FT151-7

-

Upload

kweeniegene -

Category

Documents

-

view

216 -

download

0

Transcript of FT151-7

-

7/31/2019 FT151-7

1/4

1

Experiment No. 7

Batch Sedimentation

Queenie Gene D. Gadong

Date Performed: February 22, 2012

Date Submitted: March 18, 2012

I. IntroductionMany biological substances around us are made up of two or more components of either gas, liquid,

or solid phases. By understanding the behavior of these individual components and by applying proper

conditions these different phases can be separated from each other, the other may be enriched in the

medium or otherwise depleted. (Geankoplis, 1995)

Mechanical separation is a process where individual phases of matter are separated into specific

materials. These forces that separate the particles depend on the character of the particles being

separated, the size, density, and shape, in addition to the fluids specific density and viscosity. This

separation process is accomplished by action of gravitational, centrifugal, mechanical, and kinetic forces

to the specific particles of the different phases of matter. (Geankoplis, 1995) There are three generalclassifications of mechanical-physical separation processes a.)filtration b.) centrifugal separation and c.)

sieving. (Earle, 1983)

a.) Filtration.In filtration a fluid is left to flow in a screen, where the large solid particles are blocked for passage,

while the liquid is allowed to pass through. (Geankoplis, 1995)

b.) Sedimentation.In sedimentation, two immiscible liquids, or a liquid and a solid, differing in density, are separated

allowing them to come in equilibrium under the action of gravity, the heavier material falling with respect

to the lighter. (Earle, 1983)c.) Seiving.Is a separation process wherein the solid particles are classified according to size by using a screen

which acts as barrier against passage of larger particles. It is used often in classifying solids by size.(Earle, 1983)

The separation of a dilute slurry or suspension by gravity settling into a clear fluid and a slurry ofhigher solids content is called Sedimentation. (Geankoplis, 1995) Sedimentation employs the action ofgravitational forces to separate particles from the fluid, which may be a liquid or gaseous fluid.

Sedimentation can be applied in the removal of solid particles in sewage wastes, and dirt and other debris

from a fluid stream. (Geankoplis, 1995) In the food industry sedimentation is used as a process of

separating formed from the mother liquor, and separation of solvent from an extraction process. At times

the separated materials are also recovered as the main product in a process; it can also be used to classify

particles in terms of size or density. (Earle, 1983)

Movement of particles in a fluid, which is when they settle or separate from the fluid, is influenced by

the size, shape and density of the particles. This movement of particles at its maximum is termed,

Terminal velocity. There are also forces acting upon the particles which influence its velocity in the fluid,one which causes motion and another that offers resistance. The difference in the density of the fluid and

the moving particle offers a net force which causes the motion of the particle. The applied force of gravity

creates a driving force which starts the motion of the particle. The drag force or the force which hinders

the movement of the particles through a solution is produced by the frictional action of the fluid,

particularly to the walls of the fluids container.

The settling rate of a particle is also influenced by the concentration of the particles in a solution. In

hindered settling the velocity of each particle is affected by the nearby presence of another particle. The

-

7/31/2019 FT151-7

2/4

2

distance of the wall of a container to a particle can also affect the terminal velocity of a particle, this kind

of settling is termed as hindered settling. (Geankoplis, 1995)

During a batch sedimentation process a slurry is placed inside a graduated cylinder. There will be an

initial suspension wherein the particles will be evenly distributed in the solution. Slowly, different layers

will be noticed in the solution. The initial suspension would be the zone B. As time passes and the

particles slowly settle at the bottom the clear liquid in the upper layer would be the zone A, followed by

the zone B. The settled particles at the bottom of the cylinder would be the zone D, while zone C ismerely a transition between the settles particles in zone D, and the suspended particles in zone B.

(Geankoplis, 1995)

For this experiment the students will be taught to experimentally obtain the settling rate of a solid

material immersed in a fluid and be able to generate a settling curve. The students would also gain

experience on the effect of slurry concentration on a particular materials sedimentation characteristics.

II. MethodologyStarch was used as sample for this experiment. The internal diameter of the graduated cylinder to be

used was measured. Flour was weighed, one part was measured at 50g, and another part as 25g. The flour

were then placed into separate bowls and mixed with 950 mL of water. The substances were mixed

uniformly in a blender. The homogenous solutions were then transferred into separate cylinder and werecovered with aluminum foil on top. For every 5 minute interval the height of the fallen particles at the

bottom of the cylinder was measured, until the no more changes in can be noted.

III. ResultsTable 1: Summary of calculated results for sedimentation rate of starch.

t, min.Sediment Volume, V (m3)

A (50g) B (25g)

5 14.53143682 9.247277976

10 14.00302093 13.21039711

15 12.15356534 21.1366353720 11.62514946 23.7787148

25 11.36094151 29.06287364

30 11.36094151 30.38391335

35 11.62514946 29.06287364

40 11.36094151 29.06287364

45 11.36094151 31.70495306

50 11.36094151 31.70495306

55 11.36094151 31.70495306

60 11.36094151 30.38391335

65 11.36094151 29.06287364

70 11.36094151 29.06287364

75 11.36094151 29.06287364

80 11.36094151 29.06287364

85 11.36094151 29.06287364

90 11.36094151 29.06287364

-

7/31/2019 FT151-7

3/4

3

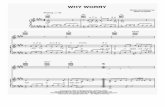

Figure 1: Time-volume plot for sedimentation of starch.

IV. DiscussionFrom Figure 1, which is a plot of the volume of the particles in the slurry that have settled at a given

time interval, we could note the difference in the behavior of the settled particles. In slurry A with a

greater solute concentration the volume of particles that have settled decreased. Despite its greater solute

concentration, which would have ensured a bigger volume to settle at the bottom, slurry A was

significantly smaller in volume of its particles than in Slurry B. This could phenomena could be explained

by the fact that the overall solute particles in slurry A was heavier as compared to slurry B which made

the volume of particles settled at the bottom of the cylinder more compact.

This tendency of the particles in slurry A to be more compact can be attributed to the effect of gravity

on the individual particles. Since the overall weight of the particles in slurry A are heavier than in slurry Bthe action of gravity on the its particles are also greater, creating a more compact sediment.

V. ConclusionThe differences of the components in a mixture can be utilized to be able to separate these

components from each other. Sedimentation is one of these processes, which is more suitable in

separating particles in fluids.

VI. References Earle, R. (1983). Unit Operations in Food Processing. The New Zealand Institute of Food

Science and Technology Inc. .

Geankoplis, C. J. (1995). Transport Processes and Unit Operations 3rd Ed. University ofMinnesota: Prentice-Hall International, Inc.

0

5

10

15

20

25

30

35

0 20 40 60 80 100

V,mL

t, min.

Slurry A

Slurry B

-

7/31/2019 FT151-7

4/4

4

VII. AnnexTable 2: Summary of Raw data obtained in sedimentation of starch.

t, min.Sediment Height, mm

Radius (mm)Sediment Volume, V (mm3)

A (50g) B (25g) A (50g) B (25g)

5 5.5 3.5 29 14531.43682 9247.27797610 5.3 5 29 14003.02093 13210.39711

15 4.6 8 29 12153.56534 21136.63537

20 4.4 9 29 11625.14946 23778.7148

25 4.3 11 29 11360.94151 29062.87364

30 4.3 11.5 29 11360.94151 30383.91335

35 4.4 11 29 11625.14946 29062.87364

40 4.3 11 29 11360.94151 29062.87364

45 4.3 12 29 11360.94151 31704.95306

50 4.3 12 29 11360.94151 31704.95306

55 4.3 12 29 11360.94151 31704.95306

60 4.3 11.5 29 11360.94151 30383.91335

65 4.3 11 29 11360.94151 29062.87364

70 4.3 11 29 11360.94151 29062.87364

75 4.3 11 29 11360.94151 29062.87364

80 4.3 11 29 11360.94151 29062.87364

85 4.3 11 29 11360.94151 29062.87364

90 4.3 11 29 11360.94151 29062.87364

Sample Calculations:

Cylinder diameter: 58mm

Radius = Diameter/2

= 29 mm

To determine sediment volume:

)

V= 14531.43682 m3

![[XLS]dev.eiopa.europa.eu · Web view2 6 6 7/7/2014 8 7/7/2014 1 7 7 7/7/2014 9 7/7/2014 1 8 8 7/7/2014 10 7/7/2014 1 9 9 7/7/2014 11 7/7/2014 1 10 10 7/7/2014 12 7/7/2014 1 11 11](https://static.fdocuments.us/doc/165x107/5ae5800d7f8b9a8b2b8bf1f3/xlsdeveiopa-view2-6-6-772014-8-772014-1-7-7-772014-9-772014-1-8-8-772014.jpg)