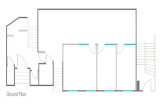

G-01 - GROUND FLOOR PLAN - - - Rev 3

Transcript of G-01 - GROUND FLOOR PLAN - - - Rev 3

6

6

5.1

5.1

5

5

4

4

4.1

4.1

F

E

D4

D

CB

A

3

3

2

2

1

1

M

L

K1

K

J

H

G

STEELWORK NOTES

1. STEELWORK HAS BEEN DESIGNED AND SPECIFIED AND IS TO BE SUPPLIED AND CONSTRUCTEDIN ACCORDANCE WITH BS5950 AND THE NATIONAL STRUCTURAL STEELWORK SPECIFICATION FORBUILDING CONSTRUCTION (NSSS). ALL STEELWORK TO BE EXECUTION CLASS 2 (EXC2) TO BS EN1993-1-1 ANNEX C. ALL STEELWORK UTILISED ON THE PROJECT IS TO BE EUROPEANMANUFACTURED STEEL. ALL SECTIONS USED ARE TO BE HOT ROLLED STRUCTURAL STEELSECTIONS GRADE S355 J2H. NO COLD FORMED SECTIONS ARE PERMITTED TO BE USED SAVE FORPROPRIETARY C OR Z PURLIN SECTIONS. CONTRACTOR TO HAVE COPY OF NSSS ON SITE FORREFERENCE. ALL STEELWORK HAS BEEN DESIGNED TO DEFLECTION LIMITS OF L/250 FOR TOTALLOAD, L/360 FOR IMPOSED LOAD AND L/500 FOR TOTAL LOAD IN MEMBERS SUPPORTING MASONRYWALLS.

2. ALL STEEL TO STEEL/CONCRETE/TIMBER/GLASS CONNECTIONS AND ARE TO BE DESIGNED BYTHE MAIN CONTRACTOR UNLESS NOTED OTHERWISE. DESIGN CALCULATIONS MUST BEUNDERTAKEN BY A CHARTERED STRUCTURAL ENGINEER AND BE SUPPLIED TO THE ENGINEERAND ARCHITECT FOR REVIEW A MINIMUM 15 WORKING DAYS PRIOR TO MANUFACTURE.

3. THE MAIN CONTRACTORS STEELWORK FABRICATION DRAWINGS ARE TO BE SUPPLIED TO THEENGINEER AND ARCHITECT FOR REVIEW A MINIMUM 10 WORKING DAYS PRIOR TO MANUFACTURE.THE MAIN CONTRACTORS PROGRAM SHOULD ALLOW 5 DAYS FOR T4C COMMENT FOR EACH ANDEVERY RE-ISSUE.

4. STEELWORK CONFORMITY CERTIFICATES/MANUFACTURERS INSPECTION DOCUMENTS ARE TOBE PROVIDED TO THE ENGINEER FOR REVIEW PRIOR TO MANUFACTURE.

5. ALL STEEL TO STEEL CONNECTIONS ARE TO BE FORMED USING 10mm THK (S275) FLEXIBLEENDPLATES, 6mm FULL PROFILE FILLET WELDS (FPFW) AND 4No. M20 GRADE 8.8 BOLTS IN 22mmDIA STANDARD CLEARANCE HOLES UNLESS NOTED OTHERWISE. CONNECTIONS ARE TO BE INACCORDANCE WITH THE BCSA GREEN BOOK FOR SIMPLE CONNECTIONS. ALL SECTIONS ARE TOBE SAWN SQUARE FOR CONNECTIONS TO END PLATES, CAP PLATES AND BASEPLATES. AllCONNECTIONS ARE TO BE WEB TO WEB CONNECTIONS AND TO NODE OUT ON THE CENTRELINESOF THE MEMBERS BEING CONNECTED. WHERE THIS IS NOT POSSIBLE THEN T-SECTIONS SHOULDBE ADOPTED TO TRANSFER THE LOADS TO THE MEMBER AXIS. COLUMN BASEPLATES TO BEBEDDED ON MINIMUM 25mm NON-SHRINK CEMENTITIOUS GROUT.

6. ALL STEEL TO CONCRETE PADSTONE CONNECTIONS ARE TO BE FORMED WITH 2No. (WHEREBEAM RUNS PERPENDICULAR TO WALL) OR 1No. (WHERE BEAM RUNS PARALLEL TO WALL) M10HILTI HVU-HAS CHEMICAL ANCHOR(S) WITH 130mm EMBEDMENT IN 12mm DIA HOLES, 10mm THKSEATING PLATES (S275), 8mm FULL PROFILE FILLET WELDS (FPFW) WITH MAXIMUM 10mm NONSHRINKLEVELLING GROUT (CONBEXTRA GP BY FOSROC OR SIMILAR APPROVED BY T4C) UNLESSNOTED OTHERWISE. BEAMS TO BEAR FULL WIDTH/LENGTH OF PADSTONE UNLESS NOTEDOTHERWISE. CONCRETE PADSTONES TO BE MINIMUM 50N/mm2 CONCRETE.

7. STEELWORK TO BE PROTECTED TO THE FOLLOWING MINIMUM SPECIFICATION TO MAINCONTRACTORS PROPOSALS (MAIN CONTRACTOR TO PROVIDE SPECIFICATION TO THE ENGINEERAND ARCHITECT FOR REVIEW PRIOR TO MANUFACTURE) UNLESS NOTED OTHERWISE:

a. INTERNAL STEELWORK PAINTED – SHOT BLAST SA2.5 THEN 25MICRONSBLAST PRIMER. AFTER FABRICATION 75MIRONS MINIMUM SINGLE PACK EPOXYZINC PHOSPHATE PRIMER.EXTERNAL STEELWORK PAINTED – GALVANISING TO BE STRICTLY INACCORDANCE WITH EN ISO1461. FABRICATED STEELWORK TO HAVE AMINIMUM COATING OF 85 MICRONS.ENVIRONMENT CATEGORIES ARE SPECIFIED IN BS EN ISO 12944 AND ISO 9223.

8. ALL INTERNAL STEELWORK COLUMNS TO BE FIRE PROTECTED WITH INTUMESCENT PAINT TOMAIN CONTRACTORS PROPOSALS (MAIN CONTRACTOR TO PROVIDE SPECIFICATION TO THEENGINEER AND ARCHITECT FOR REVIEW PRIOR TO MANUFACTURE) FOR 1 HOURS FIREPROTECTION UNLESS NOTED OTHERWISE. INTUMESCENT PAINT IS TO BE COMPATIBLE WITH THECORROSION PROTECTION SYSTEM.

9. ALL STEELWORK IN EXTERNAL WALLS TO BE PAINTED WITH ADDITIONAL 2No. COATS OF HEAVYDUTY BITUMINOUS PAINT UNLESS NOTED OTHERWISE. ALL STEELWORK BELOW GROUND TO BEPAINTED WITH ADDITIONAL 3No. COATS OF HEAVY DUTY BITUMINOUS PAINT OR SURROUNDEDWITH MINIMUM 50mm CONCRETE WITH D49 WRAPPING MESH, UNLESS NOTED OTHERWISE.

20.09.20213 MARKS UPDATED RG

08.09.20212 FOR APPROVAL RG31.08.20211 FOR APPROVAL RG

13.08.20210 FOR APPROVAL RGIndex Date Description Author

PROJECT No.

CLIENT

PROJECT

REVDRAWING No.

DRAWING TITLE

DATE SCALEDRAWN BY CHECKED BY

GROUND FLOOR PLAN

RG 13.08.2021 1:151:50

G-01 3

STEEL CONTRACTOR

610

2639

1584

2366

563

1972

100

100

100

100

175175175 175

100

100

950 3300 950

C C

B B

C101 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

C102 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

AR101 - D20

GROUND FLOOR

AR102 - D20 AR102 - D20

950

1504

3205

100

100

100

100

100

180 20

D

DC127 -

RHS300*

100*8

.0

BOS= 1723

45

GALVANISED

C123 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

BR103 - FLT8*100

C118 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

C120 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

C117 -

SHS100*

100*6

.3

BOS= 1723

45

GALVANISED AR101 - D20

AR101 - D20

SP101 - D20

C105 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

C116 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

AR101 - D20

2404

396

3681

A AAR103 - D20

C104 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

C110 -

UC203*2

03*86

BOS= 1723

45

GALVANISED

C112 -

UC203*2

03*86

BOS= 1723

45

GALVANISED

AR103 - D20

100

C107 -

RHS300*

100*8

.0

BOS= 1723

45

GALVANISED

100 100

100

100

AR101 - D20

100

C127 -

RHS300*

100*8

.0

BOS= 1723

45

GALVANISED

2366

C104 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

100 100

100

100 AR101 - D20

AR101 - D20

180 20

100

100

100

100

SP101 - D20

C125 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

250 250

61

150

150

1584

250 250

29

150

150

563

1972

100

100

175175

175

9601045

305

C113 -

SHS80*8

0*6.3

BOS= 1723

45

GALVANISED

C114 -

RHS300*

100*8

.0

BOS= 1723

45

GALVANISED

AR102 - D20

100100

100 100

10.2

°

AR101 - D20

100

100

175

AR102 - D20

1950

100

100

100 100

100

100 100100 1002005

100

C115 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

AR101 - D20

100

100

100

96

150 50

AR101 - D20

100 100 100

100

BR103 - FLT8*100

AR101 - D20

100

100

100

100 100100 100 C12

4 - SHS10

0*10

0*10.0

BOS= 1723

45

GALVANISED

BR104 - FLT8*100

BR104 - FLT8*100

C122 -

SHS100*

100*1

0.0

BOS= 1723

45

GALVANISED

AR101 - D20

AR101 - D20

100

100

320

110

3060

20G

RO

UT

UC

203*

203*

86

BOS

A - A

92TBC

175

95

2015

60

20G

RO

UT

BOS

SHS1

00*1

00*1

0.0

B - B

87TBC

175

95

2015

60

20G

RO

UT

BOS

SHS1

00*1

00*1

0.0

C - C

300

95

2015

60

20G

RO

UT

BOS

RH

S300

*100

*8.0

D - D

4.1

4.1

4

4

5

5

5.1

5.1

6

6

BC

3

3

A

1

1

2

2

D

D4

E

F

G

H

J

K

K1

L

M+175.96 +175.96

2

2

+175.96 +175.96

3

3

3

3

+175.96 +175.96

4

4 +175.96 +175.96

2

2

+175.96 +175.96

3

3

+175.96 +175.96

2

2

1

1

F

F

STEELWORK NOTES

1. STEELWORK HAS BEEN DESIGNED AND SPECIFIED AND IS TO BE SUPPLIED AND CONSTRUCTEDIN ACCORDANCE WITH BS5950 AND THE NATIONAL STRUCTURAL STEELWORK SPECIFICATION FORBUILDING CONSTRUCTION (NSSS). ALL STEELWORK TO BE EXECUTION CLASS 2 (EXC2) TO BS EN1993-1-1 ANNEX C. ALL STEELWORK UTILISED ON THE PROJECT IS TO BE EUROPEANMANUFACTURED STEEL. ALL SECTIONS USED ARE TO BE HOT ROLLED STRUCTURAL STEELSECTIONS GRADE S355 J2H. NO COLD FORMED SECTIONS ARE PERMITTED TO BE USED SAVE FORPROPRIETARY C OR Z PURLIN SECTIONS. CONTRACTOR TO HAVE COPY OF NSSS ON SITE FORREFERENCE. ALL STEELWORK HAS BEEN DESIGNED TO DEFLECTION LIMITS OF L/250 FOR TOTALLOAD, L/360 FOR IMPOSED LOAD AND L/500 FOR TOTAL LOAD IN MEMBERS SUPPORTING MASONRYWALLS.

2. ALL STEEL TO STEEL/CONCRETE/TIMBER/GLASS CONNECTIONS AND ARE TO BE DESIGNED BYTHE MAIN CONTRACTOR UNLESS NOTED OTHERWISE. DESIGN CALCULATIONS MUST BEUNDERTAKEN BY A CHARTERED STRUCTURAL ENGINEER AND BE SUPPLIED TO THE ENGINEERAND ARCHITECT FOR REVIEW A MINIMUM 15 WORKING DAYS PRIOR TO MANUFACTURE.

3. THE MAIN CONTRACTORS STEELWORK FABRICATION DRAWINGS ARE TO BE SUPPLIED TO THEENGINEER AND ARCHITECT FOR REVIEW A MINIMUM 10 WORKING DAYS PRIOR TO MANUFACTURE.THE MAIN CONTRACTORS PROGRAM SHOULD ALLOW 5 DAYS FOR T4C COMMENT FOR EACH ANDEVERY RE-ISSUE.

4. STEELWORK CONFORMITY CERTIFICATES/MANUFACTURERS INSPECTION DOCUMENTS ARE TOBE PROVIDED TO THE ENGINEER FOR REVIEW PRIOR TO MANUFACTURE.

5. ALL STEEL TO STEEL CONNECTIONS ARE TO BE FORMED USING 10mm THK (S275) FLEXIBLEENDPLATES, 6mm FULL PROFILE FILLET WELDS (FPFW) AND 4No. M20 GRADE 8.8 BOLTS IN 22mmDIA STANDARD CLEARANCE HOLES UNLESS NOTED OTHERWISE. CONNECTIONS ARE TO BE INACCORDANCE WITH THE BCSA GREEN BOOK FOR SIMPLE CONNECTIONS. ALL SECTIONS ARE TOBE SAWN SQUARE FOR CONNECTIONS TO END PLATES, CAP PLATES AND BASEPLATES. AllCONNECTIONS ARE TO BE WEB TO WEB CONNECTIONS AND TO NODE OUT ON THE CENTRELINESOF THE MEMBERS BEING CONNECTED. WHERE THIS IS NOT POSSIBLE THEN T-SECTIONS SHOULDBE ADOPTED TO TRANSFER THE LOADS TO THE MEMBER AXIS. COLUMN BASEPLATES TO BEBEDDED ON MINIMUM 25mm NON-SHRINK CEMENTITIOUS GROUT.

6. ALL STEEL TO CONCRETE PADSTONE CONNECTIONS ARE TO BE FORMED WITH 2No. (WHEREBEAM RUNS PERPENDICULAR TO WALL) OR 1No. (WHERE BEAM RUNS PARALLEL TO WALL) M10HILTI HVU-HAS CHEMICAL ANCHOR(S) WITH 130mm EMBEDMENT IN 12mm DIA HOLES, 10mm THKSEATING PLATES (S275), 8mm FULL PROFILE FILLET WELDS (FPFW) WITH MAXIMUM 10mm NONSHRINKLEVELLING GROUT (CONBEXTRA GP BY FOSROC OR SIMILAR APPROVED BY T4C) UNLESSNOTED OTHERWISE. BEAMS TO BEAR FULL WIDTH/LENGTH OF PADSTONE UNLESS NOTEDOTHERWISE. CONCRETE PADSTONES TO BE MINIMUM 50N/mm2 CONCRETE.

7. STEELWORK TO BE PROTECTED TO THE FOLLOWING MINIMUM SPECIFICATION TO MAINCONTRACTORS PROPOSALS (MAIN CONTRACTOR TO PROVIDE SPECIFICATION TO THE ENGINEERAND ARCHITECT FOR REVIEW PRIOR TO MANUFACTURE) UNLESS NOTED OTHERWISE:

a. INTERNAL STEELWORK PAINTED – SHOT BLAST SA2.5 THEN 25MICRONSBLAST PRIMER. AFTER FABRICATION 75MIRONS MINIMUM SINGLE PACK EPOXYZINC PHOSPHATE PRIMER.EXTERNAL STEELWORK PAINTED – GALVANISING TO BE STRICTLY INACCORDANCE WITH EN ISO1461. FABRICATED STEELWORK TO HAVE AMINIMUM COATING OF 85 MICRONS.ENVIRONMENT CATEGORIES ARE SPECIFIED IN BS EN ISO 12944 AND ISO 9223.

8. ALL INTERNAL STEELWORK COLUMNS TO BE FIRE PROTECTED WITH INTUMESCENT PAINT TOMAIN CONTRACTORS PROPOSALS (MAIN CONTRACTOR TO PROVIDE SPECIFICATION TO THEENGINEER AND ARCHITECT FOR REVIEW PRIOR TO MANUFACTURE) FOR 1 HOURS FIREPROTECTION UNLESS NOTED OTHERWISE. INTUMESCENT PAINT IS TO BE COMPATIBLE WITH THECORROSION PROTECTION SYSTEM.

9. ALL STEELWORK IN EXTERNAL WALLS TO BE PAINTED WITH ADDITIONAL 2No. COATS OF HEAVYDUTY BITUMINOUS PAINT UNLESS NOTED OTHERWISE. ALL STEELWORK BELOW GROUND TO BEPAINTED WITH ADDITIONAL 3No. COATS OF HEAVY DUTY BITUMINOUS PAINT OR SURROUNDEDWITH MINIMUM 50mm CONCRETE WITH D49 WRAPPING MESH, UNLESS NOTED OTHERWISE.

20.09.20213 MARKS UPDATED RG

08.09.20212 FOR APPROVAL RG31.08.20211 FOR APPROVAL RG

13.08.20210 FOR APPROVAL RGIndex Date Description Author

PROJECT No.

CLIENT

PROJECT

REVDRAWING No.

DRAWING TITLE

DATE SCALEDRAWN BY CHECKED BY

FIRST FLOOR PLAN

RG 13.08.2021 1:101:50

G-02 3

STEEL CONTRACTOR

147

15BR

AKE

TBC

THER

MA

L

1 No M 10 * 160HILTI-HVUHAS

1 No M 10 * 160HILTI-HVUHAS

G G

E E

B101

- SH

S100

*100

*10.

0TO

S=17

5765

GAL

VAN

ISED

B105 - UC203*203*46GALVANISED

C103 -

SHS100*

100*1

0.0

GALVANISED

C125 -

SHS100*

100*1

0.0

GALVANISED

C105 -

SHS100*

100*1

0.0

GALVANISED

C102 -

SHS100*

100*1

0.0

GALVANISED

C104 -

SHS100*

100*1

0.0

GALVANISED

C113 -

SHS80*8

0*6.3

GALVANISED

C101 -

SHS100*

100*1

0.0

GALVANISED

C104 -

SHS100*

100*1

0.0

GALVANISED

2 No M 10 * 160HILTI-HVUHAS

C108 -

SHS100*

100*1

0.0

B115 - UC203*203*71TOS= 175960

C107 -

RHS300*

100*8

.0

GALVANISED

C127 - R

HS 300*

100*8

.0

GALVANISED

FIRST FLOOR

NOTE:ARCHITECTURAL FIRST FLOORPLAN OVERLAID

462

15BR

AKE

TBC

THER

MA

L

H

H

THERMAL_BRAKE 15TB203

THERMAL_BRAKE 15TB205

THERMAL_BRAKE 15TB206

THERMAL_BRAKE 15TB210

THERMAL_BRAKE 15TB202

THERMAL_BRAKE 15TB201

BR104 - FLT8*100GALVANISED

C120 -

SHS100*

100*1

0.0

GALVANISED

B161 - UB127*76*13TOS= 175828GALVANISED

C122 -

SHS100*

100*1

0.0

GALVANISED

B166 - UB203*133*30GALVANISED

B156 - UC152*152*37GALVANISED

B158 - UC203*203*46TOS= 175858

C116 -

SHS100*

100*1

0.0

GALVANISED

B122 - UC203*203*86GALVANISED

C123 -

SHS100*

100*1

0.0

GALVANISEDC12

1 - SHS10

0*10

0*10.0

GALVANISED

BR101 - FLT8*100GALVANISED

B159 - UC203*203*60TOS= 175810

BR103 - FLT8*100GALVANISED

BR103 - FLT8*100GALVANISED

C111 -

SHS100*

100*1

0.0

GALVANISED

B157 - RHS200*150*10.0TOS= 175960

B153 - UC203*203*71TOS= 175960

B127 - UC152*152*23GALVANISED

C110 -

UC203*2

03*86

GALVANISED

C127 -

RHS300*

100*8

.0

GALVANISED

B136 - RHS200*100*10.0

TOS= 175960

B131 - UC203*203*71

TOS= 175865

B133 - UB152*89*16

TOS= 175801

GALVANISED

C126 -

SHS100*

100*1

0.0

B123

- R

HS2

00*1

00*8

.0TO

S=17

5422

B124

- R

HS2

00*1

00*8

.0TO

S=17

5422

147

B102

- R

HS2

00*1

00*1

0.0

TOS=

1758

10G

ALVA

NIS

ED

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

D

D

B B

C108 -

SHS100*

100*1

0.0

B148

- U

C20

3*20

3*86

TOS=

1759

60

B103

- R

HS2

00*1

50*1

6TO

S=17

5810

GAL

VAN

ISED

C108 - S

HS10

0*10

0*10.0

B129

- R

HS2

00*1

00*1

0.0

TOS=

1759

60

B147 - UC203*203*71TOS= 175960

B126 - UB152*89*16

TOS= 175801

GALVANISED

B130 - UB152*89*16

TOS= 175801

GALVANISED

C114 -

RHS300*

100*8

.0

GALVANISED

B137 - RHS200*100*10.0TOS= 175810GALVANISED

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

C C

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

RSA100*100*10

B112 - UC203*203*46TOS= 175828GALVANISED

C106 -

RHS300*

100*8

.0

GALVANISED

C106 -

RHS300*

100*8

.0

GALVANISED

B128 - U

C203*203*71

TOS=

175859

B125

- R

HS2

00*1

00*8

.0TO

S=17

5422

B109 - UC203*203*46TOS= 175960

B110 - UC203*203*71TOS= 175960

B104

- U

C20

3*20

3*46

TOS=

1758

28G

ALVA

NIS

ED

B121

- U

C20

3*20

3*86

TOS=

1758

53G

ALVA

NIS

ED

B111 - UC203*203*46TOS= 175828

B108 - UC203*203*46TOS= 175960

RSA100*100*10

A ARSA200*100*12

2 No M 10 * 160HILTI-HVUHAS

F F

C112 -

UC203*2

03*86

GALVANISED

RSA200*100*12

4621343

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

THERMAL_BRAKE 15TB204

B146 - UB152*89*16GALVANISED

B144 - UB152*89*16GALVANISED

1941 No M 10 * 160HILTI-HVUHAS

B137 - RHS200*100*10.0TOS= 175810GALVANISED

462

4621424

984

1 No M 10 * 160HILTI-HVUHAS

RSA200*100*12

C115 -

SHS100*

100*1

0.0

GALVANISED

B135 - RHS200*100*10.0

TOS= 175859

B135 - RHS200*100*10.0

TOS= 175859

B145 - U

C203*203*71

TOS=

175859

B106 - UC203*203*71

TOS= 175859

GALVANISED

B140 - UC203*203*86

TOS= 175865

B138 - RHS200*100*10.0

TOS= 175960

B141 - UC152*152*23

TOS= 175828

GALVANISED

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

C119 -

SHS100*

100*1

0.0

GALVANISED

C118 -

SHS100*

100*1

0.0

GALVANISED

119

B163 - UC203*203*46GALVANISED

B143

- U

C20

3*20

3*46

TOS=

1758

58

C117 -

SHS100*

100*6

.3

GALVANISED

B142

- U

C15

2*15

2*23

TOS=

1758

28G

ALVA

NIS

ED

B119 - UC152*152*23TOS= 175828GALVANISED

THERMAL_BRAKE 15TB207

THERMAL_BRAKE 15TB209

THERMAL_BRAKE 15TB208

B164 - UC203*203*60GALVANISED

B154 - UB127*76*13GALVANISED

BR102 - FLT8*100GALVANISED

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

2 No M 10 * 160HILTI-HVUHAS

B165 - UB127*76*13GALVANISED

C124 -

SHS100*

100*1

0.0

GALVANISED

BR104 - FLT8*100GALVANISED

B162 - UC254*254*132TOS= 175931GALVANISED

B152

- U

C20

3*20

3*46

TOS=

1758

58

THERMAL_BRAKE 15TB210

THERMAL_BRAKE 15TB210

B167 - UB203*133*30GALVANISED

B155 - UB203*133*30GALVANISED

102

150+175.678

RSA200*100*12

A - A

102

175

+175.678

RSA200*100*12

B - B

+175.222

FLT8*300

C - C

102

150+175.810

RSA200*100*12

D - D

+175.810

RSA100*100*10

E - E

+175.214

+175.810

RSA100*100*10

FLT8*300

F - F

+175.810

RHS200*100*10.0

RHS200*150*16SHS100*100*10.0

G - G

150

RSA200*150*12

+175.678RSA200*100*12

UC203*203*46 UC203*203*46

RSA150*150*12

+175.828

H - H

L

3

3

2

2

1

1

K1

K

J

H

G

6

6

5.1

5.1

5

5

4

4

4.1

4.1

D4

D

CB

A

F

E

M

STEELWORK NOTES

1. STEELWORK HAS BEEN DESIGNED AND SPECIFIED AND IS TO BE SUPPLIED AND CONSTRUCTEDIN ACCORDANCE WITH BS5950 AND THE NATIONAL STRUCTURAL STEELWORK SPECIFICATION FORBUILDING CONSTRUCTION (NSSS). ALL STEELWORK TO BE EXECUTION CLASS 2 (EXC2) TO BS EN1993-1-1 ANNEX C. ALL STEELWORK UTILISED ON THE PROJECT IS TO BE EUROPEANMANUFACTURED STEEL. ALL SECTIONS USED ARE TO BE HOT ROLLED STRUCTURAL STEELSECTIONS GRADE S355 J2H. NO COLD FORMED SECTIONS ARE PERMITTED TO BE USED SAVE FORPROPRIETARY C OR Z PURLIN SECTIONS. CONTRACTOR TO HAVE COPY OF NSSS ON SITE FORREFERENCE. ALL STEELWORK HAS BEEN DESIGNED TO DEFLECTION LIMITS OF L/250 FOR TOTALLOAD, L/360 FOR IMPOSED LOAD AND L/500 FOR TOTAL LOAD IN MEMBERS SUPPORTING MASONRYWALLS.

2. ALL STEEL TO STEEL/CONCRETE/TIMBER/GLASS CONNECTIONS AND ARE TO BE DESIGNED BYTHE MAIN CONTRACTOR UNLESS NOTED OTHERWISE. DESIGN CALCULATIONS MUST BEUNDERTAKEN BY A CHARTERED STRUCTURAL ENGINEER AND BE SUPPLIED TO THE ENGINEERAND ARCHITECT FOR REVIEW A MINIMUM 15 WORKING DAYS PRIOR TO MANUFACTURE.

3. THE MAIN CONTRACTORS STEELWORK FABRICATION DRAWINGS ARE TO BE SUPPLIED TO THEENGINEER AND ARCHITECT FOR REVIEW A MINIMUM 10 WORKING DAYS PRIOR TO MANUFACTURE.THE MAIN CONTRACTORS PROGRAM SHOULD ALLOW 5 DAYS FOR T4C COMMENT FOR EACH ANDEVERY RE-ISSUE.

4. STEELWORK CONFORMITY CERTIFICATES/MANUFACTURERS INSPECTION DOCUMENTS ARE TOBE PROVIDED TO THE ENGINEER FOR REVIEW PRIOR TO MANUFACTURE.

5. ALL STEEL TO STEEL CONNECTIONS ARE TO BE FORMED USING 10mm THK (S275) FLEXIBLEENDPLATES, 6mm FULL PROFILE FILLET WELDS (FPFW) AND 4No. M20 GRADE 8.8 BOLTS IN 22mmDIA STANDARD CLEARANCE HOLES UNLESS NOTED OTHERWISE. CONNECTIONS ARE TO BE INACCORDANCE WITH THE BCSA GREEN BOOK FOR SIMPLE CONNECTIONS. ALL SECTIONS ARE TOBE SAWN SQUARE FOR CONNECTIONS TO END PLATES, CAP PLATES AND BASEPLATES. AllCONNECTIONS ARE TO BE WEB TO WEB CONNECTIONS AND TO NODE OUT ON THE CENTRELINESOF THE MEMBERS BEING CONNECTED. WHERE THIS IS NOT POSSIBLE THEN T-SECTIONS SHOULDBE ADOPTED TO TRANSFER THE LOADS TO THE MEMBER AXIS. COLUMN BASEPLATES TO BEBEDDED ON MINIMUM 25mm NON-SHRINK CEMENTITIOUS GROUT.

6. ALL STEEL TO CONCRETE PADSTONE CONNECTIONS ARE TO BE FORMED WITH 2No. (WHEREBEAM RUNS PERPENDICULAR TO WALL) OR 1No. (WHERE BEAM RUNS PARALLEL TO WALL) M10HILTI HVU-HAS CHEMICAL ANCHOR(S) WITH 130mm EMBEDMENT IN 12mm DIA HOLES, 10mm THKSEATING PLATES (S275), 8mm FULL PROFILE FILLET WELDS (FPFW) WITH MAXIMUM 10mm NONSHRINKLEVELLING GROUT (CONBEXTRA GP BY FOSROC OR SIMILAR APPROVED BY T4C) UNLESSNOTED OTHERWISE. BEAMS TO BEAR FULL WIDTH/LENGTH OF PADSTONE UNLESS NOTEDOTHERWISE. CONCRETE PADSTONES TO BE MINIMUM 50N/mm2 CONCRETE.

7. STEELWORK TO BE PROTECTED TO THE FOLLOWING MINIMUM SPECIFICATION TO MAINCONTRACTORS PROPOSALS (MAIN CONTRACTOR TO PROVIDE SPECIFICATION TO THE ENGINEERAND ARCHITECT FOR REVIEW PRIOR TO MANUFACTURE) UNLESS NOTED OTHERWISE:

a. INTERNAL STEELWORK PAINTED – SHOT BLAST SA2.5 THEN 25MICRONSBLAST PRIMER. AFTER FABRICATION 75MIRONS MINIMUM SINGLE PACK EPOXYZINC PHOSPHATE PRIMER.EXTERNAL STEELWORK PAINTED – GALVANISING TO BE STRICTLY INACCORDANCE WITH EN ISO1461. FABRICATED STEELWORK TO HAVE AMINIMUM COATING OF 85 MICRONS.ENVIRONMENT CATEGORIES ARE SPECIFIED IN BS EN ISO 12944 AND ISO 9223.

8. ALL INTERNAL STEELWORK COLUMNS TO BE FIRE PROTECTED WITH INTUMESCENT PAINT TOMAIN CONTRACTORS PROPOSALS (MAIN CONTRACTOR TO PROVIDE SPECIFICATION TO THEENGINEER AND ARCHITECT FOR REVIEW PRIOR TO MANUFACTURE) FOR 1 HOURS FIREPROTECTION UNLESS NOTED OTHERWISE. INTUMESCENT PAINT IS TO BE COMPATIBLE WITH THECORROSION PROTECTION SYSTEM.

9. ALL STEELWORK IN EXTERNAL WALLS TO BE PAINTED WITH ADDITIONAL 2No. COATS OF HEAVYDUTY BITUMINOUS PAINT UNLESS NOTED OTHERWISE. ALL STEELWORK BELOW GROUND TO BEPAINTED WITH ADDITIONAL 3No. COATS OF HEAVY DUTY BITUMINOUS PAINT OR SURROUNDEDWITH MINIMUM 50mm CONCRETE WITH D49 WRAPPING MESH, UNLESS NOTED OTHERWISE.

20.09.20213 MARKS UPDATED RG

08.09.20212 FOR APPROVAL RG31.08.20211 FOR APPROVAL RG

13.08.20210 FOR APPROVAL RGIndex Date Description Author

PROJECT No.

CLIENT

PROJECT

REVDRAWING No.

DRAWING TITLE

DATE SCALEDRAWN BY CHECKED BY

ROOF PLAN

RG 13.08.2021 1:50

G-03 3

STEEL CONTRACTOR

C114 -

RHS300*

100*8

.0

GALVANISED

C108 -

SHS100*

100*1

0.0

C119 -

SHS100*

100*1

0.0

GALVANISED

BR101 - FLT8*100GALVANISED

B160 - UB254*146*37GALVANISED

C121 -

SHS100*

100*1

0.0

GALVANISED

B150 - UB203*102*23

BR102 - FLT8*100GALVANISED

B150 - UB203*102*23

ROOF PLAN

B113 - SHS100*100*8.0TOS= 178325

C108 -

SHS100*

100*1

0.0

B107 - UB203*102*23 B107 - UB203*102*23

C108 -

SHS100*

100*1

0.0

C107 -

RHS300*

100*8

.0

GALVANISED

B114 - UB254*146*37GALVANISED

C127 -

RHS300*

100*8

.0

GALVANISED

B132 - RHS200*100*10.0

TOS= 178528

GALVANISED

B134 - RHS200*100*10.0

TOS= 179856

GALVANISED

B116

- U

B254

*146

*37

TOS=

1802

28

B113 - SHS100*100*8.0TOS= 178325

B169 - UB203*102*23

C111 -

SHS100*

100*1

0.0

GALVANISED

B120 - UB203*102*23

B117 - UB254*146*37GALVANISED

B169 - UB203*102*23

C106 -

RHS300*

100*8

.0

GALVANISED

C106 -

RHS300*

100*8

.0

GALVANISED

C103 -

SHS100*

100*1

0.0

B120 - UB203*102*23

B139 - RHS200*100*10.0

TOS= 178528

GALVANISED

NOTE:ARCHITECTURAL ROOFPLAN OVERLAID

C126 -

SHS100*

100*1

0.0

C127 -

RHS300*

100*8

.0

GALVANISED

B113 - SHS100*100*8.0TOS= 178325

B151 - UB203*102*23

B151 - UB203*102*23

B114 - UB254*146*37GALVANISED

B149

- U

B254

*146

*37

TOS=

1802

28

4.1 45

5.1

G

H

J

F

1 23

A

BC

D

D4

E

6

KK1

LM

D4

D

CB

A3

L

K1

K

J

4.1

F

E

21

M

H

G

65.154

STEELWORK NOTES

1. STEELWORK HAS BEEN DESIGNED AND SPECIFIED AND IS TO BE SUPPLIED AND CONSTRUCTEDIN ACCORDANCE WITH BS5950 AND THE NATIONAL STRUCTURAL STEELWORK SPECIFICATION FORBUILDING CONSTRUCTION (NSSS). ALL STEELWORK TO BE EXECUTION CLASS 2 (EXC2) TO BS EN1993-1-1 ANNEX C. ALL STEELWORK UTILISED ON THE PROJECT IS TO BE EUROPEANMANUFACTURED STEEL. ALL SECTIONS USED ARE TO BE HOT ROLLED STRUCTURAL STEELSECTIONS GRADE S355 J2H. NO COLD FORMED SECTIONS ARE PERMITTED TO BE USED SAVE FORPROPRIETARY C OR Z PURLIN SECTIONS. CONTRACTOR TO HAVE COPY OF NSSS ON SITE FORREFERENCE. ALL STEELWORK HAS BEEN DESIGNED TO DEFLECTION LIMITS OF L/250 FOR TOTALLOAD, L/360 FOR IMPOSED LOAD AND L/500 FOR TOTAL LOAD IN MEMBERS SUPPORTING MASONRYWALLS.

2. ALL STEEL TO STEEL/CONCRETE/TIMBER/GLASS CONNECTIONS AND ARE TO BE DESIGNED BYTHE MAIN CONTRACTOR UNLESS NOTED OTHERWISE. DESIGN CALCULATIONS MUST BEUNDERTAKEN BY A CHARTERED STRUCTURAL ENGINEER AND BE SUPPLIED TO THE ENGINEERAND ARCHITECT FOR REVIEW A MINIMUM 15 WORKING DAYS PRIOR TO MANUFACTURE.

3. THE MAIN CONTRACTORS STEELWORK FABRICATION DRAWINGS ARE TO BE SUPPLIED TO THEENGINEER AND ARCHITECT FOR REVIEW A MINIMUM 10 WORKING DAYS PRIOR TO MANUFACTURE.THE MAIN CONTRACTORS PROGRAM SHOULD ALLOW 5 DAYS FOR T4C COMMENT FOR EACH ANDEVERY RE-ISSUE.

4. STEELWORK CONFORMITY CERTIFICATES/MANUFACTURERS INSPECTION DOCUMENTS ARE TOBE PROVIDED TO THE ENGINEER FOR REVIEW PRIOR TO MANUFACTURE.

5. ALL STEEL TO STEEL CONNECTIONS ARE TO BE FORMED USING 10mm THK (S275) FLEXIBLEENDPLATES, 6mm FULL PROFILE FILLET WELDS (FPFW) AND 4No. M20 GRADE 8.8 BOLTS IN 22mmDIA STANDARD CLEARANCE HOLES UNLESS NOTED OTHERWISE. CONNECTIONS ARE TO BE INACCORDANCE WITH THE BCSA GREEN BOOK FOR SIMPLE CONNECTIONS. ALL SECTIONS ARE TOBE SAWN SQUARE FOR CONNECTIONS TO END PLATES, CAP PLATES AND BASEPLATES. AllCONNECTIONS ARE TO BE WEB TO WEB CONNECTIONS AND TO NODE OUT ON THE CENTRELINESOF THE MEMBERS BEING CONNECTED. WHERE THIS IS NOT POSSIBLE THEN T-SECTIONS SHOULDBE ADOPTED TO TRANSFER THE LOADS TO THE MEMBER AXIS. COLUMN BASEPLATES TO BEBEDDED ON MINIMUM 25mm NON-SHRINK CEMENTITIOUS GROUT.

6. ALL STEEL TO CONCRETE PADSTONE CONNECTIONS ARE TO BE FORMED WITH 2No. (WHEREBEAM RUNS PERPENDICULAR TO WALL) OR 1No. (WHERE BEAM RUNS PARALLEL TO WALL) M10HILTI HVU-HAS CHEMICAL ANCHOR(S) WITH 130mm EMBEDMENT IN 12mm DIA HOLES, 10mm THKSEATING PLATES (S275), 8mm FULL PROFILE FILLET WELDS (FPFW) WITH MAXIMUM 10mm NONSHRINKLEVELLING GROUT (CONBEXTRA GP BY FOSROC OR SIMILAR APPROVED BY T4C) UNLESSNOTED OTHERWISE. BEAMS TO BEAR FULL WIDTH/LENGTH OF PADSTONE UNLESS NOTEDOTHERWISE. CONCRETE PADSTONES TO BE MINIMUM 50N/mm2 CONCRETE.

7. STEELWORK TO BE PROTECTED TO THE FOLLOWING MINIMUM SPECIFICATION TO MAINCONTRACTORS PROPOSALS (MAIN CONTRACTOR TO PROVIDE SPECIFICATION TO THE ENGINEERAND ARCHITECT FOR REVIEW PRIOR TO MANUFACTURE) UNLESS NOTED OTHERWISE:

a. INTERNAL STEELWORK PAINTED – SHOT BLAST SA2.5 THEN 25MICRONSBLAST PRIMER. AFTER FABRICATION 75MIRONS MINIMUM SINGLE PACK EPOXYZINC PHOSPHATE PRIMER.EXTERNAL STEELWORK PAINTED – GALVANISING TO BE STRICTLY INACCORDANCE WITH EN ISO1461. FABRICATED STEELWORK TO HAVE AMINIMUM COATING OF 85 MICRONS.ENVIRONMENT CATEGORIES ARE SPECIFIED IN BS EN ISO 12944 AND ISO 9223.

8. ALL INTERNAL STEELWORK COLUMNS TO BE FIRE PROTECTED WITH INTUMESCENT PAINT TOMAIN CONTRACTORS PROPOSALS (MAIN CONTRACTOR TO PROVIDE SPECIFICATION TO THEENGINEER AND ARCHITECT FOR REVIEW PRIOR TO MANUFACTURE) FOR 1 HOURS FIREPROTECTION UNLESS NOTED OTHERWISE. INTUMESCENT PAINT IS TO BE COMPATIBLE WITH THECORROSION PROTECTION SYSTEM.

9. ALL STEELWORK IN EXTERNAL WALLS TO BE PAINTED WITH ADDITIONAL 2No. COATS OF HEAVYDUTY BITUMINOUS PAINT UNLESS NOTED OTHERWISE. ALL STEELWORK BELOW GROUND TO BEPAINTED WITH ADDITIONAL 3No. COATS OF HEAVY DUTY BITUMINOUS PAINT OR SURROUNDEDWITH MINIMUM 50mm CONCRETE WITH D49 WRAPPING MESH, UNLESS NOTED OTHERWISE.

20.09.20213 MARKS UPDATED RG

08.09.20212 FOR APPROVAL RG31.08.20211 FOR APPROVAL RG

13.08.20210 FOR APPROVAL RGIndex Date Description Author

PROJECT No.

CLIENT

PROJECT

REVDRAWING No.

DRAWING TITLE

DATE SCALEDRAWN BY CHECKED BY

ISOMETRIC VIEW

RG 13.08.2021 1:50

G-04 3

STEEL CONTRACTOR

ISOMETRIC VIEW

![ÀÀij¦a¤ PROPOSED GROUND FLOOR LAYOUT PLAN · proposed ground floor layout plan ... ¡]¨Ó·½¡id¡ ¦a¤u¥± comparison of ground floor plans ²{¦³¦a¤uexisting ground](https://static.fdocuments.us/doc/165x107/5f59ced8559a814b617ecff6/a-proposed-ground-floor-layout-plan-proposed-ground-floor-layout-plan.jpg)