Fuzzy Evaluation Model for Karst Highway Tunnel Safety

Transcript of Fuzzy Evaluation Model for Karst Highway Tunnel Safety

Fuzzy Evaluation Model for Karst Highway Tunnel Safety

Rao Jun-ying*, Fu He-lin, Yin Quan, Li Wen-bo

School of Civil Engineering, Central South University, Changsha, Hunan 410004, China

*e-mail: [email protected]

ABSTRACT Referring to the railway tunnel health evaluation model, the safety ranks karst highway tunnel to five grades, which are safe, general safe, minor unsafe, unsafe and extremely unsafe. After that, the hierarchical division for those factors with the multi-grade fuzzy evaluation was carried out. Then, according to the influence of tunnel safety, the qualitative indexes were classified into five levels: no influence, slight influence, minor serious influence, serious influence and extremely serious influence. Furthermore, the membership function, which followed the Gaussian Distribution, was applied to determine quantitative evaluation indexes. Meanwhile, relied on the expert scoring method from system theory, the weight allocation for various factors and the treated karst caves model were set up as uncompacted backfill model. Finally, the three-grade fuzzy comprehensive evaluation model was built for in-service highway tunnel safety in karst area. With this model, the safety of Hui-long-shan tunnel was evaluated and the results were judged by the maximum membership law.

KEYWORDS: highway tunnel; karst; safety; fuzzy theory; evaluation model

FOREWORD "Safety First, Precaution Crucial” is the main purpose during engineering construction and its

service. The underground engineering, especially tunnel, is particularly important in this regard. Most of the traditional decision methods for the tunnel structural safety are based on the investigation and detection of tunnel diseases, and then establish the diagnosis model to analyze the tunnel safety. However, the traditional methods are still not perfect enough: firstly, they can’t create a calculation model for all tunnel diseases; secondly, the correlations between diseases are not fully concerned, it is unable to assess the tunnel safety accurately with a solitary analyzing. Therefore, we should take the coupling effect of multi-factor on the tunnel safety into account.

- 5173 -

Vol. 18 [2013], Bund. U 5174

Fuzzy theory provides a new idea for the comprehensive evaluation. Based on the fuzzy theory and the fuzzy relation composite principle, the factors with fuzzy boundaries can be quantified simply. Meanwhile, fuzzy comprehensive evaluation can guarantee the qualitative evaluation indexes to quantify and the quantitative indexes to approximate the accurate values [1-7]. In addition, some scholars establish the multi-level fuzzy comprehensive judgment model for the safety of railway tunnels and deep foundation pit support structures, such as: Jiang tried to establish a mathematical model for the quantitative determination of railway tunnel health, but this model is just in the qualitative determination phase[8]; Lu built a multi-level fuzzy comprehensive evaluation model for a deep excavation engineering and its support system[9]; Fu and Lu provided a evaluation method for a complex soft ground with fuzzy comprehensive evaluation and discrete sample model[10]; Huang and Wu classified the tunnel diseases and evaluated the health status for a in-service tunnel with three-grade fuzzy evaluation model, but the influence of karst caves were not involved in their model[11].

From the current available information [1-14], a certain amount of research has been achieved at the aspect of structural safety assessment with fuzzy theory. However, no studies on the structural safety of in-service karst tunnel are found with the fore-mentioned methods. While, involving the karst highway tunnel safety evaluation, there are many qualitative and quantitative indexes with uncertainty, ambiguity or complexity. To this end, based on the fuzzy theory, we proposed the fuzzy comprehensive evaluation method for evaluating the in-service karst highway tunnel safety, and verified this method was feasible and reasonable by an engineering example.

THE KARST HIGHWAY TUNNEL SAFETY CLASSIFICATION

Refer to the related health evaluation model of railway tunnel, the safety classification on karst highway tunnel are shown in Table 1[15]. According to the seven major parameters, the highway tunnel safety is divided into five levels: safe (Ⅰ), basic safe (Ⅱ), minor unsafe (Ⅲ), unsafe (Ⅳ) and extremely unsafe (Ⅴ). The Ⅰ level means no potential safety hazard and no influence to traffic, the in-service tunnel structure system can maintain normal repair and maintenance; the Ⅱ level means some safety hazards to in-service tunnel structure system, but without influence to traffic safety, it can return to Ⅰ level by the necessary maintenance; the Ⅲ level expresses that the in-service tunnel structure system involves some potential safety hazards, the unsafety is developing, but not yet has an influence to traffic safety, it needs to enhance the maintenance for back to Ⅱ level; Ⅳ level is unsafe to in-service tunnel, it may endanger the traffic safety, if failed to take timely and reliable conservation measures, it will develop to Ⅴ level; Ⅴ level is extremely unsafe, the insecure factors are endangering traffic safety, maintenance measures should be taken immediately.

The tunnel safety level relates to the tunnel defects and lining cracks, original engineering geology and hydrogeology, structural design and construction process. More importantly, it concerns to following factors: surrounding rock deterioration during tunnel service, load changes

Vol. 18 [2013], Bund. U 5175 caused by lining dehiscence, lining deterioration caused by leakage or frost damage, rapid lining deformation and tunnel clearance deficiency. Obviously, it is very difficult to accurately assess the influence of these factors on the tunnel safety. So, in our evaluation model, first of all, the data of tunnel construction, service state, tunnel diseases, observational data and test data of lining state were collected and analyzed. Then, the main parameters that affect the tunnel safety were graded, as shown in Table 1.

Table 1: The karst highway tunnel safety classification Safe grade Major parameters

Ⅰ Ⅱ Ⅲ Ⅳ Ⅴ

Safe General safe Minor unsafe Unsafe Extremely

unsafe Contact state between surrounding rock and lining

None 1 1 or 2 2 1 or 2

or 3 1 or 2 or 3 3 1 or 2 or

3 or 4 1 or 2 or 3 or 4 4 4 3

Surrounding rock deterioration None 1 1 or

2 2 1 or 2 or 3

1 or 2 or 3 3 1 or 2 or

3 1 or 2 or 3 4 1 or 2

or 3

A param

eter rate as level 4.

Lining dehiscence None 1 1 2 2 1 or 2 3 3 1 or 2 or 3 4 1 or 2

or 3 Leakage and frost damage None 1 1 or

2 2 1 or 2 or 3

1 or 2 or 3 3 1 or 2 or

3 or 4 1 or 2 or 3 or 4 4 1 or 2

or 3

Lining deterioration None 1 1 2 1 or 2 2 3 1 or 2 or 3 3 4 1 or 2

or 3 Lining deformation and clearance deficiency

None 1 1 or 2 2 1 or 2

or 3 1 or 2 or 3 3 1 or 2 or

3 1 or 2 or 3 4 1 or 2

or 3

Impact on traffic safety None 1 2 3 4

Notes: in this table, 1, 2, 3, 4 respectively represent the main parameter level; "or" indicates that meet the requirements as long as one case occurs.

HIERARCHICAL DIVISION OF INFLUENCING FACTORS IN TUNNEL SAFETY

In the fuzzy theory, the evaluation of many complex systems, not only need to consider many factors which are fuzzy, but most of these factors are in different layers. That means some of these factors are determined by a number of others. For example, in the safety evaluation of highway tunnel, the state of the contact between the surrounding rock and lining, the surrounding rock deterioration, lining deterioration, leakage, frost damage and lining material deterioration must be mentioned. These factors are in the first level. Some of these first level factors include multiple levels too. Such as the evaluation of the contact state between the surrounding rock and lining, which is decided by the cavity behind lining, uncompacted backfill behind lining and the uncompacted basis, these factors are in the second level. Some of the second level factors is determined by the third level factors, such as the evaluation of cavities behind the lining is decided by the kLc (Notes: kLc - The continuous length of hoop or longitudinal horizontal survey line with cavities behind the lining; sLc - The continuous length of hoop or longitudinal horizontal survey line with uncompacted backfill behind the lining; dLc - The continuous length of hoop or longitudinal horizontal survey line with uncompacted basis.) of vault and haunch. So, in order to

Vol. 18 [2013], Bund. U 5176 evaluate the multi-factor and multi-level system, a multi-level fuzzy comprehensive evaluation should be adopted.

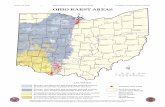

Figure 1: Hierarchical divisions of tunnel safety factors

According to the multi-level fuzzy comprehensive evaluation method, the hierarchical divisions to the various factors are carried out, as shown in Figure 1. In this situation, 21 pieces of single factor are included in the one-grade evaluation. These single factors are used to evaluate 10 pieces of two-grade factors which are cavity, uncompacted backfill, vault crushing, cracks, construction joints leakage, cracks leakage, lining concrete leakage, drainage system, hanging ice and rock frost heave. Then, in the two-grade evaluation, including those two-grade factors and 17 pieces of new single factors, which are applied to evaluate 6 pieces of three-grade factors, which are contact state between surrounding rock and lining, lining dehiscence, leakage, frost damage,

Vol. 18 [2013], Bund. U 5177 lining deterioration, lining deformation and tunnel clearance deficiency. Finally, in the three-grade evaluation, the three-grade factors and 2 pieces of new single factor are selected to evaluate the in-service tunnel safety.

THREE-GRADE FUZZY COMPREHENSIVE EVALUATION MODEL FOR TUNNEL SAFETY

Main parameters in that model

By the hierarchical division of factors for tunnel safety, we can set up the three-grade fuzzy comprehensive evaluation model, as shown in Eq.(1).

11 11

12 121

1 1

21 211 1

22 222 2 2

2 2

1 1

2 2

A P

A PA

A Pn nA P

A PA P

A P AB A P A A

A Pn nA Pn n

A Pn nA Pn nAn

A Pnn nn

= = =

(1)

In Eq.(1), A is weight vector in three-grade evaluation, Ai (i=1,2,… , n) means weight vector from two-grade evaluation, Aij (i=1,2,…,n; j=1,2,…,m) plays the role of weight vector in one-grade evaluation; P acts as fuzzy evaluation matrix for three-grade evaluation, Pi (i=1,2,…,

n) shows as fuzzy evaluation matrix from two-grade evaluation, Pij (i=1,2,…,n;j=1, 2,…,m) presents fuzzy evaluation matrix of one-grade evaluation; B is the object of fuzzy comprehensive evaluation; “ ” indicates composition operator in that fuzzy matrix. So, there are three weight vectors (A, Ai, Aij), three fuzzy matrixes (P, Pi, Pij) and a composition operator (“ ”) need to be determined in Eq.(1).

The Fuzzy Evaluation Matrix

In this fuzzy evaluation matrix, the membership function is applied to determine the quantitative evaluation indexes. Now, take the Gaussian Distribution for these quantitative indexes on the tunnel safety level, and the membership function of safety level N for the evaluation indexes Rij and Rijk, shows as:

2[( ) ]( ) x a bNA x e− −= (2)

Vol. 18 [2013], Bund. U 5178

In Eq.(2), x means the index value of Rij or Rijk, a comes from the average value of upper and lower limit in the interval of [x1,x2] for Rij or Rijk, that is a=(x1+x2)/2. When the boundary values of indexes belong to two levels, it has the same membership in these two levels. So, they are set as 0.5, as shown in Eq.(3).

21 2[( ) (2 )] 0.5x x be− − = (x=x1) (3)

Then, b can be calculated from Eq.(3), as shown in Eq.(4).

1 2( ) 1.665b x x= − (4)

In Eq.(3) and Eq.(4), x1 means lower limit value, x2 is upper limit value. When Eq.(5) is satisfied, respond to normalize the membership.

5

1( ) 1k

kA x

=

≠∑ (5)

The quantitative indexes values are determined from Table 2. Every qualitative index, in Figure 1, is a discrete single factor and we can obtain their membership values from in Table 3. By the influence of tunnel safety, the qualitative indexes are classified to five levels, which are no influence, slight influence, minor serious influence, serious influence and extremely serious influence. In the case of no influence, the membership function value is determined by the axial compressive strength standard value with 95% guaranteed rate in the design of concrete structures. The classification refers to the reference of [15].

Table 2: Quantitative assessment indexes values and divisions Single factors Safe General safe Minor unsafe Unsafe Extremely unsafe

R13 / m 0~3 3~9 9~15 15~18 >18 R35 / cm 0~1 1~3 3~5 5~10 >10 R111 / m 0~3 3~5 5~7 7~L2 L2 R112 / m 0~3 3~5 5~7 7~L2 L2 R121 / m 0~3 3~5 5~7 7~L2 L2 R122 / m 0~3 3~5 5~7 7~L2 L2

R311 / ㎡ 0~0.2 0.2~1 1~3 3~5 >5

R312 / cm 0~1 1~3 3~5 5~10 >10 R322 / m 0~3 3~5 5~10 10~15 >15 R323 / mm 0~3 3~5 5~10 10~20 >20

Notes: L2 means the length of construction section.

Table 3: Qualitative indexes membership function values

Single factors Index values Safe General safe

Minor unsafe Unsafe Extremely

unsafe

R1~R8, R11~R12, R31~R34, R41~R45, R51~R57,

R61~R63, R71~R73, R321, R411~R412, R421~R422, R431~R432, R441~R442, R511~R512, R551~R552

No influence 0.95 0.03 0.02 0.00 0.00

Slight influence 0.35 0.30 0.20 0.10 0.05 Minor serious

influence 0.20 0.20 0.40 0.10 0.10

Serious influence 0.10 0.25 0.30 0.20 0.15 Extremely serious

influence 0.05 0.15 0.20 0.25 0.35

Vol. 18 [2013], Bund. U 5179

Weight Vector

In all levels of fuzzy comprehensive evaluation, the weight vector determines the impact of various factors; the weight assignation affects the evaluation results directly. Additionally, this weight assignation comes from the fuzzy statistical theory and the use of expert scoring method. So, according to a number of engineering and scientific research units experienced experts, on the basis of the importance degree for the various factors that affect the in-service highway tunnel safety, then take the average values as the weight set of the fuzzy evaluation, as shown in Table 4.

Table 4: The weight vectors of fuzzy evaluation Relations between

layers Weight vectors Relations between layers Weight vectors

B←R1~R8 A=[0.15,0.10,0.20, 0.10, 0.10, 0.10, 0.15, 0.10] R31←R311~R312 A31=[0.40, 0.60]

R1←R11~R13 A1=[0.40, 0.40, 0.20] R32←R321~R323 A32=[0.40,0.30,0.30] R3←R31~R35 A3= [0.25, 0.25, 0.10, 0.20, 0.20] R41←R411~R412 A41=[0.55, 0.45] R4←R41~R45 A4=[0.20, 0.20, 0.20, 0.25, 0.15] R42←R421~R422 A42=[0.55, 0.45] R5←R51~R57 A5=[0.20, 0.20, 0.10, 0.10, 0.10, 0.20, 0.10] R43←R431~R432 A43=[0.55, 0.45] R6←R61~R63 A6=[0.30, 0.40, 0.30] R44←R441~R442 A44=[0.45, 0.55] R7←R71~R73 A7=[0.20, 0.30, 0.50] R51←R511~R512 A51=[0.60, 0.40] R11←R111~R112 A11=[0.60, 0.40] R55←R551~R552 A55=[0.45, 0.55] R12←R121~R122 A12=[0.60, 0.40]

Matrix Operation

In order to retain all the useful information in this fuzzy model, the operator of M(●,+) is used for the fuzzy matrix composition operation by fuzzy mathematics theory. Both of the weight coefficients and evaluation matrix coefficients are without upper limit, so it satisfies the requirements of this project.

ENGINEERING APPLICATIONS——HUI-LONG-SHAN TUNNEL

Overview of Hui-long-shan Tunnel

The Hui-long-shan tunnel was built in 2010; it’s a separated tunnel, which belongs to Shaogan Highway with six lanes in bi-direction. Its net width is 14.5m in main section, while 17.0m in emergency parking section. The left Hui-long-shan tunnel is 1155m (ZK3+790 ~ K4+945), while the right is 1145m (YK3+800 ~ YK4+945), as shown in Figure 2. It is the typical karst tunnel for 27 karst caves have been treated with mortar flag stones during construction. Although the karst area has been disposed meticulously, the health status and the potential risk of the tunnel will still be ambiguous after serving in sustained overload.

Vol. 18 [2013], Bund. U 5180

Figure 2: Vertical section of left line at Hui-long-shan tunnel

(a) Lining cracks (b) Lining seepage

(c) Lining breakage (d) GPR scanning

Figure 3: Diseases investigation and detection for Hui-long-shan tunnel

For getting to know the health status of this tunnel, the geological radar, lining strength, lining surface imaging and headroom sectional measurements are carried out, which can provide a technical support for the safe and efficient service to Hui-long-shan tunnel, as shown in Figure 3. The main diseases can be summarized as follows:

Reverse CompassKarstcave

Ponor Attitude of rocks ProfileNormal

Geological ExploratorydataDip AngleMarginal accumulation

boundary bore-hole

directions

series

fault

fault

sandstone

Vol. 18 [2013], Bund. U 5181

(1) There are five cavities behind the vault lining of left tunnel (as shown in Table 5), the length of them respectively are 2m, 0.5m, 1m, 3m, 3m, 2m, while only one cavity exists with the length of 2m at the same position of right tunnel.

(2) Lining diseases develop in some degree, but not yet have an impact on traffic safety. From the Guangzhou to Ganzhou direction, a ring through-crack is found at the left tunnel, the maximum width is about 3mm, this crack roughly parallels to the tunnel cross section. To concern the right tunnel, six cracks are discovered. Their maximum width respectively are 1.5mm, 1mm, 1mm, 1mm, 1.5mm and 2mm. These cracks are circumferential, throughout the entire cross-section, the fracture strike roughly parallels with the tunnel cross-section and cracks develop slowly, a few cracks are in leakage. As a whole, the breakage of entire lining is in a slow development.

(3) Without crushing and material deterioration happening, the effective lining thickness still corresponds to the design. However, a tiny peeling occurs at the vault lining with the area of 0.3m2 and the thickness of 1.5cm, the lining concrete strength turns into slightly lower too.

(4) Behind the longitudinal lining of the vault and haunch, the backfill is compacted, but there are intensive caves. As the elastic modulus of karst cave filler is smaller than that of surrounding rock, which can be simplified by uncompacted backfill model. The continuous length is the original cave size. The uncompacted backfill continuous length respectively is 7.5m, 7m and 6.8m behind the vault, haunch and soffit within measuring line.

(5) Some settlement exists in vault, but it is in a steady state. The clearance is in slow convergence, no intrude tunnel limit and leakage situation happen.

Table 5: Lining quality defects of Hui-long-shan tunnel

Positions Stakes Measuring lines Diseases Surrounding rock grades

Left tunnel

ZK4+264~ZK4+262 vault cavity Ⅴ

ZK4+102~ZK4+101 vault cavity Ⅲ

ZK4+008~ZK3+007 vault cavity Ⅳ

ZK3+878~ZK3+875 vault cavity Ⅴ

ZK3+860~ZK3+857 vault cavity Ⅴ

Right tunnel YK4+869~YK4+871 vault cavity Ⅴ

The Fuzzy Evaluation Process and Results Analysis

From the detection and investigation of Hui-long-shan tunnel, the index values of various quantitative and qualitative indexes are shown in Table 6 and Table 7.

Vol. 18 [2013], Bund. U 5182

Table 6: Values of quantitative indexes Indexes Values Indexes Values Indexes Values

R111 / m 3 R13 / m 6.8 R323 / mm 3 R112 / m 5 R311 / ㎡ 0.3 R35 / cm 0.8

R121 / m 7.5 R312 / cm 1.5 R122 / m 7 R322 / m 3

Table 7: Values of qualitative indexes Indexes Values Indexes Values Indexes Values

R2 Slight influence R441 Slight influence R56 No influence R321 Minor serious influence R442 Slight influence R57 No influence R33 Slight influence R45 No influence R61 Slight influence R34 Slight influence R511 No influence R62 Slight influence R411 Slight influence R512 No influence R63 No influence R412 Slight influence R52 No influence R71 Slight influence R421 No influence R53 No influence R72 Slight influence R422 Slight influence R54 No influence R73 No influence R431 No influence R551 No influence R8 Slight influence R432 Slight influence R552 No influence

Now, plug each single factor into the membership function or membership table respectively, work out the fuzzy evaluation matrix, and then the evaluation results at all grades can be solved according to Eq.(1) in proper order.

First of all, the third grade fuzzy evaluation is shown as follows:

[ ]11 11 11 0.305 0.474 0.178 0.043 0B A P= = , [ ]12 12 12 0 0 0.348 0.652 0B A P= = [ ]31 31 31 0.066 0.815 0.070 0.011 0.038B A P= = , [ ]32 32 32 0.349 0.349 0.217 0.045 0.040B A P= = [ ]41 41 41 0.35 0.30 0.20 0.10 0.05B A P= = , [ ]42 42 42 0.680 0.152 0.101 0.045 0.022B A P= =

[ ]43 43 43 0.680 0.152 0.101 0.045 0.022B A P= = , [ ]44 44 44 0.35 0.30 0.20 0.10 0.05B A P= = [ ]51 51 51 0.95 0.03 0.02 0 0B A P= = , [ ]55 55 55 0.95 0.03 0.02 0 0B A P= =

And then, the second grade fuzzy evaluation is shown as follows:

[ ]1 1 1 0.122 0.455 0.210 0.213 0B A P= = , [ ]3 3 3 0.343 0.445 0.132 0.045 0.035B A P= = [ ]4 4 4 0.572 0.200 0.134 0.063 0.031B A P= = , [ ]5 5 5 0.95 0.03 0.02 0 0B A P= = [ ]6 6 6 0.530 0.219 0.146 0.070 0.035B A P= = , [ ]7 7 7 0.650 0.165 0.110 0.050 0.025B A P= =

Finally, the first grade fuzzy evaluation is shown as follows:

0.15 0.122 0.455 0.210 0.213 00.10 0.350 0.300 0.200 0.100 0.0500.20 0.343 0.445 0.132 0.045 0.0350.10 0.572 0.200 0.134 0.063 0.0310.10 0.950 0.030 0.020 0 00.10 0.530 0.219 0.146 0.070 00.150.10

T

B A P

= =

[ ]0.520 0.260 0.126 0.072 0.022

.0350.650 0.165 0.110 0.050 0.0250.950 0.030 0.020 0 0

=

Vol. 18 [2013], Bund. U 5183

The fuzzy evaluation results show that: based on the principle of maximum membership, the safety level of this in-service karst tunnel is safe in this measuring section, and tends to general safe. Its only needs to maintain a normal conservation continuously, individual diseases should be repaired by the maintenance remediation, such as the flaking decorative layer and falling cuttings at vault.

CONCLUSIONS

(1) The fuzzy comprehensive evaluation method for the safety of in-service karst highway tunnel is put forward. This method combines qualitative index with quantitative index which makes up for the deficiencies for the traditional evaluation methods based on empirical judgments.

(2) The influence of treated karst caves is taken into account for the safety of in-service karst highway tunnel. The karst cave filler, with a lower elastic modulus than that of surrounding rock, can be simplified by uncompacted backfill model which is used to build the three-grade fuzzy comprehensive evaluation model, and this model is applied in Hui-long-shan tunnel successfully.

(3) In this built fuzzy evaluation model, the assessment parameters is based on the information of a real in-service karst highway tunnel, which can reflect its health status in great extent. So, this safety evaluation is valuable.

(4) In this fuzzy evaluation model, the membership function and membership value of each single factor index weight attach great importance to results. It also needs to constantly optimize and improve in engineering application for achieving more reasonable and reliable evaluation results.

ACKNOWLEDGEMENT This paper is sponsored by Chinese Fund of Natural Science (50878213, 51008308), Hunan

Provincial Graduate Innovation Fund Project, and Guangdong Provincial Highway Administration Bureau Science Project (201114), here thank them.

REFERENCES [1] Kaufmann A. Theory of expertons and fuzzy logic [J]. Fuzzy Sets and Systems, 1988, 28(3):

295 - 304.

[2] Joo H M, Chang S K. Application of fuzzy decision making method to the evaluation of spent fuel storage options [J]. Progress in nuclear energy, 2001, 39(3): 345 - 351.

[3] Panou K D, Sofianos A I. A fuzzy multicriteria evaluation system for the assessment of tunnels vis-a-vis surface roads: the WPMA case-Part II [J]. Tunneling and Underground Space Technology, 2002, 17(2): 195 - 207.

[4] Li Fan. Fuzzy information processing system [M]. Beijing: Peking University Press, 1991. (in Chinese)

Vol. 18 [2013], Bund. U 5184 [5] Xin Mingjun, Li Wei-hua, He Hua-can. An approach to fuzzy comprehensive evaluation model

and its algorithm for the distributed problem solving planning [J]. Computer Engineering and Applications, 2001, 37(15): 40 - 42. (in Chinese)

[6] Lu Lan, Yang Jing, Qin Song. A Study on the safety assessment on building sites [J]. China Civil Engineering Journal, 2003, 36(9): 46 - 50. (in Chinese)

[7] Chen Shouyu. Engineering fuzzy set theory and application [M]. Beijing: National Defense Industry Press, 1998(11): 188 - 204. (in Chinese)

[8] Jiang Song-hu, Guan Bao-shu. Diagnostician system of railway tunnel disease [J]. The Proceedings of the First National Youth Rock Mechanics Seminar, 1991(12): 89 - 96.

[9] Lv Pei-yin. Multistrata and comprehensive decision by fuzzy of the supporting and protecting system on deep foundation pit [J]. Journal of Liaoning Institute of Technology on Social Science, 1999, 19(5): 42 - 46. (in Chinese)

[10] Lv Jian-bing, Fu He-lin. Fuzzy comprehensive evaluation of reinforcement Plan for filling karst soft soil foundation and engineering application [J]. Rock and Soil Mechanics, 2005, z26: 244 - 248. (in Chinese)

[11] Huang Bo, Wu Jiang-min. Comprehensive assessment on tunnel operation condition [J]. Journal of World Tunnel, 2000(1): 58 - 60. (in Chinese)

[12] Zhang Yong-jie, Cao Wen-gui, Zhao Ming-hua, e tal. Interval fuzzy judgment method for roadbed stability in karst area [J]. Chinese Journal of Geotechnical Engineering, 2011, 33(1): 38 - 44. (in Chinese)

[13] Cheng Ye, Cao Wen-gui, Zhao Ming-hua. Synthetic judgment on the two stages fuzzy of the stability of karst top slab beneath expressway [J]. China Journal of Highway and Transport, 2003, 16(4): 21 - 24. (in Chinese)

[14] Liu Yao-jun. Fuzzy comprehensive evaluation of railway tunnel surrounding rock classifications [J]. Journal of Shijiazhuang Railway Institute, 1992, 5(4): 80 - 88. (in Chinese)

[15] Yang Yan-qing. Study on health diagnosis and evaluation of residual life for the operation tunnel [D]. Beijing: Beijing Jiaotong University, 2012: 27 - 28. (in Chinese)

© 2013, EJGE

![Original Research Risk Assessment of Water Inrush in Karst … Assessment of... · [17] integrated the artificial neural network (ANN), wavelet, analysis and fuzzy mathematics –](https://static.fdocuments.us/doc/165x107/6046b3ece87910699651aaf7/original-research-risk-assessment-of-water-inrush-in-karst-assessment-of-17.jpg)