discrete, sulphide-rich lenses in which regular metal zoning rarely occurs);

• the lateral persistence of the mineralized grades intersected thus far (September 2007);

• the history of G-9 exploration drilling (that has consistently resulted in additional resource tonnes at ever-higher average resource grades); and

• the robust financial returns reflected by the results of MineFill’s preliminary assessment.

MINEFILL SERVICES, INC. Page 10 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Infill and step-out surface drilling should continue to concentrate on more fully defining the G-9 deposit. However, other potential opportunities to the north of San Raphael fault, in what appears to be a stratigraphic horizon below the previously identified VMS deposits (i.e. at the same apparent stratigraphic horizon as the G-9 deposit), should not be overlooked. The last point is emphasized because the Campo Morado project area has many of the characteristics of a growing VMS/base metal district in which additional resources and/or new deposits might yet be found. In view of this, MineFill supports the continuation of the Company’s program to advance the G-9 Project through to the end of March 2008 and concurs with the Company’s G-9 technical program to end March 2008 (Table 3.7).

Table 3.7 Summary of The Company’s Planned Technical Program, October 2007

to end March 2008, G-9 Project Activity Period Objective Infill surface exploration drilling at 25 metre spacings into the North Zone

October 2007 to end February 2008

To facilitate upgrade of resources to the Measured and Indicated categories

Step-out and infill surface exploration drilling at 25 metre spacings into the Abajo Zone

January 2008 to end February 2008

To allow Measured and Indicated resources to be estimated

New target drilling at 50 to 100 metre spacings, to the north of G-9

March 2008 To explore for additional, G-9 mineralized occurrences

Decline advance October 2007 to end March 2008

To facilitate underground drilling and to thereby facilitate the definition of a mineral reserve base

Resource Estimation December 2007 and March 2008

To update November 2006 resource estimates (Sub-Section 19.2)

Mine planning, engineering, economic evaluation and reporting to at least pre-feasibility level

January 2008 to end March 2008

To facilitate production decision, based on Southeast, Southwest and North Zone mineral resources

The all-in estimated cost for the Company’s G-9 technical program summarized on Table 3.7 is US$24.89 million. The project budget proposed in the G-9 Technical Report dated December 2006 comprised a C$55 million program, including surface and underground drilling, access decline development, metallurgical testing and mine planning. MineFill has reviewed the budget and what has been completed to date (September 2007). It is anticipated that the December 2006 budget will cover the costs of the G-9 underground access, surface exploration and site preparation programs through to early 2008. It is further anticipated that studies will continue beyond the end of March 2008.

MINEFILL SERVICES, INC. Page 11 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

4 INTRODUCTION

This report is entitled ‘Technical Report on the 2007 Program at the G-9 Deposit, Campo Morado Project, Guerrero State, Mexico’ (this “Technical Report”); the data cut-off date is September 23, 2007. It has been prepared for Farallon Resources Limited (the “Company”) with the purpose of:

• providing a NI 43-101 compliant report on the G-9 deposit, which forms part of the larger Campo Morado Project;

• documenting the results of the Company’s drilling and metallurgical testing programs carried out since the December 2006 Project report; and

• fulfilling Part 4.2 (1) (j) (i) of National Instrument (“NI”) 43-101 (obligation to file a Technical Report in connection with a written disclosure about a mineral project).

The Company is based in Vancouver, British Columbia, Canada. It is listed on the Toronto Stock Exchange (trading symbol: FAN) and it trades in the United States on the Over-the-Counter Bulletin Board (trading symbol: FRLLF). The Company is engaged in exploration and mine development in the Campo Morado Project area (the “Project area”), which comprises the Company’s only material mineral property.

The Campo Morado Project is located some 160 kilometres south-southwest of Mexico City, in the Sierra Madre del Sur range. The Project area comprises 11,813.9 hectares in six mining concessions in which the Company holds a 100 percent interest through its wholly owned Mexican subsidiary Farallon Minera Mexicana S.A. de C.V. (“Farallon”).

4.1 Qualified Persons

The Qualified Persons (authors) of this Technical Report are:

Dr. David Stone, P.Eng., Consulting Engineer and President of MineFill Services, Inc., Vancouver, British Columbia. Dr. Stone is a co-author of this Technical Report. He provided technical oversight during the preparation of this Technical Report and discussed the approach regarding the preliminary assessment presented in Section 20;

Mr. Stephen Godden, F.I.M.M.M., C.Eng., Consulting Engineer, Director of SGA Limited, Welwyn Garden City, UK and Associate of MineFill Services, Inc. Mr. Godden is the principal author of this Technical Report. He is responsible for compiling all the report sections, for reviewing previous reports, documents and news releases and for verifying the information by means of due diligence, in part through discussions with the professionals who completed studies on the G-9 project. He prepared the preliminary assessment presented in Section 20 of this Technical Report.

MINEFILL SERVICES, INC. Page 12 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Mr. David Gaunt, P.Geo. – Geologist and Manager of Resources for Hunter Dickinson Inc. from May 2000 to present, during which time he has been responsible for assay certificate and drill database verification, three-dimensional deposit modelling, geostatistical modelling, resource estimation and completion of the G-9 resource estimate.

4.2 Site Visits by the Authors

David Stone, P.Eng., visited the Campo Morado Project on numerous occasions since 1996; his last visit was in February 2004. Mr. Stone’s past involvement with the Campo Morado Project included the preparation of preliminary mining scoping studies and managing the preparation of engineering studies for mining the Naranjo and Reforma deposits.

Stephen Godden, F.I.M.M.M., C.Eng., visited the Campo Morado Project between June 19 and June 21, 2007. During the visit he toured the G-9 Project site, reviewed the project plans, visited the G-9 underground excavations, observed the on-going drilling program, examined core, examined geology plans and sections and held discussions with Farallon staff members. Mr. Godden made several visits to the Company’s head office in Vancouver between June 22 and June 29, 2007 to discuss a broad range of Project-related issues with Company staff members and to collect and collate Company information about the Campo Morado Project.

David Gaunt, P.Geo., has visited the Campo Morado Project on numerous occasions in his capacity of Manager of Resources for Hunter Dickinson Inc. His last site visit was made between October 24 and 28, 2005.

4.3 Data Sources

Portions of Sections 6 to 11 of this Technical Report were compiled by MineFill Services Inc. (“MineFill”) from the following NI 43-101 compliant Technical Reports, following their review (both of the listed reports are filed on www.sedar.com):

• ‘Technical Report on the Campo Morado Project, Guerrero State, Mexico’ by D. Kilby, P. Taggart and Q. Deng and dated June 24, 2005 (the “June 24, 2005 Technical Report”); and

• ‘Technical Report on the Campo Morado project, Revised Update on Exploration, Resources and Metallurgical Activities for the G-9 Deposit, Guerrero State, Mexico’ by R. Banner, D. Gaunt, D. Kilby, P. Taggart, Q. Deng and D. Dreisinger and dated December 13, 2006 (the “December 13, 2006 Technical Report”).

The current G-9 resource estimate was reported by the Company in the December 13, 2006 Technical Report and in the Company’s November 14, 2006 news release. Portions of the December 13, 2006 Technical Report repeat or directly reference information contained in the June 24, 2005 Technical Report. The following Qualified Persons were responsible for those portions of the December 13, 2006 Technical Report that are relevant to the G-9 Project:

MINEFILL SERVICES, INC. Page 13 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Daniel Kilby, P.Eng. – Geologist and site manager for the Company’s/Farallon’s exploration program from November 1995 to October 1998 and from August 2004 to present, during which time he has overseen local and regional geological reconnaissance on the Campo Morado Project area, as well as diamond drilling, core logging, sampling, sample security and sample integrity.

Qingping Deng, Ph.D., C.P.G. - Behre Dolbear’s Vice President of US Operations and Global Director of Ore Reserves and Mining Planning. Mr. Deng was responsible for the data verification and resource estimates for the El Largo, El Rey, Naranjo and Reforma deposits.

Peter Taggart, P.Eng. – Consulting Metallurgist and Principal, P. Taggart & Associates Limited. Mr. Taggart has provided metallurgical assistance to the Company since 1997. Mr. Taggart has been responsible for directing flotation testwork on samples of El Largo, G-9, Naranjo and Reforma deposits.

This Technical Report is also based on information provided by the Company, observations made during various site visits made by MineFill and various documents and reports, including documents sourced by means of a web search. The key documents referenced herein include:

• a consultancy report to the Company by Laura Diaz Nieves of Diaz Nieves and Bouchot entitled ‘Farallon Minera Mexicana, S.A. de C.V. Mining Concessions’ and dated August 15, 2006;

• a document by Baker & McKenzie entitled ‘Mining Law in Mexico: An Overview’ (source:www.bakernet.com/NR/rdonlyres/9D4AA2AF-D856-4ECC-828A-D306D05A2564/ 40322/MiningLawinMexBron1.pdf);

• the Company’s Form 20-F to the United States Securities and Exchange Commission, Washington D.C. 20549, dated June 30, 2006;

• a document entitled ‘Overview of the Environmental Laws of Mexico’ by Haight, Brown & Bonesteel LLP (source: www.natlaw.com/pubs/spmxen13.htm);

• a document by Biologist J. Ricardo Juárez Palacios, of the Mexican Secretariat of Environmental and Natural Resources (Secretaría de Medio Ambiente y Recursos Naturales, or SEMARNAT), to Farallon that is dated March 29, 2007;

• G&T Metallurgical Services Limited (“G&T Services”) report number KM 1881 (Report #3) to the Company entitled ‘An Assessment of the Metallurgical Response for the G-9 Master Composite, Farallon Resources Ltd, Campo Morado Project, Guerrero State, Mexico’ and dated October 4, 2006;

• G&T Services report number KM 1951 (Report #4) to the Company entitled ‘An Assessment of the Metallurgical Response for the High Grade Master Composite, Farallon Resources Ltd, Campo Morado Project, Guerrero State, Mexico’ and dated April 18, 2007;

• Advanced Mineral Technology Laboratory report to the Company entitled ‘Deportment of Gold and Silver in Campo Morado Zinc Rougher Tails’, dated October 3, 2006”;

MINEFILL SERVICES, INC. Page 14 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

• SGS Lakefield Research Limited Project 11335-001 report to the Company entitled ‘An Investigation into an Innovative Grinding System for the Campo Morado Circuit Based on Small-Scale Data’ that is dated October 4, 2006;

• a project memorandum by Xstrata Technology to the Company entitled ‘Isamill Circuit Design for Campo Morado’ and dated October 23, 2006;

• McIntosh Engineering Inc. consultancy report for the Company entitled ‘Campo Morado, G-9 Scoping Study Report’ dated August 31, 2006;

• various internal Company documents, prepared by Company/Farallon staff members, that deal with the Company’s environmental and socio-economic programs; and

• various Company news releases filed on www.sedar.com.

MineFill has relied on data and information derived from work completed by Farallon, the Company’s consultants and various data sources. Although MineFill has reviewed most of the available data and has made various site visits (the latest in June 2007 – Sub-Section 4.1), these tasks validate only a portion of the entire data set. MineFill has also assumed the data contained in the above listed reports is both accurate and valid, which assumption is based on the professional status of the reports’ authors and the nature of their reports.

5 RELIANCE ON OTHER EXPERTS

The Campo Morado concession information presented in this Technical Report is based on a title opinion by Laura Diaz Nieves, as detailed in the above listed report by Diaz Nieves and Bouchot and dated August 15, 2006. MineFill has made no attempt to verify the legal ownership or title to the Campo Morado Project area and MineFill is not qualified to assess the validity of the Company’s concessions in Mexico.

MineFill is not qualified to assess environmental issues in Mexico and has made no attempt to comment on, verify or assess environmental issues or liabilities on the Campo Morado Project area. MineFill can report on observations made during its site visits only, as well as issues that Minefill is made aware of by the Company/Farallon, but this should not be considered a comprehensive overview of the environmental issues. An environmental impact manifest (Manifestación de Impacto Ambiental, or MIA-P) has been prepared for the Company/Farallon by Corporación Ambiental de México, S.A. de C.V. (Project CAM05009 entitled ‘Proyecto de Explotación y Beneficio de Minerales Campo Morado, Municipio de Arcelia, Guerrero’, dated October 2006 and written in Spanish as Mexican Law requires).

MINEFILL SERVICES, INC. Page 15 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

6 PROPERTY DESCRIPTION AND LOCATION

Farallon Resources Limited (“the Company”) is engaged in exploration and mine development in the Campo Morado Project area (the “Project area”), which comprises the Company’s only material mineral property. The Company, through its wholly owned Mexican subsidiary, Farallon Minera Mexicana S.A. de C.V. (“Farallon”), holds a 100 percent interest in Campo Morado Project.

6.1 Property Location

The Project area is centered on Latitude 18° 12’ South and Longitude 100° 08’ West, which is in the Sierra Madre del Sur range in the north-eastern part of Guerrero State, Mexico, in the Municipality of Arcelia. The Project area is approximately 160 kilometres south-southwest of Mexico City (Figure 6.1).

Figure 6.1 – General Location Maps

6.2 Mineral Rights

The Project area comprises 11,813.9 hectares in the six mining concessions listed on Table 6.1. Figure 6.2 is a plan of the concessions, in UTM co-ordinates. The concessions are reported by the Company to be in good standing. The reader is, however, advised that the boundaries of the concession blocks have not legally been surveyed.

MINEFILL SERVICES, INC. Page 16 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Table 6.1 Campo Morado Project Concessions held by Farallon Resources Limited, through its

wholly owned Mexican subsidiary Farallon Minera Mexicana S.A. de C.V.

Concession Name Title

Number File

Number Area

Hectares Date

Issued Expiry Date

Reducción La Alina Campo Morado 2A Reducción Farallon Reducción El Mil La Trinidad Farallon 2

219148 213074 218979 219874 210718 227412

5/2.4/659 5/1.3/00561

05/1/693 5/1/720

DGM/CO2/99.9 33/9731

4,631.000 1,111.000 1,820.925 1,250.000 2,750.000 251.000

14 Feb. 2003 02 Mar. 2001 28 Jan. 2003 29 Apr. 2003 17 Nov. 1999 16 Jun. 2006

13 Feb. 2051 01 Mar. 2051 27 Jan. 2053 28 Apr. 2053 16 Nov. 2049 15 Jun. 2056

Total - - 11,813.925 - -

Note: Prior to March 02, 2001 the original Exploitation Title of La Alina mining concession was issued under Title number 213073. Due to an application of reduction to the surface area of the La Alina concession on February 14, 2003, it was issued with a new title (Reducción La Alina), which is the reason why the effective period for the mining concession is not 50 years, as the Mining Law of Mexico provides (Sub-Section 6.3.3).

Figure 6.2 – Concession Plan, in UTM Co-ordinates

MINEFILL SERVICES, INC. Page 17 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

The information presented on Table 6.1 and its subsequent text was compiled by MineFill from the December 13, 2006 Technical Report. Key information was checked by cross-referencing both the aforementioned report by Diaz Nieves and Bouchot dated August 15, 2006 and the Company’s aforementioned Form 20-F to the United States Securities and Exchange Commission dated June 30, 2006.

Figure 6.2 reflects the fact that five primary mineral deposits (El Largo, El Rey, G-9, Naranjo and Reforma) have been identified in the Campo Morado concession block, along with a number of other, less well-defined mineralized occurrences. Various gravity anomalies have also been identified in the same, broad mineralized trend. Farallon geologists have reported there is a weak link/poor correlation between the gravity anomalies and mineralized occurrences; the anomalies are not considered further.

Figure 6.3 summarizes the known mineral deposits and occurrences in more detail. The metals with economic potential include gold, silver, copper, lead and zinc (not listed in order of economic significance). The G-9 deposit is the primary target for current project development and it is the technical details of the G-9 deposit that are the main focus of this Technical Report. There are no historical mine workings on the G-9 deposit.

Figure 6.3 – Deposits’ Location Plan

6.2.1 Campo Morado and Reducción La Alina Concessions

The following text, as well as the text contained in Sub-Sections 6.2.2 and 6.2.3, was compiled by MineFill from the December 13, 2006 Technical Report. Key information was checked by cross-referencing both the aforementioned report by Diaz Nieves and Bouchot dated August 15, 2006 and the Company’s aforementioned Form 20-F to the United States Securities and Exchange Commission dated June 30, 2006.

MINEFILL SERVICES, INC. Page 18 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Pursuant to an option agreement (the “Option Agreement”), finalized in January 1996, among Sres. Alvaro J. Villagrán Garcia, J. Pedro Villagrán and J. Pedro Villagrán Ochoa (collectively the “Villagráns”) and their company Minera Summit de Mexico S.A. de C.V. (“Minera Summit”), as optioner, and Farallon, as optionee, Farallon was granted the exclusive option (the “Option”) to acquire from Minera Summit a 100 percent interest in the Campo Morado and La Alina exploration concessions. The Option Agreement was negotiated at arm’s length because the Villagráns were not directors, officers or significant shareholders at the time of the negotiation of the Option Agreement. Subsequent to the signing of the Option Agreement the Villagráns were appointed to Farallon’s board of directors in 1998; the Villagráns remained on Farallon’s board until March 2002.

Minera Summit won the Campo Morado and La Alina concessions on October 31, 1994, in an open bid process. Interested parties were invited to propose an exploration program for the concessions, for consideration by the General Bureau of Mines (Dirección General de Minas, or “Bureau”). The Bureau considered the bids with a view to, among other things, the best interests of furthering the mineral wealth of Mexico. Minera Summit’s proposal was chosen and the Campo Morado and La Alina concessions were conditionally granted to it. Minera Summit’s agreement with the Mexican Mineral Resources Council (Consejo de Recursos de Minerales, or “CRM”) required a minimum expenditure of 14.7 million (Mexican) Pesos on staged exploration on the concessions, over a three-year period ending September 14, 1997. The expenditure requirement had been exceeded by January 1997.

Under the Option Agreement (hence to earn its 100 percent interest in the Campo Morado and La Alina concessions), Farallon was required to pay to Minera Summit the aggregate sum of US$1,235,388 in staged amounts (which aggregate amount has been paid) and issue 750,000 common shares of the Company (which shares have been issued). Farallon also completed a three-stage exploration program, which CRM required to satisfy the minimum expenditure requirements under Minera Summit’s agreement with CRM. The Company’s/Farallon’s expenditure on the required program totalled nearly US$2 million, which amount was well in excess of the required expenditures. CRM accepted the transfer of title of the concessions from Minera Summit to Farallon on January 10, 1997.

Under the terms of the Option Agreement, if and when Farallon completes a feasibility study with respect to the Campo Morado and La Alina concessions (the “Feasibility Study”), the Company will be obligated to issue to Minera Summit up to 750,000 additional common shares of the Company. The number of shares to be issued will be based on the value of the Campo Morado and La Alina concessions, as assessed in an independent calculation of the property’s Recoverable Gold Equivalent Ounces from the Feasibility Study. For these purposes, the term “Recoverable Gold Equivalent Ounces” means economically recoverable, net payable, gold ounces after smelting deductions for gold and silver ounces (with silver ounces converted to the gold equivalent at the then-prevailing prices for gold and silver) from any mineable reserves on the property and any other property owned by Farallon within a defined Area of Influence (as defined in the Option Agreement and which includes all concessions comprising the Campo Morado Project).

The Option Agreement also acknowledges that the Campo Morado and La Alina concessions could be subject to moral claims of some previous investors, who had invested money in certain private companies that had sought an interest in Campo Morado prior to the

MINEFILL SERVICES, INC. Page 19 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Company’s/Farallon’s involvement. In 1996, Farallon purchased 97 percent of the shares of the private companies from those investors, for an amount totalling approximately US$578,000. Farallon also agreed to waive Minera Summit’s obligation to contribute one-half of the private company share purchase amount, as a consideration for continuing and future assistance being provided to Farallon by the Villagráns in Mexico and for Minera Summit consenting to Farallon acquiring all the private company’s shares. All of the investors in the defunct private companies were at all times at arm’s length to the Company/Farallon.

6.2.2 La Trinidad Concession

Farallon won the La Trinidad concession on November 16, 1999, in an open bid process. Interested parties were invited to propose a purchase price for consideration by the Bureau, which proposals would be reviewed to, among other things, determine the maximum bid and to ensure that the bid exceeded the minimum level set by the Bureau. Farallon’s bid was chosen and the concession was granted to Farallon. The purchase price of the concession was US$150,000, of which 60 percent (US$90,000) was paid on November 16, 1999. The balance (US$60,000) was paid before November 16, 2000.

6.2.3 Reducción El Mil, 2A Reducción Farallon and Farallon 2 Concessions

On June 29, 2001, Farallon filed an application before the Mining Agency in Puebla, Mexico, to obtain a reduction of the surface area of El Mil exploitation concession, to a new surface area of 1,250 hectares. The application was admitted by the Mining Agency under File Number 05/2.4/612. On August 23, 2002 Farallon was issued Exploration Title 214969 for the re-named Reducción El Mil concession. Following the amendment to the Mining Law of April 28, 2005, distinctions were no longer made between the exploration and exploitation concessions - mining concessions only were deemed to exist and the Title Number for the Reducción El Mil mining concession was changed to 219874.

Farallon filed an application to reduce the Farallon concession from 14,145 hectares to 5,345 hectares in 1999; on May 31, 2000 the new exploration title (211550) for the renamed Reducción Farallon concession was received. On June 29, 2001, Farallon filed an application before the Mining Agency in Puebla, Mexico, to obtain a reduction of area with respect to the Reducción Farallon mining claim, from 5,345 hectares to 1,820 hectares, with the new name of 2A Reducción Farallon. The application was admitted under File Number 05/2.4/613 of the Mining Agency. On January 28, 2003, Farallon was issued Exploitation Title 218979 for the 2A Reducción Farallon concession. Following the amendment to the Mining Law of April 28, 2005 the File Number for the 2A Reducción Farallon mining concession was changed to 05/1/693.

The Farallon 2 concession (Title Number 227412) was acquired by Farallon on June 16, 2006.

6.3 Mining Law

The following text, as well as the text contained in Sub-Sections 6.3.1 to 6.3.5, inclusive, was compiled by MineFill from the aforementioned document by Baker & McKenzie and the aforementioned report by Diaz, Nieves and Bouchot dated August 15, 2006, the validity and

MINEFILL SERVICES, INC. Page 20 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

accuracy of which MineFill is not qualified to assess. However, following a web search for, and consideration of, various available documents, Minefill concluded that the cited documents probably fairly reflect the current status of Mexican Mining Law.

6.3.1 Legal Framework

The Mining Law was originally published in the Federal Official Gazette on June 26, 1992. The section regarding bids was amended on December 24, 1996. Amendments to a number of other sections were enacted on April 28, 2005.

Article 27 of the Mexican Constitution states that the lands and waters within the national territory originally belong to the Mexican United States (Mexico) and that Mexico has the right to transfer the title thereto to private persons to thereby constitute private property. Article 27 also provides that Mexico has direct ownership of mineral deposits within the national territory, which cannot be transferred. The use and exploitation of such national resources by private parties is only permitted by means of concessions granted by the Mexican Federal Executive Branch, through its corresponding government agencies.

6.3.2 Government Agencies

The Mining Law is a federal statute that governs the grant, use, cancellation and expiration of mining concessions, hence all mining matters pursuant to Article 27 of the Constitution. The Ministry of Economy (Secretaria de Economia, or “Ministry”) has the authority and regulatory powers to enforce compliance with the Mining Law. The Ministry exercises its legal authority through its Mining Division (Coordinación General de Mineria, or “CGM”), a central agency established by the internal regulations of the Ministry. The CGM in turn relies on the Bureau.

The main responsibilities of the Bureau include the management and control of mining concessions. For such tasks, the Bureau relies on the support of various subordinate agencies, including the Public Registry of Mining (the “Registry”). The main purpose of the Registry is to record concessions, allotments, agreements, arrangements and administrative actions that might affect mining rights. Any act or agreement required by law to be registered with the Registry is binding on third parties and on the Ministry only when publicly recorded at the Registry.

The Mexican Geological Service (Servicio Geologico Mexicano, or “SGM”) is a decentralized entity, with independent legal capacity, that is coordinated by the Ministry, under Article 9 of the Mining Law. SGM is required, in part, to identify and record the potential mineral resources of Mexico, to assist the government with the promotion and development of such resources and to determine which resources should be made available as concessions. Prior to the amendment to the Mining Law of April 28, 2005, SGM was called the Mineral Resources Council (Consejo de Recursos de Minerales), under which title it dealt with the Company’s/Farallon’s concessions, as earlier described.

6.3.3 Foreign Investment

During December 1990, the country’s changed economic and political climate resulted in a more transparent definition of the scope of power granted to government authorities. Unnecessary

MINEFILL SERVICES, INC. Page 21 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

obligations and procedures for mining concessions were also eliminated. As part of these changes, foreign capital was authorized to participate in 100 percent of the stock of mining corporations/companies, once they were incorporated as Mexican entities. In other words, it is possible for Mexicans to acquire the mining concessions on their own behalf. However, foreigners are required to do so thorough a Mexican mining corporation that they have to set up. Mexicans as well as foreigners are both permitted to acquire up to 100 percent of the Mexican (mining) company they set up in order to hold mining concessions. In this regard, it is stated the aforementioned report by Diaz, Nieves and Bouchot dated August 15, 2006 that:

“Farallon (Minera Mexicana S.A. de C.V.) is a Mexican mining company duly incorporated in accordance with Public Instrument number 68,245 dated November 10, 1994……”; and

“Farallon (i) has a corporate purpose that refers to the exploration and exploitation of minerals or substances subject to the application of Mining Law; (ii) has its legal domicile in the Mexican Republic; (iii) participation of foreign investors is adjusted to the provisions of the Foreign Investment Law; (iv) has all requisite corporate power and authority to conduct its business now carried on by it; and (v) is duly registered or licensed to carry out business in Mexico.”

6.3.4 Concessions

Concessions are granted over free land, pursuant to the first in time, first right principle, which establishes that the first person to request a concession over a portion of land will have the right to the same, provided all other requirements under the Mining Law and its associated regulations are met.

Following the amendment to the Mining Law of April 28, 2005, no distinction is made between exploration on and exploitation of mining concessions. The amendment to the designation of a single type of mining concession (exploration and exploitation) was conditioned to the publication of the amendment to the Federal Fees Law (Lay Federal de Derechos) in connection with fees payable by mining concessions holders, which amendment was published on December 21, 2005. Current mining law therefore allows a concession owner to perform:

• exploration works on the ground to identify mineral deposits and quantifying and evaluating economically viable reserves and accordingly perform work to develop areas containing mineral deposits; and

• exploitation works to detach and extract minerals from such deposits.

Mining concessions may be obtained either through a public bid or by an application process filed by the interested party before the relevant mining agency. Public bids apply when either the government considers it necessary to exploit certain mining reserve areas or as a result of the cancellation of mining allotments granted to the SGM, who had carried out prior exploration works.

MINEFILL SERVICES, INC. Page 22 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Mining concessions are valid for 50 years from the date of their registration at the Registry. They may be extended for an equal term if the holder: does not cause cancellation of the concession by any act or omission defined in the Mining Law; and requests an extension within five years prior to the expiration date. They confer rights with respect to all minerals covered and provided for by Article 4 of the Mining Law, including gold, silver, copper, lead and zinc found in veins, mantles, masses or deposits.

6.3.5 Surface Rights and Obligations

Mining concession licenses do not grant rights comparable to a freehold or leasehold, given that they do not confer property rights to the parcel of land involved, except for the rights to carry out works and development required of and for mining and related activities. Farallon is not restricted in this regard because the titles to the relevant blocks of land (or hacienda, which in this case cover the Project area) have been purchased by Farallon.

6.3.6 Mining Obligations

The obligations with which the holders of mining concessions must comply in order to maintain their concessions in full force and effect, pursuant to the Mining Law of Mexico and the Federal Fees Law, are: Assessment of Work Report – during May of each year, the concession holder must file Work Assessment Reports with the Bureau, for each concession or group of concessions for the preceding calendar year. The regulations of Mexican Mining Law establish the minimum investment amounts that must be made on a concession. The amounts vary annually, according to variations in the Mexican Consumer Price Index. Mining Duties – during January and July of each calendar year, concession holders must pay the mining duties for the areas that pertain to each concession, on a hectare basis, and file before the Bureau evidence of payment during February and August of the same year that the payments are made. Production Report – during the first 21 labor days of each calendar year, the concession holders must file Production Reports with the Bureau, compiled for each concession or group of concessions for the preceding calendar year. The Company has verbally reported to Minefill that the various required reports and duties for the Campo Morado Project are in good standing. In the opinion of the author of this Technical Report, there is no readily identifiable reason to suppose that the Company’s claim is incorrect.

6.4 Taxes and Royalties

Table 6.2 summarizes the main corporate, value added and payroll taxes that are currently applicable in Mexico (as at September 2007). Tax treaties exist between Mexico and both the United States and Canada.

MINEFILL SERVICES, INC. Page 23 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Table 6.2 A Summary of the Mexican Tax Regime

Tax Category

Payments(number)

Statutory Tax Rate

Tax Base

Corporate Income Tax Asset Tax Value Added Tax (VAT) Social Security Tax (IMSS) Housing Tax (INFONAVIT) Premium for Occupational Risk Local Tax

1 1

12 12 6

12 1

35% (maximum) 1.8% 15%

16.7% 5%

Various Various

Taxable profits Asset value Value added Gross salaries Gross salaries Gross salaries

- Sources: www.mexicolaw.com/LawInfo18.htm; www.solutionsabroad.com/d_mexicantaxlaw.asp

Under the terms of the Option Agreement between Farallon and Minera Summit regarding the Campo Morado and Reducción La Alina concessions (Sub-Section 6.2.1), Farallon is subject to what is effectively a sliding scale, three percent net profits royalty to a government entity. The Bureau retains a sliding scale, two percent net profits royalty on the La Trinidad concession. Royalty payments on the Reducción El Mil, 2A Reducción Farallon and Farallon 2 concessions have yet to be defined. The Company has verbally advised MineFill that there are no other royalties, back-in rights, payments or other agreements and encumbrances to which the Property is subject.

6.5 Metal Sales

There are no reported Government restrictions or constraints on the exporting and/or sale of concentrates or metals that do not contain radioactive material.

6.6 Environmental Regulations

The following text, as well as the text contained in Sub-Sections 6.6.1 and 6.6.2, was compiled by MineFill from the aforementioned document by Haight, Brown & Bonesteel LLP and the aforementioned document by Biologist J. Ricardo Juárez Palacios dated March 29, 2007. MineFill is not qualified to assess the validity or accuracy of the cited documents. However, following a web search for, and consideration of, various available documents, Minefill concluded that the cited documents probably fairly reflect the current status of Mexican Environmental Law.

6.6.1 Legal Framework

The North American Free Trade Agreement (NAFTA) addresses the issue of environmental protection in the three participating countries (Canada, Mexico and United States). However, it leaves the establishing of environmental rules and standards to the three participating countries, with two exceptions: they are to comply with existing treaties; and they are not to reduce their environmental standards as a means of promoting investment in business.

MINEFILL SERVICES, INC. Page 24 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

Mexican Environmental Law is defined in the General Law of Ecologic Equilibrium and Environmental Protection (Lay General de Equilibrio Ecológico y Protección al Ambiente, or

“LGEEPA”). In its first draft (effective March 01, 1988) it comprised Mexico’s first comprehensive environmental law. It was amended ten times between 1996 and February 2007.

LGEEPA establishes the framework and authority for all environmental regulations in Mexico. It addresses a broad range of environmental issues, including the protection of natural areas, exploitation of natural elements (including land and water) and protection of the environment (including atmospheric pollution, water and soil pollution), hazardous activities and waste, nuclear energy and other forms of pollution. LGEEPA also defines control and safety measures, penalties for non-compliance and guidelines for environmental impact statements and risk assessment.

6.6.2 Government Agencies

Mexico’s primary federal environmental agency is the Secretariat of Environmental and Natural Resources (Secretaría de Medio Ambiente y Recursos Naturales, or “SEMARNAT”), which agency has sole jurisdiction over the development enforcement, administration and control over Mexico’s environmental laws and standards. It fulfils its roles through various decentralized administrative departments, including:

• National Institute of Ecology (Instituto Nacional de Ecologia, or “INE”) that is responsible for ecological matters and the protection of the environment by means of developing environmental programs, issuing administrative orders and standards, determining the adequacy of environmental impact statements, co-ordinating the development of environmental programs with state agencies and granting federal approval on environmental impact studies);

• National Water Commission (Comisión Nacional del Agua, or “CAN”) that is responsible for the administration and safekeeping of national waters and related property such as wetlands, marshes and beaches, overseeing compliance with the Law of National Waters (Ley de Aguas Nacionales, or “LAN”), issuing orders necessary to ensure the preservation and quality of the national waters, overseeing concessions and waste water discharge permits affecting national waters; and

• Federal Agency for the Protection of the Environment (Procuraduría Federal de Protección al Ambiente, or “PROFEPA”) that is responsible for enforcing the law, for investigations and inspections of facilities and for reporting violations to the Federal Prosecuting Attorney (Ministerio Público Federal).

6.6.3 Environmental Studies

Exploration Phase - At the time of the exploration phase for certain mineral projects, such as Campo Morado, LGEEPA requires a concession holder to submit a preventative report, prepared by an independent registered environmental consultant, to INE before the concessionaire commences exploration activities. The report provides the government with the concessionaire’s

MINEFILL SERVICES, INC. Page 25 CAMPO MORADO PROJECT, G-9 DEPOSIT

FARALLON RESOURCES LTD.

plans for developing the project and sets out actions it will take to minimize impacts on the environment. INE reviews the preventative report to ensure that the information fulfils the requirements of LGEEPA. Once the report is approved a permit is granted and issued by SEMARNAT.

Development Phase - Article 30 of LGEEPA establishes that to obtain authorization for the ‘execution of works and activities that may cause an ecological disequilibrium or exceed the limits and conditions established in the applicable provisions’ …… in law, interested parties must submit to SEMARNAT an environmental impact manifest (Manifestación de Impacto Ambiental, or “MIA-P”), written in Spanish. Documentation in support of a change of land use to allow construction and mining activities is also required (specifically a Change of Use of Soil [Cambio de Uso de Suelo, or “CUS”]).