Furnaces International April 2016

description

Transcript of Furnaces International April 2016

www.aluminiumtoday.com/furnaces/ Issue 1

ALUMINIUM GLASS STEEL GLASS

Finding the right furnace A NOx removal process from exhaust gas in a glass furnace

Increasing energy efficiency in electric arc furnaces

Advancements in regenerative gas burner technology

‘Ipsen’s UK & Ireland agents’

Comment

2 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

Comment

Editor:

Sally Love

Tel: +44 (0) 1737 855132

Email:

Designer: Nikki Weller

Sales/

Advertisement production:

Esme Horn

Tel: +44 (0) 1737 855136

Email:

Sales director:

Ken Clark

Email:

Managing Editor:

Steve Diprose

Chief Executive Officer:

Paul Michael

Subscription:

Elizabeth Barford

Email:

Published by Quartz Business Media Ltd,Quartz House, 20 Clarendon Road,Redhill, Surrey RH1 1QX, UK.

Tel: +44 (0)1737 855000.Fax: +44 (0)1737 855034.

Email:[email protected]:www.aluminiumtoday.com/furnaces/

Furnaces International is published quarterly and distributed worldwide digitally

Annual subscription: £90

Welcome to the first issue of the revitalised Furnaces

International, a digital reincarnation of the popular

industry magazine. I’ve been told there’s a gap in

the market for a publication focused on industrial

furnaces, and so I hope that the industry gets involved

and finds the articles informative and the community

helpful.

From my initial foray into the furnaces industry,

it seems that it is often affected by elements

that are out of its control. For example, in Europe

manufacturing industries face government emissions

targets and energy taxes that are not imposed in

other countries around the world. These are issues

that can negatively impact the productivity of

manufacturing industries, and thus filter down to

become a priority for furnace makers.

This is where furnace manufacturers can (attempt

to) come to the rescue, when governments can’t or

won’t: more and more often, producers of metals,

glass, and ceramics, etc. are looking directly to the

furnace to solve their energy problems.

The industrial furnace is, after all, essential to

industrial manufacturing, and to that end this

magazine will provide a variety of articles on

developments and initiatives from across the industry

that demonstrate improvements in the field of heat

treatment and furnace technology.

If you have any comments, news items that you

think should be broadcast, case studies, or technical

features that you would like to share with the

industry, then just get in touch.

Sally Love

Editor, Furnaces International

© Quartz Business Media Ltd, 2016

www.aluminiumtoday.com/furnaces/ Issue 1

ALUMINIUM GLASS STEEL GLASS

Finding the right furnace A NOx removal process from exhaust gas in a glass furnace

Increasing energy efficiency in electric arc furnaces

Advancements in regenerative gas burner technology

‘Ipsen’s UK & Ireland agents’

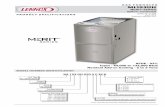

Front cover: Ipsen

www.ipsen.de

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 3

4 News

Aluminium 6 Finding the right furnace 9 Long-life rollers

Heat Treatment11 Efficient heat treatment

Glass14 Prolonging the campaign life of a glass furnace17 A NOx removal process from exhaust gas in a glass furnace20 Energy saving concepts for glass containers and tableware furnaces

BIFCA23 Introducing BIFCA

Glass24 Advancements in regenerative gas burner technology Steel28 Increasing energy efficiency in electric arc furnaces

6 11

24

9

Contents

4 r Furnaces International Issue 1

UK-based electric melting

specialist Electroglass has

reported a ten-year record in its

2015 results.

“Despite uncertainty and

slow-down in a number of

world markets, we have had an

excellent year”, said Managing

Director Richard Stormont.

“All-electric furnace and

forehearths projects for fluoride

opal tableware glass, in south

Asia in particular, have been

significant contributors to

this, along with borosilicate

electric forehearths work in the

USA; gas-to-electric soda-lime

forehearth conversions in South

Korea; electric boosting projects

in Indonesia and elsewhere; and

continuing development and

sales of our Precision Control

Bubbling Systems.

“Also holding up well are

sales of hardware, notably

the Molycool and Vertical

Splashguard ranges of electrode

holders and our dry-type

forehearth electrodes,” he added.

“The rest of 2016 sees the

commissioning of several

recently supplied systems and

work is expected to start on

a number of significant new

projects for the company.”

Record year for electric melting specialist

Workers at the aluminium

smelter at Fort William,

Scotland have been told that

the owners are reviewing its

operations.

The announcement from

Rio Tinto said the review

would include its assets in

Lochaber.

The plant is one of the

largest employers in the area.

It is thought to support more

the 160 full-time jobs.

The Scottish government

said Highlands and Islands

Enterprise was "engaging with

the company" to understand

the potential impacts of the

announcement.

The smelter is Rio Tinto's

only operational site in the

UK and is unique in that it

generates its own power from

two hydro electric schemes.

The Kish South Kaveh Steel

Company (SKS) in Iran says it

is investing heavily in steel

production projects that will

create around 1,000 direct and

indirect jobs in the country.

CEO Ali Dehaqin, says

that SKS intends to play an

important role in the ongoing

development of the Iranian steel

industry.

“Annual [Iranian steel]

production of 55Mt has been

envisaged until 2025,” he said,

adding that phase one of SKS’s

steel production project was

launched with a capacity of

1.2Mt/yr.

To date, SKS has produced

400 tonnes of steel using

equipment including an electric

arc furnace (EAF/EBT/170/7500

model).

The equipment in question is

a CCM/6 strand/120-150-200

foundry machine with a tundish

capacity of 30 tonnes and it

is predicted to be capable of

producing billets at nominal

capacity.

Phase two of SKS’s steel

production project is currently

under way and is expected to

come on stream in March 2017,

according to project manager

Shahram Salmasi.

Iranian steelmaker SKS plans major expansion

Amid the on-going crisis facing

the UK's steel industry, the

President of the European

Commission, Jean-Claude

Juncker, has said the EC is

investigating whether the

Chinese steel industry is

dumping subsidised steel into

the European markets.

Mr Juncker said: “The

steel industry has problems.

We are now investigating

steel production in China to

determine whether it is dumped

in the market and we will take

other measures if necessary.”

The EU has previously been

criticised by steelmakers for

its lack of action with regards

to imposing tariffs onto

Chinese steel, as has the British

government, which blocked

a previous attempt by the EU

to introduce higher tariffs on

Chinese steel imports.

This move may well have

backfired, with Tata Steel

announcing the sale of its UK

steel operations in a move that

puts up to 40,000 British jobs at

risk if no buyer can be found.

So far, only Liberty has come

forward as a potential buyer for

the Port Talbot plant in Wales.

EU considers China steel import duties

Jean-Claude Juncker

News

Fort William aluminium smelter future uncertain

News

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 5

U.S. Steel delays $230m furnaceU.S. Steel has delayed

construction of a US$230

million electric arc furnace

in Alabama, due to the

challenging market conditions

faced by both the gas, steel and

oil industries.

The project was considered

pivotal in the company’s target

of becoming more energy

efficient.

The delay comes after

the company closed its

blast furnace operations in

Birmingham, also in Alabama, in

the summer of 2015.

At that time, 1,100 of the

plant’s 1,500 workers were

made redundant.

In the past year, U.S. Steel

has also idled mills in Texas

and Illinois to cater to reduced

demand.

The company said its decision

to delay the new electric arc

furnace was caused by oil prices

hitting an eight-year low.

The resulting drop in

exploration activity by drillers

has reduced demand for steel

pipe.

Steelmakers also continue

to be affected by imports from

China.

“The company continues to

feel the effect of these energy

market conditions, along with

low steel prices and continued

high levels of imports,” U.S.

Steel said.

Glaston Corporation has closed

a significant deal with U.S based

Trulite Glass & Aluminium

Solutions for three FC500

tempering furnaces.

This includes the iControL

Quantum Automation and

Reporting system, and Glaston

Care service agreements.

The machines are to be

delivered during the first and

second quarters in 2016.

In addition to the FC500

furnace deal, the parties agreed

on major upgrades for two

Glassrobots’ machines.

Trulite Glass & Aluminum

Solutions is one of North

America’s largest architectural

glass and aluminum fabricators.

The company manufactures

and distributes architectural

aluminum, insulated units,

mirrors, tempered, laminated,

and decorative glass from their

28 locations throughout the U.S.

and Canada.

‘It was a true pleasure to meet

with Trulite’s management at

Glass Build America in Atlanta,

and hear the obvious excitement

they have for the future growth

of their operations, and how

Glaston plays a significant role

in this”, said Arto Metsänen,

Glaston Corporation’s President

& CEO.

Paul Mahedy, Executive Vice

President, Trulite Glass and

Aluminum Solutions, said:

“Trulite Glass & Aluminum

Solutions is very excited to build

on our partnership with a true

leader in convection furnace

technology.

“Glaston continues to raise

the bar, with industry leading

solutions that produce superior

optical surface quality in high

performance glass products.

“Along with these investments,

Trulite is also well underway

with four other Glaston furnace

projects and we look forward

to a mutually beneficial

partnership.”

Launched in 2011, the Glaston

FC500 tempering line has

gained a solid position on the

market.

Glaston closes deal for three FC500 furnaces in the USA

German company Sorg said

it was honoured to have

been selected as the furnace

supplier by Bastürk Glass for its

greenfield project in Turkey.

Bastürk is a new player to the

glass industry and is building

a site in Malatya in the Eastern

Province of Turkey.

The new factory will go into

operation at the beginning of

2017 and produce 300 tons per

day of glass containers.

Sorg said it 'wanted to thank

Y & H Foreign Trade Limited for

its assistance in securing the

prestigious order and Bastürk

Glass for placing its trust in us'.

Bastürk Glass selects Sorg

PaneraTech has released

a dedicated website for

SmartMelter, a technical

solution for furnace life

optimisation.

SmartMelter provides

comprehensive asset

management for glass melting

furnaces.

The website allows glass

manufacturers to learn more

about the technology and

outlines service and licensing

options.

The website is designed

to answer the most frequent

questions that glass

manufacturers ask about the

solution.

The content also illustrates

exactly how its patented

sensors work to map erosion

of furnace walls and measure

residual wall thickness.

The site includes detailed

papers about Research &

Development, and a blind

validation trial of the RTS

Sensor.

PaneraTech plans to release

additional validation trial in

the near future.

PaneraTech invites

manufacturers to visit

smartmelter.com and contact

their office to discuss service

options.

Furnace life website for manufacturers

depending upon the properties required. Temperatures

may be 155°C to 175°C for precipitation, and 525°C to

545°C for solution treatment. Cooling may be carried

out in air or hot water.

SlabSlabs will almost always be ‘rolled’ either hot or

cold, depending upon fi nal usage, sheet thickness or

alloy; initially the slabs will undergo heat treatment

(re-heating). Typically, soaking pits or continuous

re-heat furnaces are used. Soaking pits will normally

be electrically heated. Slabs are loaded into the pit

with the help of an overhead crane. After heating and

soaking, aluminium slabs are discharged from the pit

one-by-one for the rolling operation. Alternatively,

continuous pre-heating furnaces are used. These

allow the slabs to be continuously charged and then

discharged onto the rolling mill one at a time.

Precipitation, annealing and homogenising processes

are carried out on slabs as required by the applications,

up to temperatures as follows:

r Precipitation - up to 210°C operating temperatures

r Annealing - up to 425°C operating temperatures

r Homogenising - up to 500°C operating temperatures

BilletBillet is normally produced for subsequent extrusion

Aluminium

6 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

By no means exhaustive, this article aims to

give a feel to the many styles and varieties of

furnace used and related to the aluminium

industry. The ‘pot’ is probably the fi rst furnace in a long

line of furnace operations aluminium will see. More

conventional furnaces appear throughout our industry,

and this article looks at a varied list of types and

applications.

Classically, we all appreciate the reverbs – or melters

and holders to most of us, as these are the backbone

of alloy production. Used for casting and alloying, with

capacities of up to >150 tonnes, they can be found in

primary and secondary aluminium plants.

So, let’s look along the production line and fi nd out

what other furnaces can be found. Once we have cast

a product, should it be ingot, slab, billet, coil or de-ox,

there will be another furnace waiting next in the queue.

IngotInevitably, ingots get re-melted again and cast into

a range of items. Those items will generally be heat

treated to fi nalise the required metallurgical properties.

Precipitation and solution heat treatments are normal,

furnaceFinding the right

The aluminium industry is dependent upon many types of industrial furnaces across all sectors of aluminium operations. Technically, even the very fi rst stage in production of aluminium is carried out inside a furnace, as Keith Watkins* explains.

Figure 1: Ageing oven

Aluminium

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 7

processing. In general the furnaces found relating to

billet are billet homogenisers, pre-heaters, ageing, and

solution heat treatments. Pre-heaters are used adjacent

to the ‘press’. As the extrusion billet must be pre-heated

to enter the canister of the press, it is important to

get the billet temperature correct. Either a gas fi red or

induction heated pre-heater may be employed. Due to

the nature of friction within the die of the press, ‘taper’

heating can be used to differentially heat the length

of the billet to compensate for friction heating while

pressing. This ensures a constant billet temperature

throughout the pressing operation. Subsequent

extrusions then need to be heat treated further.

Solution heat treatmentThis process is performed by maintaining the proper

exit temperature as the extrusion emerges from the

press during the extrusion process, and then quenching

it at the proper rate. Temperatures and rates vary by

alloy. Holding the extrusions at the proper temperature

allows the aluminium, along with any alloying

elements, to enter into a solid solution.

furnaceArtifi cial ageingMagnesium and silicon are the major alloying elements

in 6000 series alloys. These elements combine to

form magnesium silicide. The artifi cial ageing process

produces fi ne grain magnesium silicide precipitates

that will increase the strength of the 6000 alloys. Due

to the effects on the magnesium silicide precipitates,

this process may also be called precipitation heat

treatment. The ageing process also occurs naturally

(uncontrolled) over time. However, by controlling

the times and temperatures in the artifi cial ageing

ovens (Fig.1), maximum strength and benefi ts may be

achieved.

CoilOut of the mill comes rolled coil or foils. Mostly, coils

and foils have to be annealed, which takes us on to

coil and foil annealing furnaces. These furnaces for

coils are usually high fl ow furnaces that use high

velocity gas impingement at the coil sides to maximise

heat transfer and reduce heat up rates. Design is very

important for temperature uniformity. Either electrically

heated or gas heated are suitable. When it comes to foil

annealing, care has to be taken that gas fl ows are not

high enough to tear the foils during processing.

Induction meltersCommonly, induction melters are used for a variety

of aluminium melting processes. Mostly involved in

re-melt and production of castings, you will fi nd many

in the automotive industry. They are also used in the

production of aluminium-lithium alloys.

ScrapAt times it is important to pre-heat scrap prior to

re-melting. Due to the nature of scrap storage and

its origin, scrap may contain high levels of moisture.

This can cause excessive evolution of steam in a very

short time, creating explosive conditions in the re-melt

environment. Pre-heating furnaces are used to pre-dry

scrap or sows to eliminate hazardous moisture. Once

pre-heated, the material is then safe for re-melting.

Some reverbs are equipped with a hearth above the

melt line to enable pre-heating without the need for a

separate furnace.

Here, we must mention rotary furnaces. These are used

almost exclusively for scrap and dross re-melting.

Originally, rotaries were horizontal and fi xed axis, but

required a lot of salt in operation, typically 1.5:1 of the

non metallic content of the batch to be melted. With

the advent of tilting rotary furnaces, it is normal to

use ox-fuel burners and less salt: 0.35-0.5:1 salt ratio

Figure 2: Gas nitriding furnace

8 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

Aluminium

is fairly typical today. Energy requirements and yields

have also improved.

OthersIt is important to recognise that not all of the furnaces

important to the aluminium industry directly treat the

aluminium itself! So where are we going with this?

Many furnaces heat treat the steels, so are essential to

the processing of aluminium.

Inside every aluminium extrusion shop you will find ‘die

ovens’. Die ovens heat the extrusion dies prior to them

being inserted into the press. We have multi cell die

ovens, and today single cell die ovens are proving more

popular. It is important that the die is preheated to the

correct temperature before applying it in the press. The

die must not be overheated or heated for too long as

‘back tempering’ will ensue and soften the die interior,

causing premature die failure.

Of course, in the die shop of the extrusion department

you will usually find the means to harden the surface

of dies. A gas nitriding furnace (Fig.2) is used to form

a very hard surface onto the die, and brand new dies

between each use as they get older. This is normally

carried out a 535°C in an ammonia rich atmosphere.

Occasionally, plasma furnaces equipped with vacuum

systems may also be found nitriding in the die shop, but

these are rare.

It is essential that the metallurgical properties of other

‘steels’ in the aluminium industry receive the correct

heat treatments. So we also have sealed quench

furnaces, tempering furnaces, vacuum furnaces (Fig.3),

salt bath furnaces and fluidised bed furnaces.

Rolling mill rolls, extrusion dies, gravity and high-

pressure dies are mostly made from (H13) hot work

steel. During manufacture these require heat treatment

by a variety of heat treatment furnaces:

r Sealed quench furnaces are gas tight furnaces with

two chambers and are radiant tube heated. Normally,

an endothermic gas is circulated inside the furnace.

This gas can be modified to achieve varying carbon

potential. Depending upon the metallurgical

requirements, this carbon potential may be varied

for decarburising to neutral or carburising by

automatic controls. Most are fitted with internal oil

quench tanks for fast cooling.

r Tempering furnaces are utilised to modify the full

hardness of the hardened material, to achieve a

core hardness and structure appropriate to the

application. This is usually a further and separate

stage to the hardening process.

r Vacuum furnaces are more likely to be used for

the H13 steel, as it is a fully hardening steel,

where carburising is not required. Vacuum furnace

hardening will allow the rolls or dies to be kept

clean throughout the heat treatment process, by

eliminating oxygen. No oxygen means no oxidising

of the steel, and hence the dies will come out bright

and shiny. Many of the modern vacuum furnaces

combine tempering in one prolonged cycle within

the vacuum furnace. Instead of oil quenching,

high-pressure gas is used to quench the steel inside

the furnace at pressures up to 10 bars. High purity

nitrogen is typically the gas used.

Beds and bathsFinally, you may find furnaces such as salt baths and

fluid bed furnaces used for the above treatments. Salt

baths heat the products in a molten salt environment

and fluid bed furnaces utilise zircon sand fluidised

by gases as the heating media. In both cases, neutral

conditions or nitriding conditions can be applied. In

the case of the salt baths, this is achieved by the use of

special salts, which imparts a nitride layer to extrusion

dies. For fluid bed furnaces, ammonia gas is bubbled

through the sand media to fluidise and impart the

nitriding.

It is evident that there are many types of furnaces used

in the aluminium sphere, and that the variety is very

varied and complex. There are dozens of companies

manufacturing furnaces globally, and all have their

particular specialism and expertise.

Figure 3: Vacuum furnace

Keith Watkins

GW Consumables

www.furnace

consult.co.uk

Contact

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 9

First, the burners were spread around the perimeter

of the log. Past designs had the burners in a row

down the side of the logs on the smaller sizes, or

staggered 22° over/under centre on the larger sizes.

The new design has the burners 40° over/under

centre on all sizes. This promotes uniform heating,

as the flame is distributed in near perfect symmetry

about the log centreline. Also, there is a ‘sweet spot’

in the flame where maximum heat transfer occurs.

The new design accommodates a smaller range of

diameters to ensure that any log diameter in the

furnace falls into the best heat transfer range of the

burners. Older models would accommodate 6”-9”,

8”-12”, 11”-16”, etc. New models have ranges such as

10”-12” or 9”-11” or 8”-10”.

The furnace tunnel has also been redesigned to allow

the exhaust gases to flow the length of the furnace in

a chamber well away from the burners. In this fashion,

the velocity of the exhaust gases does not affect the

direction or shape of the flame, again allowing the

best possible heat transfer from the burner.

DurabilityThe focus on durability is all about the roller bed

system (Fig.1). The new roller design is four times

larger in diameter than the old roller, and therefore

rotates only once for every time the old roller rotated

four times. An added benefit to the larger diameter

is that the wear surfaces are far removed from the

flames and operate at much cooler temperatures.

Even a good design can be improved upon, and Granco Clark, a global supplier of equipment to the aluminium extrusion industry, has made some major changes to its furnace design lately. These changes are focused on a few key areas, including efficiency, durability, and ease of maintenance.

Figure 1: The new rollers in the furnace.

Aluminium

Long-life rollers

Aluminium

10 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

The faces of the roller that contact the log are

machined and are at a much steeper angle than

before, resulting in better tracking of the log

through the furnace (Fig.2). Again, the narrowed

range of diameters allows for this steeper angle. The

trunnions of the roller are also machined and ride in

machined bores in replaceable bushing blocks. All

of the machining results in rollers that run truer and

turn easier than before - you can actually push a 12”

diameter by 20” log into the furnace by hand.

Granco Clark expects a lifespan of at least five years,

at which time the roller trunnions can be sleeved

and re-machined to extend their service another five

years.

Ease of maintenanceThe company’s final focus was on ease of

maintenance (Fig.3). The crown blocks still hinge

open like before, but the side panels of the burner

section can also be removed with just a few bolts.

That means the roller bed can be serviced while

standing on the floor with everything waist high –

instead of working from only the top, as before. The

removable side panels come out with the gas train

and burner blocks intact, meaning that they can

be rebuilt remotely rather than in place. One could

conceivably maintain a second replacement set of

panels for a quick rebuild when downtime must be

minimised.

The new furnace design is not for everyone – for

example, the larger diameter roller limits the length

of precut billets to a minimum of 16”. If you require

a wide range of log diameters, or very short precut

billets, then the old design would still be the best

choice.

www.grancoclark.com

Contact

Figure 3: Granco Clark’s improved furnace design aims to increase energy efficiency.

Figure 2: The new roller design has an anticipated lifespan of five years.

Heat Treatment

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 11

Whether hardening, tempering, brazing or annealing,

the Turbo2Treater furnace’s new technical details are

engineered to save electricity, cooling gas and time

(in the form of a higher throughput rate).

At the same time, critical power components in this

universal single-chamber vacuum furnace were

optimised for maximum performance.

To improve quenching performance, the cooling gas

pressure was increased to 12 bars, which is ideal for

hardening low-alloyed materials. The quenching rate

at the start of the cooling phase is also significantly

increased with Ipsen’s patented LCP (Low Current

Power) Start. This is possible as the fan motor starts

during the vacuum phase, thus ensuring that gas

flows in when the cooling fan is running at maximum

speed.

To ensure that all workpieces in the work zone

are uniformly cooled, Ipsen has also optimised

the cooling gas circulation by running gas flow

simulations. Targeted cooling gas circulation in the

Turbo2Treater allows the cooling gas to cover the

entire width and length of the batch at high flow

rates. Besides the standard vertical cooling gas

circulation, alternating flow direction of the cooling

gas is also available as an option.

FlexibilityDue to its wide range of standard and optional

functions and its process variety, the Turbo2Treater

offers maximum flexibility and can meet the

requirements of a large number of industries

Ipsen, a specialist in industrial furnaces, has updated its Turbo²Treater vacuum furnace with several new technical details and functions. Martina Satzinger* explains how the new addi-tions work to make heat treatment processes more efficient and varied.

Efficientheat treatment

Heat Treatment

12 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

and companies. The Turbo2Treater is used in the

aerospace and automotive industries, in commercial

heat treatment plants, in the medical sector and in

the toolmaking industry, to name a few.

Besides the standard processes (e.g. hardening,

annealing, tempering and soldering), processes such

as low-pressure carburising (AvaC), low-pressure

carbonitriding (AvaC-N), high-temperature solution

nitriding (SolNit) and deep cooling are also available

as options with this new heat treatment furnace.

The Turbo2Treater can be adapted to suit a plethora

of materials, geometries and loads and can be used

for the heat treatment of a wide range of parts –

long and thin workpieces, multilayer batches, tools,

stamped parts, gears, drills, saw blades, etc.

Ipsen, Germany

www.ipsen.de/EN/

Contact

Worthy of special mention are the Turbo2Treater

furnace’s new functions for extended automatic

control of the quenching parameters for the cooling

gas pressure and the cooling motor operation.

S, M or XL Due to its compact design, this vacuum furnace fits

into a standard truck or container, allowing it to be

delivered and installed quickly. The Turbo2Treater is

available in three standard sizes with a maximum

batch width of 910mm, batch length of 1,220mm,

batch height of 910mm and batch weight of 2,000kg.

The Ipsen Vacu-Prof 4.2 control software guarantees

process reliability and simple, intuitive operation of

the Turbo2Treater vacuum furnace.

HARDENING BRAZING

TEMPERING ANNEALING

BENEFITS: Short standard delivery time

Rapid startup at customer site

Capacity: 800 kg

High heating rate by convective heating

High quenching speed and directed gas fl ow

High pressure gas quenching (12 bar) and automatic redirection of cooling gas fl ow

High process reliability with Ipsen program control Vacu Prof 4.2

We set Standards

in Heat Treatment.

Turbo2Treater ® Effi ciency in Power

Ipsen International GmbHFlutstraße 78 | 47533 Kleve | GermanyeMail: [email protected] | www.ipsen.de

In recent years, there has been an increased need

to extend the campaign life of a furnace. In order

to reduce hot glass costs by reducing manpower

requirements and capital costs, glass companies have

increased the size and reduced the number of their

glass furnaces. In many cases there is no longer a

standby furnace to be brought into operation during

furnace rebuilds. Consequently, long campaigns with

minimum repair periods are essential. As well as this,

the cost of rebuilding or the cold repair of a furnace

can be very high, and may represent a large proportion

of the total capital expenditure of a company.

The techniques for prolonging the life of of glass

furnaces can be summarised into three categories:

r Operational practices: The control of the glass

furnace process has an important effect on the life

of the furnace. The furnace must be operated in a

manner that maximizes furnace life, compatible

with production requirements. To do this, it will

often be necessary to modify operating practices

as the campaign progresses and in response to

problem areas.

r Remedial actions and hot repairs: Once wear or

damage that may affect the life of the furnace

becomes evident, engineering repair techniques

must be utilised or developed to maximize

campaign life (Fig.1).

r Improved designs of the future: As improved

materials and equipment are developed, they

should be incorporated into future rebuilds to

extend the life of critical areas of the furnace,

where it is cost effective to do so.

To prolong the life of existing furnaces and those that

have been rebuilt without the facilities for a long

life, or for those that operate at high productivity,

repair techniques play an important role. Engineering

techniques, planning, and the speed of execution

of repairs and rebuilds have improved markedly in

recent years. In this context, one important factor is

the development of remedial actions such as new

techniques for hot repair: mainly ceramic welding, hot

bottom repair, anchoring and overcoat.

Glass

Prolonging the campaign life of a glass furnaceFernando Salvino* reviews the techniques used to extend the campaign life of glass furnaces, and identifies operational practices, remedial actions and aspects of plant design that help achieve this

14 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

From the beginning, one of the common problems

for users of the continuous furnace in the glass

industry was its short lifespan. A series of research

and development was carried out in order to extend

the furnace campaign life. Current glass melting

technology, based on continuous furnaces initially

designed and developed around 1860 by the Siemens

Brothers in Germany, has evolved in response to

manufacturing requirements. The development of

melting techniques is, however, hampered by the

industry’s peculiar characteristic of being segmented

into the sectors of container, flat, fibre and speciality

glasses, with those segments further divided within

themselves.

Over the last 50 years, major improvements in furnace

campaign life have been achieved, and numerous

glass furnaces in Europe and around the world have

now surpassed a lifespan of 13 years. The basis of

a long campaign life is good design, equipment,

and refractory developments – primarily, replacing

original fireclay alumina by AZS; comprehensive

instrumentation; comprehensive monitoring;

continuous, smooth operation; and remedial actions.

Furnaces that have recently been rebuilt have

benefitted from the development of technology

that extends campaign life, with many furnaces now

aiming for a campaign life of 13 to 18 years or more

(Table 1).

Table 1: Campaign furnace life and total campaign production, in the period 1920–2015

Years Life t/m2

1920 0.5 300

1940 2 1150

1960 4 2000

1980 6 5000

2000 10 10000

2015 13 12000

Glass

Prolonging the campaign life of a glass furnace

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 15

Hot repair techniquesInternal ceramic welding: Using a special lance, a

homogeneous mixture of very fi ne refractory powder

and metal is sprayed in a stream of oxygen onto

the area to be repaired. The oxidation of the metal

particles begins at a temperature of 2500°C. The high

temperatures reached on the existing refractory part

cause it to melt on the surface, ensuring excellent

anchoring of these parts with the weld material.

This molten liquefi ed mass is able to fi ll every hole,

join or crack and solidifi es when the furnace reaches

working temperature, forming a single compact

mass with the structure. The welded refractory part

is virtually identical to the original refractory; this

eliminates stress and reactions, obtaining a longer

lasting repair (Fig. 2).

Sealing by external ceramic welding: Using lances

it is possible to externally seal every joint, spacing or

part of the superstructure in which heat dissipation

or loss of effi ciency can occur. This type of external

ceramic welding is performed with powder mixtures

specifi cally designed for the application.

Cleaning of regenerators: The sulfate deposited

on regenerator checkers causes an increase in

pressure and the consumption of the furnace, and

can be damaging to the furnace life. With regular

cleaning using special lances, the sulfates, which

clog the cruciform, can be removed in a targeted

manner and restore the effi ciency of the furnace. In

a recent case, following fi ve days of thermal checker

cleaning in a boucle furnace powered by fuel oil, the

pressure decreased from 240Pa to 160Pa resulting

in a recovery of 80Pa (33.3%). If the number of days

is increased it is possible to reach a pressure of

120/110Pa (50%).

Anchoring blocks: Preserving the integrity of the

original blocks is better than any replacement or

ceramic welding, which is why in the case of cracked

or unstable blocks we act promptly, drilling holes

with thermal lances and anchoring them with Inconel

bars to the carpentry. In the case of crumbling walls,

it is possible to prevent their collapse by inserting

cooled hooks. The large holes that arise on the crown

can be repaired with the positioning of pendulums

– bricks tied to the carpentry using chains, and

subsequently fi xed with internal welding or externally

with a layer of special concrete for high temperatures.

Grenaillage bottom repair: If the fl oor has consumed

zones, the grenaillage technique can be used.

Grinded refractory material is inserted on to the

target area, in order to restore the original level and

reduce the consumption process, using the same

quality refractory material as the original bottom.

This method can be performed while the melt tank

is full or empty, so with or without draining. With an

empty tank we can easily look at the condition of the

damaged areas during this hot repair.

Furnace inspectionsInspections and audits are important tools to

analyse the conditions of the furnace, refractories

and steelworks during the campaign life. A variety

of inspection services is available, using state of the

Figure 2: Remedial actions for each zone of glass furnaces

Figure 1: Burner ports repair by ceramic welding. 2A (left) is before ceramic welding, and 2B (right) shows after ceramic welding.

Glass

16 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

art instruments such as infrared cameras and water-

cooled video cameras.

Thermography: A technique that is particularly

effective in locating local hot spots.

The outside temperature of a refractory-lined

construction is determined with an infrared camera.

The remaining thickness of the refractory lining is

calculated using the temperature measured and the

design temperature. On the basis of the inspection

results, an estimate can be made of the remaining

life time or, if required, a repair procedure can be

determined.

Clavé endoscope: Clavé is a linear endoscope

with water-cooling which, by connecting high-

performance SLR cameras, allows internal inspections

to be performed in every part of the furnace

(superstructure, walls, breast walls, chambers,

regenerators, feeders, etc.). (Fig. 1 photo by clavé

endoscope).

Video endocope: The video endoscope (or the

endoscope for welding) has the same structure of

the lances used for welding, to ensure a constant

cooling of the camera. Its use arises from the

need to see in real time the points where it is not

possible to weld at sight, in order to improve the

performance of these interventions. It is often

performed with ad hoc shapes dependent on the

accessibility within the furnace and the position of

the area to be repaired. The technology allows us to

record videos during the work, which is the reason

it is also used to inspect the regenerator cruciform

from the basement (Fig. 3).

ConclusionsFor a long campaign life, a glass furnace should be

operated at a productivity that enables stable and

smooth operation. Comprehensive instrumentation

and routine techniques, such as furnace inspections,

are essential for stable operation and to enable the

early detection of problem areas so that remedial

actions can be scheduled, such as ceramic welding, to

extend furnace life.

Maximum use should be made of computers

to process and analyse primary data, giving the

operations staff both rapid information and advice on

potential problem areas.

Proactive works, remedial actions such as hot

repairs, and furnaces inspections are key elements

in maximizing campaign life, especially on existing

furnaces which may not incorporate the most modern

design features. These repairs include ceramic

welding (with a variety of mixtures of powders

available to prolong refractory retention).

With more advanced repair techniques available,

and the large capital and production costs involved

in a full furnace rebuild, more glass companies are

adopting the philosophy of hot repairs, particularly to

extend the pay-back and save money and also when

there is no stock capacity to cover furnaces under

cold repair.

For further improvements in glass furnace campaign

life, the continual development of materials and

techniques is essential, particularly in critical

areas. The effect of hot repairs is important when

prolonging the campaign life, and an extension of

this is improvements in anchoring, new materials, and

new techniques.

The reduction in cooling member failure and

subsequent glass leakage is also an important factor

in extending furnace life, as are scheduled audits

including for visual, thermography and endoscopy, as

a means of identifying key maintenance work.

As the age of the furnace increases, all of these

aspects need to be run in conjunction to prolong the

furnace campaign life to the maximum.

Figure 3: Regenerator crowns repair by ceramic welding. Left is before ceramic welding and right is after ceramic welding.

Fernando Salvino

Engineering Manager

IRF Europa

Casier

Italy

www.irf-europa.com

Contact

Background The NOx emission regulation (450 ppm at O2 =15%

conversion) defined in the Air Pollution Control

Law of Japan is lax compared to other countries.

As global environmental problems increase, NOx

emission regulation is also expected to become

more stringent for exhaust gas from glass melting

furnaces. In fact, local regulation levels are more

stringent than the law.

As for de-NOx, the Selective Catalytic Reduction

method (SCR), generally used for exhaust gas

treatment in coal-fired power plants, and the Low

Air Ratio Combustion method, are famous.

In the SCR method, NOx is reduced by NH3 through

a catalyst. The main reaction to remove NOx can be

sustained if the temperature is held between 250C

and 450C.

Glass

A NOx removal process from exhaust gas in a glass furnace

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 17

Nihon Yamamura Glass (NYG) has four major

business fields, namely glass bottle, plastics,

new glass, and engineering with extensive

domestic and overseas networks throughout these

fields. In its glass bottle business, NYG has the largest

market share in Japan with three glass bottle plants,

nine furnaces and 28 production lines, totaling a

production capacity of approximately 450,000 tons/

year.

In NYG, the Environment Affairs Department is one of

the main departments in the company headquarters,

and has environmental ‘defense’ and ‘offence’ as

its core mission. ‘Defense’ refers to environmental

management, such as ISO-14001, waste management,

and upholding government regulations, etc. ‘Offense’

refers to the development of environmental business,

such as exhaust heat utilisation and the improvement

of rare metal handlings, etc. This paper is about de-

NOx technology, which is a part of ‘offense’.

Production processIn glass manufacturing plants, materials are dissolved

at approximately 1500C by liquefied natural gas

combustion or heavy oil in the melting furnace.

The exhaust gas of the melting process contains

environmental pollutants such as NOx, SOx, and dust.

In general, SOx is removed by semi-dry or wet de-SOx

equipment to be used as a desulfurising agent such

as caustic soda. Dust is removed by an electrostatic

precipitator and/or bag filter.

A semi-dry type exhaust gas treatment system

consists of a semi-dry de-SOx reactor, an electrostatic

precipitator and a bag filter. In a de-SOx reactor, SOx

is reacted with ‘wet’ NaOH spray to form ‘dry’ Na2SO4,

therefore this system is called a ‘semi-dry’ system.

A wet type exhaust gas treatment system consists of

an exhaust gas heat boiler, a wet de-SOx scrubber, a

mist eliminator, and an electrostatic precipitator. SOx

is transformed into a Na2SO4 water solution by a

wet NaOH shower, and therefore this system is called

a ‘wet’ system. Both systems do not include de-NOx

equipment.

Ryota Tsuji* outlines how an investigation by Nihon Yamamura Glass has increased the reaction efficiency of the plasma process and in de-NOxing thanks to the use of a plasma and chemical hybrid process.

Figure 1: Production equipment at the glass bottle plant.

PCHP technology is the preferred system in gas

boilers and ship exhausts. NYG has been involved in

a collaborative investigation with Osaka Prefecture

University since 2011 for practical use of PCHP in

glass melting furnaces.

Outline of PCHP PCHP is a technology that combines the plasma

process, de-SOx process and chemical process. PCHP

can achieve simultaneous de-SOx and de-NOx.

When PCHP is applied to the exhaust gas treatment

system of a glass melting furnace, the NOx removal

process is explained below.

First, NO in the exhaust gas is oxidised to water-

soluble NO2 by a plasma process, using ozone

(O3) generated from non-equilibrium plasma

at atmospheric pressure (Reaction O2+O➝O3,

NO+O3➝NO2+O2). Sodium Sulfite (Na2SO3) is

then produced as a by-product of a de-SOx process

(Reaction SO2+2NaOH➝Na2SO3+H2O), after

which NO2 is reduced to N2 gas by a chemical

process involving Sodium Sulfite (Reaction

2NO2+4Na2SO3➝N2+4Na2SO4). NOx is thus

removed. The Na2SO4 generated by the reduction

of NO2 can be reused as a raw material for glass

manufacturing.

Unlike SCR, a high concentration of SOx and the

existence of adhesive dust does not affect the

PCHP. This process requires low maintenance and

can also be applied easily into existing exhaust

gas treatment equipment for de-SOx, consequently

reducing the initial and running costs compared to

installing an SCR.

Glass

18 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

However, when SOx is included in exhaust gas,

(NH4)2SO4 or NH4HSO4 is generated by a different

side reaction. This side reaction, including dust,

develops catalyst poison and clogging problems.

Therefore, SCR is difficult to use in glass melting

furnaces because the exhaust gas includes the

adhesive dust derived from raw materials and high-

concentration SOx.

For the Low Air Ratio Combustion method, the

generation mechanism of thermal NOx is explained

by the reaction:

N2 + O ↔ _NO + N, O2 + N ↔ _NO + O, and

N + OH ↔ _NO + H

The NOx generated by combustion is mainly NO.

While N2 and O2 in the air and retention time

increase, the NOx generation also increases.

Therefore, NOx can be decreased by lowering the

air ratio of the combustion. However, low air ratio

combustion causes an incomplete combustion,

consequently losing heat energy.

For these reasons, NYG investigated de-NOx

systems available for use in glass furnaces.

However, suitable systems could not be found,

so NYG developed a new technology called the

Plasma and Chemical Hybrid Process (PCHP) for

simultaneously removing NOx and SOx from the

exhaust gas of glass furnaces.

PCHP is de-NOx technology without the use of

catalysts that cause clogging problems when SOx

and dust are included in the exhaust. Therefore,

Figure 3: showing the placement of the demonstration equipment at the wet type system.

Figure 2: Semi-dry type and wet type exhaust gas treatment systems.

Glass

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 19

The issue with installing PCHP in a glass

furnace is the high temperature of the exhaust

gas which is between 300C and 450C at the

entrance of the system. The O3 is broken down

to O2 in temperatures of more than 150C, losing

effectiveness in NO oxidation. The temperature of

exhaust gas should be cooled to less than 100C for

effective NO oxidation by O3.

Therefore, the focus of this development is to form

a localised low-temperature area by spraying water

before introducing the O3. This low-temperature

area is necessary for the Plasma and Chemical

reaction process, both of which are required to

remove NOx from the exhaust gas.

Demonstration For a pilot scale test of the PCHP, NYG had a

demonstration in 2013 for the wet type system in

Harima plant. O3 is produced by seven ozonisers

connected with four machines supplying oxygen

(3.6kW) and three machines with PSA (3.1kW) to

supply O2. The resulting O3 is then injected into a

cooling zone with the water spray at the entrance

of the de-SOx scrubber.

In this demonstration, exhaust gas volume was

8,030Nm3/h, and injected O3 volume was 1,443g/h.

During the demonstration’s elapsed time, O3 was

injected from the 20 minute to the 120 minute

mark, consequently reducing NOx emission from

322ppm to 211ppm during that time frame. Due

to the small pilot scale of this demonstration, NYG

had a limited supply of ozone, but nevertheless a

high reaction efficiency was achieved. The reaction

efficiency of injected O3 was 86%, which indicated

that more ozone injected into the system results in

the removal of more NOx. The de-SOx process was

not affected because SOx emissions decreased more

than 99% at the exit. With the wet type exhaust gas

treatment system demonstration, it was concluded

that application of the PCHP to an actual exhaust

gas of a glass furnace is effective for a wet type

exhaust gas treatment system.

Current development status Due to lower cost and simpler operation, the semi-

dry type system is more popular than the wet-type

variation. Therefore, NYG is currently developing a

semi-dry type of de-NOx system. For effective NO

oxidation by O3, an area with a temperature lower

than 100C is necessary. However, the temperature of

the exhaust gas at the outlet of the system should

0 20 40 60 80 100 120 1400

50

100

150

200

250

300

350

400

450

500

Elapsed time (minutes)

NO

x co

ncen

trat

ion

[O2=

15%

] (pp

m) 50

45

40

35

30

25

20

15

10

500

The conc. and removal efficiency of NOx by PCHP

Rem

oval

effi

cien

cy (%

)

Removal efficiency

Outret of reactor

Inlet of reactorExhaust gas volume: 8,030 m3NH/hInjected ozone volume: 1,443 g/h

NOx removal efficiency 34%From 322 ppm to 211 ppm

Reaction efficiency86%

from 120 ppm to more thanSOx > 99%NO2 30 ppm

NO2 31 ppm

Before processing After processing

NO291 ppm

NOx

322 ppmNO

180 ppmNOx

211 ppm

Figure 3: showing the placement of the demonstration equipment at the wet type system.

be 200C to protect the duct, bag filter and so on.

To succeed demonstration of the semi-dry type

system, NYG has to achieve two items concurrently:

One is the formation of a localised low-temperature

area for oxidation by O3 and NO2 reduction by

Na2SO3; another is to maintain the temperature of

the outlet exhaust gas at 200C.

Conclusion NYG began a collaborative investigation with Osaka

Prefecture University in 2011, and a laboratory

experiment was performed in 2012. Demonstration

of the wet type system succeeded in 2013, with the

first trial of the semi-dry type system in 2014. The

second trial was done in August 2015.

Comparing both results, it showed that there was

progress in increasing the reaction efficiency of

the Plasma process and total de-NOx, yet NYG was

able to identify more room for improvement, thus

a third trial is being planned for the end of the

year. After a successful demonstration, NYG will

push forward with the commercialisation of the

de-NOx equipment for a semi-dry type exhaust gas

treatment system.

Ryota Tsuji

Assistant Manager

Environmental Affairs Office

Nihon Yamamura Glass, Hyogo, Japan

www.yamamura.co.jp

Contact

Glass

AGC Ceramics Co (AGCC) has been a refractory specialist since 1916 and an engineering services company since 1976. Here, Masami Kitano* outlines some energy saving concepts that have recently been certified by the Japanese government for their environmental credentials.

20 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

To meet the cost reduction needs of the glass

industry today, performance improvement of

the melting furnace has inevitably been put

on the agenda. It is not easy to find the right answer

due to the many factors involved with a high

temperature operation.

Two topics are discussed in this paper. First,

an energy saving concept is introduced. AGCC’s

concept, which consists of a hyper-regenerator

and a thermotect-wall, has attained 10% to 15%

energy savings compared to a conventional design.

A milestone in 2015 was AGCC’s technology

being certified by the Japanese Environment

Ministry, while one Japanese customer received a

government subsidy for its forthcoming project.

Second, refractory corrosion and glass defects

are also discussed. For example, to improve glass

quality, high temperature melting is an effective

method but an excessively high temperature

damages the refractory. A large amount of corrosion

affects intractable quality issues, the so-called

‘cat scratch’. AGCC has analysed the defects and

has proposed a counter measure to minimise cat

scratch.

Energy saving conceptThe main concept of the hyper-regenerator is the

double-pass chamber for the checker package as

shown in Fig. 1. A longer passage is logically better

for the heat exchange, however, maintaining the

flow route, adjusting gas velocity and optimum

utilisation of the checker package are tougher

subjects. In the past, the double pass concept was

introduced in Europe but it is not widely used today

due to checker troubles and insufficient energy

performance.

One of the important issues of the double pass is

to prevent the gas/air flow separation and make it a

synchronised route (Fig. 1).

The other issue is checker clogging. This is

improved by setting up the temperature area of

Na2SO4 condensation near the rider arch to easily

drop it off to below the rider arch. Improvements

such as this over the 40 years of AGCC’s engineering

services lifetime have produced highly efficient

for glass container and tableware furnaces

Energy saving concepts

Double pass regenerator Single pass regenerator

2ndchamber 1st chamber

Basicchecker

Fire claychecker

PortPortPort

Basic checker

Fire clay checker

Figure 1: Schematic diagram of AGCC’s concept furnace.

between 10% to 15% energy savings compared with

a conventional design as shown in Fig. 2.

Refractory corrosion and cat-scratch The pull rate for the melting area, indicated by ton/

day/m2, is one of the most important factors for

furnace performance. The excessive pursuit of it (the

so called ‘Glass Load Olympic’) often causes over-

heating because it requires higher temperature

melting in a small furnace. It may damage the

refractory and shorten the furnace life. A well-

known case is the sagging of the silica crown due

to a high melting temperature over 1600C.

Fig. 3 shows the corrosion speed of a fused cast

refractory at the laboratory. If the temperature

increases by 50C, the corrosion speed roughly

becomes more than double.

Fig. 4 shows the change in thickness of the sidewall

refractory at the furnace with both a simulation

result and an actual measured result. The corrosion

progress is rapid at the initial stage and the

progress becomes slower due to the cooling effect

from outside, if the residual thickness becomes

thinner. For instance, if operation temperature

is 1600C, more than 200mm of fused cast AZS is

corroded within 12 months. It means that many

sources of the refractory defects, such as cat scratch,

flow into the molten glass at the initial stage.

Glass

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 21

products with a lifetime of more than 10 years.

AGCC now confidently presents its 4th generation of

hyper-regenerator.

Thermotect-wall The thermotect-wall consists of an insulation

material by the trade name of Thermotect (TMT).

TMT is a high thermal insulating monolithic

material, which has the same performance as

ceramic fibre. Therefore, this monolithic is usable at

a temperature up to 1600C with excellent volume

stability. The advantages of TMT compared to

ceramic fibre are durability for long-term operation

and joint-free configuration. It is also safer for

operators, as it does not contain RCF (Refractory

Ceramic Fiber), which is identified by the World

Health Organisation (WHO) as a possible human

carcinogen. AGCC developed TMT using internal raw

material technologies.

AGCC also integrated other improvements such as oil/

gas burner to the concept furnace, and has attained

0 50 100 150 200 250 300Pull rate [tonne/day]

Uni

t req

uire

men

t (lit

re/T

G)

10-15% lower

1250 1300 1350 1400 1450 1500 1550 16000

2

4

6

8

Corr

osio

n de

pth

[mm

]

Temperature [˚C]

Soda lime glass 48 hrs TEST

MB-GAβ-Alumina

ZB-168133%-AZS

ZB-169135%-AZSZB-171141%-AZS

250

200

150

100

50

0

Refr

acto

ry c

orro

sion

(mm

)

0 3 6 9 12 15Time (month)

18 21 24 27 30 33 36

1300˚C1350˚C1400˚C1450˚C1500˚C1550˚C1580˚C1600˚CHigher curve(measured)Lower curve (meansured)

0.5 15

10

5

0

0.4

0.3

0.2

0.1

08.25 8.3 8.35 8.4 8.45 8.5 8.55

Oth

ers

(wt%

)

ZrO

2 (w

t%)

Distance (cm)

CaO

ZrO2

Na2O

Al2O3

Figure 2: The flow of secondary air and waste gas in a double pass and single pass regenerator.

Figure 3: Fuel consumption at the furnaces supplied by AGCC. The red dots are furnaces that are furnished with the 4G hyper regenerator and thermotect-wall.

Figure 4: The relation between temperature and corrosion speed of fused-cast refractory.

Glass

22 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

The Glass Load Olympic obviously requires melting

at a higher temperature in a small furnace. This is

feasible in the short term period, but a damaged

refractory negatively impacts the rate of energy

consumption, glass quality and furnace life in the

long term. As a result, it may not be a good cost

performance overall.

Multiple factors should be considered when aiming

for a well-balanced furnace, as well as selection and

application of refractory.

Cat-scratchMany cat-scratches have been analysed, and they

are now classifi ed into three types.

The fi rst is ZrO2. This generates predominantly from

the AZS refractory type in the melter. Ordinarily, the

mark is not very strong, has multiple knots, and the

diffusion speed is slow.

The second is Al2O3. It normally generates from

the alumina refractory in the working-end and the

forehearth. Generally, the mark is strong with a

single knot, and the diffusion speed is fast.

The third is the mixed type, as shown in Fig. 5.

Al2O3 is hidden behind ZrO2 .

Unfortunately, cat scratch is an unavoidable

symptom, however it can be reduced by solutions

such as optimum operation, and a reduction of

stagnant glass by design and refractory selection. As

a supportive care, a stirrer is recommend to mix the

condensation.

ConclusionA fundamental knowledge of glass furnaces is

essential for good performance. A solid concept,

for structure, material selection and innovative

application, contributes to increased energy savings

and glass quality.

AGCC has produced refractory materials for 100

years and engineering service for 40 years, and

the hyper-regenerators and thermotect-walls are a

good example of the culmination of the company’s

activities.

250

200

150

100

50

0

Refr

acto

ry c

orro

sion

(mm

)

0 3 6 9 12 15Time (month)

18 21 24 27 30 33 36

1300˚C1350˚C1400˚C1450˚C1500˚C1550˚C1580˚C1600˚CHigher curve(measured)Lower curve (meansured)

250

200

150

100

50

0

Refr

acto

ry c

orro

sion

(mm

)

0 3 6 9 12 15Time (month)

18 21 24 27 30 33 36

1300˚C1350˚C1400˚C1450˚C1500˚C1550˚C1580˚C1600˚CHigher curve(measured)Lower curve (meansured)

Masami Kitano

AGC Ceramics Co., Ltd.

Glass Engineering

Division

Osaka, Japan

www.agcc.jp

Contact

Figure 5: The corrosion speed of sidewall, calculated by one dimensional refractory corrosion model.

The Glassman Middle East exhibition and conference takes place in Abu Dhabi’s ADNEC centre this 10th and 11th May. The conference and exhibition are free to attend, and will feature a variety of heat treatment, melt-ing technology, and furnace manufacturers including Stara Glass, Horn Glass, LWN Lufttechnik, Sorg, Electro-glass, and Henry F. Teichmann, amongst others.The conference also has a focus on furnaces and furnace technology, with presentations from the Technical Director of Stara Glass, who will discuss its Centauro furnace technology; the Technical Leader from Eurotherm at Schneider Electric, who will discuss recent improvements in electrical glass furnace boosting systems; and Fernando Salvino, Engineering Manager at IRF Europa, who will present his paper on prolonging glass furnace life which can be found in this magazine.

To fi nd out more and pre-register for the event visit: www.glassmanevents.com/mid-east/

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 23

BIFCA

National

Metalforming Centre

47 Birmingham Road

West Bromwich, UK

B70 6PY

enquiry @bifca.org.uk

www.bifca.org.uk

Contact

BIFCA

The British Industrial Furnace Constructors

Association (BIFCA) has seen considerable

changes since it first began its life in 1947, as

the Society for Industrial Furnace Engineers (SIFE).

It is now the UK Trade Association representing the

interests of designers, manufacturers, and the leading

component suppliers of thermprocessing equipment

and services to the furnace industry.

Through its involvement with government and

industry bodies, meetings, seminars, conferences and

exhibitions, BIFCA seeks to promote and represent

the views of its members and the industry in general,

helping to influence EU and UK policy, legislation,

and industry standards relevant to the manufacture

and use of industrial furnaces and laboratory ovens.

BIFCA will present a column in each issue of Furnaces

International and will discuss a range of these topics.

Membership of BIFCA is open to companies with

registered offices in the UK who are involved in

the design and manufacture of industrial furnaces

and ovens, or who supply component and ancillary

equipment to the industry.

The association provides a series of technical courses

that focus on furnace operation and efficiency, with

courses on burner technology, furnace controls,

modelling and induction technology. These courses

have been designed to meet the requirements of the

furnace industry for specialist information, knowledge

and training.

The courses are reviewed, assessed and updated

regularly to take advantage of any advancement in

technology or amendments to legislation.

BIFCA is continually monitoring the industry for topics

that can be added to its technical programme, with

courses on vacuum technology, refractories and gas

safety awareness all currently being considered.

Introducing BIFCA

BIFCA will be supplying a regular column for Furnac-es International, and took the opportunity to use this first issue to introduce themselves and what they do.

BIFCA courses are aimed primarily at

end users, but are equally beneficial to

manufacturers and suppliers with attendees

having originated from international

companies on numerous occasions in recent

years.

BIFCA also actively participates in the work

of CECOF, the European Federation of Furnace

Associations, where BIFCA is represented on the

Executive Committee and where its members are

able to benefit from the activities of CECOF.

In partnership with CECOF, BIFCA endorses certain

European and worldwide furnace exhibitions that are

visited in their thousands by delegates from many

high profile companies throughout the global furnace

industry.

BIFCA is involved with a number of activities and

initiatives that are aimed at promoting the UK

furnace industry and best practice within it. One

of the initiatives implemented by BIFCA is the

promotion of an energy efficiency mark. This is open

to manufacturers and suppliers who can demonstrate,

through product design or installation, a saving in

energy costs via increased productivity, lower energy

usage or higher throughput.

End users can also qualify for this mark in

partnership with their supplier by demonstrating an

energy saving gained through investment in product,

process or installation.

British Industrial Furnace Constructors Association

Glass

24 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

Eclipse, Inc has introduced its upgraded natural gas

regenerative burner, BrightFire 200. The company has

a successful history with regenerative natural gas

burners, with the 03R then the 03V developed in the

late 1970s and 1980s.

These were the first ‘sealed-in’ burners that improved

flame control and reduced energy. According to the

company, they were also the first easily adjustable

burners in the industry, allowing flame length to be

adjusted ‘on the fly’, without removing the burners

from the port and changing tips.

In the mid-1990s, the company improved the burner

further with the development of its dual gas injection

technology in the original BrightFire burner. This

allowed two separate streams of gas to be injected

through a single burner, inhibiting the formation of

NOx and improving flame control. The BrightFire

burner was widely accepted in the industry, with

thousands of burners installed throughout the world

in every type of glass furnace.

The glass industry continues to push for

advancements in regenerative gas burner technology,

including:

1) improved heat transfer for lower energy use;

2) reduced NOx emissions;

3) easy to use, setup, and adjust; and

4) enhanced flexibility in flame adjustment and

performance.

To address these needs, Eclipse developed the

BrightFire 200 burner, shown in Fig. 1. The burner

includes the following features:

r Completely separate inner and outer gas jets

r Simple controls for each gas jet located on the

burner

Advancements in regenerative gas burner technology

Dave Fontes* describes how an upgraded natural gas regenerative burner has been installed in several container, float, and tableware furnaces in Europe, Asia and the Americas.

Figure 1: The Eclipse BrightFire 200 Burner with gimbal bracket and refractory block.

Glass

www.aluminiumtoday.com/furnaces/ Issue 1 Furnaces International r 25

r Single gas inlet

r Continued use of the Eclipse sealed-in burner

design

r A nozzle design updates using the most successful

design-base in the industry

Referencing the burner in Fig. 2, the area adjustment

and flow adjustment are identified. The area

adjustment allows the area between the inner and

outer nozzles to be increased or decreased, which

alters the overall length of the flame and the flame

velocity.

The second adjustment is the flow adjustment. This

changes the distribution of gas between the inner

and outer nozzles. Flow adjustments are typically

made to move the heat transfer from the flame closer

to or further from the burner/port. Additionally, the

flow adjustment provides the operator with a tool to

lower NOx for a given flame length setting.

The area and flow variables can be altered

independently. This provides various settings to

tailor the flame shape and performance to the exact

situation at hand, including furnace design, glass

chemistry and production rate.

Both mechanisms employ an easy to read scale

to allow a precise and repeatable setting of the

adjustments.

Up to 25% less NOxThe combination of these two adjustments has

shown an improvement in flame control. In one case

with an underport firing arrangement on a large float

furnace, the flame length could be adjusted from

30% to more than 80% of the furnace width without

altering the gas flow.

Additionally, NOx was demonstrated to be 15% to

25% less compared to other burners on end port and

side port furnaces. NOx was reduced substantially on

an end port furnace in Europe where a typical burner

supplied by a furnace designer was replaced.

A NOx reduction greater than 20% was realised,

achieving the goal of less than 550 mg/Nm3. Fig. 3 shows a BrightFire 200 burner installed in an under

port arrangement.

The ability to alter the heat release position within

the flame and thus within the melter has shown

promising gains in energy efficiency. In one case

involving a container furnace, the under glass

electric boost was reduced by more than 10% with

Advancements in regenerative gas burner technology

Area adjustment

Flow adjustment

Figure 2: BrightFire 200 adjustments.

Glass

26 r Furnaces International Issue 1 www.aluminiumtoday.com/furnaces/

a small reduction in natural gas use and no effects

on production. In this case, the burner includes

an optional gas swirler for the outer gas jet, which

increases the flame surface area and further improves

the heat release to the glass melt.

Fig. 4 shows the BrightFire 200 operating in a small

cross-fired furnace. Thermal imagery was used to

better assess the flame characteristics and to more

thoroughly understand other interactions occurring

inside the melter.

Improved heat transferImproved batch line control was observed due to

the improved heat transfer of the BrightFire 200.

This resulted in the batch line pulling back and

subsequently a reduced seed count was reported by

the customer. An additional benefit of the BrightFire

200 was improved flame stability, which kept the

flame off of the batch piles and reduced carryover

into the regenerators.

Better heat transfer from the flame also put

more heat into the glass melt, reducing crown

temperatures and increasing bottom temperatures.

These improvements can help increase the life of the

furnace while simultaneously reducing the overall

energy costs associated with production.

Another key feature of the BrightFire 200 is the single

gas inlet. This allows the burner controls for the inner

and outer gas jets to be located on the burner. In

many other dual injection burners, there are separate

inlets for each gas jet, complicating the gas piping to

the burner and increasing the associated costs.

Other burners today have the inner and outer gas

jet controls on the burner, but they have no means

of adjusting the inner nozzle relative to the outer

nozzle. Only the BrightFire 200 combines all these

features into one burner, using updated burner tip

technology based on 40 years of experience with the

most successful regenerative burner systems in the

glass industry.

The BrightFire 200 is currently installed in several

container, float, and tableware furnaces in Europe,

Asia and the Americas. All firing arrangements are in

use: side of port and under port firing on both side

and end port furnaces. In many locations, customers

are adding the BrightFire 200 to multiple furnaces

based on the improvements realised on an initial

furnace installation.

Along with the adjustment features and design

elements described above, the burner can be

provided with an oil lance for easy change to oil