Electrical Theory and Application for Electric Kilns _ l&l Electric Kilns - Built to Last

Furnace & Kilns by Fel

23

FURNACES I. GENERAL DESCRIPTION A furnace is a device used for heating. The name derives from Latin fornax, oven. It is essentially a thermal enclosure and is employed to process raw materials at high temperatures both in solid state and liquid state. Several industries like iron and steel making, non-ferrous metals production, glass making, manufacturing, ceramic processing, calcination in cement production etc. employ furnace. The principle objectives are a) To utilize heat efficiently so that losses are minimum, and b) To handle the different phases (solid, liquid or gaseous) moving at different velocities for different times and temperatures such that erosion and corrosion of the refractory are minimum. Generally, furnaces that operate at temperatures under 1000°F are called ovens. Furnaces and ovens have very similar features. Both are primarily used to heat treat metals, using gas, oil, or electricity. II. GENERAL FUNCTION Furnaces are usually made of either insulating firebrick or firebrick covered with refractory material. The charge, or inlet material, is introduced by chutes, conveyors or pipes. The furnace can run in batch mode, or in continuous mode. The charge moves through the furnace on skids or rolls, or by gravity, rotation, slope, or mechanical pushers such as screws.

-

Upload

junafel-dela-cruz -

Category

Education

-

view

2.953 -

download

0

Transcript of Furnace & Kilns by Fel

- 1. FURNACES I. GENERAL DESCRIPTION A furnace is a device used for heating. The name derives from Latin fornax, oven. It is essentially a thermal enclosure and is employed to process raw materials at high temperatures both in solid state and liquid state. Several industries like iron and steel making, non-ferrous metals production, glass making, manufacturing, ceramic processing, calcination in cement production etc. employ furnace. The principle objectives are a) To utilize heat efficiently so that losses are minimum, and b) To handle the different phases (solid, liquid or gaseous) moving at different velocities for different times and temperatures such that erosion and corrosion of the refractory are minimum. Generally, furnaces that operate at temperatures under 1000F are called ovens.Furnaces and ovens have very similar features. Both are primarily used to heat treat metals, using gas, oil, or electricity. II. GENERAL FUNCTION Furnaces are usually made of either insulating firebrick or firebrick covered with refractory material. The charge, or inlet material, is introduced by chutes, conveyors or pipes. The furnace can run in batch mode, or in continuous mode. The charge moves through the furnace on skids or rolls, or by gravity, rotation, slope, or mechanical pushers such as screws. In a continuous furnace, the hearth may be stationary or rotary. Rotation speed can be adjusted based on the size, weight, and load of the charge. Open spaces beneath the hearth circulate air. Sidewalls support the arch-shaped roof. Heat in furnaces is generated by combustion of fuel or conversion of electric energy. Fuel and air enter via burners fired through burner tiles. Heat is transferred to the material by or a combination ofinduction, conduction, convection, and radiation. The products of fuel combustion exit through vents, flues, and a high temperature stack, carrying with it some heat. To recover this heat, flue gases are used to preheat the stock or material being heated, the combustion air, or the fuel. The flue is located at the top or bottom, depending on whether the furnace is updraft or downdraft respectively.

- 2. Furnaces can be direct fired, over fired, under fired, or side fired. In direct fired furnaces, the heat is produced on the inside of the furnace chamber. In over, under, and side fired furnaces, heat is produced in a chamber in the respective area and flows throughout the furnace. III. TYPES / CLASSIFICATION / CLASSES Furnaces are broadly classified into two types based on the heat generation method: combustion furnaces that use fuels, and electric furnaces that use electricity. Combustion furnaces can be classified in several based as shown in Table 1: type of fuel used, mode of charging the materials, mode of heat transfer and mode of waste heat recovery. Table 1 Classification of Combustion Furnaces Classification Method Types and Examples Combustion Type Oil-fired Gas-firedType of fuel used Coal-fired Mode of charging materials Intermittent / Batch Periodical Forging Re-rolling (batch/pusher) Pot Continuous Pusher Walking beam Walking hearth Continuous recirculating bogie furnaces

- 3. Rotary hearth furnaces Mode of heat transfer Radiation (open fire place) Convection (heated through medium) Mode of waste heat recovery Recuperative Regenerative Oil Fired Furnace Furnace oil is the major fuel used in oil fired furnaces, especially for reheating and heat treatment of materials. LDO is used in furnaces where presence of sulphur is undesirable. The key to efficient furnace operation lies in complete combustion of fuel with minimum excess air. Furnaces operate with efficiencies as low as 7% as against up to 90% achievable in other combustion equipment such as boiler. This is because of the high temperature at which the furnaces have to operate to meet the required demand. For example, a furnace heating the stock to 1200C will have its exhaust gases leaving at least at 1200C resulting in a huge heat loss through the stack. However, improvements in efficiencies have been brought about by methods such as preheating of stock, preheating of combustion air and other waste heat recovery systems. Gas Furnace Gas furnaces have a thermostat that signals the furnace to ignite the gas once the temperature drops below the specified level. Natural gas supplies heat in a convenient and cost-efficient manner. It consumes less energy compared to other types of furnaces. Another way to utilize furnaces more efficiently is having a heat exchange for warming water. A separate water heater running in your house gives a remarkable increase on the electric bill. Typical Furnace System i) Forging Furnaces The forging furnace is used for preheating billets and ingots to attain a forge temperature. The furnace temperature is maintained at around 1200 to 1250C. Forging furnaces use an open fireplace system and most of the heat is transmitted by radiation. The typical loading in a forging furnace is 5 to 6 tonnes with the furnace operating for 16 to 18 hours daily. The total operating cycle can be divided into (i) heat-up time (ii) soaking time and (iii) forging time. Specific fuel consumption depends upon the type of material and number of reheats required.

- 4. ii) Rerolling Mill Furnace a) Batch type. A box type furnace is employed for batch type rerolling mill. The furnace basically used for heating up scrap, small ingots and billets weighing 2 to 20 kg. for rerolling. The chargingand discharging of the material is done manually and the final product is in the form of rods, strips etc. The operating temperature is about 1200C. The total cycle time can be further categorized into heat-up time and rerolling time. During heat-up time the material gets heated upto the required temperature and is removed manually for rerolling. The average output from these furnaces varies from 10 to 15 tonnes / day and the specific fuel consumption varies from 180 to 280 kg. of coal / tonne of heated material. b) Continuous Pusher Type. The process flow and operating cycles of a continuous pusher type is the same as that of the batch furnace. The operating temperature is about 1250C. Generally, these furnaces operate 8 to 10 hours with an output of 20 to 25 tonnes per day. The material or stock recovers a part of the heat in flue gases as it moves down the length of the furnace. Heat absorption by the material in the furnace is slow, steady and uniform throughout the cross-section compared with batch type. iii) Continuous Steel Reheating Furnaces The main function of a reheating furnace is to raise the temperature of a piece of steel, typically to between 900C and 1250C, until it is plastic enough to be pressed or rolled to the desired section, size or shape, The furnace must also meet specific requirements and objectives in terms of stock heating rates for metallurgical and productivity reasons. Incontinuous reheating, the steel stock forms a continuous flow of material and is heated to the desired temperature as it travels through the furnace. Types of Continuous Reheating Furnace Continuous reheating furnaces are primarily categorized by the method by which stock is transported through the furnace. There are two basic methods: Stock is butted together to form a stream of material that is pushed through the furnace. Such furnaces are called pusher type furnaces. Stock is placed on a moving hearth or supporting structure which transports the steel through the furnace. Such types include walking beam, walking hearth, rotary hearth and continuous recirculating bogie furnaces. The major consideration with respect to furnace energy use is that the inlet and outlet apertures should be minimal in size and designed to avoid air infiltration. i) Pusher Type Furnaces The pusher type furnace is popular in steel industry. It has relatively low installation and maintenance costs compared to moving hearth furnaces. The furnace may have a solid hearth, but it is also possible to push the stock along skids with water-cooled supports that allow both

- 5. the top and bottom faces of the stock to be heated. The design of a typical pusher furnace design is shown schematically in Figure 4.5. Pusher type furnaces; however, do have some disadvantages, including: Frequent damage of refractory hearth and skid marks on material Water cooling energy losses from the skids and stock supporting structure in top and bottom fired furnaces have a detrimental effect on energy use; Discharge must be accompanied by charge Stock sizes and weights and furnace length are limited by friction and the possibility of stock pile-ups. All round heating of the stock is not possible. ii) Walking Hearth Furnaces The walking hearth furnace (Figure.4.6) allows the stock to be transported through the furnace in discrete steps. Such furnaces have several attractive features, including: simplicity of design, ease of construction, ability to cater for different stock sizes (within limits), negligible water cooling energy losses and minimal physical marking of the stock. The main disadvantage of walking hearth furnaces is that the bottom face of the stock cannot be heated. This can be alleviated to some extent by maintaining large spaces between pieces of stock. Small spaces between the individual stock pieces limits the heating of the side faces and increases the potential for unacceptable temperature differences within the stock at discharge. Consequently, the stock residence time may be long, possibly several hours; this may have an adverse effect on furnace flexibility and the yield may be affected by scaling. iii) Rotary hearth furnace The rotary hearth furnace (Figure 4.7) has tended to supersede the recirculating bogie type. The heating and cooling effects introduced by the bogies are eliminated, so heat storage losses are less. The rotary hearth has, however a more complex design with an annular shape and revolving hearth. iv) Continuous Recirculating Bogie type Furnaces These types of moving hearth type furnaces tend to be used for compact stock of variable size and geometry. In bogie furnaces (Figure 4.8), the stock is placed on a bogie with a refractory hearth, which travels through the furnace with others in the form of a train. The entire furnace length is always occupied by bogies. Bogie furnaces tend to be long and narrow and to suffer from problems arising from inadequate sealing of the gap between the bogies and furnace shell, difficulties in removing scale, and difficulties in firing across a narrow hearth width. v) Walking Beam Furnaces The walking beam furnace (Figure 4.9) overcomes many of the problems of pusher furnaces and permits heating of the bottom face of the stock. This allows shorter stock heating times and furnace lengths and thus better control of heating rates, uniform stock discharge temperatures

- 6. and operational flexibility. In common with top and bottom fired pusher furnaces, however, much of the furnace is below the level of the mill; this may be a constraint in some applications. Electric Furnace Nowadays an electric furnace is taking major role both for domestic and industrial application. A chamber heated by electric current is known as Electric Furnace. Electric furnaces are cheaper than oil fired furnaces and gas fired furnaces. Operating Principle The source of heat is a continuous electric arc that is formed between the electrodes and the charged metal (Fig. 1). Temperatures as high as 1925C (3500F) are generated in this type of furnace. There are usually three graphite electrodes, and they can be as large as 750 mm (30 in.) in diameter and 1.5 to 2.5 m (5 to 8 ft.) in length. Their height in the furnace can be adjusted in response to the amount of metal present and the amount of wear of the electrodes. Steel scrap and a small amount of carbon and limestone are dropped into the electric furnace through the open roof. The roof is then closed, and the electrodes are lowered. Power is turned on, and, within a period of about two hours, the metal melts. The current is then shut off, the electrodes are raised, the furnace is tilted, and the molten metal is poured into a ladle, which is a receptacle used for transferring and pouring molten metal. Electric furnace capacities range from 60 to 90 tons of steel per day. For smaller quantities, electric furnaces can be of induction type. The metal is placed in a crucible, a large pot made of refractory material and surrounded with a copper coil through which alternating current is passed. The induced current in the charge melts the metals. These furnaces are also used for re-melting metal for casting. Fig. 1 Schematic illustration of types of Electric Furnaces: (a) direct arc, (b) indirect arc , and (c) induction.

- 7. Material of Construction To make Electric Furnace refractory bricks, heating elements, compensating cables, thermocouples, temperature indicator-cum-controller etc. are required. Refractory Bricks: Best quality refractory bricks must be used in the furnaces either for coil holding or for insulation purpose, now a days, also ceramic bricks or ceramic blankets are used for insulation and this is also found to be the best insulation material for furnace. Resistance temperature of insulation material should be more than working temperature of furnace. Heating Elements: The main function of heating elements is to convert electricity to heat. Nichrome 80/20 and also Kanthal A1 found to be the best heating elements within continuous working temperature of 1050 to 1100C; available both strip, ribbon and also wire form. Another heating element is Silicon Carbide. Silicon Carbide heating elements is also a best heating element. Silicon Carbide works continuously at a high temperature up to 1450C & no support require this heating element. Common Maximum Temperature of Heating Elements: Kanthal A1 max 1400C Kanthal AF max 1300C Silicon Carbide max range between 1300 to 1500C Thermocouples: Thermocouples are pair of dissimilar material wired and joined at least one end. The function of any thermocouple wire is to convert heat or cool to millivolt. In 1821, the German-Estonian Physicist John Allen discovered that when any conductor such as metal is subjected to a thermal gradient, it will generate a Voltage. Compensating Cables: It is also very important that the right compensating cable is used between the controller and the thermocouple probe. Every different type of thermocouple has its own compensating cables. Compensating cable use the actual thermocouple materials but in cheaper forms. When connecting a thermocouple to temperature controller through compensating cable most important to know what is positive and what is negative wire of compensating cable. Continuous Working Temperature Range for Most Common Use Thermocouples: Type-K (Cromel - Alumel) Temperature Range 0 to +1200C Type-J Temperature range 0 to +750C. Type-R Pt/Pt-Rh13% Temperature range 0 to +1600C Type-B Used Platinum and Rhodium contain each conductor one 30% rhodium and another 6% rhodium +200 to 1200C Type-S Suitable for higher temperature range between 0 to 1600C Type-T Copper and Constantant, both conductors are non-magnetic (-)185 to +300C Type-E Cromel and Constantan, both conductors are non-magnetic 0 to +800C

- 8. RTDs (Resistance Temperature Detectors) used in widely industrial sector for its more accuracy within its range (-)200 to +500C Temperature Controllers: To control the temperature of any furnace, a temperature controller is inevitable. It may be blind temperature controller or Digital Temperature indicator-cum-controller. Price Quotation IV. COMPONENTS & PARTS All furnaces have the following components as shown in Figure 2: A refractory chamber constructed of insulating materials for retaining heat at the high operating temperatures. A hearth to support or carry the steel. This can consist of refractory materials or an arrangement of metallic supports that may be water-cooled. Burners that use liquid or gaseous fuels to raise and maintain the temperature in the chamber. Coal or electricity can be used in reheating furnaces. Chimney to remove the combustion exhausts gases from the chamber. Charging and discharging doors through which the chamber is loaded and unloaded. Loading and unloading equipment include roller tables, conveyors, charging machines and furnace pushers.

- 9. Figure 2: Typical Furnace Components V. APPLICATION AND USES Furnaces are primarily used to heat treat metals. High temperatures soften, melt, and annealthe metals. Heating can also cause the absorption of carbon. Furnaces are used in various stages of heat treatment, as shown in the table below for steel treatment. Treatment heat-treating annealing hardening heating reheating Temperature Range up to 1200F 1200-1600F 1500-1600F up to 2300F up to 2300F Furnaces are also used to melt glass, coke coal, distill zinc, and many other processes. Hearth furnaces can be used to remove hazardous waste. They are also used in the microelectronics industry in semiconductor wafer production. Semiconductor ingots are grown within furnaces.

- 10. KILNS I. GENERAL DESCRIPTION A kiln is a thermally insulated chamber, a type of oventhat produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Various industries and trades use kilns to harden objects made from clay into pottery, bricks etc. Various industries use rotary kilns for pyroprocessingto calcinate ores, produce cement, lime, and many other materials. A rotary kiln is a cylindrical steel tube lined with insulating brick. The large ones can be as long as 760 feet with a diameter of 25 feet. The kiln turns on a horizontal axis at an angle of 2 to 3 percent to the horizontal. II. GENERAL FUNCTION Charge, or material to be heated, enters tunnel kilns on trays or trucks at one end, contacts the gas, and exits at the other end. The trays or trucks move on tracks or monorails. Heating is provided by reheat coils, and large propeller-type fans circulate the combustion gases. III. TYPES / CLASSIFICATION / CLASSES Ceramic Kilns Kilns are an essential part of the manufacture of all ceramics, which require heat treatment, often at high temperatures. During this process, chemical and physical reactions occur that permanently alter the unfired body. In the case of pottery, clay materials are shaped, dried and then fired in a kiln. The final characteristics are determined by the composition and preparation of the clay body, by the temperature at which it is fired, and by the glazes that may be used. Although modern kilns often have sophisticated electrical systems to control the firing temperatures, pyrometric devices are also frequently used. Types of ceramic kiln In the broadest terms, there are two types of kiln, both sharing the same basic characteristics of being an insulated box with controlled inner temperature and atmosphere. In using an intermittent kiln, the ware to be fired is loaded into the kiln. The kiln is closed, and the internal temperature increased according to a schedule. After the firing is completed, both the kiln and the ware are cooled.

- 11. Kilns in this type include: Clamp kiln Skove kiln Scotch kiln Down-Draft kiln A continuous kiln, sometimes called a tunnel kiln, is a long structure in which only the central portion is directly heated. From the cool entrance, ware is slowly transported through the kiln, and its temperature is increased steadily as it approaches the central, hottest part of the kiln. From there, its transportation continues and the temperature is reduced until it exits the kiln at near room temperature. A continuous kiln is energy-efficient, because heat given off during cooling is recycled to pre-heat the incoming ware. In some designs, the ware is left in one place, while the heating zone moves across it. Kilns in this type include: Hoffman kiln Bulls Trench kiln Habla (Zig-Zag) kiln A special type of kiln, common in tableware and tile manufacture, is the roller-hearth kiln, in which ware placed on batts is carried through the kiln on rollers. Anagama kiln - the Asian anagama kiln has been used since medieval times and is considered the oldest style of production kiln, brought to Japan from China via Korea in the 5th century. This kiln usually consists of one long firing chamber, pierced with smaller ware stacking ports on one side, with a firebox at one end and a flue at the other. Firing time can vary from one day to several weeks. Traditional anagama kilns are also built on a slope to allow for a better draft. Bottle kiln - a type of intermittent kiln, usually coal-fired, formerly used in the firing of pottery; such a kiln was surrounded by a tall brick hovel or cone, of typical bottle shape. Catenary arch kiln, typically used for the firing of pottery using salt, these by their form (a catenary arch) tend to retain their shape over repeated heating and cooling cycles, whereas other types require extensive metalwork supports. Electric kilns - kilns operated by electricity were developed in the 20th century, primarily for smaller scale use such as in schools, universities, and hobby centers. The atmosphere in most designs of electric kiln is rich in oxygen, as there is no open flame to consume oxygen molecules. However, reducing conditions can be created with appropriate gas input, or by using saggars in a particular way. Feller kiln brought contemporary design to wood firing by re-using un-burnt gas from the chimney to heat intake air before it enters the firebox. This leads to an even shorter firing cycle and less wood consumption. This design requires external ventilation to prevent the in-

- 12. chimney radiator from melting, being typically in metal. The result is a very efficient wood kiln firing one cubic meter of ceramics with one cubic meter of wood. Microwave assisted firing - this technique combine microwave energy with more conventional energy sources, such as radiant gas or electric heating, to process ceramic materials to the required high temperatures. Microwave-assisted firing offers significant economic benefits. Noborigama kiln - the Noborigama is an evolution from Anagama design as a multi- chamber kiln, usually built on a slope, where wood is stacked from the front firebox at first, then only through the side-stoking holes with the benefit of having air heated up to 600 C from the front firebox, enabling more efficient firings. The Svres kiln was invented in Svres, France and efficiently generated high- temperatures (1280 C) to produce water-proof ceramic bodies and easy to obtain glazes. It features a down-draft design that produces high temperature in shorter time, even with wood-firing. Top-hat kiln - an intermittent kiln of a type sometimes used to fire pottery. The ware is set on a refractory hearth, or plinth, over which a box-shaped cover is lowered. Wood Drying Kiln A variety of wood drying kiln technologies exist today: conventional, dehumidification, solar, vacuum and radio frequency. Conventional wood dry kilns (Rasmussen, 1988) are either package-type (sideloader) or track-type (tram) construction. Most hardwoodlumber kilns are sideloader kilns in which fork trucks are used to load lumber packages into the kiln. Most softwood lumber kilns are track types in which lumber packages are loaded on kiln/track cars for loading the kiln. Modern high-temperature, high-air-velocity conventional kilns can typically dry 1-inch-thick (25 mm) green lumber in 10 hours down to a moisture content of 18%. However, 1-inch- thick green Red Oak requires about 28 days drying down to a moisture content of 8%. Heat is typically introduced via steam running through fin/tube heat exchangers controlled by on/off pneumatic valves. Less common are proportional pneumatic valves or even various electrical actuators. Humidity is removed via a system of vents, the specific layout of which is usually particular to a given manufacturer. In general, cool dry air is introduced at one end of the kiln while warm moist air is expelled at the other. Hardwood conventional kilns also require the introduction of humidity via either steam spray or cold water misting systems to keep the relative humidity inside the kiln from dropping too low during the drying cycle. Fan directions are typically reversed periodically to ensure even drying of larger kiln charges. Dehumidification kilns are similar to other kilns in basic construction. Drying times are usually comparable. Heat comes primarily from an integral dehumidification unit that also removes humidity. Auxiliary heat is often provided early in the schedule, where the heat required may exceed the heat generated by the dehumidification unit.

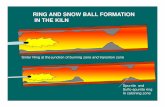

- 13. Solar kilns are conventional kilns, typically built by hobbyists to keep initial investment costs low. Heat is provided via solar radiation, while internal air circulation is typically passive. Rotary Kilns A Rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include: Cement Lime Refractories Metakaolin Titanium dioxide Alumina Vermiculite Iron ore pellets Operating Principle The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter- current). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or "firing pipe") which acts like a large bunsen burner. The fuel for this may be gas, oil or pulverized coal. Material &Construction The basic components of a rotary kiln are the shell, the refractory lining, support tyres and rollers, drive gear and internal heat exchangers. Kiln Shell This is made from rolled mild steel plate, usually between 15 and 30 mm thick, welded to form a cylinder which may be up to 230 m in length and up to 6 m in diameter. This will be usually situated on an east/west axis to prevent eddy currents. Upper limits on diameter are set by the tendency of the shell to deform under its own weight to an oval cross section, with consequent flexure during rotation. Length is not necessarily limited, but it becomes difficult to cope with changes in length on heating and cooling (typically around 0.1 to 0.5% of the length) if the kiln is very long. This is cylindrical.

- 14. Refractory Lining The purpose of the refractory lining is to insulate the steel shell from the high temperatures inside the kiln, and to protect it from the corrosive properties of the process material. It may consist of refractory bricks or cast refractory concrete, or may be absent in zones of the kiln that are below around 250C. The refractory selected depends upon the temperature inside the kiln and the chemical nature of the material being processed. In some processes, such as cement, the refractory life is prolonged by maintaining a coating of the processed material on the refractory surface. The thickness of the lining is generally in the range 80 to 300 mm. A typical refractory will be capable of maintaining a temperature drop of 1000C or more between its hot and cold faces. The shell temperature needs to be maintained below around 350C in order to protect the steel from damage, and continuous infrared scanners are used to give early warning of "hot-spots" indicative of refractory failure. Tyres& Rollers Tyres, sometimes called riding rings, usually consist of a single annular steel casting, machined to a smooth cylindrical surface, which attach loosely to the kiln shell through a variety of "chair" arrangements. These require some ingenuity of design, since the tyre must fit the shell snugly, but also allow thermal movement. The tyre rides on pairs of steel rollers, also machined to a smooth cylindrical surface, and set about half a kiln-diameter apart. The rollers must support the kiln, and allow rotation that is as nearly frictionless as possible. A well-engineered kiln, when the power is cut off, will swing pendulum-like many times before coming to rest. The mass of a typical 6 x 60 m kiln, including refractories and feed, is around 1100 tonnes, and would be carried on three tyres and sets of rollers, spaced along the length of the kiln. The longest kilns may have 8 sets of rollers, while very short kilns may have only two. Kilns usually rotate at 0.5 to 2 rpm, but sometimes as fast as 5 rpm. The Kilns of most modern cement plants are running at 4 to 5 rpm. The bearings of the rollers must be capable of withstanding the large static and live loads involved, and must be carefully protected from the heat of the kiln and the ingress of dust. In addition to support rollers, there are usually upper and lower "retaining (or thrust) rollers" bearing against the side of tyres, that prevent the kiln from slipping off the support rollers. Friction between tyre and rollers causes concave, convex or conical wear on both surfaces of tyre and rollers. This wear deforms the cylindrical shape of these units and causes vibration, shell deformation, more power consumption and if not resurfaced these problems takes the level up to changing the shell and tyre which takes more budget and shut down time. Drive Gear The kiln is usually turned by means of a single Girth Gear surrounding a cooler part of the kiln tube, but sometimes it is turned by driven rollers. The gear is connected through a gear train to a variable-speed electric motor. This must have high starting torque in order to start the kiln with a large eccentric load. A 6 x 60 m kiln requires around 800 kW to turn at 3 rpm. The speed of material flow through the kiln is proportional to rotation speed, and so a variable speed drive is needed in order to control this. When driving through rollers,

- 15. hydraulic drives may be used. These have the advantage of developing extremely high torque. In many processes, it is dangerous to allow a hot kiln to stand still if the drive power fails. Temperature differences between the top and bottom of the kiln may cause the kiln to warp, and refractory is damaged. It is therefore normal to provide an auxiliary drive for use during power cuts. This may be a small electric motor with an independent power supply, or a diesel engine. This turns the kiln very slowly, but enough to prevent damage. Internal Heat Exchanger Heat exchange in a rotary kiln may be by conduction, convection and radiation, in descending order of efficiency. In low-temperature processes, and in the cooler parts of long kilns lacking preheaters, the kiln is often furnished with internal heat exchangers to encourage heat exchange between the gas and the feed. These may consist of scoops or "lifters" that cascade the feed through the gas stream, or may be metallic inserts that heat up in the upper part of the kiln, and impart the heat to the feed as they dip below the feed surface as the kiln rotates. The latter are favoured where lifters would cause excessive dust pick-up. The most common heat exchanger consists of chains hanging in curtains across the gas stream. Price Quotation

- 16. IV. COMPONENTS & PARTS V. APPLICATION & USES Tunnel kilns are used to vitrify clay bricks, particulate solids, and large solid objects. They are also used to sinter capacitors, soft ferrite, composite materials, and capacitors used in computers and cellular telephones also. Rotary kilns are used to make cement and to calcine small waste stone and free-flowing, granular solids. Downdraft kilns are used to produce brick, pipe, tile, and stoneware, while updraft kilns are used for pottery burning. Other uses of kiln include: To dry green lumber so it can be used immediately Drying wood for use as firewood Heating wood to the point of pyrolysis to produce charcoal For annealing, fusing and deforming glass, or fusing metallic oxide paints to the surface of glass For cremation (at high temperature) Drying of tobacco leaves Drying malted barley for brewing and other fermentations Drying hops for brewing (known as a hop kiln or oast house) Drying corn (grain) before grinding or storage, sometimes called a corn kiln, corn drying kiln. Smelting ore to extract metal Heating limestone with clay in the manufacture of Portland cement Heating limestone to make quicklime or calcium oxide