Fused Deposition Modeling (FDM)

-

Upload

harsh-ranjangaonkar -

Category

Documents

-

view

70 -

download

4

Transcript of Fused Deposition Modeling (FDM)

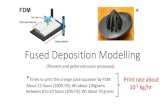

Fused Deposition Modeling (FDM)

Stratasys, Eden Prarie, MN Patent 1992 Robotically guided fiber extrusion Accuracy 0.127 mm Casting and machinable waxes, polyolefin, ABS (Acrylonitrile butadiene styrene), and

PC (polycarbonate)

• Introduction

Fused Deposition Modeling

• Advantages

Any thermoplastic material can be used. The parts are very strong and durable.

Does not uses lasers hence safe.Can be kept in an office environment as a 3D printer.

Very easy to remove the support. Easiest of all RP processes.

Water proof and paint able.

This is the cheapest machine.

Limitations

As every point of the volume is addressed by a mechanical device, it is very slow.

Not very accurate compared SLA, SGC etc.

No special finishing due to toughness of material.

SAMPLE FDM PARTS

SAMPLE FDM PARTS